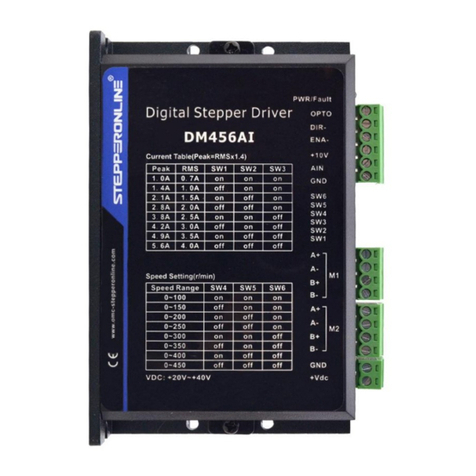

MA860H Microstepping Driver Manual V1.0

www.omc-stepperonline.com

8 lead motors offer a high degree of flexibility to the system designer in that they may be connected in series or parallel, thus

satisfying a wide range of applications.

Series Connections

A series motor configuration would typically be used in applications where a higher torque at lower speeds is required. Because this

configuration has the most inductance, the performance will start to degrade at higher speeds. In series mode, the motors should

also be run at only 70% of their rated current to prevent over heating.

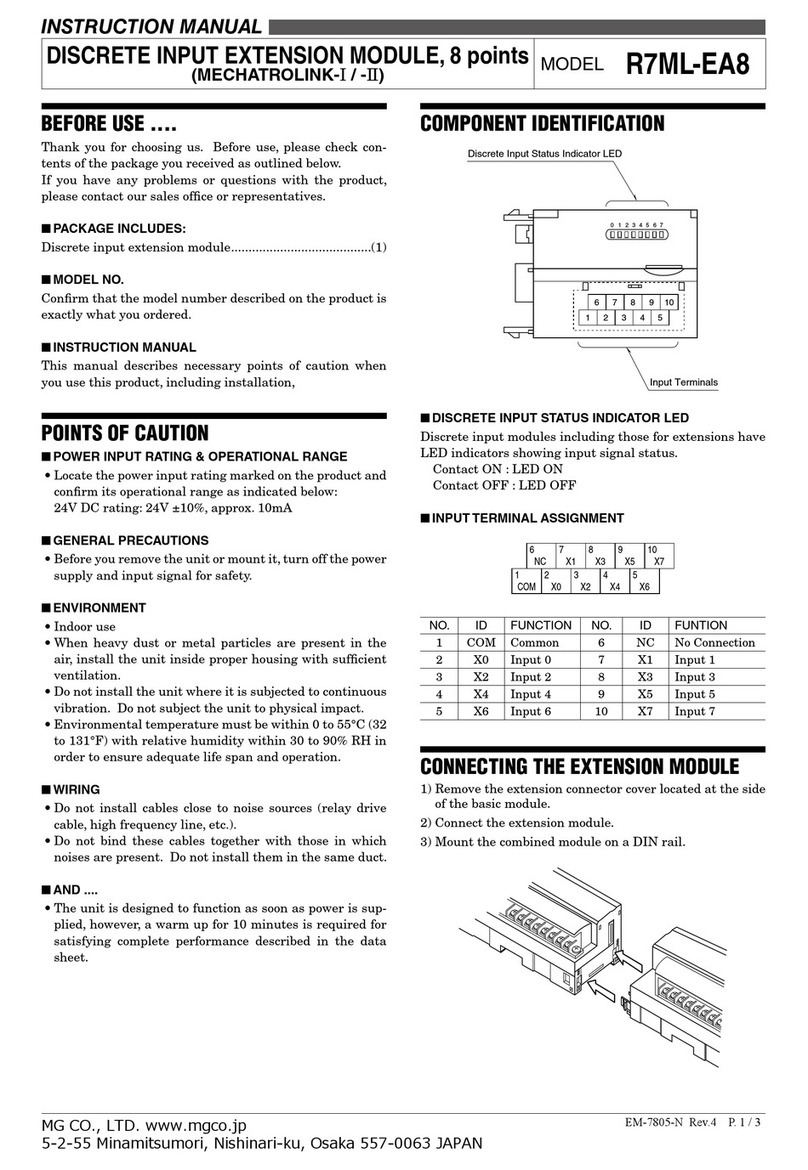

Figure 8: 8-lead motor series connections

An 8 lead motor in a parallel configuration offers a more stable, but lower torque at lower speeds. But because of the lower

inductance, there will be higher torque at higher speeds. Multiply the per phase (or unipolar) current rating by 1.96, or the bipolar

current rating by 1.4, to determine the peak output current.

6. Power Supply Selection

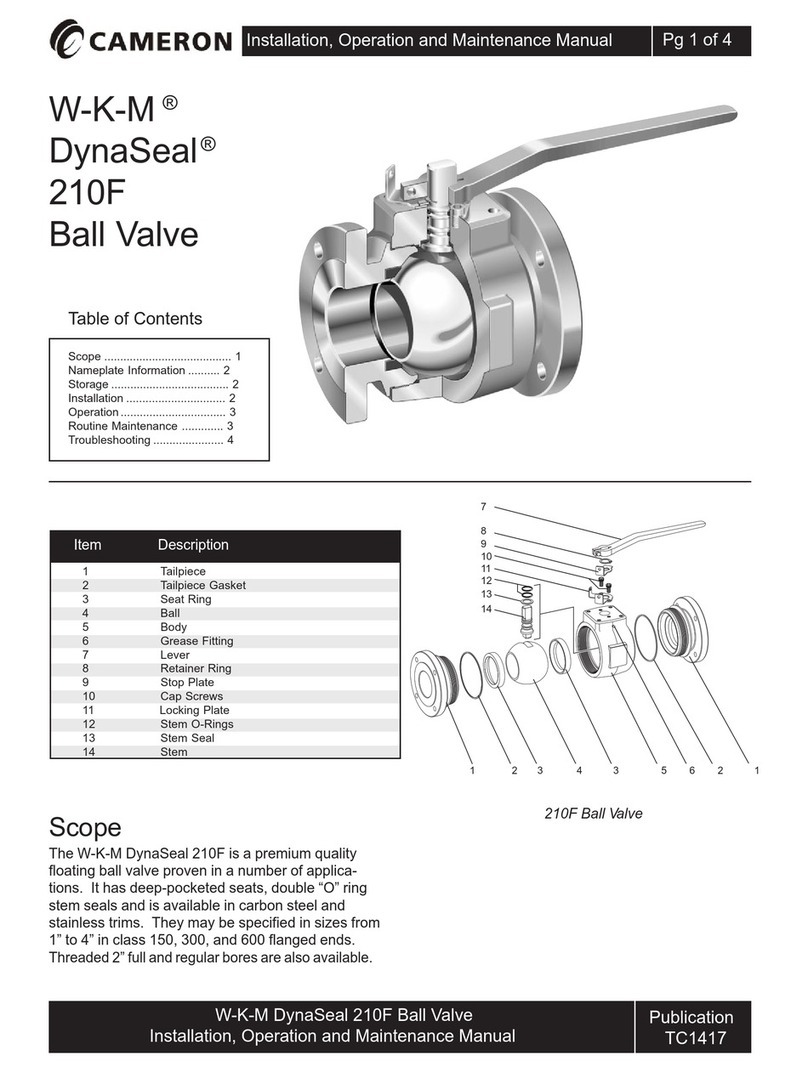

Figure 9: 8-lead motor parallel connections

The MA860H can match Large and small size stepping motors (from Nema size 17 to 42) made by NC-Tech or other motor

manufactures around the world. To achieve good driving performances, it is important to select supply voltage and output current

properly. Generally speaking, supply voltage determines the high speed performance of the motor, while output current determines

the output torque of the driven motor (particularly at lower speed). Higher supply voltage will allow higher motor speed to be

achieved, at the price of more noise and heating. If the motion speed requirement is low, it’s better to use lower supply voltage to

decrease noise, heating and improve reliability.

Regulated or Unregulated Power Supply

Both regulated and unregulated power supplies can be used to supply the driver. However, unregulated power supplies are

preferred due to their ability to withstand current surge. If regulated power supplies (such as most switching supplies.) are indeed

used, it is important to have large current output rating to avoid problems like current clamp, for example using 4A supply for 3A

motor-driver operation. On the other hand, if unregulated supply is used, one may use a power supply of lower current rating than

that of motor (typically 50%~70% of motor current). The reason is that the driver draws current from the power supply capacitor of

the unregulated supply only during the ON duration of the PWM cycle, but not during the OFF duration. Therefore, the average

current withdrawn from power supply is considerably less than motor current. For example, two 3A motors can be well supplied by

one power supply of 4A rating.

It is recommended to have multiple drivers to share one power supply to reduce cost, if the supply has enough capacity. To avoid

cross interference, DO NOT daisy-chain the power supply input pins of the drivers. (Instead, please connect them to power supply