Steris Basil 1000 User manual

OPERATOR MANUAL

Basil® 1000

Feeder Bottle Filler

(2004-03-04) P122994-772

i

Table of Contents Operator Manual 122994-772

A WORD FROM STERIS CORPORATION

This manual contains important information on proper use and maintenance

of the Basil®1000 Feeder Bottle Filler. All personnel involved in the use and

maintenance of this equipment must carefully review and comply with

the warnings, cautions, and instructions contained in this manual. These

instructions are important to protect the health and safety of personnel

operating this equipment and should be retained in a conveniently accessible

area for quick reference.

Complete instructions for uncrating and connecting utilities, as well as

equipment drawings, have been furnished. If missing, contact STERIS for

replacement copies, giving the unit serial and model numbers.

STERIS carries a complete line of accessories for use with this equipment. A

STERIS representative will gladly review these with you.

A listing of the

Safety Precautions

to be observed when operating and

servicing this equipment can be found in Section 1 of this manual. Do not

operate or service the equipment until you have become familiar with this

information.

Any alteration of this equipment not authorized or performed by STERIS which

could affect units operation will void the warranty, could violate federal, state

and local regulations, and could jeopardize your insurance coverage.

The Basil 1000 Feeder Bottle Filler is a manifold-type filler designed for filling

basket loads of feeder bottles used in the care of laboratory animals.

A thorough preventive maintenance program is essential to safe and proper

unit operation. This manual contains maintenance schedules and procedures

which should be followed for satisfactory equipment performance.

You are encouraged to contact STERIS concerning extended service main-

tenance agreements to give your unit planned maintenance, assuring equip-

ment performance according to factory specifications. A global network of

skilled service specialists can provide periodic inspections and adjustments

to assure low-cost peak performance. STERIS can provide information

regarding annual maintenance agreements.

See inside back cover for contact information.

Indications for Use

Service Information

Advisory

©2004, STERIS Corporation. All rights reserved. Printed in Canada

ii

122994-772 Operator Manual Table of Contents

THIS PAGE INTENTIONALLY LEFT BLANK

iii

Table of Contents Operator Manual 122994-772

TABLE OF CONTENTS

Section Title Page

A WORD FROM STERIS CORPORATION ................................................... i

1 LISTING OF SAFETY PRECAUTIONS AND SYMBOLS ..................... 1-1

2 UNCRATING/INSTALLATION INSTRUCTIONS ................................. 2-1

2.1 Uncrating Instructions ............................................................................................. 2-1

2.1.1 Open Crate ....................................................................................................... 2-1

2.1.2 Move Unit and Remove Skid ............................................................................ 2-1

2.1.3 Prepare Unit for Installation............................................................................... 2-1

2.2 Installation Instructions ............................................................................................ 2-3

2.2.1 Before Installing Equipment .............................................................................. 2-3

2.2.2 Technical Specifications ................................................................................... 2-3

2.2.3 Install Anchorage System ................................................................................. 2-4

2.2.4 Connect Utilities ................................................................................................ 2-4

2.2.5 Cleanup ............................................................................................................ 2-4

2.3 Installation Checklist ................................................................................................ 2-5

3 COMPONENT IDENTIFICATION ....................................................... 3-1

3.1 Component Identification ........................................................................................ 3-1

3.2 Controls ................................................................................................................... 3-1

3.3 Accessories ............................................................................................................. 3-2

3.3.1 Filler Header ..................................................................................................... 3-2

3.3.2 Bottle Baskets................................................................................................... 3-3

4 OPERATING INSTRUCTIONS ........................................................... 4-1

4.1 Before Operating Equipment ....................................................................................... 4-1

4.2 Filling the Bottles.......................................................................................................... 4-1

5 ROUTINE MAINTENANCE ................................................................ 5-1

5.1 General ........................................................................................................................ 5-1

5.2 Daily Cleaning.............................................................................................................. 5-2

5.3 Weekly Cleaning .......................................................................................................... 5-2

6 TROUBLESHOOTING ....................................................................... 6-1

7 REPLACEMENT PARTS AND PRODUCTS ........................................ 7-1

iv

122994-772 Operator Manual Table of Contents

THIS PAGE INTENTIONALLY LEFT BLANK

1-1

Listing of Safety Precautions and Symbols OperatorManual 122994-772

The following list of

Safety Precautions

must be observed when operating and servicing this equipment. WARNINGS

indicate the potential for danger to personnel, and CAUTIONS indicate the potential for damage to equipment. These

Safety Precautions

are repeated, where applicable, throughout the manual.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Only fully qualified service personnel should assemble and/or make adjustments to this equipment. Assembly

or adjustments done by inexperienced, unqualified personnel could cause personal injury or result in costly

damage.

Regularly scheduled preventive maintenance, in addition to the faithful performance of the minor maintenance

described within this manual, is required for safe and reliable operation of this equipment. Contact STERIS to

schedule preventive maintenance.

When moving the unit, use a forklift.

WARNING – ELECTRIC SHOCK AND/OR BURN HAZARD:

Disconnect all utilities to equipment before servicing. Do not service the equipment unless all utilities have been

properly locked out. Always follow electrical safety-related work practice standards.

Disconnect main power switch before opening cover and working on electrical components.

For continued protection against fire hazard replace only with same type and rating of fuse.

WARNING – CHEMICAL BURN EYE AND/OR INJURY HAZARD:

Liquid descaler is corrosive and can cause adverse effects to exposed tissues. Do not get in eyes, on skin, or

attempt to swallow. Avoid breathing of mists. Read and follow the precautions and instructions on the Descaler

label and in the Material Safety Data Sheet (MSDS) prior to use.

Wear gloves and eye protection when using a descaling product. Avoid contact with eyes or skin. If spilled or

splashed, flush with plenty of water for 15 minutes. If swallowed, do NOT induce vomiting. Administer an alkali

with plenty of water. Seek medical attention immediately.

WARNING – LACERATION HAZARD:

When removing bolts, wear gloves to protect your hands.

WARNING – HEALTH HAZARD:

Vapors from solvent can be harmful. Use with adequate ventilation. Follow directions on the container.

WARNING – SLIPPING HAZARD:

To prevent slips, keep floors dry. Promptly clean up any spills or condensation.

LISTING OF SAFETY PRECAUTIONS AND

SYMBOLS 1

(See next page for cautions)

1-2

122994-772 OperatorManual Listing of Safety Precautions and Symbols

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Use non-abrasive cleaners when cleaning unit. Follow directions on containers and rub in a back and-forth motion

(in same direction as surface grain). Abrasive cleaners will damage stainless steel. Cleaners rubbed in a circular

motion or applied with a wire brush or steel wool can be harmful to stainless steel. When using Pry Cream, rub

in a back-and-forth motion (in same direction as surface grain). Do not rub with a rotary or circular motion.

When removing adhesives from stainless steel, use a slovent specially formulated for that purpose. Rub in a back-

and-forth motion (in same direction as surface grain). Solvent rubbed in a circular motion or applied with a wire

brush or steel wool on assembies can be harmful to stainless steel. Do not use solvents on painted surfaces.

Symbols Symbols on the Unit:

Symbol Definition

Warning. Refer to Manual for Further

Information.

Symbols on the Crate:

TIP'N TELL Indicator.

"If TIP'N TELL arrow point is blue, this package has

been on its side or tipped over in transit. Make note on

bill of ladding and check for damage. Any claims for

tipping will be based on this notation."

This Side Up.

Do Not Stack.

Fragile.

Keep Dry.

Information on the Nameplate:

MOD. Model of the Unit.

SER. Serial Number of the Unit.

kV Power Rating of the Unit.

VVolt, Number of the Phase (Three or One [blank])

Alternating Current.

AAmperage Rating of the Unit.

PH/Hz Hertz – Frequency of the Unit.

2-1

Uncrating/Installation Instructions Operator Manual 122994-772

UNCRATING/INSTALLATION INSTRUCTIONS

A room layout, floor plan, and equipment drawing, showing all utility and space

requirements, were shipped with the unit. The clearance space, specified on

the floor plan, is necessary for proper installation, operation, and maintenance

of the unit. If any of these documents are missing or misplaced, contact

STERIS, giving the unit serial number and model numbers. Replacement

copies will be sent to you promptly.

NOTE: When uncrating unit, note the following:

1) Uncrate on a level floor, as close to installing site as possible.

2) Crate dimensions are: 51 x 32 x 68" (1295 x 812 x 1727 mm).

3) Crate maximum weight is 300 lb (136 kg). Use a forklift to move crates.

1. Verify Tip’N Tell indicator located outside crate (see Figure 2-1). Tip

indicator contains a blue compound at the bottom of the indicator. If unit has

been tipped, residue from the blue compound will be found higher up in the

indicator. If unit has been tipped, notify STERIS and arrange to have a

service technician review the equipment and determine if unit was dam-

aged.

2. Assure crate is positioned so it can be opened from the top. Provide a clear

work area on all sides.

3. Carefully cut and remove bands from crate. Discard bands before continu-

ing.

4. Using a nail puller, remove and discard top wooden panel.

5. Remove and discard side wooden panels.

6. Remove and discard polystyrene wrap from around unit.

1. With the unit still mounted on the skid, position forklift under unit frame and

move unit to installation site.

2. Unscrew and discard lag bolts holding anchorage brackets to skid.

3. Pull out and discard base.

1. Remove all tape and/or foam packing from Bottle Filler.

2. Remove tape securing drain cap to sump.

3. Slide Filler Header Manifold (accessory) into connection.

2

2.1 Uncrating

Instructions

WARNING – LACERATION

HAZARD: When removing

bolts, wear gloves to pro-

tect your hands.

2.1.1 Open Crate

2.1.2 Move Unit and

Remove Skid

WARNING – PERSONAL

INJURY AND/OR EQUIP-

MENT DAMAGE HAZARD:

When moving the unit, use

a forklift.

2.1.3 Prepare Unit for

Installation

2-2

122994-772 Operator Manual Uncrating/Installation Instructions

Figure 2-1. Crate

Tip Indicator

Skid

2-3

Uncrating/Installation Instructions Operator Manual 122994-772

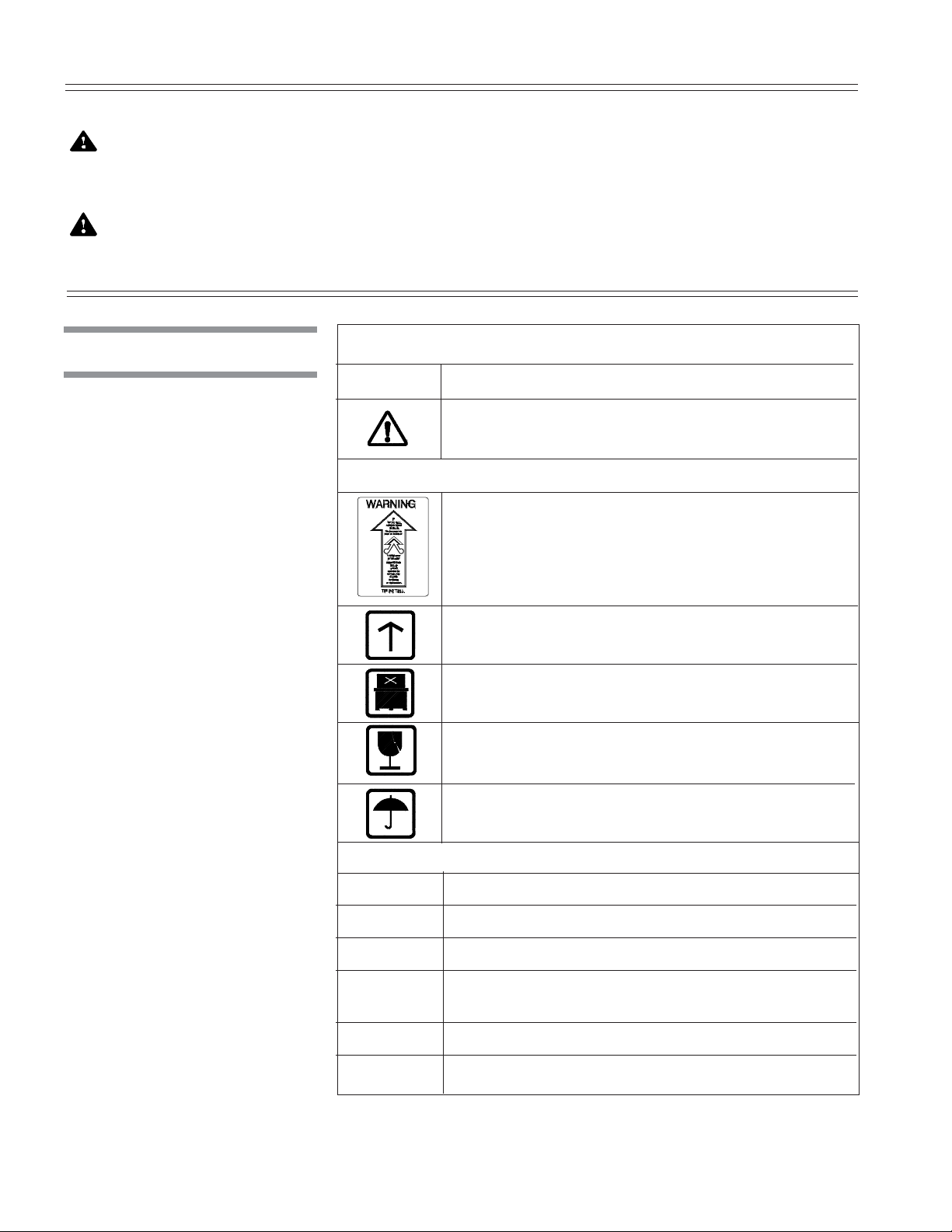

1. Review the installation requirements:

a. Clearance - The clearance space shown on the equipment drawing

indicates the space necessary for easy installation and proper operation

and maintenance of the Basil® 1000 Feeder Bottle Filler.

b. Utility service lines:

• Disconnect switch (not by STERIS) must be installed in the electric

supply line near the bottle filler (see Figure 2-2). Disconnect switch

must be capable of being locked in the OFF position only.

• If this machine is installed next to other equipment, disconnect switch

should be located so that service can be shut off to one piece of

equipment at a time.

• Utility service requirements are as shown on the equipment drawing.

Verify the equipment drawing or identification plate (located over

electrical box cover) for proper voltage.

2. Assure the unit is placed, as shown on equipment drawing, in correct

relation to building supply lines.

3. Verify that the bottle filler is level.

a. Place a spirit level end-to-end and side-to-side on top of filling area.

b. If necessary, level the unit end-to-end and side-to-side, by adjusting the

leveling legs.

4. Unit is installed on Non-slip floor surface.

These specifications are intended to describe the technical information given

on the nameplate of your unit and to state other relevant information. Verify

Equipment Drawing or nameplate, for proper voltage and amperage.

• Voltage, Amperage, and Power Consumption

The Basil 1000 Feeder Bottle Filler

operates on:

• 120 V~, 60 Hz, 1-phase, 2-wire

• Maximum current and power consumptions are:

• 120 V~, 1A, 0.12 kW

• Permissible Environmental Conditions

This equipment is designed to give optimal results in an indoor environment

where temperature is maintained between 41-104 °F (5-40 °C) and where

maximum relative humidity is 80% for temperatures up to 88 °F (1 °C) decreas-

ing linearly to 50% relative humidity at 104 °F (40 °C).

• Seismic Anchorage System

A Seismic Tie Down System is available for high risk seismic zones.

2.2 Installation

Instructions

2.2.1 Before Installing

Equipment

2.2.2 Technical

Specifications

Figure 2-2. Disconnect

Switch

2-4

122994-772 Operator Manual Uncrating/Installation Instructions

Once unit is level, install anchorage system as follows:

1. Mark floor holes position. (If anchoring brackets do not touch the floor use

shims.)

2. Using a forklift, move the unit to clear area.

3. Drill holes in floor.

4. Using a forklift, bring unit back into position.

5. Bolt brackets into position using bolts provided.

1. DRAIN - Connect building waste line to unit drain line.

2. COLD WATER - Connect cold water supply line from building to unit as

described in the Equipment Drawing.

3. ELECTRICITY - Connect building electrical supply line to unit electrical

supply box as described in the Equipment Drawing.

1. Remove any adhesive found on panels with a small amount of nonflam-

mable cleaning solvent. Keep solvents away from all painted surfaces or

damage may result.

2 Remove all protective paper from the unit cabinet panels. Slowly peel paper

away from stainless steel to reduce the level of static discharge.

3. Inspect filler head and filling area to assure all materials used during

installation have been removed.

THIS COMPLETES THE INSTALLATION.

Before operating equipment,

confirm that all items on installation checklist have been satisfactorily imple-

mented and operational test is conducted by a qualified service technician.

Follow procedure described in Section 4.2,

Filling the bottles

.

2.2.4 Connect Utilities

2.2.5 Cleanup

WARNING – HEALTH HAZ-

ARD: Vapors from solvent

can be harmful. Use with

adequate ventilation. Fol-

low directions on the con-

tainer.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

When removing adhesives

from stainless steel, use a

solvent specially formu-

lated for that purpose. Rub

in a back-and-forth motion

(in same direction as sur-

face grain). Solvent rubbed

in a circular motion or ap-

plied with a wire brush or

steel wool on assemblies

can be harmful to stainless

steel. Do not use solvents

on painted surfaces.

2.2.3 Install Anchorage

System

2-5

Uncrating/Installation Instructions Operator Manual 122994-772

2.3 Installation

Checklist

After installing the unit, complete the following checklist to assure complete

and correct installation. Contact STERIS to schedule a demonstration of proper

equipment operation.

Shutoff valve (not provided by STERIS), for maintenance purposes, is

installed on the water line and is in compliance with local codes.

Disconnect switch, capable of being locked in OFF position only, is installed

on electrical supply line near the unit and in compliance with local codes.

NOTE: If unit is installed next to other equipment, shutoff valve and disconnect

switch should be located so that service can be shut off to one piece of

equipment at a time.

Feeder Bottle Filler is positioned, as shown on floor plan, with required

clearance space and in relation to building water supply line.

Feeder Bottle Filler is level. If necessary, use adjustable legs and/or add

shims (not included) to level unit.

Building waste line is connected to unit as specified on equipment drawing.

Non-slip floor surface (not provided by STERIS) installed around unit.

2-6

122994-772 Operator Manual Uncrating/Installation Instructions

THIS PAGE INTENTIONALLY LEFT BLANK

3-1

Component Identification Operator Manual 122994-772

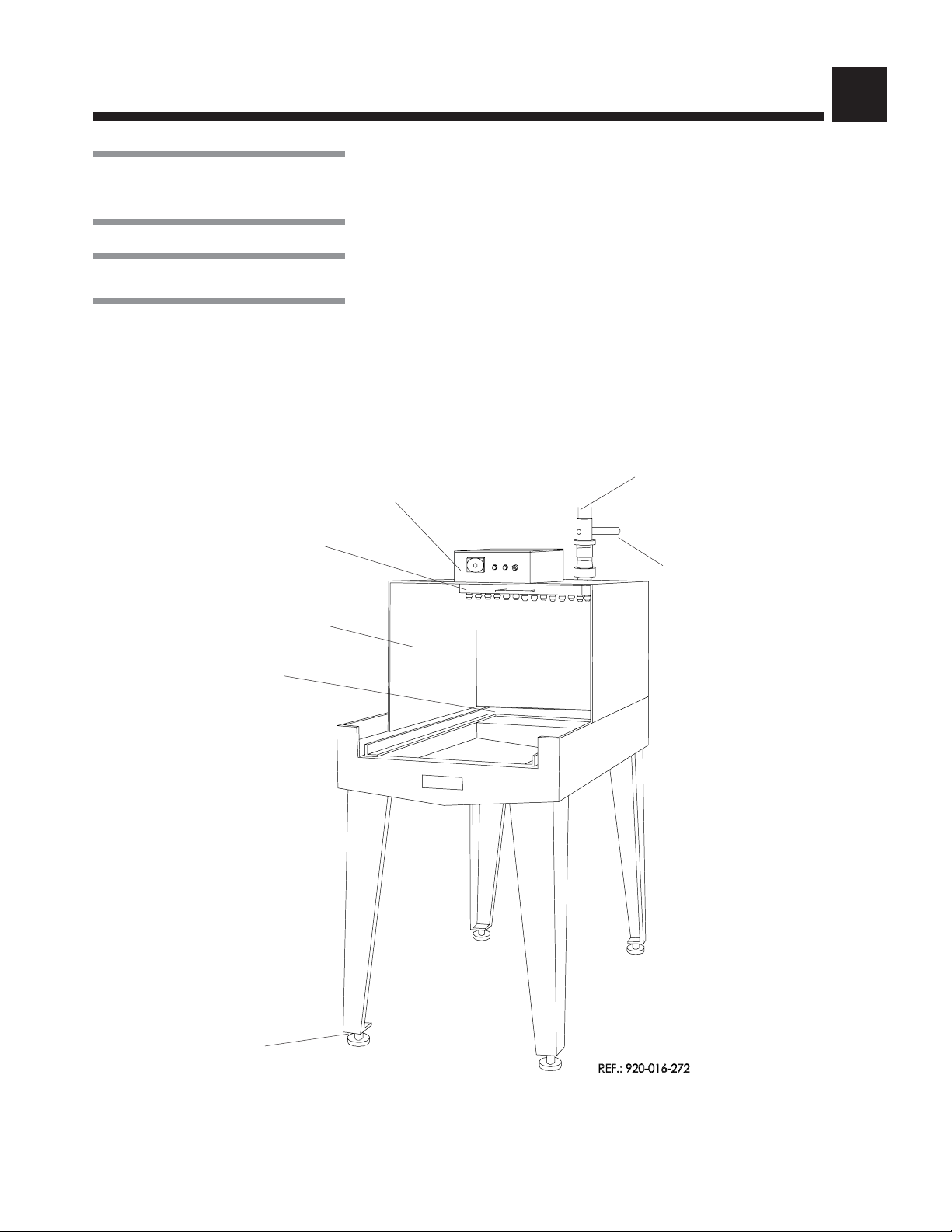

3.1 Component

Identification

COMPONENT IDENTIFICATION

Become familiar with all component and control locations and functions before

operating the Basil®Feeder Bottle Filler (see Figure 3-1).

See Figures 3-1 and 4-1.

Electrical control panel is composed of the following elements:

•Main Power ON/OFF selector switch;

•START-MAN Pushbutton - For manual operation, press and hold green

lighted pushbutton to obtain desired filling level for bottles;

•START-AUTO Pushbutton - For automatic operation, press blue lighted

pushbutton to activate timer;

•Timer - Set desired filling time to automatically fill the bottles.

3

Figure 3-1. Basil 1000 Feeder Bottle Filler

Adjustable Feet

Electrical Control Panel

Shutoff Valve

Filler Header with Jets

Water Line Connection

Splash Hood

Basket Stop

3.2 Controls

3-2

122994-772 Operator Manual Component Identification

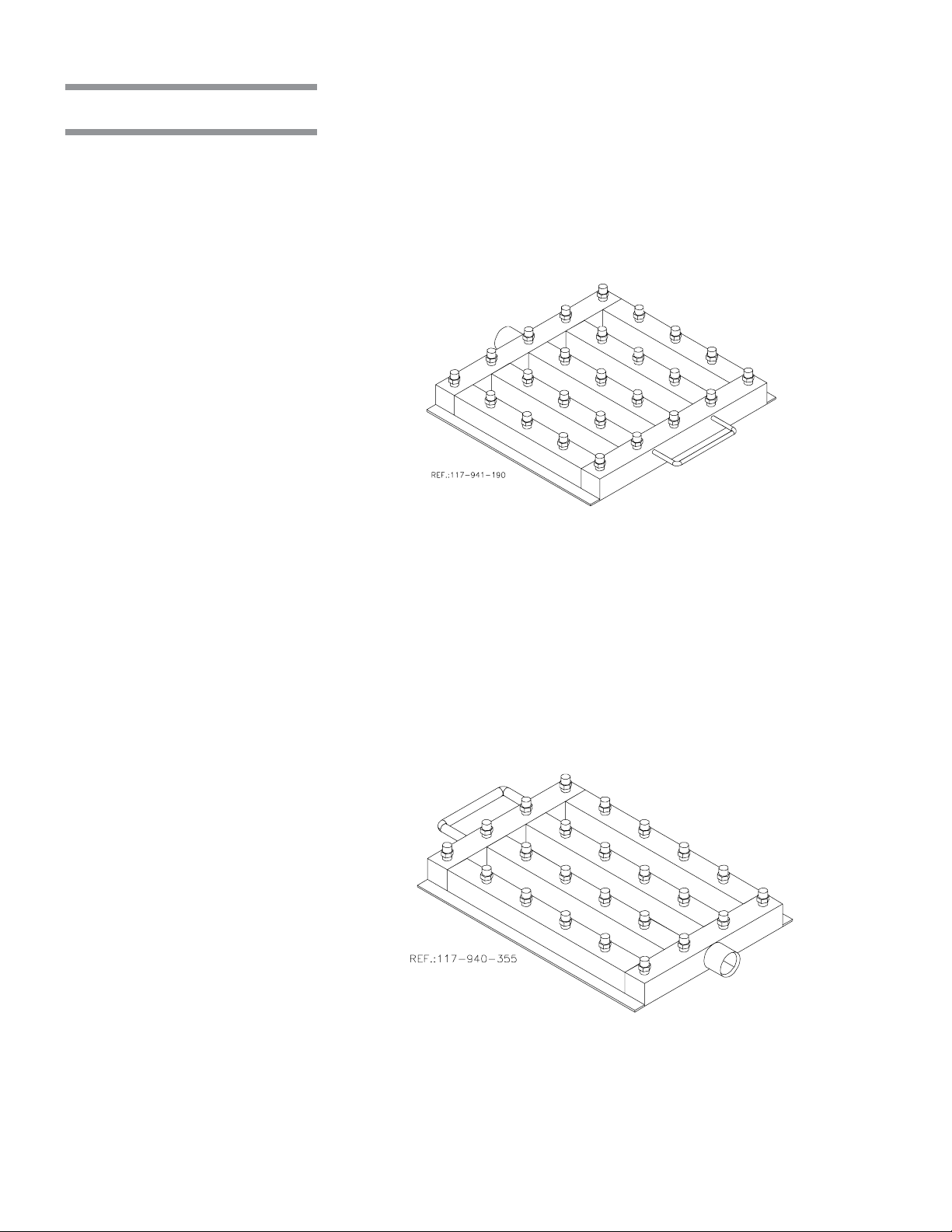

3.3 Accessories

Stainless-steel manifold headers can accommodate different bottle/basket

sizes. Each manifold has individual stainless-steel jets for each bottle. It

connects to Bottle Filler by a quick-disconnect clamp.

•5 x 5 Filler Header (Figure 3-2):

Dimensions: 14-3/4 x 16-3/4 x 2-3/4" (370 x 430 x 70 mm)

Coverage: 25 bottles

3.3.1 Filler Header

Figure 3-2. 5 x 5 Filler Header

Figure 3-3. 4 x 6 Filler Header

• 4 x 6 Filler Header (Figure 3-3):

Dimensions: 11-1/2 x 20-1/2 x 2-3/4" (290 x 520 x 70 mm)

Coverage: 24 bottles

3-3

Component Identification Operator Manual 122994-772

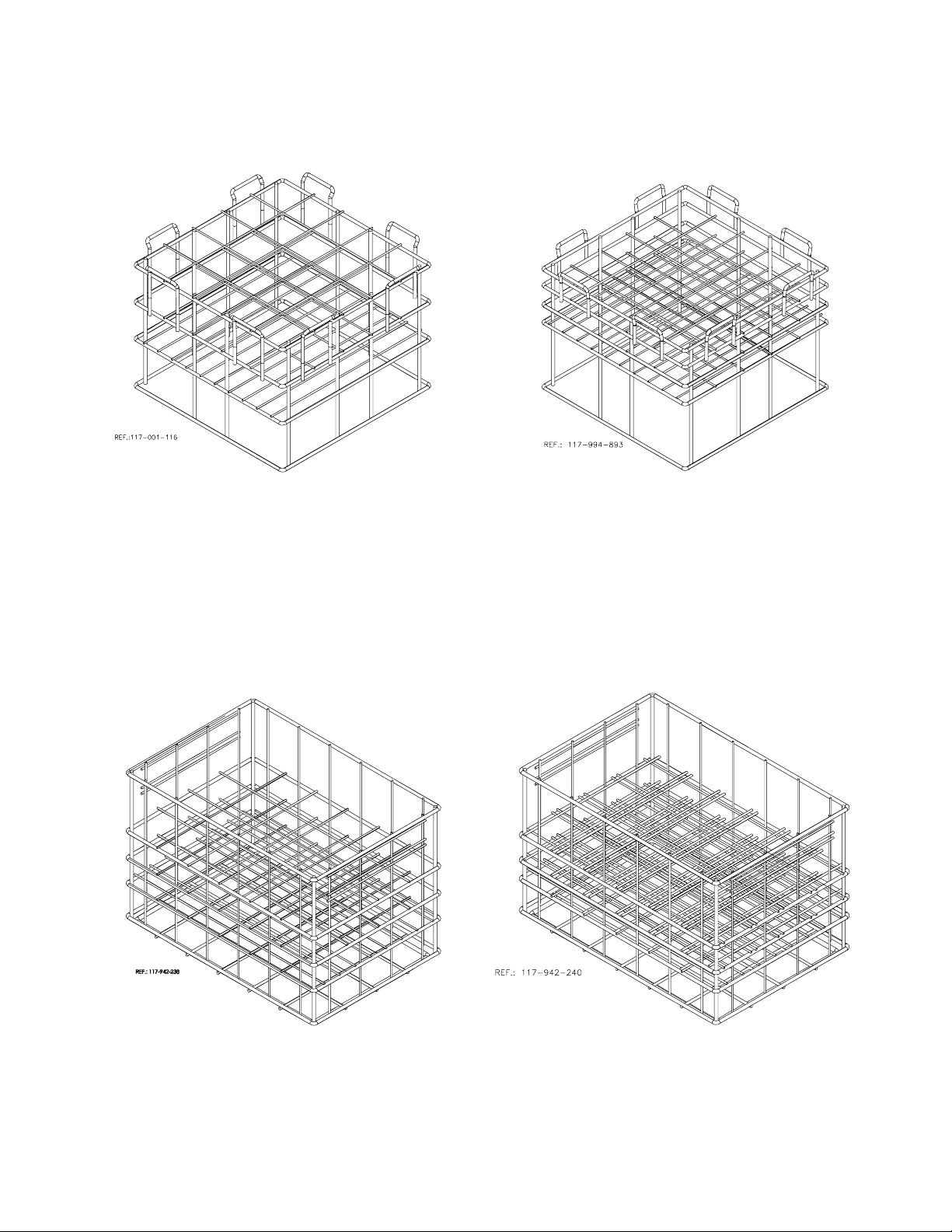

3.3.2 Bottle Baskets Stainless-steel bottle baskets can accommodate different bottle sizes. Refer

to Figures 3-4 through 3-7

Figure 3-4. 5 x 5 Bottle Basket

(16 oz bottles [454 mL])

Figure 3-6. 4 x 6 Bottle Basket

(16 oz bottles [454 mL])

Figure 3-5. 5 x 5 Bottle Basket

(8 oz bottles [227 mL])

Figure 3-7. 4 x 6 Bottle Basket

(8 oz bottles [227 mL])

3-4

122994-772 Operator Manual Component Identification

THIS PAGE INTENTIONALLY LEFT BLANK

4-1

Operating Instructions Operator Manual 122994-772

4.1 Before Operating

Equipment

OPERATING INSTRUCTIONS

NOTE: Refer to Section 3 for location of components.

Check that unit shutoff valve (water) is open.

See Figure 4-1

1. Place a basket of clean bottles under the filler header manifold up to the

basket stops.

2. Fill all bottles simultaneously as follows:

•Manual Operation

a. Turn Main Power ON/OFF selector switch to ON position.

b. Press and hold START-MAN button (green) until desired filling level for

bottles is reached. Release button

•Automatic Operation

a. Turn Main Power ON/OFF selector switch to ON position.

b. Set timer to desired filling time.

c. Press START-AUTO button (blue) to activate timer and start filling the

bottles. If the timer is set properly, it times out as bottles are filled.

NOTE: To set, turn the timer knob to the desired time necessary to fill bottles

(time may vary depending on size of bottles). A few trials with a basket in the

filling area may be necessary to determine the appropriate fill time.

d. Remove basket of filled bottles.

4

4.2 Filling the

Bottles

WARNING – SLIPPING

HAZARD: To prevent slips,

keep floors dry. Promptly

cleanup any spills or con-

densation.

Figure 4-1. Control Panel

Timer

Main Power ON/OFF

Selector Switch

(Red)

START-MAN Button

(Green)

START-AUTO Button

(Blue)

4-2

122994-772 Operator Manual Operating Instructions

THIS PAGE INTENTIONALLY LEFT BLANK

Table of contents