Sterling Scale DW800 User manual

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

Pure Fun

Pure Fun 9008TS owner's manual

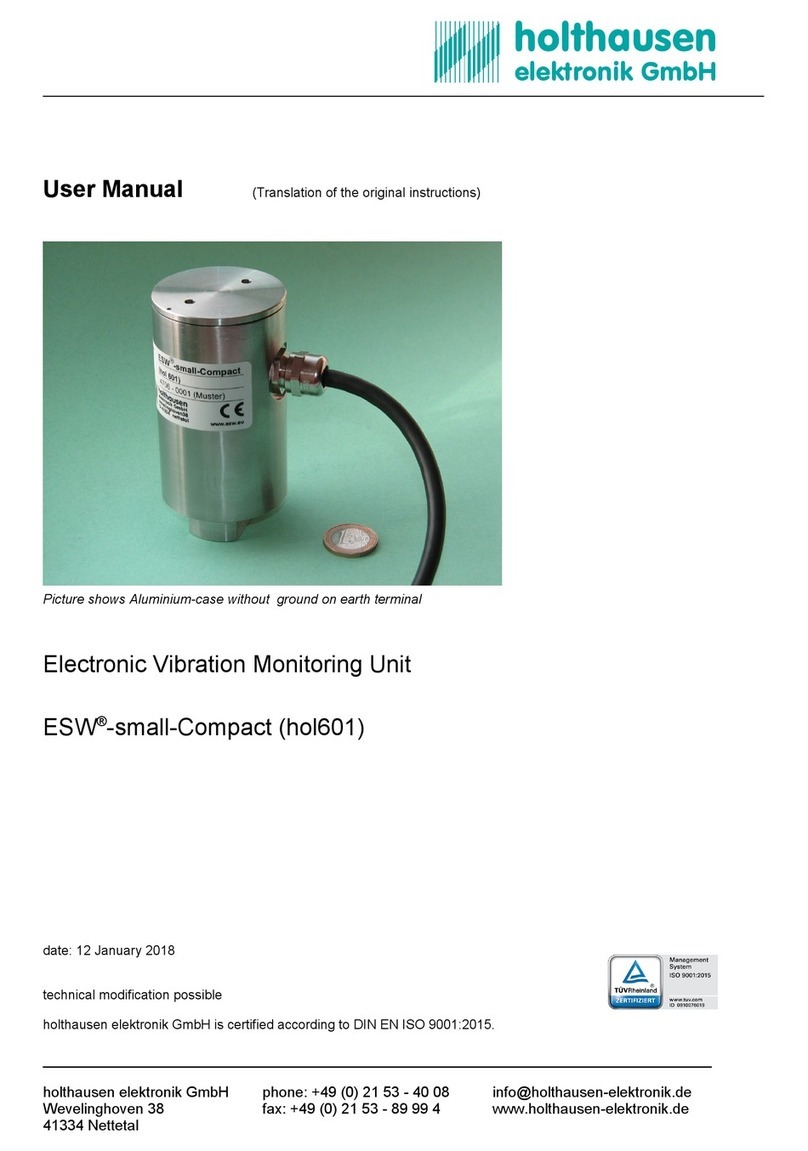

holthausen elektronik

holthausen elektronik ESW-small-Compact user manual

T'nB

T'nB SHPLUG01 user manual

Chef's Choice

Chef's Choice Pronto Diamond Hone 463 user manual

Sleep Sense

Sleep Sense Micro-Effort Piezo Crystal Infant Sensor user manual

CCL ELECTRONICS

CCL ELECTRONICS C6082A user manual

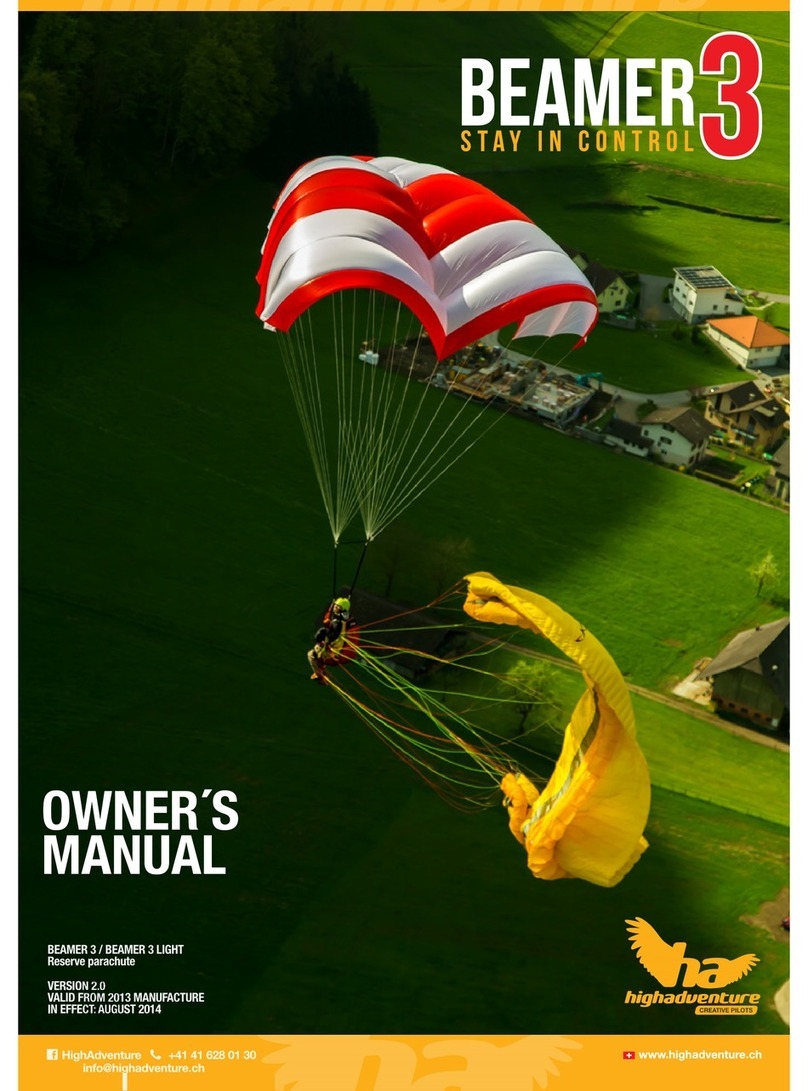

High Adventure

High Adventure BEAMER 3 owner's manual

Gamma+

Gamma+ ST II owner's manual

Pegasus Astro

Pegasus Astro POCKET POWERBOX product manual

BLACKHAWK!

BLACKHAWK! Electric user manual

wattstopper

wattstopper CH-250 installation instructions

Rocket Fish

Rocket Fish InvisiShell RF-GWU1301 Guide d'installation rapide

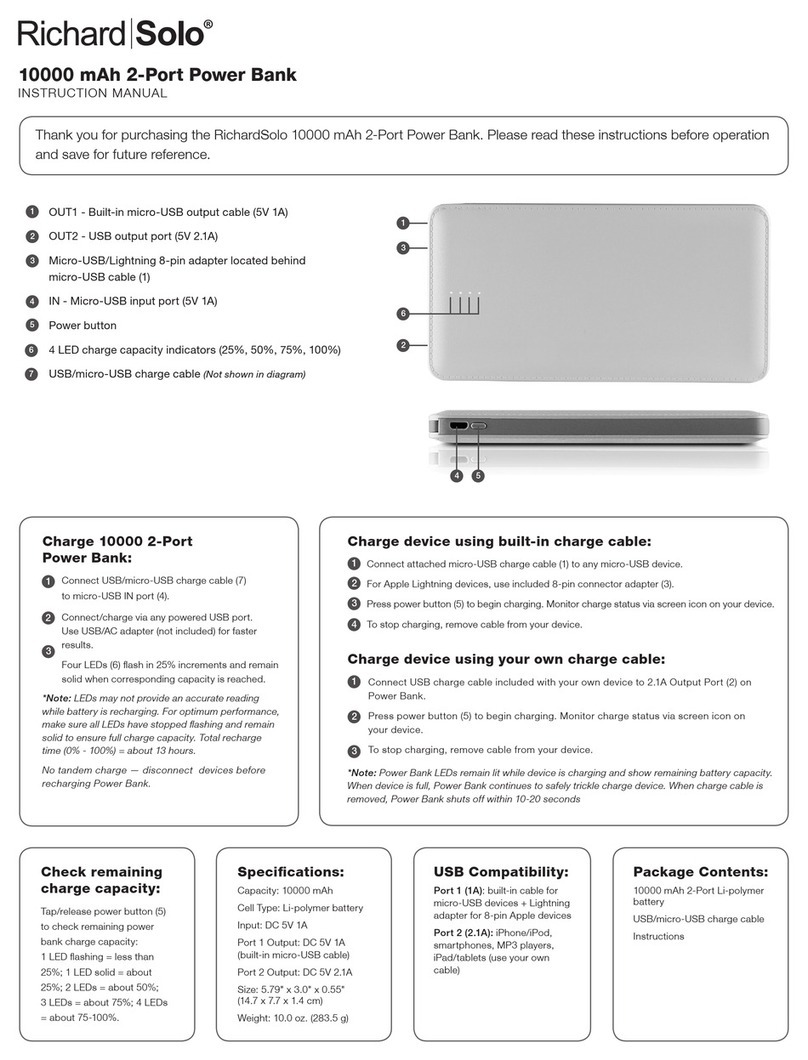

RichardSolo

RichardSolo 10000 mAh 2-Port Power Bank instruction manual

Bin Master

Bin Master CNCR-230 operating instructions

Lightwave

Lightwave LP70 instructions

ICON

ICON Ultra 4 user manual

Silvercrest

Silvercrest RCR DP3 3711-A IP44 FR 3726 Operation and safety notes

Cambridge Scale Works, Inc.

Cambridge Scale Works, Inc. SSCSW-20AT-B Installation, set-up & Operation