Steri-Cult 3307 Series Operating instructions

Steri-Cult

Model 3307 and 3310 Series CO2 Incubator

Controlled RH with Sterilization Cycle

Operating and Maintenance Manual 7023307 Rev. 15

Thermo Scientific

MANUAL NUMBER 7023307

15 28727 6/18/12 Clarified nebulizer flush instructions - pg 7-4 & 7-5 ccs

14 28408 5/18/12 Chg’d 95% non-condensing in Specifications to 90% ccs

13 27891 10/27/11 Clarified Water Empty alarm language on pg 5-3 ccs

12 27292/IN-4073 9/28/11 400119 to 400201 switcher kit - pg 11-1 ccs

11 27162/IN-4071 3/24/11 Added pilasters and shelf channels to Parts Listccs

-- -- 11/24/10 Corrected typo in chart above: 3308/3310, medium/large ccs

10 25128/IN-3882 4/7/10 Missed correction from water bottle change (pgs 1-10, 7-3 & 7-4) ccs

9 25480/SI-10033 11/4/09 Common shelf channel (pg 1-7 & 1-8 artwork and 11-1 parts list) ccs

8 25128/IN-3882 9/21/09 Updated water bottle to current production (0.5 gal) ccs

7 25387/SI-10033 4/2/09 Removed soft-stops from page 1-8 ccs

Preface

7023307 Steri-Cult i

Model Size Voltage

3307 Medium 115

3308 Medium 230

3310 Large 115

3311 Large 230

Thermo Scientificii 7023307 Steri-Cult

Preface

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

CAUTION

Important Read this instruction manual. Failure to read, understand and follow the instructions in this manual

may result in damage to the unit, injury to operating personnel, and poor equipment performance. s

Caution All internal adjustments and maintenance must be performed by qualified service personnel. s

Caution If the incubator is not used in the manner specified in this operating manual, the protection provided

by the equipment design may be impaired. s

Material in this manual is for information purposes only. The contents and the product it describes are subject

to change without notice. Thermo Fisher Scientific makes no representations or warranties with respect to this

manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising out of or related

to the use of this manual.

©2007 Thermo Fisher Scientific Inc. All rights reserved.

Thermo Scientific 7023307 Steri-Cult iii

Preface

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this

symbol.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be

damaged by elevated temperatures.

Marking of electrical and electronic equipment, which applies to electrical and electronic equipment

falling under the irective 2002/96/EC (WEEE) and the equipment that has been put on the market

after 13 August 2005.

This product is required to comply with the European Union’s Waste Electrical & Electronic

Equipment (WEEE) irective 2002/96/EC. It is marked with the WEEE symbol. Thermo Fisher

Scientific has contracted with one or more recycling/disposal companies in each EU Member State

European Country, and this product should be disposed of or recycled through them. Further

information on Thermo’s compliance with this directive, the recyclers in your country and

information on Thermo Scientific products will be available at www.thermofisher.com.

4Always use the proper protective equipment (clothing, gloves, goggles, etc.)

4Always dissipate extreme cold or heat and wear protective clothing.

4Always follow good hygiene practices.

4Each individual is responsible for his or her own safety.

Thermo Scientificiv 7023307 Steri-Cult

Preface

Do You Need Information or Assistance on

Thermo Scientific Products?

If you do, please contact us 8:00 a.m. to 6:00 p.m. (Eastern Time) at:

1-740-373-4763 Direct

1-800-438-4851 Toll Free, U.S. and Canada

1-877-213-8051 FAX

http://www.thermoscientific.com Internet Worldwide Web Home Page

service.led.marietta@thermofisher.com Tech Support Email Address

Certified Service Web Page

Thermo Fisher Scientific

401 Millcreek Road, Box 649

Marietta, OH 45750

Our staff can provide information on pricing and give you quotations. We can

take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Our staff can supply technical information about proper setup, operation or

troubleshooting of your equipment. We can fill your needs for spare or replacement parts or

provide you with on-site service. We can also provide you with a quotation on our Extended

Warranty for your Thermo Scientific products.

Whatever Thermo Scientific products you need or use, we will be happy to discuss your

applications. If you are experiencing technical problems, working together, we will help you

locate the problem and, chances are, correct it yourself...over the telephone without a service

call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to your

satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist you

Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time. Please contact us by

telephone or fax. If you wish to write, our mailing address is:

International customers, please contact your local Thermo Scientific distributor.

Sales Support

Service Support

www.unitylabservices.com

Thermo Scientific 7023307 Steri-Cult v

Preface

Warranty Notes

Information You Should Know Before Requesting Warranty Service

•Locate the model and serial numbers. A serial tag is located on the unit itself.

• For equipment service or maintenance, or with technical or special application inquiries, contact Technical

Services at 1-800-438-4851 or 1-740-373-4763 (USA and Canada). Outside the USA, contact your local

distributor.

Repairs NOT Covered Under Warranty

• Calibration of control parameters. Nominal calibrations are performed at the factory; typically ±1°C for

temperature, ±1% for gases, and ±5% for humidity. Our service personnel can provide precise calibrations as

a billable service at your location. Calibration after a warranty repair is covered under the warranty.

• Damage resulting from use of improper quality water, chemicals or cleaning agents detrimental to

equipment materials.

• Service calls for improper installation or operating instructions. Corrections to any of the following

are billable services:

1) electrical service connection

2) tubing connections

3) gas regulators

4) gas tanks

5) unit leveling

6) room ventilation

7) adverse ambient temperature fluctuations

8) any repair external to the unit

• Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, or improper

installation.

• Repairs to parts or systems resulting from unauthorized unit modifications.

• Any labor costs other than that specified during the parts and labor warranty period, which may

include additional warranty on CO2sensors, blower motors, water jackets, etc.

7023307 Steri-Cult viThermo Scientific

Table of Contents

Installation and Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Inventory Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Control Panels Keys, isplays & Indicators . . . . . . . . . . . . . . . . . . . .1-2

Operation of the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

isplays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installing the Incubator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Stacking the Incubators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Preliminary Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Installing the Access Port Filter Assembly . . . . . . . . . . . . . . . . . . . .1-8

Installing the HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Leveling the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Connecting the Unit to Electrical Power . . . . . . . . . . . . . . . . . . . .1-10

Filling the Humidity Water Bottle . . . . . . . . . . . . . . . . . . . . . . . .1-10

Connecting the CO2Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Humidity and Loading the Chamber . . . . . . . . . . . . . . . . . . . . . .1-12

Incubator Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Setting the Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Setting the Overtemp Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Setting the CO2Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Setting the Relative Humidity (RH) Setpoint . . . . . . . . . . . . . . . . . .2-3

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Calibrating the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Calibrating the Infrared CO2System . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Calibrating Relative Humidity (RH) . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Section 1

Section 2

Section 3

vii 7023307 Steri-Cult Thermo Scientific

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Turning the Audible Alarm ON/OFF . . . . . . . . . . . . . . . . . . . . . . . .4-1

New HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Setting the REPLACE HEPA Filter Reminder . . . . . . . . . . . . . . . . . .4-2

Setting an Access Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Setting a Low Temp Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Enabling Temp Alarms to Trip Contacts . . . . . . . . . . . . . . . . . . . . . .4-3

Setting a Low CO2Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Setting a High CO2Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Enabling CO2Alarms to Trip Contacts . . . . . . . . . . . . . . . . . . . . . . .4-5

Setting a Low RH Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Setting a High RH Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Enabling RH Alarms to Trip Contacts . . . . . . . . . . . . . . . . . . . . . . . .4-6

Selecting a Primary Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

isabling the Gas Guard System . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Setting a RS485 Communications Address . . . . . . . . . . . . . . . . . . . .4-8

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Temp Controller Failure TEMP CNTRL ERROR . . . . . . . . . . . . . .5-2

RH System Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Sensor Fault Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Gas Guard Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Water Level Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

oor Open Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Routine aintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Cleaning the Incubator Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Cleaning the Humidity System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Flushing the Humidity System . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

HEPA Filter Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-

Sterilization Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Table of Contents

Section 4

Section 5

Section 6

Section 8

Section 7

Factory Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Remote Alarm Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

RS485 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Connecting the Analog Output Boards . . . . . . . . . . . . . . . . . . . . . . .9-3

CO2Gas Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Operation of the CO2Gas Guard . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

e-activating the Gas Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Connecting the CO2Gas Supplies . . . . . . . . . . . . . . . . . . . . . . . . .9-5

ataloggger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Replacing the CO2and RH Air Filters . . . . . . . . . . . . . . . . . . . . . . .11-3

Exploded Parts rawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

Wiring iagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-10

7023307 Steri-Cult viiiThermo Scientific

Table of Contents

Section 9

Section 10

Section 11

7023307 Steri-Cult 1-1Thermo Scientific

Section 1 Installation and Start-Up

The incubator’s major components are described below.

• Chamber Gas Sample Port - Used for sampling chamber CO2content

using a FYRITE or similar instrument.

• Power On/Off Switch - Mains disconnect

• Control Panel - Keypad, isplays & Indicators (Figure 1-3)

• Fold-down Storage Area - Store manuals, markers, etc.

• Leveling Feet - Used to level the unit

Note The incubators are stackable. Information follows in this section.

Figure 1-1. Steri-Cult Components

1-2 7023307 Steri-Cult Thermo Scientific

Section 1

Installation and Start-Up

Included in the parts bag shipped with each unit is an inventory

management system. This system consists of:

• A steel plate

• Five different colored magnets

• Five heat-resistant shelf labels

• ry-Erase marker

Hang the plate on the inside of the outer

door, using the keyholes and hardware already

installed on the door. Attach a colored shelf

label to the front edge of each shelf. The

magnets may be aligned on the plate, in order

according to shelf label color. Use the marker

to record information about the product on

corresponding shelves. The magnets can be

erased as needed and rewritten.

Caution The inventory management system magnet plate will not

withstand the heat of the sterilization cycle. Simply unhook the whole

plate from the outer door and set aside before initiating the cycle, then

reinstall afterward. s

Figure 1-2. Inventory System

Inventory

anagement System

Control Panels Keys,

Displays & Indicators

Figure 1-3. Control Panel Components

7023307 Steri-Cult 1-3Thermo Scientific

Section 1

Installation and Start-Up

Silence - Silences the audible alarm.

Alarm indicator - Light pulses on/off during an alarm condition in the

cabinet.

Mode select switc - Used to select Run, Setpoints, Calibration and

System Configuration Modes.

Message center - isplays system status.

Mode select indicators -

Run: Run Menu

Settings: Set Points Menu

Calibrate: Calibration Menu

Configuration: Configuration Menu

Up / down arrows - Increments number values, toggles between choices.

Enter - Stores the value into computer memory.

Heat indicator - Lights when power is applied to the heaters.

Heat display - isplays temperature (°C)

Humidity indicator - Lights when humidity is required

RH display - isplays humidity (%)

Left and rig t arrows - Moves the operator through the choices of the

selected mode.

Inject indicator - Lights when CO2is being injected into the incubator

chamber.

CO2display - isplays CO2(%)

Sterilization button - Starts Sterilization Cycle

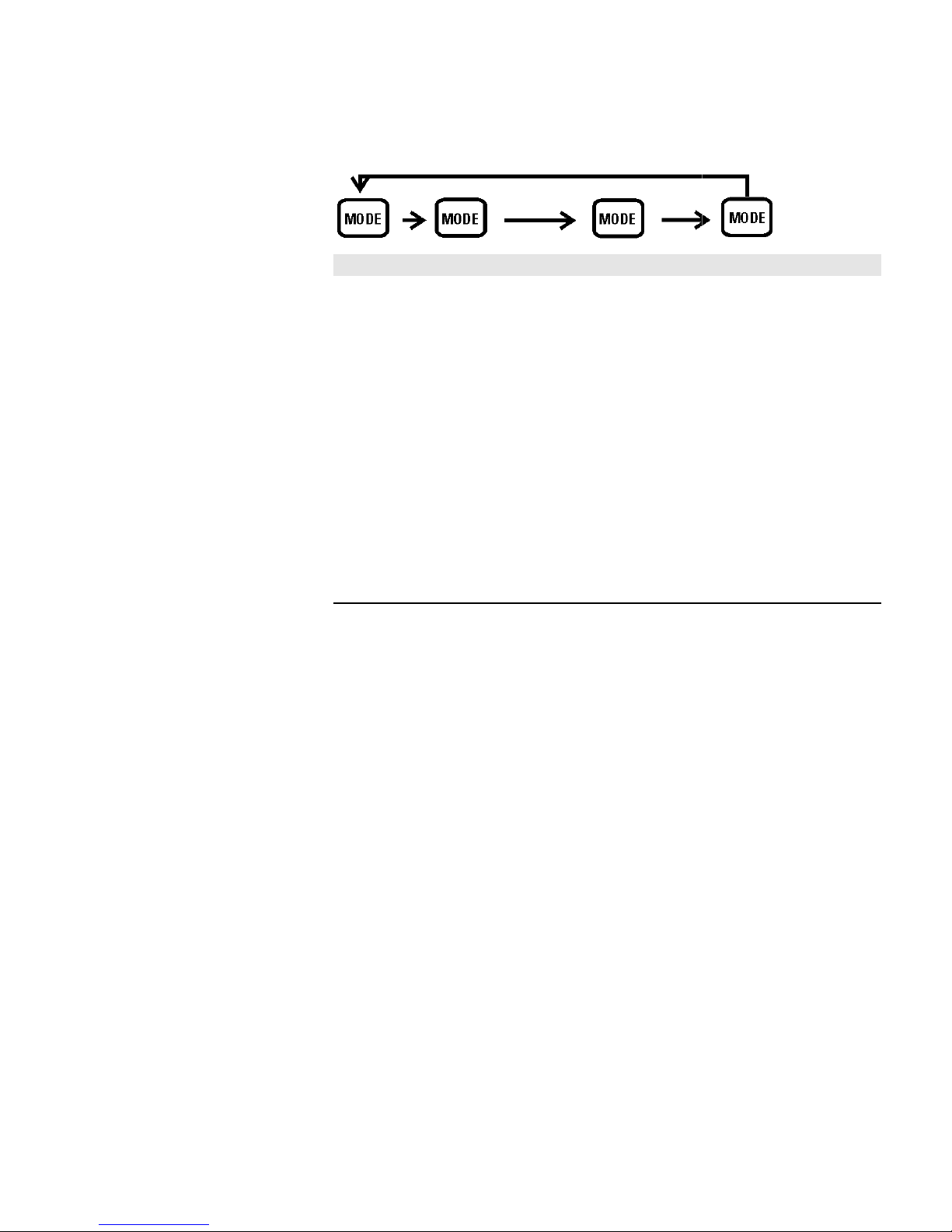

The Steri-Cult incubator has four basic modes which allow incubator

setup: Run, Settings, Calibrate and System Configuration.

Run is the default mode which the incubator will normally be in during

operation.

Settings is used to enter system setpoints for incubator operation.

Calibrate is used to calibrate various system parameters.

Configuration allows for custom setup of various options.

Control Panel

(continued)

Operation of the

Keypad

The chart below shows the selections under each of the Modes. Base Unit

Displays are in bold type and Option Displays are in italics.

Rig t and Left Arrows: Steps the operator through the parameters of

Settings, Calibrate and Configuration Modes. The right arrow goes to the

next parameter, the left arrow returns to the previous parameter.

Up Arrow: Increases or toggles the parameter value that has been selected

in the Settings, Calibrate, and Configuration Modes.

Enter: Must press Enter key to save to memory all changed values.

Down Arrow: ecreases or toggles the parameter values that have been

selected in the Settings, Calibrate and Configuration Modes.

Silence Key: Press to silence the audible alarm. See Section 5 for alarm

ringback times.

1-4 7023307 Steri-Cult Thermo Scientific

Section 1

Installation and Start-Up

Keypad (continued)

Run Settings Calibrate Configure

Default Temperature Temp Cal Audible

Overtemp CO2 Cal New HEPA Timer

CO2 RH Cal Replace HEPA Reminder

RH Access Code

Temp Lo Alarm

Temp Relay

CO2 Lo Alarm

CO2 Hi Alarm

CO2 Relay

RH Lo Alarm

RH Hi Alarm

RH Relay

Tank Select

Gas Guard

RS485 Address

Message Center: isplays the system status (Mode) at all times. isplays

CLASS 100, SYSTEM OK or RH WAITS ON TEMP (see Setting the

RH Setpoint for further details) during normal operation. Alarm messages

display if the system detects an alarm condition. See Section 5, Alarms.

The display message CLASS 100 is a timing mechanism indicating that,

under normal operating conditions with the HEPA filter installed, the air

inside the chamber meets the Class 100 air cleanliness standard for

particulates of 0.5 micron size or larger per cubic foot of air. (For further

information on the Class 100 classification of air quality, see Appendix A.)

3 Upper Displays: The first upper display shows the temperature. The

second display shows the percentage of CO2. The third display shows the

humidity percentage.

Caution Single and stacked units must be installed against a wall or similar

structure. s

1. Maintain a three-inch clearance behind the incubator for electrical and

gas hook-ups. In addition, a three-inch ventilation space is needed on

each side of the unit.

2. Locate the unit on a firm level surface capable of supporting the unit’s

weight (340 lbs.-Models 3307 & 3308, 410 lbs.-Models 3310 &

3311).

3. Locate the unit away from doors and windows and heating and air

conditioning ducts.

Caution Lift the unit only by the sides of the cabinet base. o not attempt

to lift by the front and back. This places stress on the outer door hinges. s

7023307 Steri-Cult 1-5Thermo Scientific

Section 1

Installation and Start-Up

Displays

Installing the

Incubator

Warning With incubators in a stacked configuration, do not leave both

exterior doors open at the same time. s

Warning If the units have been in operation, turn them both off and

disconnect the power before beginning any service work. s

Four stacking brackets (one shown at right) are included

in the parts bag shipped with each incubator.

1. Unscrew and remove the 4 leveling feet from the unit

to be stacked on top and lift it onto the base unit.

Align all sides.

Warning This incubator weighs 340 lbs. for Models 3307 & 3308, 410 lbs.

for Models 3310 & 3311. Have sufficient personnel available when lifting.

Lift the unit by the sides of the cabinet base to avoid placing stress on the

outer door hinge. s

2. Remove the hole plugs from the stacking bracket holes (Figure 1-6).

3. Align the holes in the brackets with the

mounting holes on the sides of the top and

bottom incubator. Secure the two brackets with

the stainless steel screws and washers provided in

the parts bag. See Figure 1-5.

4. The stacked incubators are ready for service.

1-6 7023307 Steri-Cult Thermo Scientific

Section 1

Installation and Start-Up

Stacking the Incubators

Figure 1-4.

Stacking Bracket

Figure 1-5. Stacking

Brackets Installed

Figure 1-6. Sides and Back of Stacked Units

Installing the Shelves

Using a suitable laboratory disinfectant, thoroughly clean all interior

surfaces.

Caution Before using any cleaning or decontamination method except

those recommended by the manufacturer, users should check with the

manufacturer that the proposed method will not damage the equipment.

Accidental spills of hazardous materials on or inside this unit are the

responsibility of the user. s

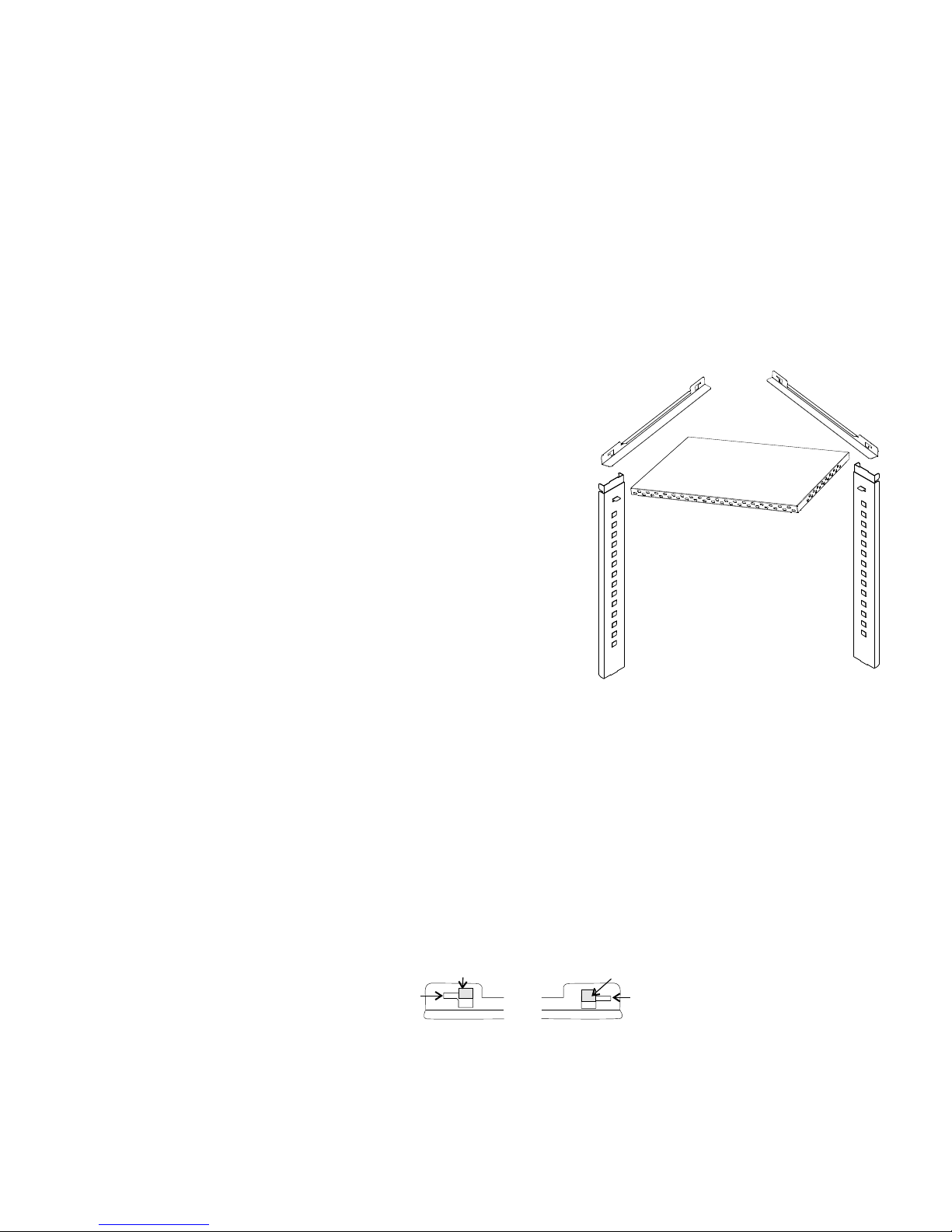

1. Install the pilasters, two on

each side, with the tab

facing into the center of the

chamber with their slots up.

Press downward on the top

section of each pilaster to

locate, then release when in

position (Figure 1-9). Fit

each pilaster securely into

the indentations at each

side of the ceiling and the

floor of the chamber. Figure

1-7 shows the diffuser pan,

pilasters, and shelf channels.

2. Install the diffuser pan in

the bottom of the unit with

the flanges down. See Section

9 at this point if your unit

includes a factory-installed

datalogger (P/N 201912).

3. Install the shelf channels by placing the channel’s rear slot over the

appropriate rear tab on the pilaster. Pull the shelf channel forward and

engage the channel’s front slot into the pilaster’s appropriate forward

tab. Refer to Figure 1-8.

7023307 Steri-Cult 1-7Thermo Scientific

Section 1

Installation and Start-Up

Preliminary Cleaning

Pilaster

Shelf Channels

Diffuser Pan

Side

toward

pilaster

Side

toward

pilaster

Pilaster

Figure 1-7. Shelf Installation

Figure 1-8. Slots and Tabs

Side duct

tab

Shelf channel

rear slot Shelf channel

front slot

Side duct

tab

FRONT

4. Figure 1-9 shows a shelf channel installed on pilasters on the right side

of the chamber.

5. Slide the shelves in, side flanges upward, along the channels into the

chamber.

1. Locate the opening in the top left corner on the inside of the chamber.

Remove the tape covering the opening on the outside of the unit.

2. Install the the filter/stopper assembly into the opening inside the

chamber. See Figure 1-10.

Caution Filter MUST be installed inside the chamber or it will become

plugged with condensation and inhibit the recovery of the RH system. o

not replace this filter with a solid cover of any kind. s

1-8 7023307 Steri-Cult Thermo Scientific

Section 1

Installation and Start-Up

Detail

Figure 1-9. Installed Shelf Channel

Installing the Access Port

Filter Assembly

Figure 1-10. Access Port Filter Installation

Installing the Shelves

(continued)

Caution Use care when handling the filter. The media can be damaged if it

is mishandled. To avoid damage to the incubator, do not operate the unit

without the HEPA filter in place. s

1. Remove the filter from the shipping box.

2. Remove the plastic covering from the filter, using caution not to touch

the filter media.

3. Loosen black wingnuts in front corners of the chamber ceiling (Figure

1-11/1-12).

4. Locate the metal lip at the upper back of the chamber. Hook the

HEPA filter carefully over the back edge of the metal lip.

5. Lift the front of the filter to the ceiling of the chamber. Push filter

bracket back over the filter frame. Tighten the wingnuts.

6. Refer to Section 6 for HEPA filter maintenance.

7023307 Steri-Cult 1-9Thermo Scientific

Section 1

Installation and Start-Up

Installing the HEPA Filter

Figure 1-11. EPA Orientation for Model 3307/3308

Figure 1-12. EPA Orientation for Model 3310/3311

This manual suits for next models

1

Table of contents