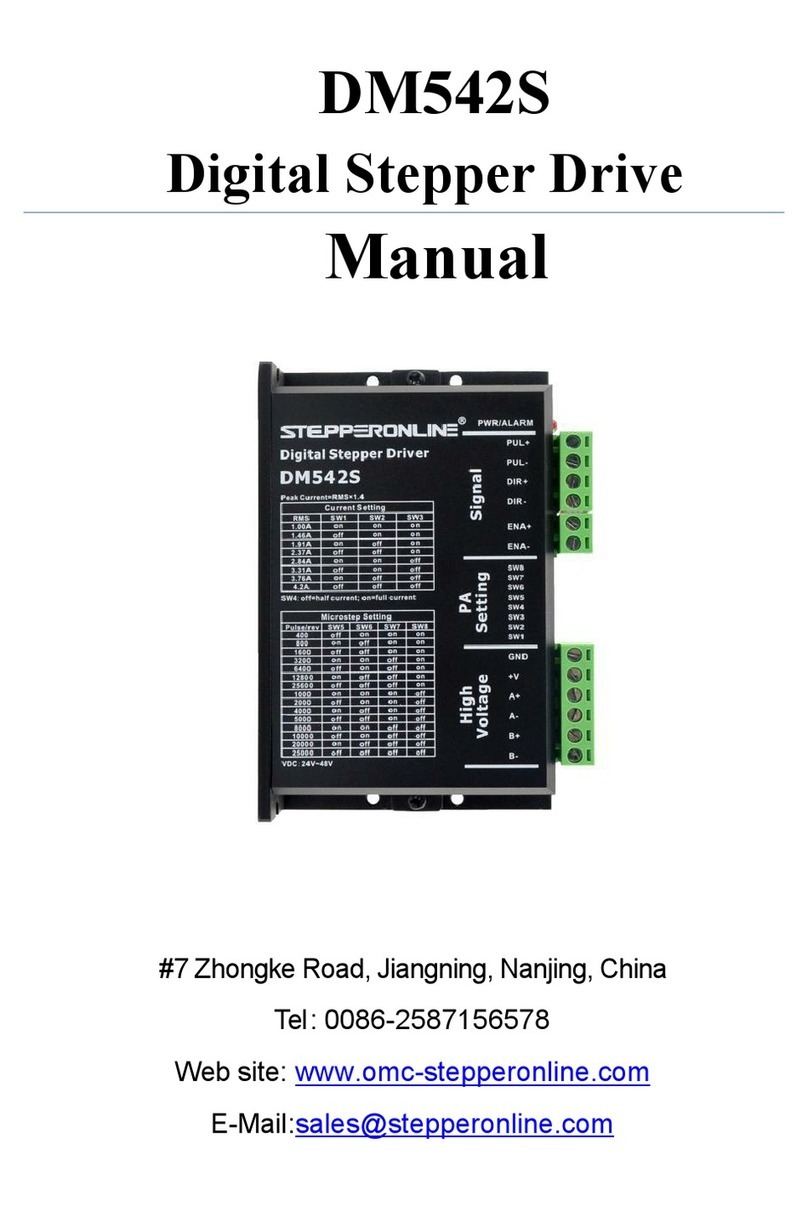

CL86T(V4.0) Closed Loop Stepper Drive User Manual

Table of Content

1. Features ..........................................................................................................................................................................1

2. Specifications .................................................................................................................................................................1

2.1 Electrical Specifications ..................................................................................................................................... 1

2.2 Environment .........................................................................................................................................................1

2.3 Mechanical Specifications .................................................................................................................................2

2.4 Heat Dissipation .................................................................................................................................................. 2

3. Connections and LED Indication ................................................................................................................................ 3

3.1 Control and Digital Output Connections ......................................................................................................... 3

3.2 Encoder Signals Input Connector .................................................................................................................... 3

3.3 Motor Connector ................................................................................................................................................. 4

3.4 LED Status Lights ............................................................................................................................................... 4

4. Power Supply Selection ....................................................................................................................................... 4

4.1 Power Supply Sharing ....................................................................................................................................... 4

4.2 Selecting Supply Voltage ...................................................................................................................................4

5.Switch Configurations ....................................................................................................................................................5

5.1 Rotating Switch Configurations ........................................................................................................................ 5

5.2 DIP Switch Configurations .................................................................................................................................5

5.2.1 Micro Step (SW1-SW4) .......................................................................................................................... 6

5.2.2 Mode Setting (SW5 - SW8) ................................................................................................................... 6

6. Typical Connection ........................................................................................................................................................6

6.1 Digital Input Connection .....................................................................................................................................6

6.2 Fault Output Connection ....................................................................................................................................7

7. Sequence Chart of Control Signals ............................................................................................................................8

8. Fault Protections & Troubleshooting ..........................................................................................................................9