STERIFLOW Mark 95 Series Installation and operating instructions

Please read these instructions carefully!

Your Steriflow/Jordan Valve product will provide you with

long, trouble-free service if it is correctly installed and main-

tained. Spending a few minutes now reading these instruc-

tions can save hours of trouble and downtime later. When

making repairs, use only genuine Jordan Valve parts, avail-

able for immediate shipment from the factory.

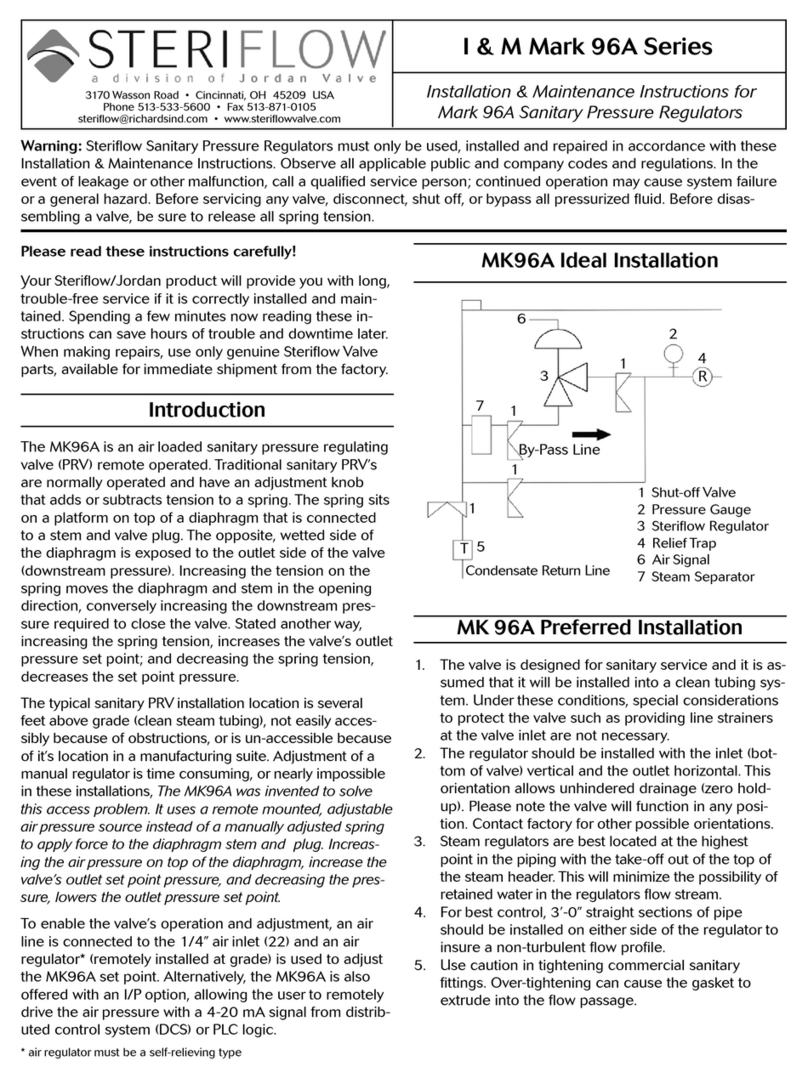

Ideal Installation Schematic

Preferred Installation

1. The valve is designed for sanitary service and it is as-

sumed that it will be installed into a clean system. Un-

der these conditions, special considerations to protect

the valve such as providing line strainers at the valve

inlet are not necessary.

2. The regulator is to be installed with the inlet horizontal

and the outlet pointed down. This will provide the best

drainage inside the valve. These restrictions apply only

for drainage considerations; the valve will function in

any position. Contact factory for other possible orienta-

tions.

3. Steam regulators are best located at the highest point

in the piping with the take-off out of the top of the steam

header. This will minimize the possibility of water in the

regulator.

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

I&M 95

Installation & Maintenance Instructions for

Mark 95 Sanitary Back Pressure Regulators

Warning: Steriflow Sanitary Pressure Regulators must only be used, installed, and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event of

leakage or other malfunction, call a qualified service person; continued operation may cause system failure or a general

hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be

sure to release all spring tension.

4. For best control, 3’-0” straight sections of pipe should

be installed on either side of the regulator.

5. Use caution in tightening commercial sanitary fittings.

Over-tightening can cause the gasket to extrude into

the flow passage.

6. If possible, install a relief valve downstream from the

regulator. Set at about 30% above the control point of

the regulator.

7. In gas or vapor service, select outlet piping that is at

least one pipe size larger than the inlet.

8. Operate the regulator within its pressure and tempera-

ture rating as stamped on the valve nameplate.

Start-Up

1. Slowly open the inlet shutoff valve and slowly turn the

adjusting screw until the desired inlet pressure is shown

on the inlet pressure gauge, without discharging fluid.

2. To change the controlled pressure, turn the adjusting

screw clockwise to increase the pressure, or counter-

clockwise to decrease the pressure.

3. Once the desired setpoint is obtained, run the thumb-

lock down until it reaches the top of the spring housing.

Then run the hex jam nut down to the top of the thumb-

lock and lock the two together. This will effectively keep

the adjusting screw from turning due to vibration, etc.

This is useful during the cleaning cycle (see section on

Clean-In-Place/Steam-In-Place.)

Warning: Never substitute an longer length adjusting

screw. The valve may fail to open and personal injury or

property damage could occur

.

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any fittings or joints. The fol-

lowing steps are recommended:

1. Close the inlet shutoff valve.

2. Turn the adjusting screw counterclockwise until there is

no pressure on the spring, allowing any trapped pres-

sure to release downstream.

PROTECT VALVES WITH LINE STRAINERS

STERIFLOWTM

Sanitary Products by Jordan Valve

3. Allow pressure to bleed off through the downstream

piping. Do not attempt to reverse the flow through the

valve by bleeding pressure from the upstream side of

the valve

4. When the pressure gauges indicate that all pressure

has been removed from the system, close the outlet

shutoff valve. The valve may be removed from the line

and serviced.

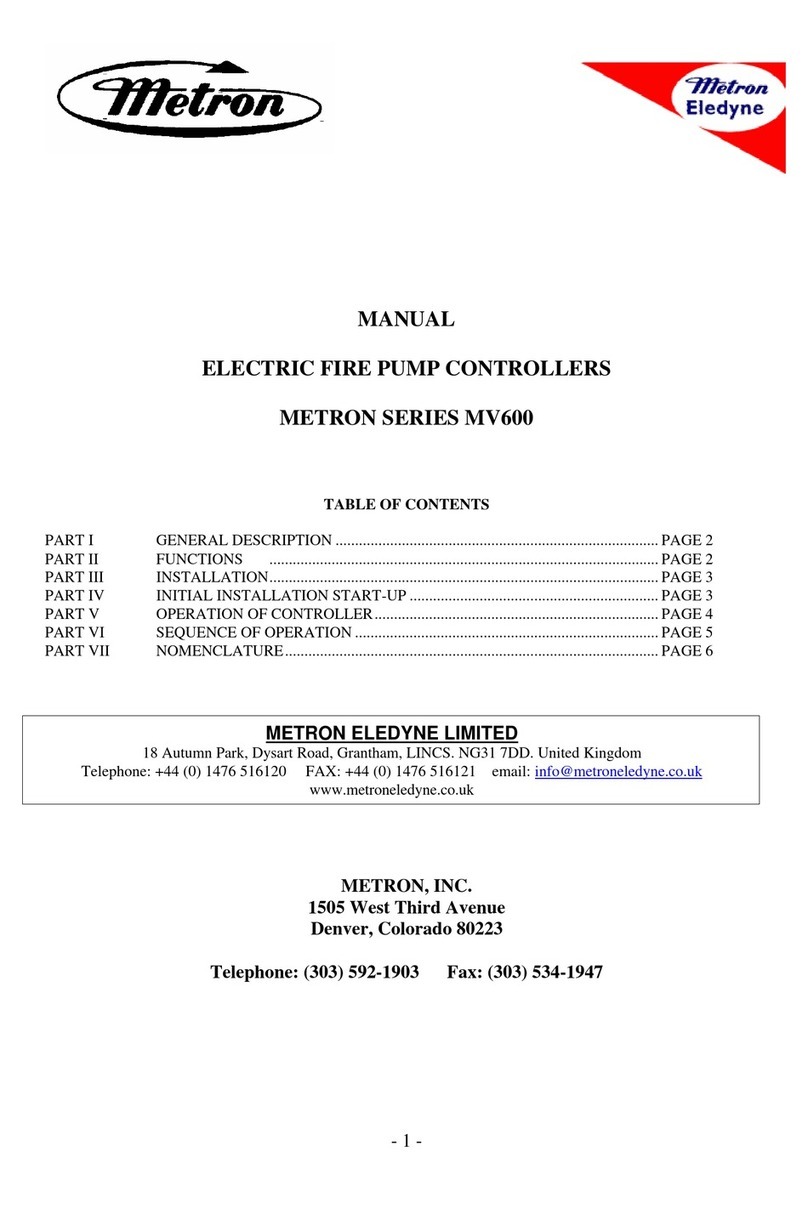

Note: refer to the drawing at the end of this document

for description and proper orientation of parts.

Clean-In-Place/Steam-In-Place

To manually open the valve for cleaning, back off the ad-

justing screw to remove all range spring load. Maintain the

position of the thumb-lock and hex jam nut on the stem so

that the adjusting screw can be returned to its normal posi-

tion to maintain the set point. There is a CIP spring inside

the spring housing that will open the valve automatically

once the range spring load is removed. This will allow the

valve to drain completely during the cleaning cycle .After

cleaning return the adjusting screw back to the original set

point by using the thumb-lock and an indicator.

NOTE: 2” Valves do not use a thumb-lock, but instead

use two jam nuts.

Disassembling Valve

1. Follow the instructions under the “Maintenance” section

to remove the valve from line.

2. Back off the adjusting screw to remove the load from

the range spring.

3. Remove the spring housing by removing the hex head

cap screws.

4. Remove the spring and spring guide.

5. Remove the cylinder by removing the hex jam nut along

with lockwasher on valves with a Stainless Steel dia-

phragm. This will allow you to remove the CIP/SIP

spring and adapter.

6. Remove the spacer, upper diaphragm plate and dia-

phragm from the stem. Remove the lower diaphragm

plate and o-ring where applicable.

CAUTION: If the valve is equipped with a metal diaphragm,

the edges are very sharp. Exercise caution to avoid lacera-

tions.

7. Remove the stem and the o-ring [on ¾” and 1” valves

with a metal diaphragm only] from the body.

Preparing Valve For Assembly

1. All parts should be cleaned and examined. Damaged

parts should be replaced.

2. O-rings should be lubricated. You may use any lubri-

cant that is compatible with both your process and the

o-ring material. EPDM o-rings must not be exposed to

mineral oil as it will cause them to swell and make

them difficult to install.

NOTE: for all assembly lubrication requirements, Jor-

dan Valve/Steriflow uses Bostik NEVER_SEEZ, White

Food Grade with PTFE, Cat. No. NSWT-14

(improved

version without mineral oils).

3. For soft-seated valves: clean threads on the stem and

on retainer with Loctite primer “T”. Allow to dry. Install

new soft seat onto retainer [or onto stem when appli-

cable on low flow versions]. Apply Loctite No. 620 to

threads and thread the retainer onto the stem. Tighten

until the screw threads run out. Allow to cure.

Assembling the Valve

1. Lubricate o-ring and install into the groove in the body

[not required on valves with elastomer diaphragm].

2. Lubricate o-ring and install into the groove in the lower

diaphragm plate. Install lower diaphragm plate onto stem

[not required on valves with elastomer diaphragm].

3. Install O-Ring to steam.

4. Install diaphragm onto stem.

5. Install upper diaphragm plate onto stem.

6. Install spacer onto stem.

7. Install stem into body. Center diaphragm onto body.

8. Install adapter onto body. The adapter should engage

the pilot diameter on the body.

9. Install the CIP/SIP spring onto the spacer.

10. Install the cylinder onto the stem.

11. Install lockwasher onto stem [not required on valves

with elastomer diaphragm].

12. Install hex jam nut onto stem and tighten. If valve has

an elastomer diaphragm, tighten only ¼ turn and apply

Loctite No. 290 to the threads to lock joint.

13. Install spring into the cylinder.

14. Install spring guide onto the spring.

15. Lubricate the O.D. surfaces of the cylinder and install

the spring housing.

16. Attach the nameplate to the body with one of the hex

head cap screws.

17. Install hex jam nut and thumb-lock (or second hex jam

nut) onto the adjusting screw and lubricate the thread

on the adjusting screw. Thread adjusting screw into the

spring housing only about four threads.

18. Secure spring housing to the body. Hand-tighten two of

the hex head cap screws. Place a light spring load on

the stem by turning the adjusting screw clockwise. This

will center the plug on its seat. Torque hex head cap

screws to 200 in/lbs. (17 ft/lbs.).

Troubleshooting

Erratic Control

Regulator may be oversized. Oversizing causes cycling and

hunting, and reduces the rangeability of the valve – make

certain that your valve has been correctly sized according

to your application conditions.

Valve seat may be defective - replace stem and/or body.

Valve plug may not be moving freely – inspect the cylinder

and spring housing.

Upstream Pressure Build-up or Inability to Maintain

Regulated Pressure

Inspect for jamming between cylinder and spring housing.

Diaphragm may have failed – replace if necessary.

Piping may be blocked or undersized.

Range spring may be set too high or may be broken – in-

spect and reset or replace as necessary.

The valve may be undersized for required flow – make cer-

tain that the valve has been sized correctly.

ORDERING SPARE PARTS

Use only genuine Jordan Valve parts to keep your valve in

good working order. So that we can supply the parts, which

were designed for your valve, we must know exactly which

product you are using. The only guarantee to getting the

correct replacement parts is to provide your Jordan Valve

Representative with the valve serial number. This num-

ber is located on the valve identification tag. If the serial

number is not available, the parts needed for your valve

might be able to be determined with the following informa-

tion:

· Model Number

· Valve Body Size

· Seat Material and CV rating

· Spring Range and Set Point

· Trim Material

· Part Name – Number and Quantity

(See parts list chart on the back)

NOTE: Without a valve serial number, any parts ordered

incorrectly are subject to up to a minimum 25% restock

charge when returned.

Ordering Spare Parts

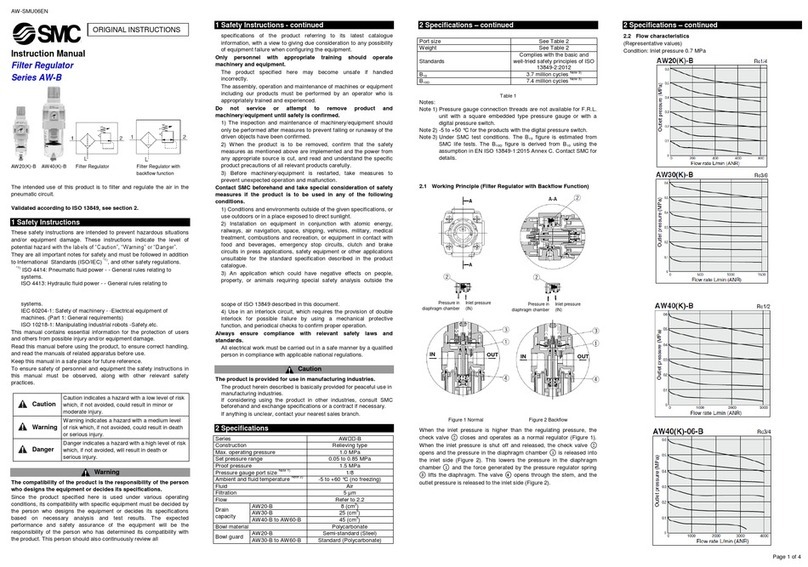

Illustration & Parts List

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

Phone Toll-Free: 800-543-7311

E-Mail: [email protected]

www.jordanvalve.com

STERIFLOWTM

Sanitary Products by Jordan Valve

Mark95 I&M/0907

17

36

15

13

11

14

10

3

4

5

9

8

35

7

21

31

37

38

30

26

25

2

1

.oNnoitpircseDYTQ

1A/SydoB1

2metS1

3etalPmgarhpaiDreppU1

4mgarhpaiD1

5gniR-O1

7recapS1

8rehsawkcoL1

9tuNmaJxeH1

01rednilyC1

11gnirpSegnaR1

31ediuGgnirpS1

41gnisuoHgnirpS1

51kcolbmuhT1

71A/SwercSgnitsujdA1

12SCHH8

52gniR-O1

62etalPmgarhpaiDrewoL1

03gniR-O1

13re

tpadA1

53gnirpSPIS/PIC1

63tuNmaJxeH1

73dnalG1

83gnihsuB1

Notes:

Items 5, 8 and 30 are not required when using an elas-

tomer diaphragm.

Items 5 is not required when using a Jorlon diaphragm.”

Other STERIFLOW Controllers manuals