Sterimax SP-4.5 User manual

Ultra Low Volume Fogger

SUITABLE FOR RAPID DEEP DISINFECTION OF:

OFFICES, SCHOOLS, COLLEGES, WAREHOUSES,

SHOPS, BANKS, HOTELS, B&Bs, BARS, RESTAURANTS,

SURGERIES, DENTAL PRACTICES, BUSES, TAXIS,

PRIVATE CARS, COMMON ACCESS AREAS,

WAITING ROOMS, PUBLIC CONCOURSES,

CARE HOMES, RESIDENTIAL PROPERTIES

AND MANY OTHER LOCATIONS

User Guide

Please read before use

Model SP-4.5

Technical Specifications

➢ Power rating:1400 watts

➢ Voltage: 220-240V

➢ Plug: UK 3-pin

➢ Electrical Lead Length: approx 5m

➢ Spray Volume Rate: 150-260ml/minute

➢ Max spraying range (with no wind or other airow): 8m

➢ Spray Fluid Tank Capacity: 4.5 litres

➢ Net Weight (dry without uid):2.9kg

➢ Dimensions (cm) approx: 33 x 20.5 x 43

➢ Brand: Sterimax

➢ Model: SP-4.5

➢ European Conformity Certication: CE

➢ Made in China

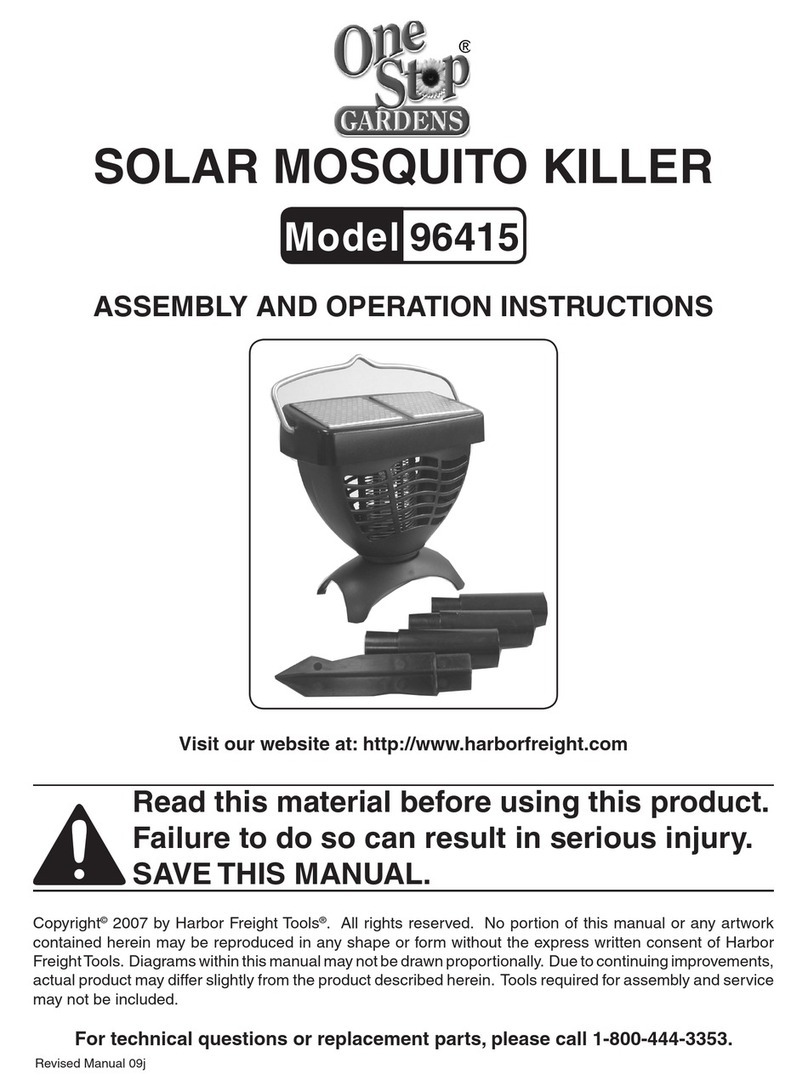

Figure 1

1

Flow control screws

Spray output nozzle

On/o switch

Top section

Spray Angle Pivot

Fluid reservoir cap

Fluid reservoir

Introduction

Thank you for purchasing this electric fogging machine. This

machine atomises liquid chemical products in order to create and

distribute a pervasive ne fog to a wide-area target environment.

The most common uses for this equipment are:

✓ deep-clean disinfection of industrial, commercial, educational

and residential locations to protect humans against viral and

bacterial infection.

✓ Insecticidal and pesticidal spraying in horticultural and

agricultural locations.

Obviously the operator needs to use an appropriate chemical

solution to achieve their required objective. If you are planning

to use this machine for the purposes of deep-clean disinfection

against viruses or bacteria within a workplace, public facility,

residential or other setting then please see page 6 for further

assistance on choosing the correct chemical product.

Please note that the fog droplets emitted by the machine will

not suspend in the air for more than a minute. However when it

settles it will contact every exposed surface in a way that would

be impossible with a more traditional“spray and wipe” cleaning

method – including soft furnishings, carpets, walls, windows,

ceilings, doors & door handles and any high touch objects where

viruses and bacteria may be lurking.

We hope you love the eectiveness and the speed at which

this machine can complete its task. As with all other industrial

cleaning equipment however, please read the instructions before

use, handle the machine carefully, wear correct PPE to avoid

inhaling the fog during use and ensure it is not operated in the

direct presence of other humans or animals.

2

1) Unscrew Fluid Reservoir

Cap and fill reservoir with

appropriate chemical fluid up

to a maximum 4.5 litres.

➢ if the uid that you will be

using requires dilution then

predilute in an appropriate

mixing container such as

large jug before pouring into

the uid reservoir.

2) Replace Fluid Reservoir Cap

tightly, ensuring it is completely

air tight.

3) Connect power supply to the

supplied plug-in RCD (Residual

Current Device) and plug the

RCD into a wall plug socket.

Press reset button on the RCD to

ensure it is live.

4) Ensure the Flow Control

Screw is opened at least 3

full turns from the closed

position (anticlockwise will

increase output fog volume and

clockwise will reduce it).

5) Hold machine level and press

the On/O Switch to the On

position.

6) Re-adjust Flow Control Screw

to achieve the required fog

output ow

7) Spray in a smooth motion,

not aggressively rocking the

machine or tilting the reservoir

backwards (as that will cause

intermittent supply of uid to

the pick-up pipe in the Fluid

Reservoir).

8) To alter angle of spray

upwards or downwards simply

change the angle of the Top

Section using the Spray Angle

Pivot.

9) When machine is operating

keep the Fluid Reservoir tilted

slightly downwards towards

the front of the machine to

ensure the suction pick up

tube located beneath the Flow

Control Screw is continuously

fed with uid.

10) Cordon off the sprayed

area for at least 15-20 minutes

to allow disinfection to be

completed.

11) For common high touch

areas such as door handles

and work surfaces continue to

frequently manually disinfect

with spray & wipe cleaning

techniques in addition to

fogging as per normal or

enhanced cleaning routines.

Instructions for Use Refer to Figure 1 as required

3

Emptying and Cleaning

Once operation has nished it is strongly recommended to empty

the uid reservoir of any remaining chemical uid back into its

original container.

Then add about 1 litre of water into the uid reservoir and spray in an

outdoor area for 1-2 minutes to rinse any residual chemical uid out

of the internal parts of the appliance.

Finally, empty any residual water from the uid reservoir after

cleansing, ready for the next use.

This will greatly prolong the life of the machine as some chemicals

may degrade the internal tubes and moving parts if they are not

rinsed out during down-time.

Disinfection times:

Surfactant disinfectants will normally kill bacteria within a minute of

contact. Data on viruses is less common but it is considered to take

up to 5 minutes after contact to destroy a virus.

Wetness and drying time:

Under low to medium settings and spraying within ambient

indoor locations of between 18 and 22ºC all surfaces sprayed will

be dry to the touch within 5 to 8 minutes. This includes both hard

surfaces such as oors / doors / walls and soft surfaces such as

carpets /chairs /curtains.

Visual residue on glass and mirrors:

Some disinfecting chemicals may leave a slight smear appearance

on mirrors and glass after drying. This actually provides a good

visual indication of eective coverage. These surfaces can easily be

wiped clean with a microbre cloth or similar after about 10 minutes

without having any negative impact on the disinfection process.

Be Aware

4

➢ Never operate this equipment directly from an electrical plug

socket without rst connecting it to a plug-in Residual Current

Device (RCD) which will prevent serious injury or death in the

event of an electrical malfunction.

➢ Do not operate this machine for more than 20 minutes

continuously. Leave to fully cool between periods of extended

use.

➢ Ensure the Fluid Reservoir Cap is screwed down tightly before

each use.

➢ Never spray ammable liquids, bleach, acid or other unsuitable

or dangerous liquids through this machine.

➢ Never spray a viscous liquid through this machine.

➢ Conduct an appropriate risk assessment before use.

➢ Always wear suitable PPE when operating this machine. This

should at least include an appropriate face mask and safety

glasses.

➢ Never spray directly towards people or animals.

➢ Never spray on valuable items such as artworks or paintings.

➢ Never spray directly onto electrical items.

➢ If using a concentrated cleaning uid requiring dilution then

ensure correct pre-dilution before use.

➢ Ensure power cable is not damaged or frayed before each use.

➢ Ensure visible ow tubes are not kinked or damaged before and

during use.

➢ Never operate this machine dry (without a suitable liquid).

➢ Always read and understand the Material Safety Data Sheet

(MSDS) of each chemical uid that you use in this machine

before use.

➢ Do not allow water or uid ingress into the Top Section of this

machine. It houses all the electrical components.

➢ When not in use store in a cool and dry location.

5

WARNING

Guide to Suitable Disinfection

Fluids for Coronavirus

Most industrial cleaning uids are anti-

bacterials. Some are also rated for killing viruses

and fungal spores.

COVID-19 is caused by a type of virus called a coronavirus. The

name of this virus is SARS-CoV-2.

To reliably neutralise a virus you need to ensure that you are

using a cleaning uid that is specically certied for virucidal

properties. .

Fortunately the regulations for product labelling of disinfecting

agents in the UK and EU makes it very easy to determine if a

particular uid has the appropriate virucidal properties.

To kill viruses you need to use a disinfecting uid that is clearly

labelled with rating EN 14476. That is the relevant European

standard to demonstrate virucidal ecacy.

A quick search of the internet will give you several suitable

product options that are certied with the EN 14476 virucide

rating and are available in 5 litre containers.

Some examples are:

Non-Dilution brands (to use straight from the container):

One Chem All Clear (from Costco) and Evans Safe Zone Plus

Concentrates requiring dilution before use:

Selgiene Extreme C500 and Pro-Kleen Y12D

All products listed above are also certied for rating EN 1276

(MRSA) and other germicidal standards.

We strongly suggest that you only use unscented uids.

6

Guide to relevant

European Test Standards

for Disinfecting Agents

VIRUSES Poliovirus, Norovirus, Inuenza A,

adenovirus (EN 14476)

BACTERIA MRSA (EN 1276),

E.coli (EN 13697),

Pseudomonas aeruginosa,

Stapylococcus aureus

(EN 1276, EN 13697, EN 13727,

EN 14561)

BACTERIAL SPORES Bacilus subtilis, Clostridium dicile

(EN 13704)

FUNGI Aspergillus niger

(EN 13624, EN 13687, EN 1650),

Cabdida albicans (EN13624,

EN 13697, EN 14562, EN1650)

Table of contents

Popular Insect Control Equipment manuals by other brands

One Stop Gardens

One Stop Gardens 96415 Assembly and operation instructions

Gardigo

Gardigo 60058 instruction manual

Mosquito Magnet

Mosquito Magnet PIONEER Operation manual

PL Systems

PL Systems Satalite 18 instructions

BLACK DECKER

BLACK DECKER BDPC912 instruction manual

Synergetic

Synergetic Exocutor EX30 instructions