Sterlco AquaSnap 30RA010-055 Operation manual

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 903 Catalog No. 533-00047 Printed in U.S.A. Form 30RA-2T Pg 1 1-03 Replaces: 30RA-1T

Book 2

Ta b 5 c

Controls, Start-Up, Operation,

Service, and Troubleshooting

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components, and

equipment location (roof, elevated structures, mechanical

rooms, etc.). Only trained, qualified installers and service

mechanics should install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature, and on tags, stickers, and labels attached to the

equipment, and any other safety precautions that apply. Follow

all safety codes. Wear safety glasses and work gloves. Use

care in handling, rigging, and setting this equipment, and in

handling all electrical components.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation and

service. There may be more than one disconnect switch.

Tag all disconnect locations to alert others not to restore

power until work is completed.

DO NOT VENT refrigerant relief valves within a building.

Outlet from relief valves must be vented outdoors in

accordance with the latest edition of ANSI/ASHRAE

(American National Standards Institute/American Society

of Heating, Refrigeration and Air Conditioning Engineers)

15 (Safety Code for Mechanical Refrigeration). The

accumulation of refrigerant in an enclosed space can

displace oxygen and cause asphyxiation. Provide adequate

ventilation in enclosed or low overhead areas. Inhalation of

high concentrations of vapor is harmful and may cause

heart irregularities, unconsciousness or death. Misuse can

be fatal. Vapor is heavier than air and reduces the amount

of oxygen available for breathing. Product causes eye and

skin irritation. Decomposition products are hazardous.

DO NOT attempt to unbraze factory joints when servicing

this equipment. Compressor oil is flammable and there is

no way to detect how much oil may be in any of the

refrigerant lines. Cut lines with a tubing cutter as required

when performing service. Use a pan to catch any oil that

may come out of the lines and as a gage for how much oil

to add to system. DO NOT re-use compressor oil.

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out

components, or to bypass or otherwise depart from recom-

mended procedures. Any short-to-ground of the control

board or accompanying wiring may destroy the electronic

modules or electrical components.

To prevent potential damage to heat exchanger, always run

fluid through heat exchanger when adding or removing

refrigerant charge. Use appropriate brine solutions in cooler

fluid loop to prevent the freezing of brazed plate heat

exchanger, optional hydronic section and/or interconnecting

piping when the equipment is exposed to temperatures

below 32 F (0 °C). Proof of flow switch and strainer are

factory installed on all models. Do NOT remove power

from this chiller during winter shutdown periods without

taking precaution to remove all water from heat exchanger

and optional hydronic system. Failure to properly protect

the system from freezing may constitute abuse and may

void warranty.

Compressors and optional hydronic system pumps require

specific rotation. Test condenser fan(s) first to ensure

proper phasing. Swap any two incoming power leads to

correct condenser fan rotation before starting any other

motors.

Refrigerant charge must be removed slowly to prevent loss

of compressor oil that could result in compressor failure.

30RA010-055

AquaSnap® Air-Cooled Chillers

with ComfortLink™ Controls

50/60 Hz

2

CONTENTS

Page

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

MAJOR SYSTEM COMPONENTS. . . . . . . . . . . . . . . . . . .3,4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Main Base Board (MBB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Scrolling Marquee Display . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Energy Management Module (EMM). . . . . . . . . . . . . . . . . 3

Enable/Off/Remote Contact Switch. . . . . . . . . . . . . . . . . . 3

Emergency On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Board Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control Module Communication . . . . . . . . . . . . . . . . . . . . 3

Sterlco ComfortNetwork Interface . . . . . . . . . .. . . . . . . . 3

OPERATING DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• T1 — COOLER LEAVING FLUID SENSOR

• T2 — COOLER ENTERING FLUID SENSOR

• T7,T8 — COMPRESSOR RETURN GAS

TEMPERATURE SENSOR (ACCESSORY)

• T9 — OUTDOOR-AIR TEMPERATURE SENSOR

• T10 — REMOTE SPACE TEMPERATURE SENSOR OR

DUAL LEAVING WATER TEMPERATURE SENSOR

Energy Management Module . . . . . . . . . . . . . . . . . . . . . . . 17

Loss-of-Cooler Flow Protection . . . . . . . . . . . . . . . . . . . . 17

Thermostatic Expansion Valves (TXV) . . . . . . . . . . . . . 17

Capacity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• MINUTES LEFT FOR START

• MINUTES OFF TIME

• LEAD/LAG DETERMINATION

• CAPACITY CONTROL OVERRIDES

Head Pressure Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operation of Machine Based on Control Method

and Cooling Set Point Selection Settings . . . . . . . . 22

Cooling Set Point Select . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Marquee Display Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional Factory-Installed Hydronic Package . . . . . . 24

Cooler Pump Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cooler Pump Sequence of Operation . . . . . . . . . . . . . . 24

Configuring and Operating Dual Chiller Control. . . . 26

Temperature Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Demand Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

• DEMAND LIMIT (2-Stage Switch Controlled)

• EXTERNALLY POWERED DEMAND LIMIT

(4 to 20 mA Controlled)

•DEMAND LIMIT (SCN Loadshed Controlled)

Cooling Set Point (4 to 20 mA) . . . . . . . . . . . . . . . . . . . . . 45

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-57

Complete Unit Stoppage and Restart . . . . . . . . . . . . . . 46

• GENERAL POWER FAILURE

• UNIT ENABLE-OFF-REMOTE CONTACT SWITCH IS

OFF

• CHILLED FLUID PROOF-OF-FLOW SWITCH OPEN

• OPEN HIGH-PRESSURE SWITCH(ES)

• OPEN COMPRESSOR INTERNAL THERMAL

PROTECTION

• OPEN 24-V CONTROL CIRCUIT BREAKERS

• COOLING LOAD SATISFIED

• THERMISTOR FAILURE

• LOW SATURATED SUCTION

Alarms and Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58-73

Electronic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• CONTROL COMPONENTS

Compressor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• BRAZED-PLATE COOLER HEAT EXCHANGER

REPLACEMENT

• BRAZED-PLATE COOLER HEAT EXCHANGER

CLEANING

Check Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Page

Condenser Section and Coils . . . . . . . . . . . . . . . . . . . . . . 60

• COIL CLEANING

• CLEANING E-COATED COILS

• CONDENSER SECTION

Check Refrigerant Feed Components . . . . . . . . . . . . . . 61

• THERMOSTATIC EXPANSION VALVE (TXV)

•FILTERDRIER

• MOISTURE-LIQUID INDICATOR

• MINIMUM LOAD VALVE

• PRESSURE RELIEF DEVICES

Compressor and Unit Protective Devices . . . . . . . . . . 62

• MANUAL STARTER

• COMPRESSOR INTERNAL THERMAL PROTECTION

Check Unit Safeties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• HIGH-PRESSURE SWITCH

• PRESSURE TRANSDUCERS

• COOLER FREEZE-UP PROTECTION

• HEATER CABLE

• WINTER SHUTDOWN

Thermistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Pressure Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Motormaster® V Controller . . . . . . . . . . . . . . . . . . . . . . . . 68

• GENERAL OPERATION

• SET POINTS

•INSTALLATION

• PROGRAMMING

•EPMCHIP

• LIQUID LINE PRESSURE SET POINT ADJUSTMENT

•LOSS OF SCN COMMUNICATIONS

• REPLACING DEFECTIVE MODULES

Hydronic Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Recommended Maintenance Schedule . . . . . . . . . . . . 74

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

START-UP AND OPERATION . . . . . . . . . . . . . . . . . . . . .74-76

Actual Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Check Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . 75

Operating Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

• TEMPERATURES

• LOW AMBIENT OPERATION

• VOLTAGE — ALL UNITS

OPERATION SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

APPENDIX A — SCN TABLES. . . . . . . . . . . . . . . . . . . .77-88

APPENDIX B — FACTORY SETTINGS FOR

COMPRESSOR, FAN, PUMP AND MANUAL

STARTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89,90

APPENDIX C — BUILDING INTERFACE . . . . . . . . . .91,92

START-UP CHECKLIST FOR 30RA LIQUID

CHILLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CL-1-CL-8

GENERAL

This publication contains Controls Start-Up, Service, Oper-

ation, and Troubleshooting information for the 30RA

AquaSnap® air-cooled chillers. See Table 1. These chillers are

equipped with ComfortLink™controls and conventional

thermostatic expansion valves (TXVs).

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out or

bypass components or otherwise depart from recom-

mended procedures. Any short-to-ground of the control

board or accompanying wiring may destroy the board or

electrical component.

3

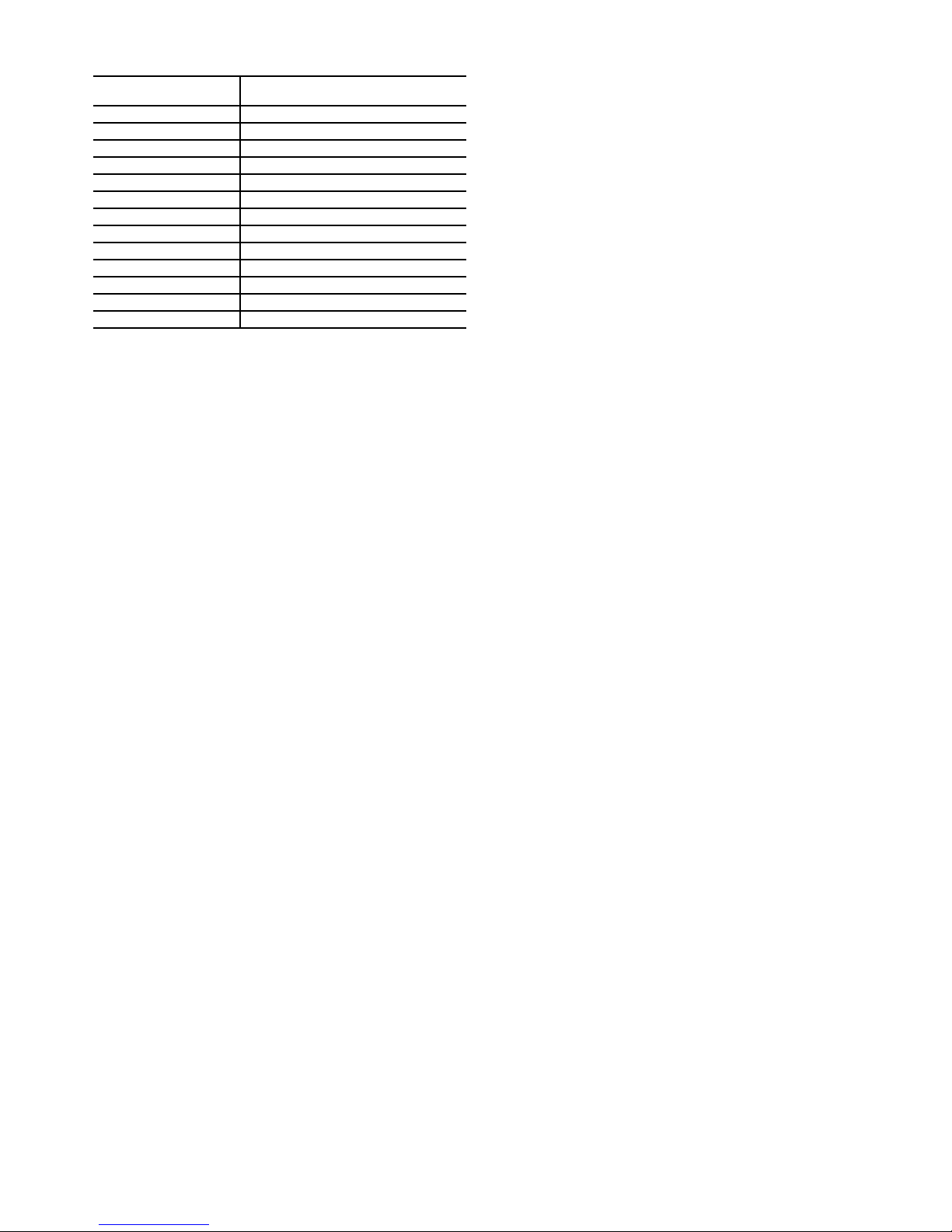

Table 1 — Unit Sizes

*60 Hz only.

†50 Hz only.

MAJOR SYSTEM COMPONENTS

General — The 30RA air-cooled reciprocating chillers

contain the ComfortLink™ electronic control system that

controls and monitors all operations of the chiller.

The control system is composed of several components as

listed in the sections below. See Fig. 1 and 2 for typical control

box drawing. See Fig. 3-6 for control schematics.

Main Base Board (MBB) — See Fig. 7. The MBB is

the heart of the ComfortLink control system. It contains the

major portion of operating software and controls the operation

of the machine. The MBB continuously monitors input/output

channel information received from its inputs and from all other

modules. The MBB receives inputs from the discharge and

suction pressure transducers and thermistors. See Table 2. The

MBB also receives the feedback inputs from each compressor

contactor, auxiliary contacts, and other status switches. See

Table 3. The MBB also controls several outputs. Relay outputs

controlled by the MBB are shown in Table 4. Information

is transmitted between modules via a 3-wire communication

bus or LEN(Local Equipment Network). The SCN (Sterlco

Comfort Network) bus is also supported. Connections to both

LEN and SCN busesare made atTB3. See Fig. 8.

Scrolling Marquee Display — This standard device

is the keypad interface used for accessing chiller information,

reading sensor values, and testing the chiller. The marquee

display is a 4-key, 4-character, 16-segment LED (light-emitting

diode) display. Eleven mode LEDs are located on the display

as well as an Alarm Status LED. See Marquee Display Usage

section on page 23 for further details.

Energy Management Module (EMM) — The EMM

module is available as a factory-installed option or as a field-

installed accessory. The EMM module receives 4 to 20 mA

inputs for the leaving fluid temperature reset, cooling set point

and demand limit functions. The EMM module also receives

the switch inputs for the field-installed 2-stage demand limit

and ice done functions. The EMM module communicates the

status of all inputs with the MBB, and the MBB adjusts the

control point, capacity limit, and other functions according to

the inputs received.

Enable/Off/Remote Contact Switch — The Enable/

Off/Remote Contact switch is a 3-position switch used to

control the chiller. When switched to the Enable position the

chiller is under its own control. Move the switch to the Off

position to shut the chiller down. Move the switch to the

Remote Contact position and a field-installed dry contact can

be used to start the chiller. The contacts must be capable of

handling a 24 vac, 50-mA load. In the Enable and Remote

Contact (dry contacts closed) positions, the chiller is allowed to

operateand respond to the scheduling configuration, SCN

configuration and set point data. See Fig. 8.

Emergency On/Off Switch — The Emergency On/Off

switch should only be used when it is required to shut the

chiller off immediately. Power to the MBB, EMM, and

marquee display is interrupted when this switch is off and all

outputs from these modules will be turned off.

Board Addresses — The Main Base Board (MBB) has

a 3-position Instance jumper that must be set to ‘1.’ All other

boards have 4-position DIP switches. All switches are set to

‘On’ for all boards.

Control Module Communication

RED LED — Proper operation of the control boards can be

visually checked by looking at the red status LEDs

(light-emitting diodes). When operating correctly, the red status

LEDs should be blinking in unison at a rate of once every

2 seconds. If the red LEDs are not blinking in unison, verify

that correct power is being supplied to all modules. Be sure that

the Main Base Board (MBB) is supplied with the current

software. If necessary, reload current software. If the problem

still persists, replace the MBB. A red LED that is lit continu-

ously or blinking at a rate of once per second or faster indicates

that the board should be replaced.

GREEN LED — The MBB has one green LED. The Local

Equipment Network (LEN) LED should always be blinking

whenever power is on. All other boards have a LEN LED

which should be blinking whenever power is on. Check LEN

connections for potential communication errors at the board J3

and/or J4 connectors. Communication between modules is

accomplished by a 3-wire sensor bus. These 3 wires run in

parallel from module to module. The J4 connector on the MBB

provides both power and communication directly to the

marquee display only.

YELLOW LED — The MBB has one yellow LED. The

Sterlco Comfort Network (SCN) LEDwillblink during times

of network communication.

Sterlco Comfort Network (SCN) Interface —

The 30RA chiller unitscan be connectedtotheSCN if

desired. The communication bus wiring is a shielded,

3-conductor cable with drain wire and is supplied and installed

in the field. See Table 5. The system elements are connected to

the communication bus in a daisy chain arrangement. The

positive pin of each system element communication connector

must be wired to the positive pins of the system elements on

either side of it. This is also required for the negative and

signal ground pins of each system element. Wiring connections

for SCN should be made at TB3. Consultthe SCN Contrac-

tor’s Manual for further information.

NOTE: Conductors and drain wire must be 20 AWG (Ameri-

can Wire Gage) minimum stranded, tinned copper. Individual

conductors must be insulated with PVC, PVC/nylon, vinyl,

Teflon, or polyethylene. An aluminum/polyester 100% foil

shield and an outer jacket of PVC, PVC/nylon, chrome vinyl,

or Teflon with a minimum operating temperature range of

–20 C to 60 C is required. Wire manufactured by Alpha (2413

or 5463), American (A22503), Belden (8772), or Columbia

(02525) meets the above mentioned requirements.

It isimportant when connecting toa SCN communication

bus that a color coding scheme be used for the entire network

to simplify the installation. It is recommended that red be used

for the signal positive, black for the signal negative, and white

for the signal ground. Use a similar scheme for cables contain-

ing different colored wires.

UNIT NOMINAL CAPACITY

(TONS) 50/60 Hz

30RA010 10/10

30RA015 14/13

30RA018 16/16

30RA022 22/20

30RA025 24/23

30RA030* 27

30RA032† 30

30RA035 35/34

30RA040* 38

30RA042† 40

30RA045 43/45

30RA050* 47

30RA055* 54

4

At each system element, the shields of its communication

bus cables must be tied together. If the communication bus is

entirely within one building, the resulting continuous shield

must be connected to a ground at one point only. If the commu-

nication bus cable exits from one building and enters another,

the shields must be connected to grounds at the lightning

suppressor in each building where the cable enters or exits the

building (one point per building only). To connect the unit to

the network:

1. Turn off power to the control box.

2. Cut the SCNwire and strip the ends of the red (+), white

(ground), and black (–) conductors. (Substitute appropri-

ate colors for different colored cables.)

3. Connect the red wire to (+) terminal on TB3 of the plug,

the white wire to COM terminal, and the black wire to the

(–) terminal.

4. The RJ14 SCN connector on TB3 can also be used, but is

only intended for temporary connection (for example, a

laptop computer running Service Tool).

Table 2 — Thermistor Designations

LEGEND

Table 3 — Status Switches

Table 4 — Output Relays

Table 5— SCN Communication BusWiring

OPERATING DATA

Sensors — The electronic control uses 3 to 6 thermistors to

sense temperatures for controlling chiller operation. See

Table 2. These sensors are outlined below. Thermistors T1, T2,

T9 and accessory suction gas temperatures (T7,T8) are 5 kΩ at

77 F (25 C) and are identical in temperature versus resistance

and voltage drop performance. Thermistor T10 is 10 kΩ at

77 F (25 C) and has a different temperature vs. resistance and

voltage drop performance. See Thermistors section for

temperature-resistance-voltage drop characteristics.

T1 — COOLER LEAVING FLUID SENSOR— On 30RA010-

030 sizes, this thermistor is installed in a friction fit well at the

bottom of the brazed-plate heat exchanger on the control box

side. For 30RA032-055 sizes, this thermistor is installed in a

well in the factory-installed leaving fluid piping coming from

the bottom of the brazed-plate heat exchanger opposite the

control box side.

T2—COOLERENTERINGFLUIDSENSOR—On 30RA010-

030 sizes, this thermistor is installed in a friction fit well at the

top of the brazed-plate heat exchanger on the control box side.

For 30RA032-055 sizes, this thermistor is installed in a well in

the factory-installed entering fluid piping coming from the top

of the brazed-plate heat exchanger opposite the control box

side.

T7,T8 — COMPRESSOR RETURN GAS TEMPERA-

TURE SENSOR (ACCESSORY) — A well for this sensor

is factory installed in each circuit's suction line. If desired, a

5 kΩthermistor (Sterling partnumber HH79NZ029) can be

installed in this well and connected to the Main Base Board

as shown in Table 2. Use the Scrolling Marquee display to con-

figure the sensor (Configuration mode, sub-mode OPT1 —

enable item RG.EN).

T9 — OUTDOOR-AIR TEMPERATURE SENSOR —

This sensor is factory-installed on a bracket at the left side of

compressor A1 on 30RA010-030 models. For models

30RA032-055, it is installed behind the panel below the

control box center door.

IMPORTANT: A shorted SCN buscable will prevent some

routines from running and may prevent the unit from start-

ing. If abnormal conditions occur, unplug the connector. If

conditions return tonormal, checkthe SCNconnector and

cable. Run new cable if necessary. A short in one section of

the bus can cause problems with all system elements on the

bus.

THERMISTOR

NO.

PIN

CONNECTION

POINT

THERMISTOR INPUT

T1 J8-13,14 (MBB) Cooler Leaving Fluid

T2 J8-11,12 (MBB) Cooler Entering Fluid

T7 J8-1,2 (MBB) Circuit A Return Gas

Temperature (Accessory)

T8 J8-3,4 (MBB) Circuit B (032-055 only) Return

Gas Temperature (Accessory)

T9 J8-7,8 (MBB) Outdoor-Air Temperature

Sensor

T10

J8-5,6 (MBB)

TB5-5,6

Accessory Remote Space

Temperature Sensor or

Dual LWT Sensor

LWT — Leaving Water Temperature

MBB — Main Base Board

STATUS

SWITCH

PIN CONNECTION

POINT

Chilled Water Pump 1 J7-1,2

Chilled Water Pump 2 J7-3,4

Remote On/Off TB5-9,10

Cooler Flow Switch J7-9,10

Compressor Fault Signal, A1 J9-11,12

Compressor Fault Signal, A2 J9-5,6

Compressor Fault Signal, B1 J9-8,9

Compressor Fault Signal, B2 J9-2,3

RELAY

NO. DESCRIPTION

K1 Energize Compressor A1 (010-030)

Energize Compressor A1 and Condenser Fan A1 (032-055)

K2

Energize Compressor B1 and Condenser Fan B1 at Low

Speed (032-040)

Energize Compressor B1 and Condenser Fan B1 (042-055)

K3 Energize Chilled Water Pump 1 Output

K4 Energize Chilled Water Pump 2 Output

K5 Energize Compressor A2 (all but 010, 015 60Hz)

K6 Energize Compressor B2 (042-055 only)

K7 Alarm Relay

K8 Cooler/Pump Heater

K9

Energize Condenser Fan at Low Speed (010-018)

Energize Condenser Fan A1 (022-030)

Energize Condenser Fan A2 (032-055)

K10

Energize Condenser Fan at High Speed (010-018)

Energize Condenser Fan A2 (022-030)

Energize Condenser Fan B1 at High Speed (032-040)

Energize Condenser Fan B2 (042-055)

K11 Minimum Load Valve

MANUFACTURER PART N O.

Regular Wiring Plenum Wiring

Alpha 1895 —

American A21451 A48301

Belden 8205 884421

Columbia D6451 —

Manhattan M13402 M64430

Quabik 6130 —

5

T10 — REMOTE SPACE TEMPERATURE SENSOR OR

DUAL LEAVING WATER TEMPERATURE SENSOR —

One of two inputs can be connected to TB5-5 and TB5-6. See

appropriate sensor below.

T10 — Remote Space Temperature Sensor — Sensor T10

(part no. 33ZCT55SPT) is an accessory sensor that is remotely

mounted in the controlled space and used for space tempera-

ture reset. The sensor should be installed as a wall-mounted

thermostat would be (in the conditioned space where it will not

be subjected to either a cooling or heating source or direct

exposure to sunlight, and 4 to 5 ft above the floor).

Space temperature sensor wires are to be connected to

terminals in the unit main control box. The space temperature

sensor includes a terminal block (SEN) and a RJ11 female

connector. The RJ11connector isused accessintothe Sterlco

Comfort Network (SCN) at the sensor.

To connect the space temperature sensor (Fig. 9):

1. Using a 20 AWG twisted pair conductor cable rated for

the application, connect 1 wire of the twisted pair to one

SEN terminal and connect the other wire to the other

SEN terminal located under the cover of the space

temperature sensor.

2. Connect the other ends of the wires to terminals 5 and 6

on TB5 located in the unit control box.

Units on the SCNcan be monitored from the space at the

sensor through the RJ11 connector, if desired. To wire the RJ11

connector into the SCN (Fig. 10):

1. Cut the SCN wire and strip ends of the red (+), white

(ground), and black (–) conductors. (If another wire color

scheme is used, strip ends of appropriate wires.)

2. Insert and secure the red (+) wire to terminal 5 of the

space temperature sensor terminal block.

3. Insert and secure the white (ground) wire to terminal 4 of

the space temperature sensor.

4. Insert and secure the black (–) wire to terminal 2 of the

space temperature sensor.

5. Connect the other end of the communication bus cable to

the remainder of the SCN communication bus.

T10 — Dual Leaving Water Temperature Sensor — For

dual chiller applications (parallel only are supported), connect

the dual chillerleaving fluid temperature sensor (5 kΩ ther-

mistor,Sterling part no. HH79NZ029) tothe space temperature

input of the Master chiller. If space temperature is required for

reset applications, connect the sensor to the Slave chiller and

configure the slave chiller to broadcast the value to the Master

chiller.

LEGEND FOR FIG. 1-6

IMPORTANT: The cable selected for the RJ11 connector

wiring MUST be identicalto the SCN communication bus

wire used for the entire network. Refer to Table 5 for

acceptable wiring.

ALMR — Alarm Relay

BR — Boiler Relay

C—Contactor, Compressor

CB — Circuit Breaker

CCB — Compressor Circuit Breaker

CHC — Cooler/Pump Heater Contactor

COMP — Compressor

CWFS — Chilled Water Flow Switch

CWP — Chilled Water Pump

DPT — Discharge Pressure Transducer

EMM — Energy Management

FIOP — factory Installed Option

FM — Fan Motor

GND — Ground

HPS — High-Pressure Switch

HR — Heat Relay

ICP — Inrush Current Protection

IP — Internal Protection Thermostat

LWT — Leaving Water Temperature

MBB — Main Base Board

MLV — Minimum Load Valve

MS — Manual Starter

OAT — Outdoor-Air Thermistor

OL — Overload

R—Relay

SPT — Suction Pressure Transducer

SW — Switch

T—Thermistor

TB — Te r m i n a l B l o c k

TNKR — Storage Tank Heater Relay

TRAN — Transformer

Te r m i n a l B l o c k

Terminal (Unmarked)

Terminal (Marked)

Splice

Factory Wiring

Field Wiring

Accessory or Option Wiring

To indicate common potential only;

not to represent wiring.

This manual suits for next models

13

Table of contents

Other Sterlco Chiller manuals

Popular Chiller manuals by other brands

Trane

Trane RTAA-70 Installation & maintenance guide

Carrier

Carrier Omnizone 50BVC Installation, Start-Up, Service and Controls Operation and Troubleshooting

York

York YGWH 115 Installation, commissioning & operation

Galletti

Galletti PERFORMA MPE Series Technical manual

SMC Networks

SMC Networks HRR Series manual

Daikin

Daikin EWAQ016CAW Installation and operation manual