StepperOnline CL57T User manual

User Manual

CL57T(V4.0)

Closed Loop Stepper Drive

Revision 4.0

Record of Revisions

Revision

Date

Description of Release

1.00

Aug, 2019

Initial Release

4.00

Oct, 2020

Add S1 rotating switch, 5/24V selector switch, brake output.

CL57T(V4.0) Closed-Loop Stepper Drive

Table of Content

1. Features.............................................................................................................................................................................1

2. Specifications.................................................................................................................................................................... 1

2.1 Electrical Specifications.......................................................................................................................................... 1

2.2 Environment............................................................................................................................................................1

2.3 Mechanical Specifications...................................................................................................................................... 2

3. Connections and LED Indication....................................................................................................................................... 3

3.1 P1 – Control and Digital Output Connections........................................................................................................ 3

3.2 P2 - Encoder Signals Input Connector.................................................................................................................... 4

3.3 P3 - Motor Connector............................................................................................................................................. 4

3.4 P4 - Power Connector............................................................................................................................................. 4

3.5 LED Status Lights.....................................................................................................................................................4

3.6 Switches.................................................................................................................................................................. 4

4. Power Supply Selection.....................................................................................................................................................5

4.1 Power Supply Sharing............................................................................................................................................. 5

4.2 Selecting Supply Voltage.........................................................................................................................................5

5.Switch Configurations........................................................................................................................................................ 6

5.1 S1 - Rotating Switch Configurations....................................................................................................................... 6

5.2 S2 - DIP Switch Configurations................................................................................................................................6

5.2.1 Micro Step (SW1-SW4)................................................................................................................................ 6

5.2.2 Mode Setting (SW5 - SW8).......................................................................................................................... 7

5.3 S3 - Selector Switch Configurations........................................................................................................................7

6. Typical Connection............................................................................................................................................................8

6.1 Digital Input Connection.........................................................................................................................................8

6.2 Fault Output Connection........................................................................................................................................ 9

6.3 Brake Output Connection....................................................................................................................................... 9

7. Sequence Chart of Control Signals................................................................................................................................... 9

8. Fault Protections & Troubleshooting..............................................................................................................................10

CL57T(V4.0) Closed-Loop Stepper Drive

1

1. Features

Input voltage 18-50VDC (recommended 24-48VDC)

No loss of step, No tuning

500 KHz max pulse input frequency

16 microstep resolutions of 200-51,200 via DIP switches SW1 - SW4

3 output current settings of 2.8A, 5.6A and 7.0A via S1 rotating switch

Gain tuning via S1 rotating switch

Auto-tuning to match wide-range NEMA 17, 23 and 24 closed-loop stepper motors

Anti-Resonance for optimal torque, extra smooth motion, low motor heating and noise

Soft-start with no “jump” when powered on

Optically isolated inputs with 5V or 24V

Fault and brake outputs

Motor rotating direction setting by SW5

Closed loop or open loop control setting by SW6

Step&Direction or CW&CCW pulse type setting by SW7

Position command filter setting by SW8

Over-voltage, over-current protections, position following error, etc

2. Specifications

2.1 Electrical Specifications

Parameters

Min

Typical

Max

Unit

Peak Current

2.4 (RMS 2A), 5.6 (RMS 4A), 7.0 (RMS 5A)

A

Operating Voltage

18

24, 36, 48

50

VDC

Logic input signal current

7

10

16

mA

Pulse input frequency

0

-

500

kHz

Brake output signal current

-

-

100

mA

Alarm output voltage

-

-

24

VDC

Minimal pulse width

1.0

-

-

μS

Minimal direction setup

2.0

-

-

μS

Isolation resistance

500

MΩ

2.2 Environment

Cooling

Natural Cooling or Forced Cooling

Operating Environment

Environment

Avoid dust, oil fog and corrosive gases

Humidity

40%RH-90%RH

Operating Temperature

0°C -40°C (32°F - 102°F)

Vibration

10-50Hz / 0.15mm

Storage Temperature

-20°C -65°C (-4°F - 149°F)

Weight

Approx. 280 g (9.9 Oz)

CL57T(V4.0) Closed-Loop Stepper Drive

2

2.3 Mechanical Specifications

(unit: mm [1inch=25.4mm])

Figure 1: Mechanical specifications

2.4 Heat Dissipation

CL57T(V4.0) reliable working temperature should be no more than 40℃(109°F)

It is recommended to mount the drive vertically to maximize heat dissipation. Mount a cooling fan nearby if

necessary.

If multiple CL57T(V4.0) drives are installed, it is suggested to keep a minimal 30mm (12 inches) between two of

them.

CL57T(V4.0) Closed-Loop Stepper Drive

3

3. Connections and LED Indication

A CL57T(V4.0) closed loop stepper drive has 4 connection blocks from P1 to P4 (see figure 2).

Figure 2: CL57T(V4.0) connectors

3.1 P1 – Control and Digital Output Connections

The P1 connector in Figure 2 contains connections for control signals and 2 digital output.

See the following table for details.

PIN

I/O

Details

PUL+ (CW+)

I

Pulse and Direction Connection:

(1) Optically isolated, high level 3.5-5V or 24V, low voltage 0-0.5V

(2) Maximum 500 KHz input frequency

(3) The width of PUL signal is at least 1.0μs, duty cycle is recommended 50%

(4) Single pulse (step & direction) or double pulse (CW/CCW) is set by DIP Switch SW7

(5) DIR signal requires advance PUL signal minimum 2 μs in single pulse mode

(6) The factory setting of control signal voltage is 24V, must need to set S3 (figure 2) if it is

5V

PUL- (CW-)

I

DIR+ (CCW+)

I

DIR- (CCW-)

I

ENA+

I

Enable Signals: Optional.

(1) Effective high level is 3.5-24V; Effective low level is 0-0.5V connection

(2) ENA signal requires advance DIR signal minimum 200ms in single pulse mode, (default

no connection)

ENA-

I

ALM

O

Alarm : They takes a sinking or sourcing 100mA current at 5-24V. Max 30V

Brake : Max. 24/100mA, connect with brake coil, relay and diode.

Common connection of single-end output signals (common-cathode)

BRK

O

COMO

O

CL57T(V4.0) Closed-Loop Stepper Drive

4

Notes: (1) Shielding control signal wires is suggested; (2) To avoid/reduce interference, don’t tie control signal cables

and power wires together; (3) Brake output need to connect a relay and diode

3.2 P2 - Encoder Signals Input Connector

The P2 connector in Figure 2 is for encoder signals connection. Refer to the following table for details.

Drive Pin Name

Description

EB+

Encoder B+ input connection

EB-

Encoder B- input connection

EA+

Encoder A+ input connection

EA-

Encoder A- input connection

VCC

Encoder +5V voltage output connection

EGND

Power ground connection

3.3 P3 - Motor Connector

PIN

Details

A+

Connect to motor A+ wire

A-

Connect to motor A- wire

B+

Connect to motor B+ wire

B-

Connect to motor B- wire

3.4 P4 - Power Connector

Pin

Details

GND

Connect to power supply ground connection.

+VDC

Connect to power supply positive connection. Suggest 24-48VDC power supply voltage

!

Warning

Warning: Don’t plug/unplug P3 or P4 connector to avoid drive damage or injury while powered on.

3.5 LED Status Lights

There are two LED lights. The GREEN one is the power indicator which should be always on in normal circumstance.

The RED one is a alarm status indication light, which will be OFF while working normally but ON and flash some times

in a 3-second period in the case of enabled alarm protections.

3.6 Switches

The CL57T(V4.0) has one rotating switch, one 8-bit DIP switch and one 1-bit selector switch.

CL57T(V4.0) Closed-Loop Stepper Drive

5

Switch

Pic

Details

Rotating

switch S1

Drive Peak Current and Gain adjustment

DIP

switch S2

Microstep resolution

Rotation direction

Pulse Mode

Positional command filter

Closed / Open Loop Mode

Selector

switch S3

5V or 24V control signal voltage selector.

The factory setting is 24V, must need to set S3 to 5V if the control

signal voltage is 5V

4. Power Supply Selection

The CL57T(V4.0) can power medium and large size stepping motors (frame size from NEMA 17 to 24). To get good

driving performances, it is important to select supply voltage and output current properly. Generally speaking, supply

voltage determines the high speed performance of the motor, while output current determines the output torque of

the driven motor (particularly at lower speed). Higher supply voltage will allow higher motor speed to be achieved, at

the price of more noise and heating. If the motion speed requirement is low, it’s better to use lower supply voltage to

decrease noise, heating and improve reliability.

4.1 Power Supply Sharing

Multiple CL57T(V4.0) drives can share one power supply to reduce cost, if that power supply has enough power

capacity. To avoid cross interference, connect each stepper drive directly to the shared power supply separately. To

avoid cross interference, DO NOT daisy-chain connect the power supply input pins of the Drivers. Instead connect

them to power supply separately.

4.2 Selecting Supply Voltage

The CL57T(V4.0) is designed to operate within 18 - 50VDC voltage input. When selecting a power supply, besides

voltage from the power supply power line voltage fluctuation and back EMF voltage generated during motor

deceleration needs also to be taken into account. Please make sure leaving enough room for power line voltage

fluctuation and back-EMF voltage charge back, it’s recommended 24 - 48VDC.

Higher supply voltage can increase motor torque at higher speeds (>300 RPM), thus helpful for avoiding losing steps.

However, higher voltage may cause bigger motor vibration at lower speed, and it may also cause over-voltage

protection or even drive damage.

CL57T(V4.0) Closed-Loop Stepper Drive

6

5. Switch Configurations

5.1 S1 - Rotating Switch Configurations

This rotating switch is used to set the peak current of the drive and motion gain, from the motor phase current and

application requirements.

Peak

Current

RMS

Current

Code

Velocity

loop Ki

Position

loop Kp

Velocity

loop Kp

Remark

2.8A

2A

0 (factory)

0

25

25

1) Velocity loop Ki Indicates the stop time

and position accuracy , “0” indicates the

stop time is long, but the position error is

smaller.“16” means the stop time is short,

but the position error is slightly larger.

2) Position loop Kp and velocity loop Kp is a

pair of composite parameters that represent

rigidity. “25” and “25”composite parameters

indicate the rigidity is weak, “100” and

“5”composite parameters indicate the

rigidity is strong. Sometimes if the motor

will rotate after stopping, it can increase the

value of position loop Kp, but if the value is

too large, the motor will have noise.

3) Usually keep factory settings

1

0

50

15

2

16

25

25

3

16

50

15

5.6A

4A

4

0

25

25

5

0

50

15

6

0

100

5

7

16

25

25

8

16

50

15

9

16

100

5

7A

5A

A

0

25

25

B

0

50

15

C

0

100

5

D

16

25

25

E

16

50

15

F

16

100

5

5.2 S2 - DIP Switch Configurations

The 8-bit is located on the side (DIP switch S2 in Figure 2) and used to configure settings of micro step resolution,

output current, and motor standstill current as shown below

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Figure 3: DIP switches

5.2.1 Micro Step (SW1-SW4)

Each CL57T(V4.0) has 16 microstep settings which can be configured through DIP switches SW1, SW2, SW3 and SW4.

See the following table for detail.

Control mode

Rotation direction

Microstep

Pulse mode

Pulse filter time

CL57T(V4.0) Closed-Loop Stepper Drive

7

Micro step

Pulses/Rev. (for 1.8°motor)

SW1

SW2

SW3

SW4

1

200

on

on

on

on

4

800

off

on

on

on

8

1600

on

off

on

on

16

3200

off

off

on

on

32

6400

on

on

off

on

64

12800

off

on

off

on

128

25600

on

off

off

on

256

51200

off

off

off

on

5

1000

on

on

on

off

10

2000

off

on

on

off

20

4000

on

off

on

off

25

5000

off

off

on

off

40

8000

on

on

off

off

50

10000

off

on

off

off

100

20000

on

off

off

off

200

40000

off

off

off

off

5.2.2 Mode Setting (SW5 - SW8)

Function

ON

OFF

SW5

Rotation Direction

CW (clockwise)

CCW (counterclockwise)

SW6

Control Mode

Open loop control

Closed loop control

SW7

Pulse Mode

CW/CCW (double pulse)

PUL/DIR (single pulse)

SW8

Pulse Filter Time

Yes (10ms)

No (1.5ms)

CL57T(V4.0) has an advanced feature called Pulse Filter Time to make the input pulse from pulse generator (controller,

PLC, etc.) S-curve acceleration, to improve motion smoothness and high-speed start frequency in many

circumstances.

The Filter Time value must be set to the same for each CL57T(V4.0) in multi-axis applications

5.3 S3 - Selector Switch Configurations

The 1-bit selector is located on the top (S3 in figure 2), used to configure the voltage of control signals. For the safety

of optically coupled, the factory setting is 24V, which no need to connect 2K resistors, making it easier to use. When

the voltage of the control signal is 5V, the S3 must be set to 5V, otherwise, the motor won't work.

CL57T(V4.0) Closed-Loop Stepper Drive

8

6. Typical Connection

A complete closed loop stepper system should include a stepper motor with encoder, CL57T(V4.0) drive, power

supply and controller (pulse generator). A typical connection is as below.

Figure 4: Typical connection

Notes: (1) Pulse and direction inputs level 5V or 24V selected by selector switch S3. When it is 24 V, the S3 selection

of 5V will damage the input photo-coupling.

(3) Enable (ENA) signal is 5V~24V compatible.

6.1 Digital Input Connection

The CL57T(V4.0) can accept can accept differential or single-ended control signals (pulse, direction, and enable) in

open-collector or PNP connection through the P1 connector (figure 2). It is recommend to add an EMI line filter

between the power supply and the drive to increase noise immunity for the drive in interference environments.

Figure 5: Connections to open-collector signal Figure 6: Connections to PNP signal

(common-anode) (common-cathode)

Notes:

(1) ENA signal is no-connected as default;

(2) Control signal amplitude is 24 V as default. If it is 12 V, please set the S3 (Figure 2) selector switch to 5 V first, then

connect 1KΩ resistor; If it is 5V, please set the S3 to 5V.

Drive

Controller

VCC

PUL-

PUL+

ENA-

PUL

DIR

ENABLE

DIR-

DIR+

ENA+

Drive

Controller

VCC PUL-

PUL+

ENA-

PUL

DIR

ENABLE

DIR-

DIR+

ENA+

CL57T(V4.0) Closed-Loop Stepper Drive

9

6.2 Fault Output Connection

When over voltage or over current protection happens, CL57T(V4.0) red status LED light will blink and the impedance

state between ALM and COM- will change (from low to high or high to low depending on configuration) and can thus

be detected. Fault output connection is optional, and it can be connected either in sinking or sourcing.

Figure 7 Sinking output Figure 8 Sourcing output

6.3 Brake Output Connection

This drive has a special brake output, it needs to drive the motor brake with a relay. The connection is below:

Figure 9 Brake output connection

7. Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide by some rules, shown as

following diagram:

CL57T(V4.0) Closed-Loop Stepper Drive

10

Figure 10: Sequence chart of control signals

Remark:

a) t1: ENA must be ahead of DIR by at least 200ms. Usually, ENA+ and ENA- are NC (not connected). See

“Connector P1 Configurations” for more information.

b) t2: DIR must be ahead of PUL effective edge by 2us to ensure correct direction;

c) t3: Pulse width not less than 1us;

d) t4: Low level width not less than 1us;

e) Duty cycle of PUL signal is recommended 50%.

8. Fault Protections & Troubleshooting

To improve reliability, the drive incorporates some built-in protection features.

Blink

time(s)

Sequence wave of red LED

Description

Trouble shooting

1

0.2S

5S

Over-current

Turn off the power immediately.

a) Check wiring is short-circuited or not;

b) Check motor is short-circuited or not.

2

0.2S

0.3S

5S

Over-voltage

Turn off the power immediately.

a) Check if the power voltage is higher

than 90VDC

3

Chip error

Restart the power supply, if the drive is

still alarm, please contact after-sale

4

Fail to lock motor

shaft

a) The drive is not connected to a

motor;

b) If alarm is occurred when connect a

motor, please check the motor power

cable.

5

EEPROM error

Restart the power supply, if the drive is

still alarm, please contact after-sale

CL57T(V4.0) Closed-Loop Stepper Drive

11

6

Fail to auto tuning

Restart the power supply, if the drive is

still alarm, please contact after-sale

7

0.2S

0.3S

5S

Position following

error

a) Set SW6 to “ON” to make motor run

in open loop mode, If alarm disappears,

it means encoder wiring error;

b) Motor torque is not enough or motor

speed is too high;

Always

-

PCB board is

burned out

Restart the power supply, if the drive is

still alarm, please contact after-sale

When above protections are active, the motor shaft will be free or the red LED blinks. Reset the drive by repowering it

to make it function properly after removing above problems.

In the event that your drive doesn’t operate properly, the first step is to identify whether the problem is electrical or

mechanical in nature. The next step is to isolate the system component that is causing the problem. As part of this

process you may have to disconnect the individual components that make up your system and verify that they

operate independently. It is important to document each step in the troubleshooting process. You may need this

documentation to refer back to at a later date, and these details will greatly assist our Technical Support staff in

determining the problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise, controller software errors,

or mistake in wiring.

Symptoms

Possible Problems

Solutions

Motor is not rotating

No power

Connect power supply correctly

Microstep resolution setting is wrong

Setting appropriate microstep

Fault condition exists

Check wiring and restart power

The drive is disabled

Drive restore factory setting, and keep

ENA+, ENA- input signals unconnected.

Wrong motor rotation direction

The Direction signal level is reverse

Toggling the SW5 DIP switch

Erratic motor motion

Control signal is too weak

Ensure the current of control signal is

within 7-16mA

Control signal is interfered

Don’t tie the control signal cable with

power cable together

Wrong motor connection

Refer to user manual of drive and motor

datasheet

Something wrong with motor coil

Check the motor is normal

CL57T(V4.0) Closed-Loop Stepper Drive

12

Motor stalls during acceleration

Current setting is too small

Choose another power supply with lager

power or increase the output current of

drive

Motor is undersized for the application

Choose another motor with higher torque

Acceleration is set too high

Reduce the acceleration

Power supply voltage too low

Choose another power supply with large

voltage output

Excessive motor & drive heating

Inadequate heat sinking / cooling

Refer to chapter 2.4

Motor peak current setting is too high

Reduce the current value refer to motor

datasheet

Motor vibration when power on

Speed loop Kp is too high

Reduce the speed loop Kp value

Other manuals for CL57T

1

Table of contents

Other StepperOnline Control Unit manuals

StepperOnline

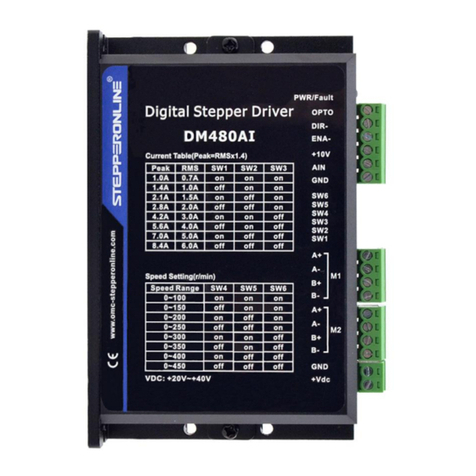

StepperOnline DM480AI User manual

StepperOnline

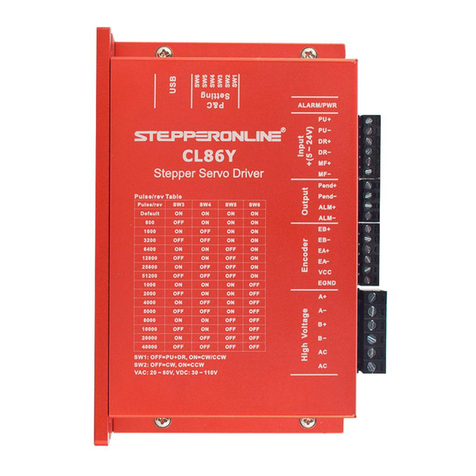

StepperOnline CL86T User manual

StepperOnline

StepperOnline Y Series Instruction Manual

StepperOnline

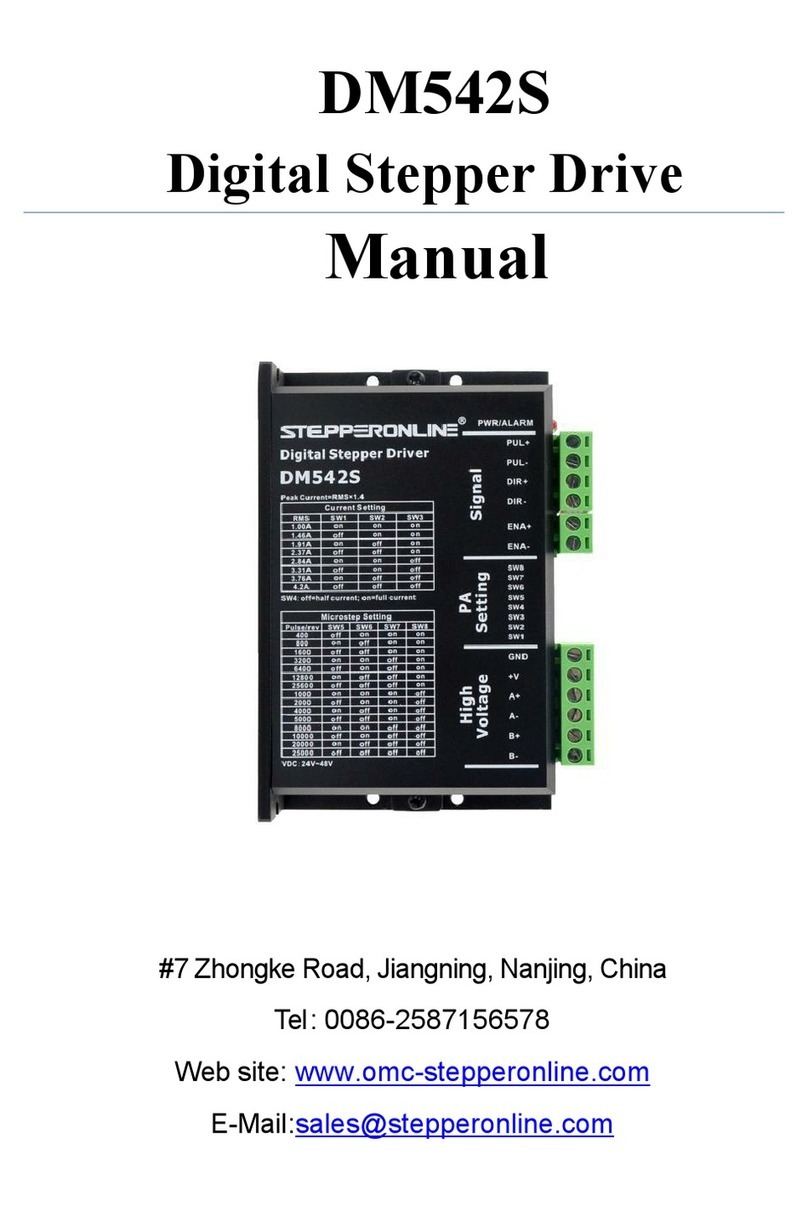

StepperOnline DM542S User manual

StepperOnline

StepperOnline DM542T User manual

StepperOnline

StepperOnline MA860H User manual

StepperOnline

StepperOnline DM542T User manual

StepperOnline

StepperOnline CL86T User manual

StepperOnline

StepperOnline DM456AI User manual

StepperOnline

StepperOnline ISD02 User manual