Tech Support: consumer.steppir.com/support | 425.453.1910 | support@steppir.com

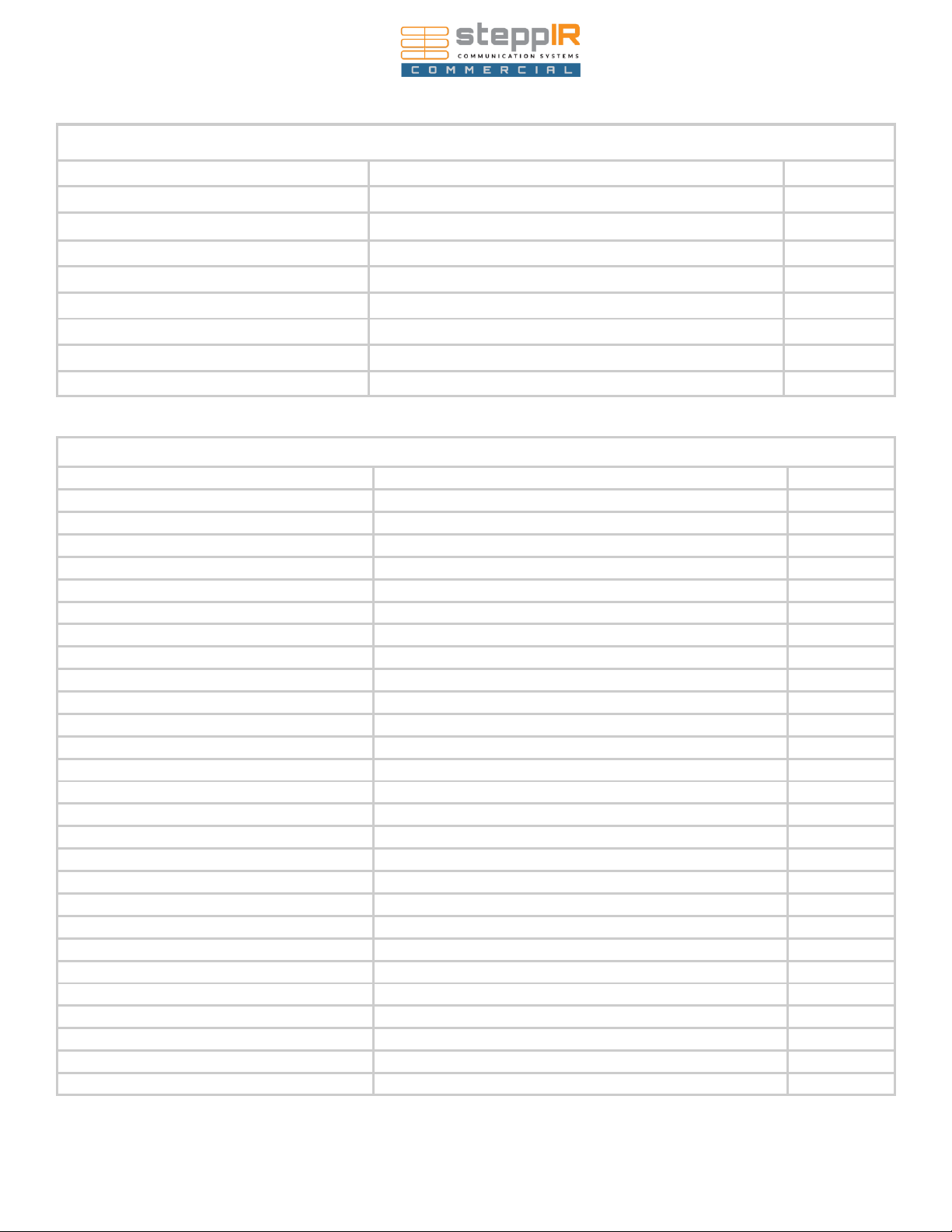

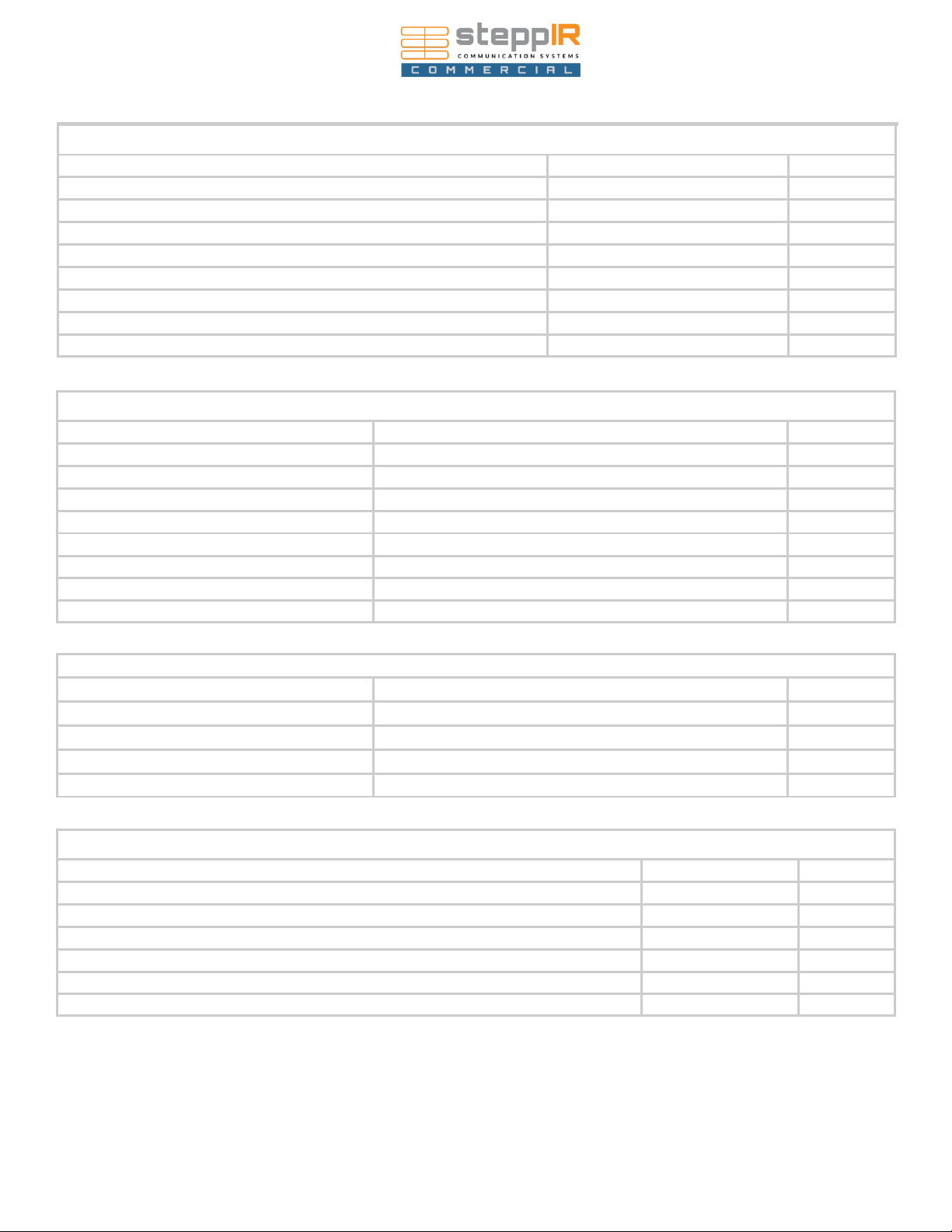

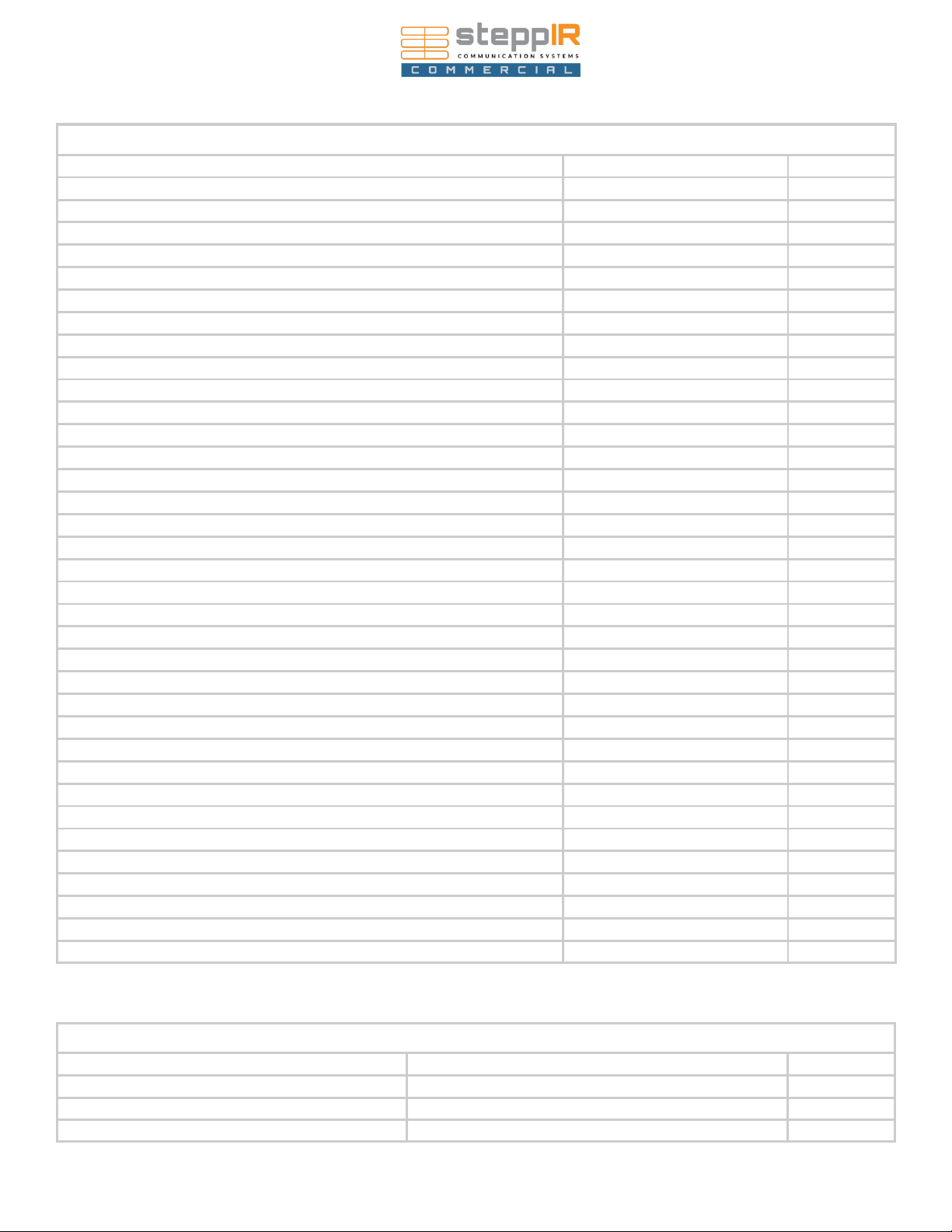

INVENTORY CHECKLIST—CONTINUED

Vinyl Cap, 1.5" x 1.5", Black, with hole

Vinyl Cap, 1.75" x 1.5", Black, with hole

Vinyl Cap, 2.5" x 1.5", Black, with hole

Vinyl Cap, 2.25" x 1.5", Black, w/o hole

Vinyl Cap, 2.5" x 1.5", Black, w/o hole

Plug for Square Tube, 4", Black

Polyolefin Heat Shrink, 1.5" x 3"

Phillystran Rubber Cap (2100i)

Phillystran Rubber Cap (for 4000i)

Urethane Adhesive, 3M Scotch-Weld DP620NS

Glue Gun, 50ml , 1:1 / 1:2

Threadlocker, No. 42, 10 ML Medium Strength

6 In. Safety Wire Twisting Pliers

Electrical Tape, 3M Super 88

Coax Seal (sold per inch)

0.032" S/S lock wire (full roll)

Element Truss Attachment Plate - 2in

Element Truss Attachment Plate - 4in

Coax Switch and Connector Junction Box Dual Mounting Bracket

Connector Junction Box, DB42

Rubber Quick-Disconnect Boot

Stress Relief Sleeve, 1.5" ID x 1.75" OD

Stress Relief Sleeve, 1.75" ID x 2" OD

Stress Relief Sleeve, 2.5" ID x 3" OD

Filter, suppressor unit, 8 position, 50v

Filter, suppressor unit, 16 position, 50v

Control Cable, 24c (customer specifies length)