StepperOnline ST-6560V3 User manual

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

1

User's Manual

For

ST-6560V3

Version 2.0

2016.08.25

All Rights Reserved

1. Key Features

Toshiba TB6560AHQ chip - High power, maximum current 3.5A

Resolution 1, 1/2, 1/8, 1/16 micro stepping output

Working voltage DC12-DC30V, rated voltage 24V

Adjustable current with 100%, 75%, 50%, 20% of full current by on-board switch.

Half current function when no signal to prevent motor heating

Build with a 277V 10A Relay

Manual Control circuit included

Overload, over-current and over-temperature safety

Protect the computer by using isolating power(1000V DC\DC) and optoelectronic coupler

Supports most parallel software MACH3, KCAM4, EMC2 etc.

Fixed in Aluminum box, better cooling function than fan and safer protection for board circuit

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

2

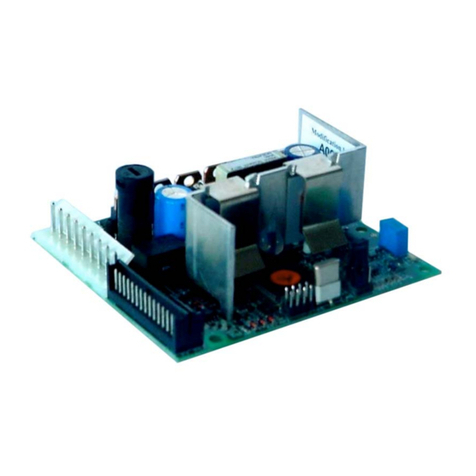

2. Photo of 3-AXIS CNC Board

DB25 LPT

Manual

control port &

4th extended

axis

Isolated power

3 axis drive module

X axis motor

12~24v

Power

Signal input

Relay output

AC 277V-10A relay

Relay output light

Power light

Y axis motor

Z axis motor

3 axis working light

overheat warning light

Parallel signal

drive &optical

coupling

interface

Microstep, decay, current setting

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

3

3. Hardware Installation

3.1 Selecting and Connecting Stepper Motors

WARNING: INCORRECT WIRING OF THE STEPPER MOTOR TO THE DRIVE BOARD CAN LEAD TO

IMMEDIATE DAMAGE OF DRIVE BOARD - DO NOT CONNECT OR DISCONNECT MOTORS WHILE POWER

IS ON.

4 Wire, 6 Wire, and 8 Wire stepper motors can be used.

4 Wire motors are recommended as they are by their manufacture true bipolar motors and easier

to properly connect to stepper motor drive controller.

It is critical to obtain a proper motor coil diagram of any motor you wish to utilize (making cross

connections between the two coils will destroy the control circuitry).

1.8 deg per step resolution is the industry standard for most automation grade stepper motors

and is recommended for most applications.

a. 4 Wire Stepper Diagram

Each wire is connected to its corresponding terminal block location (i.e. A- wire is connected at A-

location).

b. 6 Wire Stepper Diagram

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

4

Center wire of each coil not connected (insulate termination). Remaining wires are connected to their

corresponding terminal block location (i.e. A- wire is connected at A- location).

c. 8 Wire Stepper Diagram

2 center wires of each coil connected (insulate connection)

Remaining wires are connected to their corresponding terminal block location (i.e. A- wire is connected

at A- location).

If using 6 or 8 wire motors, connected using series wiring method, reduce labeled amperage rating by

50% (i.e. a motor rated at 4 amps should thus be considered now rated at 2 amps).

3.2 Connect to Computer by DB25

The following is to aid in the setup of the use of controller with various CAM software programs

operating on your computer.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

5

PIN

Signal

1

NC

2

X axis pulse input

3

X axis direction input

4

Y axis pulse input

5

Y axis direction input

6

Z axis pulse input

7

Z axis direction input

8

NC

9

NC

10

LPT input signal 1 (corresponding IN1 on the board)

11

LPT input signal 2 (corresponding IN2 on the board)

12

LPT input signal 3 (corresponding IN3 on the board)

13

LPT input signal 4 (corresponding IN4 on the board)

14

NC

15

NC

16

All axis enable input

17

Output control of relay (277V/10A)

18-25

GND

It is critical that your computer has parallel port DB25 outlet, If your computer does not feature a DB25

outlet, you must install one, (these can be achieved via PCMIA cards on laptop computers). The use of

adapters and hubs is not recommended and most likely will not work.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

6

3.3 Manual Control

PIN

Input Signal 0V~5V

1

X axis pulse input

2

X axis direction input

3

Y axis pulse input

4

Y axis direction input

5

Z axis pulse input

6

Z axis direction input

7

All axis enable input

8

Connect to the collector of NPN in relay, and connect to 24V through relay

9

NC

10

NC

11

NC

12

Connect to the base of NPN in relay, and pull-up to 5V by 4.7K resistance

13

5V power output (<50mA condition)

14

Direct connecting to IN1, as the input signal of parallel port PIN10

15

Power GND

3.4 Port for extending and relay

PIN (0V~5V)

1

2

3

4

5

6

7

8

9

10

Input Signal

IN1

IN2

IN3

IN4

GND

NC

NC

L2

NC

L1

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

7

4. Setting

4.1 Current adjusting and default testing

Working Current--> Pause current

S1

S2

S3

S4

20%-->20%

0

0

1

1

50%-->20%

0

1

0

1

75%-->20%

0

0

1

0

75%-->50%

1

0

0

0

100%-->20%

0

1

0

0

100%-->50%

0

0

0

0

EXAMPLE: 75%-->20%

Working current=3.5A *75%, Pause current=3.5A *20%

4.2 Subdivision mode & Decay mode setting

S5

S6

S7

S8

1

1

1

NO DECAY

1

1

1/2

1

0

SLOW DECAY

1

0

1/8

0

0

MID DECAY

0

1

1/16

0

1

FAST DECAY

0

0

Note: If there is bumming when motor running or locked, it can be eliminated by setting the decay mode.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

8

5. How to use MACH software?

See Pic.1: open MACH3, choose Mach3mill,click OK.

Pic.1

See Pic.2, there are common use buttons.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

9

Pic.2

See Pic.3, open config-----ports and pins

Pic.3

See Pic.4, Circle 1 frequencies setting, to control the speed, and then click Circle 2 to define ports & pins.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

10

Pic.4

See Pic. 5, X\ Y\ Z\ axis “motor outputs”

Pic.5

See Pic. 6, set “output signals”

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

11

Pic.6

See Pic. 7, pulse width setting: Step impulse: 5us, Direction impulse: 5us

Pic.7

Pls click “load G-code”, see Pic.8 and Pic.9

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

12

Pic.8

Pic.9

After open the G-code, the Reset light is blinking which means you are in stop condition. You can solve it

by clicking the Reset button(see circle 1), then click circle 2 to start“Cycle-start”.

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

13

Pic.10

If you need manual control, pls click TAB button (see Pic.11)

Pic.11

6. FAQ

1. Q: For long time working, the aluminum housing very hot, it’s normal?

A: Yes. It’s normal, at normal temperature, housing temperature reach 90℃ is normal.

2. Q: How to confirm A+, A-, B+, B- of stepper motor?

A: Choose two wire randomly, connect them, see if there is resistance when run the motor shaft

using finger, if there is resistance, then you take these two wires with A+ and A-, and the rest of

the wire will be B+ and B-.

3. Q: There is vibration when motor running or noise when motor locking, how to eliminate it?

A: You can try to set the decay mode to eliminate it.

7. Contact

3-Axis TB6560 CNC Driver Board User Manual - ST-6560V3

14

For further technical questions, please don’t hesitate contact us: technical@stepperonline.com.

Table of contents

Other StepperOnline Controllers manuals

Popular Controllers manuals by other brands

Huawei

Huawei PDU8000-0125DCV8-BXA006 user manual

Swytch

Swytch Twist manual

Sutter

Sutter MPC-200 quick start guide

Agilent Technologies

Agilent Technologies 8169A user guide

Emerson

Emerson Dixell XR30CX-4S1C1 Installing and operating instructions

Emerson

Emerson Dixell XWi70K Installing and operating instructions

Halma

Halma ALICAT SCIENTIFIC PC quick start guide

Lawn Genie

Lawn Genie L80306P Installation and operation guide

NETGEAR

NETGEAR ProSafe WC7520 Reference manual

Varian

Varian Turbo-V 81 969-9538 instruction manual

National Instruments

National Instruments cRIO-9063 manual

maxon motor

maxon motor EPOS4 50/5 Hardware reference