STERIFLOW Mark 96A Series Installation and operating instructions

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

steri[email protected] • www.steriowvalve.com

I & M Mark 96A Series

Installation & Maintenance Instructions for

Mark 96A Sanitary Pressure Regulators

Warning: Steriow Sanitary Pressure Regulators must only be used, installed and repaired in accordance with these

Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the

event of leakage or other malfunction, call a qualied service person; continued operation may cause system failure

or a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized uid. Before disas-

sembling a valve, be sure to release all spring tension.

Please read these instructions carefully!

Your Steriow/Jordan product will provide you with long,

trouble-free service if it is correctly installed and main-

tained. Spending a few minutes now reading these in-

structions can save hours of trouble and downtime later.

When making repairs, use only genuine Steriow Valve

parts, available for immediate shipment from the factory.

Introduction

The MK96A is an air loaded sanitary pressure regulating

valve (PRV) remote operated. Traditional sanitary PRV’s

are normally operated and have an adjustment knob

that adds or subtracts tension to a spring. The spring sits

on a platform on top of a diaphragm that is connected

to a stem and valve plug. The opposite, wetted side of

the diaphragm is exposed to the outlet side of the valve

(downstream pressure). Increasing the tension on the

spring moves the diaphragm and stem in the opening

direction, conversely increasing the downstream pres-

sure required to close the valve. Stated another way,

increasing the spring tension, increases the valve’s outlet

pressure set point; and decreasing the spring tension,

decreases the set point pressure.

The typical sanitary PRV installation location is several

feet above grade (clean steam tubing), not easily acces-

sibly because of obstructions, or is un-accessible because

of it’s location in a manufacturing suite. Adjustment of a

manual regulator is time consuming, or nearly impossible

in these installations, The MK96A was invented to solve

this access problem. It uses a remote mounted, adjustable

air pressure source instead of a manually adjusted spring

to apply force to the diaphragm stem and plug. Increas-

ing the air pressure on top of the diaphragm, increase the

valve’s outlet set point pressure, and decreasing the pres-

sure, lowers the outlet pressure set point.

To enable the valve’s operation and adjustment, an air

line is connected to the 1/4” air inlet (22) and an air

regulator* (remotely installed at grade) is used to adjust

the MK96A set point. Alternatively, the MK96A is also

offered with an I/P option, allowing the user to remotely

drive the air pressure with a 4-20 mA signal from distrib-

uted control system (DCS) or PLC logic.

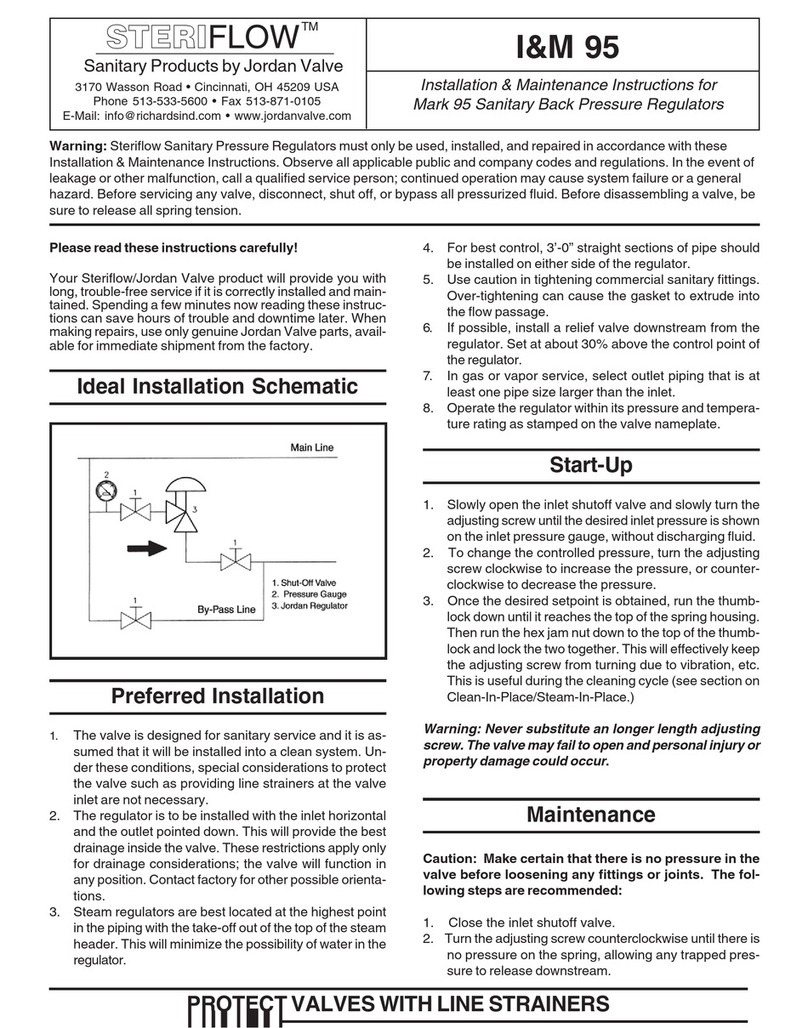

MK96A Ideal Installation

MK 96A Preferred Installation

The valve is designed for sanitary service and it is as-1.

sumed that it will be installed into a clean tubing sys-

tem. Under these conditions, special considerations

to protect the valve such as providing line strainers

at the valve inlet are not necessary.

The regulator should be installed with the inlet (bot-2.

tom of valve) vertical and the outlet horizontal. This

orientation allows unhindered drainage (zero hold-

up). Please note the valve will function in any posi-

tion. Contact factory for other possible orientations.

Steam regulators are best located at the highest 3.

point in the piping with the take-off out of the top of

the steam header. This will minimize the possibility of

retained water in the regulators ow stream.

For best control, 3’-0” straight sections of pipe 4.

should be installed on either side of the regulator to

insure a non-turbulent ow prole.

Use caution in tightening commercial sanitary 5.

ttings. Over-tightening can cause the gasket to

extrude into the ow passage.

6

31

2

4

1

7

1

1

5

Condensate Return Line

R

1 Shut-off Valve

2 Pressure Gauge

3 Steriow Regulator

4 Relief Trap

6 Air Signal

7 Steam Separator

By-Pass Line

T

* air regulator must be a self-relieving type

Clean-In-Place/Steam-In-Place

To perform this procedure, the valve is held in the open

position by applying an air load greater than the CIP/SIP

pressure.

Disassembling Valve

Insure that the valve is not pressurized by following 1.

the Caution at the beginning on the Maintenance

section.

Remove the airload.2.

Remove the actuator (4) by removing the hex bolts (17).3.

Remove the hex jam nut (16), cylinder (14) and lock-4.

washer (15). Caution- beware of spring compression.

Remove the spring and adapter (3).5.

Remove the spacer (11), upper diaphragm plate 6.

(10), and diaphragm (9) from the stem (5). Remove

the lower diaphragm plate (8) and o-rings (19), (20)

where applicable.

Remove the stem (5) from the bottom (inlet) of the 7.

body (1).

Preparing Valve For Assembly

All parts should be cleaned and examined. Damaged

parts should be replaced.

All O-rings should be lubricated with any lubricant that is

compatible with both your process and the o-ring mate-

rial. EPDM o-rings must not be exposed to mineral oil

as it will cause them to swell and make them difcult to

install.

If possible, install a relief valve downstream from the 6.

regulator. Set at about 30% above the control point of

the regulator.

In gas or vapor service, select outlet piping that is at 7.

least one pipe size larger than the inlet.

Operate the regulator within its pressure and temper-8.

ature rating as stamped on the valve nameplate.

If using an air regulator with your MK96A, install a 9.

1/4” tube tting into the 1/4” FNPT air inlet (22) on

the top of the MK96A. Connect an appropriate length

of 1/4” tubing (following local best practice) to the

tube tting and connect the other end to the air pres-

sure regulator at an accessible grade location. Follow

the instructions that come with your air regulator for

proper installation, operation and maintenance.

If using an I/P with your MK96A, connect the I/P air 10.

outlet directly to the MK96A inlet using a threaded

Hex nipple and connect the air line to a tube tting on

the I/P inlet connection. Note: Follow local electrical

code classications and best practice, and make sure

the I/P you have selected has the proper NEMA or IS

rating classication. If not, an alternative might be to

locate the I/P in the nearest Instrumentation/Electri-

cal cabinet with the proper classication. Regardless,

make sure you follow the installation, operation and

maintenance instructions that come with your I/P, and

follow all local best practices, and electrical codes

with regard to wiring and commissioning.

MK96A Start-Up

Fully open the process line block valve downstream 1.

of the regulator using manual air load regulator.

Slowly open the inlet block valve at the regulator 2.

inlet.

Slowly open and close the downstream block valve 3.

several times; this will stroke the valve and conrm

satisfactory operation.

With both block valves open, slowly increase the 4.

airload regulator’s air signal to increase downstream

pressure until it reaches the desired MK96A value.

If using an air regulator with your MK96A, follow 5.

steps 1-3 above. With both block valves open, slowly

increase the dome air signal by adjusting the air

regulator knob (following adjustment instructions in

air regulator installation manual) until the process

pressure downstream of the MK96A reaches the

desired value. Record the air regulator set point in

appropriate documents, or in the control system

information database.

If using an I/P with your MK96A, follow steps 1-3 6.

above. With both block valves open, slowly increase

the dome air pressure to the MK96A inlet by driv-

ing the I/P’s mA input to a value that produces the

desired MK96A outlet pressure. Record the mA set

point value for the PLC, or DCS programmer in the

proper document or in the control system informa-

tion database. Note: Most DCS or PLC HMI programs

allow for manual override of an output signal (manu-

ally adjust 4-20 mA output). If that is not possible,

the I/P wiring (most are two wire devices) can be

disconnected, and a process loop calibrator can be

used to articially drive the I/P to the desired output.

Maintenance

Caution: Make certain that there is no pressure in the

valve before loosening any ttings or joints. The fol-

lowing steps are recommended:

Close the regulator inlet block valve.1.

Allow pressure to bleed off through downstream 2.

piping. Do not attempt to reverse the ow through

the valve by bleeding pressure from the regulator

outlet to the inlet side.

When the upstream and downstream pressure 3.

gauges indicate that all pressure has been removed

from the system, remove the airload or disconnect

the I/P following the devices maintenance manual.

The valve can now be serviced.

Note: refer to the drawing at the end of this document

for description and proper orientation of parts.

-2-

Assembling Valve

Install stem (5) into the body (1).1.

Lubricate o-ring (19) and install into the groove on the 2.

stem (5). Install lower diaphragm plate (8) onto the

stem (5). Lubricate o-ring (20) if so required and in-

stall into the groove in the lower diaphragm plate (8).

Install diaphragm (9) onto stem (5). 3.

Install upper diaphragm plate (10) onto stem (5).4.

Install spacer (11) onto stem (5).5.

Center diaphragm (9) onto body (1). Install adapter 6.

(3) onto body (1). The adapter (3) should engage the

pilot diameter on the body (1). Lubricate o-ring (21)

and install into groove on adapter (3).

Install the spring (18) and lockwasher (15) onto the 7.

stem (5).

Install cylinder (14) onto stem (5).8.

Install hex jam nut (16) onto stem (5) and tighten; ap-9.

ply Loctite No. 290 to the threads to lock joint.

Secure actuator (4) to the body (1). Hand tighten the 10.

hex bolts (17).

Torque hex bolts (17) to 200 in-pounds (17 foot 11.

pounds).

-3-

For soft seated valves: clean threads on the stem (5) and

on the retainer (7) with Loctite primer “T”. Allow to dry.

Install new soft seat (6) on retainer (or onto stem when

application on low ow versions). Apply Loctite No. 620

to threads and thread the retainer (7) onto the stem (5).

Tighten until the screw threads bottom out. Allow to cure.

Troubleshooting

Erratic Control

Oversizing causes cycling and hunting, and reduces •

the rangeability of the valve. Make certain that your

sizing is correct.

Steam traps may require maintenance.•

Safety valve may be defective.•

Valve seat in MK 96A may be defective - Inspect •

for damage and replace stem (5) and/or body (1) if

necessary.

Valve plug in Mark 96A may not be moving freely. •

Inspect bushing (12) and replace if required.

Downstream Pressure Build-up

Valve seat in Mark 96A may be defective - replace •

stem (5) and/or body (1).

Valve plug in Mark 96A may not be moving freely. •

Inspect bushing (12) and replace is required.

Diaphragm (9) in Mark 96A may have failed; replace •

diaphragm if necessary.

Cannot Maintain Regulated Pressure

Piping may be blocked or inadequately sized.•

Inlet pressure may be set too low.•

Airload may be too low; check setting•

Valve may be undersized for required ow; make •

certain that your sizing is correct.

Cross Section View

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

steri[email protected] • www.steriowvalve.com

Bulletin IM-MK96A-0308

15

16

11

14

13

20

5

10

12

9

21

4

6

7

1

3

8

18

19

17

Item No. Description Quantity

1 Body 1

3 Adapter 1

4 Actuator 1

5 Stem 1

6 Seat 1

7 Seat Retainer 1

8 Lower Diaphragm Plate 1

9 Diaphragm 1

10 Upper Diaphragm Plate 1

11 Spacer 1

12 Bushing 1

13 Gland 1

14 Cylinder 1

15 Washer 1

16 Jam Nut 1

17 Bolt 8

18 Spring 1

19 O-Ring, Stem 1

20 O-Ring, Lower Diaphragm Plate 1

21 O-Ring, Adapter 1

22 1/4” NPT Air Inlet 1

22

Other STERIFLOW Controllers manuals