StepperOnline T6 User manual

QUICK START OF T6 AC SERVO

©2022 All Rights Reserved

Address:15-4, #799 Hushan Road, Jiangning, Nanjing, China

Tel: 0086-2587156578

Web: www.omc-stepperonline.com

Sales:[email protected]

Support: [email protected]

Table of Contents

Preparation List

Chapter 1 JOG Trail

1.1 Connection

1.2 JOG Trail

Chapter 2 Position Control (Pul + Dir)

2.1 Connection

2.2 Main Steps to Tune T6 Drives in Position Mode

Quick Start of T6 AC Servo

3

Preparation List

T6 drive

Motor

Cables

Motor power cable

Encoder feedback cable

Tune cable

Drive power cable

Tune software (Motion Studio)

The driver of tune software (if it is necessary)

Quick Start of T6 AC Servo

4

Chapter 1 JOG Trail

1.1 Connection

1.1.1 Cables connection.

1.1.2 Connect to tune software. (Perform this step if it is necessary to install

driver)

1.1.2.1 Click in turn “Device Manager”, “Ports (COM&LPT)”, “STEPPERONLINE Driver”,

“Update driver”.

L1/L2: Drive Power Cable Connection

PE: Ground Cable Connection

U/V/W: Motor Power Cable Connection

CN4: Tune Cable Connection

CN3: Encoder Feedback Cable Connection

Quick Start of T6 AC Servo

5

1.1.2.2 Click “Browse my computer for drivers”.

1.1.2.3 Search for drivers in the location

from “USB_Driver” folder in which you

placed the application that

STEPPERONLINE provide, and then

accomplish updating driver.

1.2 JOG Trail

1.2.1 Click icon of Motion Studio to enter in.

1.2.2 Click “Com Connect ”, and select

appropriate communication port and baud

rate to start connecting.

Note: Recommend communication port under

COM10.

Quick Start of T6 AC Servo

6

1.2.3 Click “Run Testing ”, and

tune Pr0.04 inertia ratio and Pr0.03

stiffness, click “download” to save

modified parameters, finally click

“Servo Enable” to start JOG trail.

Note: All parameters could be modified from

“Parameter Manage ”; clicking

“Download ” is necessary to modified

parameters under “Run Testing ”, not

necessary under “Parameter Manage ”.

1.2.4 Click “Wave Show ”, and select waveform parameters you want to

capture, finally click “Capture” to display real-time waveform.

Quick Start of T6 AC Servo

7

Chapter 2 Position Control (Pul + Dir)

2.1 Connection

2.1.1 Cables connection

2.1.1.1 Cover display.

L1/L2: Drive Power Cable Connection

PE: Ground Cable Connection

U/V/W: Motor Power Cable Connection

CN4: Tune Cable Connection

CN3: Encoder Feedback Cable Connection

CN1: Pulse+Direction Cable Connection

CN2: Digital Input/ Output Cable Connection

Quick Start of T6 AC Servo

8

2.1.1.2 Wiring sketch map.

Quick Start of T6 AC Servo

9

2.1.1.3 I/O terminal definition.

Port

Pin

Signal

Name

Explanation

CN1

1

PUL+_24

24V pulse+

Hardware filtering achieves the

maximum bandwidth of 750kHz

2

DIR+_24

24V direction+

3

PUL+

5V pulse+

4

PUL-

Pulse-

5

DIR+

5V direction+

6

DIR-

Direction-

Port

Pin

Signal

Name

Explanation

CN2

1

COM+

Digital input

common terminal,

12VDC~24VDC

Two-way digital input with

common terminal, function can

be configured.12VDC ~ 24VDC

2

SI1

Digital input 1

3

SI2

Digital input 2

4

SI3

Digital input 3

5

SI4

Digital input 4

6

COM-

Digital output

common- terminal

Low resistor output in default.

OC, the maximum

voltage/current is no more than

30V, 50mA.

Recommend the voltage: 12

V-24V.

Current :10mA

7

SO1

Digital output 1

8

SO2

Digital output 2

9

SO3+

Differential Digital

output 3

Differential Digital output,the

maximum voltage/current is no

more than 30V/50mA .

Recommended voltage: 12

-24V.

Current :10mA

10

SO3-

Quick Start of T6 AC Servo

10

2.1.1.4 I/O input signal circuit.

A. The power supply is provided by user, DC 12-24V, current ≥100mA, if the power polarity

connects reversely, the drive won’t run.

B. If the drive is enabled by internal signal, then user won’t need to connect to Pin1and Pin2.

Pr4.00=83 for internal enable.

Pr4.00=3 for external enable.

2.1.1.5 I/O output signal circuit.

A. The power supply is provided by user, if the power polarity connects reversely, the drive will be

damaged.

B. The output circuit adopts open-collector, the maximum voltage is 25V, and maximum current is

50Ma. If user overlooks the requirements or output terminal directly connected to power supply, the

drive will be damaged.

C. If the load is inductive load, etc., anti-parallel freewheeling diode must connect to the load, if the

freewheeling diode connects reversely, the drive will be damaged.

D. Pin 31/32/33/34/35 are for single-ended output, pin 18/19, 20/21are for differential output.

2.1.1.6 Pulse input signal circuit.

Wiring method of 5V differential signal (Pin 3/4/5/6)

Quick Start of T6 AC Servo

11

Wiring method of 24V single-ended signal (Pin 4/6/16/17)

A. The drive support two wiring methods: 5V differential signal and 24V single-ended signal.

B. 5V differential signal are recommended to get more accurate pulse signal data.

C. While 24V single-ended signal are adopted, the power supply is provided by user, if the power

polarity connects reversely, the drive will be damaged.

D. Pulse input signal format show as below chart, in addition, 4 times pulse frequency ≤ 500kH while

adopting 2 phase input.

2.1.2 Connect to tune software. (Perform this step if it is necessary to install

driver)

Refer to section 1.1.2 of chapter 1.

2.2 Main steps to tune T6 Drives in position mode

(1) Connect the wire correctly (motor will be recognized by drive automatically );

(2) Use “run testing” to test the motor if motor run normally or not.

(3) Set the value of Pr400 (Pr400=83 for external servo on signal ; Pr400=3 for internal signal )

(4) Choose right control mode Pr0.01. (0: position mode, 1: velocity mode, 2: torque mode).

(5) Connect the motor with load and Tuning the inertia ratio(Pr0.04)

(6) Connect the motor with load and Tuning stiffness for each axis (Pr0.02, Pr0.03).

(7) Tune Pr2.22 and Pr2.23 for smoother moving if needed.

(8) Set the value of Pr006, 007,008,009,010.

(9) Tune Pr0.00 for more stiffness if needed.

Quick Start of T6 AC Servo

12

Run Testing

Use “run testing” of software protuner to tune the drive. Make sure the shaft of motor is free before

running it, and please release the brake firstly if motor is with brake.

Control mode setting (Pr0.01)

Then connect the wire correctly and use controller to check whether motor run normally or not.

Mode of real-time auto-gain tuning setting (Pr0.02)

Select different operation mode in real-time automatic adjustment mode,

Pr0.01*

Control Mode Setup

Range

unit

default

Related

control mode

0 -10

-

0

P

S

T

Set using control mode

Setup value

Content

1st mode

2nd mode

0

Position

-

1

Velocity

-

2

Torque

-

6

Pr-Mode

When you set up the combination mode of 3.4.5, you can

select either the 1st or the 2nd with control mode switching

input(C-MODE).

When C-MODE is open, the 1st mode will be selected.

When C-MODE is shorted, the 2nd mode will be selected.

1.Set parameters for run testing:

Specially pay attention to Pr0.03 Stiffness

and Pr0.04 Inertia ratio which strongly

corresponding to better performance

2.Run testing guidance

Click button “Servo enable”

Click “CCW” to make motor run in CCW

direction , click ”Position 1” to save the

testing position limit 1

Click “CW” to make motor run in CW

direction, click ”Position 2” to save the testing

position limit 2

Click ”Run” to start Testing progress

3.During the Run Testing progress,the

wave show monitor the performance of

the current parameters setting.

Quick Start of T6 AC Servo

13

Performance adjustment—Tuning the inertia ratio(Pr0.04)

It is very important to find the ratio of inertia for one axis, in order to make best performance before

setting other parameter (for example, setting PID of position loop or velocity loop).

Connect motor with load if you need to test one axis.

Make sure the axis can be moved in safe distance, any interference should be avoided to ensure

safety and accuracy of testing.

Inertia ratio identification

Pre-conditions:

1. Servo disable.

2. Positive limit and negative limit invalid

Steps:

1 Set the Jog speed Pr6.04, and the setting should not

be too large(300~1000rpm is recommend)

Set the Acc Pr6.25 (50~100 ms/1000rpm is recommend)

Set the Default Inertia Ratio.

Download these settings, then Servo Enable.

2. Click “CCW” to make motor run to CCW direction,

click “Position 1” to save the position limit 1

Click “CW” to make motor run to CW direction,click

“Position 2” to save the position limit 2

Click “Run” to start Inertia ratio dentification.

3. After finishing,Click“Write”to save the Inertia ratio

identification result into NVM.

In Manual mode(Pr0.02=0), Kp, Ki and

other parameters can be set manually.

Pr003 is unavailable now .

About how to tune position loop, Ki can be

adjusted to a very small value in advance

and hold it constant, then enlarge the

value of Kp parameter slowly until system

oscillation occurs, at this moment enlarge

the value of Vi parameter slowly until

system oscillation occurs, at this moment

the basic adjustment of system is finished.

In Standard mode (Pr0.02=1), it is usually

for interpolation movement. It is

unavailable to modify the value of Pr1.00-

1.14, just change the value of Pr0.03 , then

all values of Pr1.00-1.14 will be changed at

the same time .

In Positioning mode(Pr0.02=2), it is

usually for point to point movement. It is

unavailable to modify the value of Pr1.00-

1.14, just change the value of Pr0.03, then

all values of Pr1.00-1.14 will be changed at

the same time.

Quick Start of T6 AC Servo

14

Performance adjustment—Gain adjustment(Pr0.03)

The definition of Pr0.03

The following figure showing Pr0.02=2, Pr0.03=70, the position error (curve in red) is unacceptable!

Keep decreasing value of Pr0.03, then the position error become smaller and smaller.

Pr0.03

Selection of machine stiffness at real-

time auto-gain tuning

Range

unit

default

Related

control mode

50 -81

-

70

P

S

T

You can set up response while the real-time auto-gain tuning is valid.

Notice: Lower the setup value, higher the velocity response and servo stiffness will be

obtained. However, when decreasing the value, check the resulting operation to avoid

oscillation or vibration.

Control gain is updated while the motor is stopped. If the motor can’t be stopped due to

excessively low gain or continuous application of one-way direction command ,any change

made to Pr0.03 is not used for update. If the changed stiffness setting is made valid after the

motor stopped, abnormal sound or oscillation will be generated. To prevent this problem, stop

the motor after changing the stiffness setting and check that the changed setting is enabled.

Quick Start of T6 AC Servo

15

Pr0.03=66

Pr0.03=62

As keep decreasing the value pf Pr0.03, the position loop gain Kp become bigger and bigger, the

integration time constant Vi become smaller and smaller, the position error become close to zero.

Pr0.03=61

Quick Start of T6 AC Servo

16

The noise of motor occurs and alarm occurs if the position loop gain becomes bigger, so just make

sure there is no noise.

Finally, set Pr0.03=62, the basic setting for position loop is finished in Position mode.

Simple debugging for position control

•Debugging steps

(1) Confirm pulse polarity Pr0.06, command input mode Pr0.07

(2) Modify Pr0.08 and set a suitable electronic gear ratio, if intend to set non-integral electronic gear

ratio, can use Pr0.09 and Pr0.10.

(3) Set suitable inertia with Pr0.04; suggest increase/decrease the value In multiples of 100.

(4) Adjust Pr0.03 to be a suitable stiffiness value. Suggest to set it from big to small until sharp noise

appear

(5) Each time you modify parameters, pls execute save steps and restart the power.

•Basic parameter debugging

Remark:

1. Default for Pr0.08 pulse per rev is 10000.

2. Electronic gear ratio can be also set by Pr0.09(numerator) and Pr0.10(denominator), Pr0.08

must be set as 0 before that.

3. Input pulse frequency which is higher than 500K can not be identified by driver. Assuming that

10000 ppr, that means corresponding command bandwidth of 3000rpm can reach to 500k. If

motor run above 3000 rpm, the pulse per rev must be lower than 10000.

Parameters

Range

Details

Pr0.01(Control mode)

0/1/2

Pr0.01=0 for Position Mode

Pr0.02

(Real-time auto configuration)

0/1/2

Pr0.02=0 for Manual mode, Real-time auto-gain tuning

function is disabled.

Pr0.02=1 for Standard mode, it is usually for interpolation

movement. It is unavailable to modify the value of Pr1.00-

1.14, just change the value of Pr0.03, then all values of

Pr1.00-1.14 will be changed at the same time.

Pr0.02=2 for Positioning mode, it is usually for point to

point movement. It is unavailable to modify the value of

Pr1.00- 1.14, just change the value of Pr0.03, then all

values of Pr1.00-1.14 will be changed at the same time .

Pr0.03(Machine rigid)

50 -81

Default value is 70, lower the setup value, higher the

velocity response and servo stiffness will be obtained.

Pr0.04(inertia ratio)

0—10000

Default value is 250, Pr0.04=( load inertia/rotate

inertia)×100%

Pr0.06(Pulse polarity setting)

0/1

Set Pr0.06 to change the rotation direction.

Pr0.07(Pulse input model)

0/1/2/3

Command Pulse Input Mode, set Pr0.07 according to

controller signal

Pr0.08(command pulse per

motor rotation)

0-8388608

1) If Pr008≠0 , the motor actual turns = pulse number /

Pr008

2) If Pr008=0 , Pr0.09 1st numerator of electronic gear and

Pr0.10 Denominator of electronic gear become valid.

Pr0.09(numerator of

electronic gear)

0-8388608

If Pr008=0 , Pr0.09 1st numerator of electronic gear and

Pr0.10 Denominator of electronic gear become valid.

Pr0.10(denominator of

electronic gear)

0-8388608

Quick Start of T6 AC Servo

17

Position command filter

To make the positional command divided or multiplied by the electronic gear smooth, set the

command filter.

Tuning the dynamic tracking performance (Pr0.00) (optional)

Notes: set Pr0.02=2 if application is point to point movement, no need to tune the dynamic tracking

performance. set Pr0.02=1 if application is interpolation movement, it is very useful to tune the

dynamic tracking performance. MFC function is very useful for better dynamic tracking control and

contouring cutting.

Model Following Control (MFC)

As a new control technology, MFC is used to enhance the performance of dynamic tracking for input

command, make positioning faster, cut down the tracking error, run more smooth and steady .

There are two different way to use it, one is set Pr0.00 =1, the other is set Pr0.00 as another integer

which is more than 10 .

It is very useful for multi-axis synchronous movement and interpolation, the performance will be better

if the value of each axis is the same.

Pr2.22

positional command smoothing filter

Range

unit

default

Related

control mode

0 -32767

0.1ms

0

P

Set up the time constant of the1st delay filter in response to the positional command.

When a square wave command for the target speed Vc is applied ,set up the time constant of

the 1st delay filter as shown in the figure below.

Pr2.23

positional command FIR filter

Range

unit

default

Related

control mode

0 -10000

0.1ms

0

P

Set up the time constant of the1st delay filter in response to the positional command.

When a square wave command for the target speed Vc is applied, set up the Vc arrival time as

shown in the figure below.

Quick Start of T6 AC Servo

18

The steps to use this function:

a. Choose the right control mode : Pr0.01 = 0

b. Set up Pr0.02=1 for interpolation movement

c. Set up the inertia ratio : Pr0.04

d. Set up the rigidity : Pr0.03

e. Set up the Pr0.00 :

1) If no multi-axis synchronous movement , set Pr0.00 as 1 or more than 10 ;

2) If multi-axis synchronous movement needed , set Pr0.00 as the same for all the axes .

3) If Pr0.00 is more than 10 , start with 100 , or 150 , 200 , 250 , …. .

Caution:

1. Set up the right control mode, the correct inertia of ratio and rigidity firstly .

2. Don’t change the value of Pr0.00 when the motor is running, otherwise vibration occurs .

3. Set up a small value from the beginning if using it in manual mode, smaller value means running

more smooth and steady, while bigger one means faster positioning.

Pr0.00

Mode loop gain

Range

unit

default

Related

control mode

0 -32767

0.1Hz

0

P

Set up the bandwidth of MFC , it is similar to the response bandwidth

Setup value

Meaning

0

Disable the function.

1

Enable the function , set the bandwidth automatically ,

recommended for most application .

2-10

Forbidden and reserved .

11-20000

Set the bandwidth manually , 1.1Hz – 2000Hz

Table of contents

Other StepperOnline Controllers manuals

Popular Controllers manuals by other brands

Hobby-Wing

Hobby-Wing Skywalker Quattro 20A*4-UBEC Series manual

Delta

Delta DVP08SM11N instruction sheet

Saia Burgess Controls

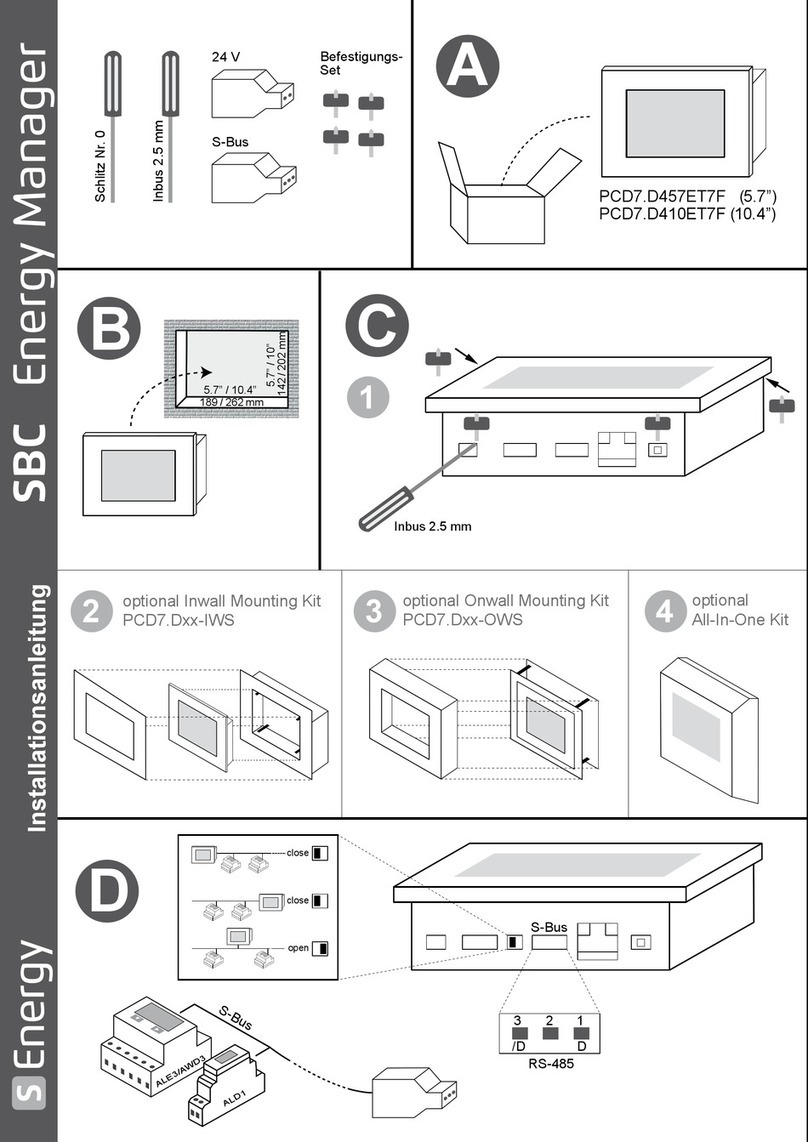

Saia Burgess Controls S Energy PCD7.D457ET7F manual

Show Tec

Show Tec LED Octostrip Set MKII 100 cm V2 manual

Show Tec

Show Tec Festoonlight Q4 Booster manual

Welbilt

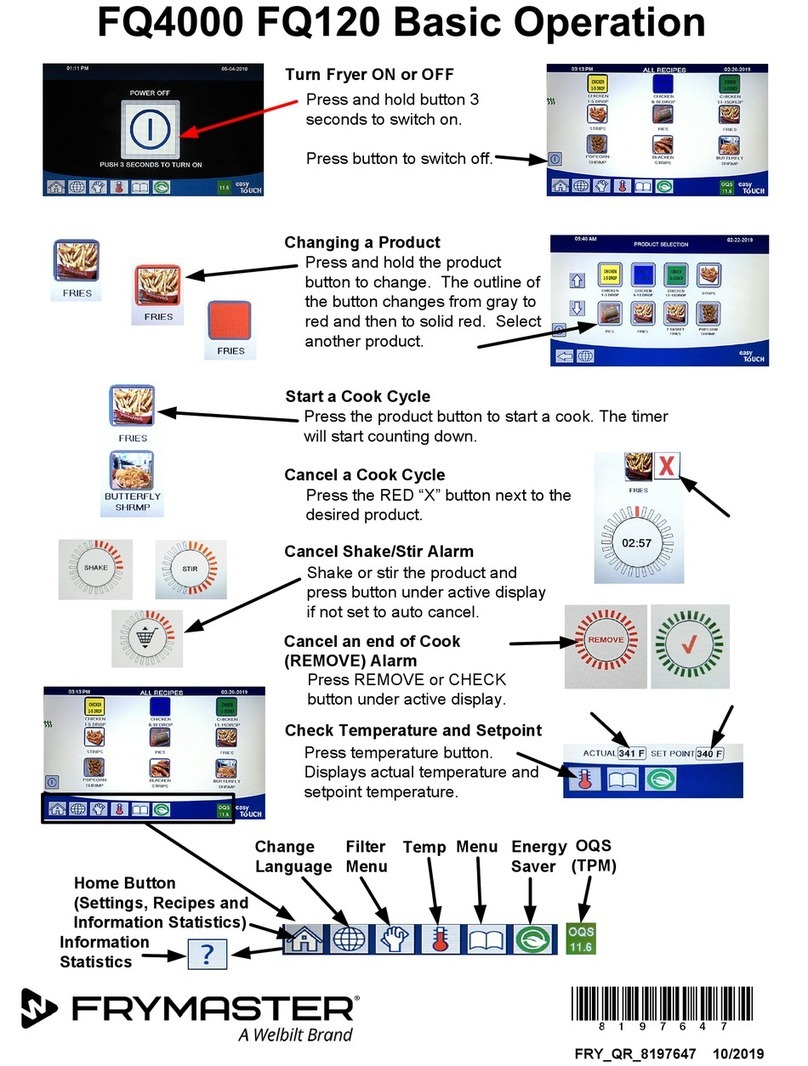

Welbilt FRYMASTER FQ4000 FQ120 Basic operation