7

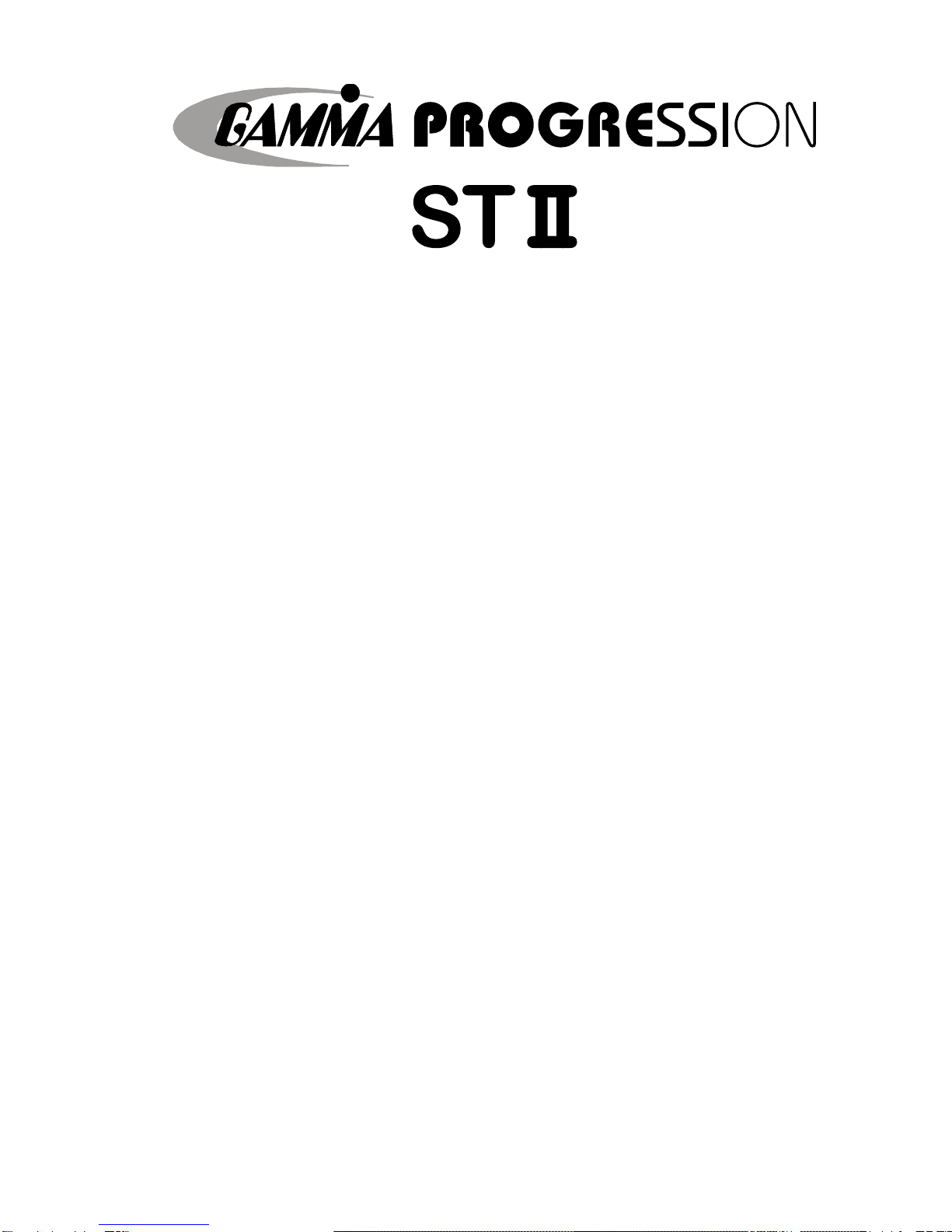

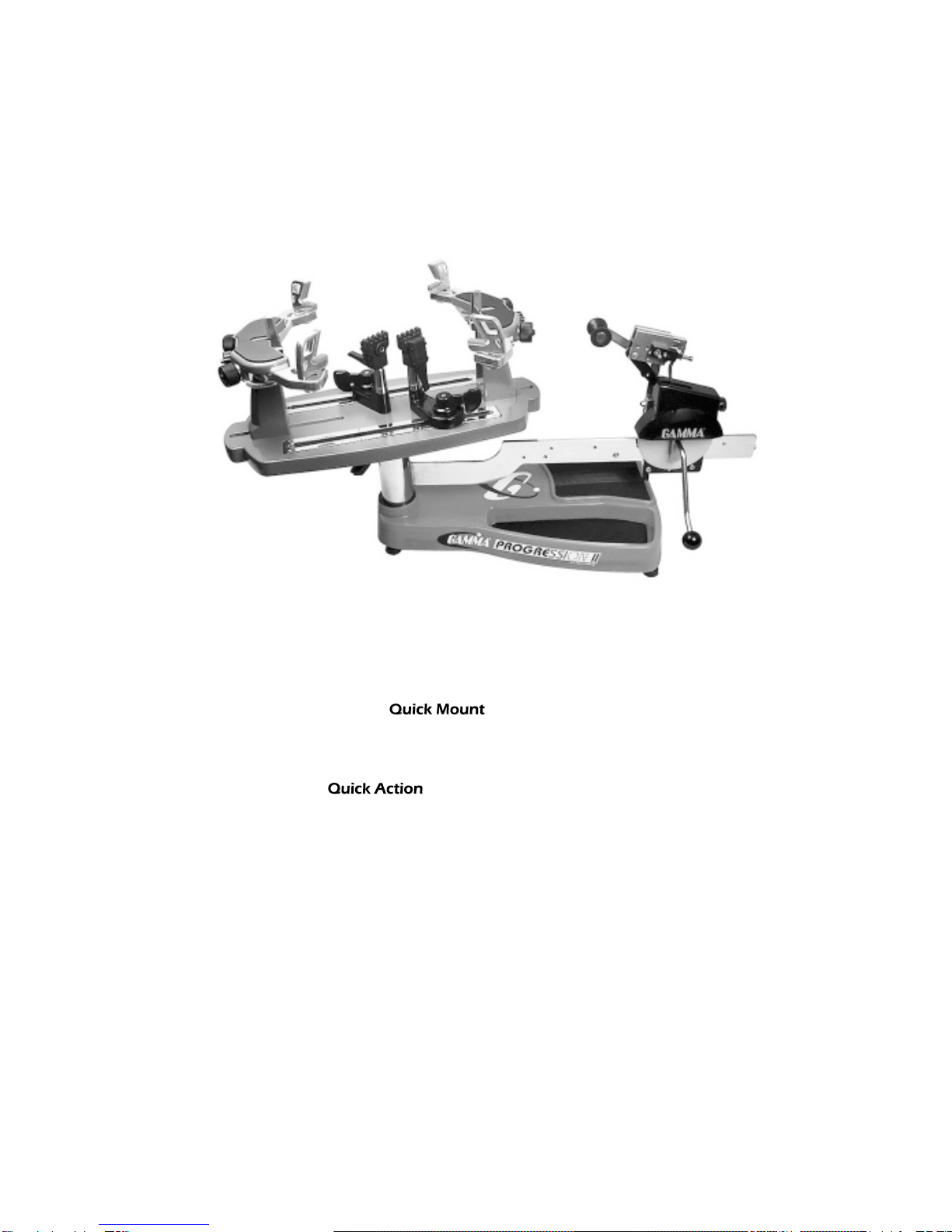

Clamp Head Operation

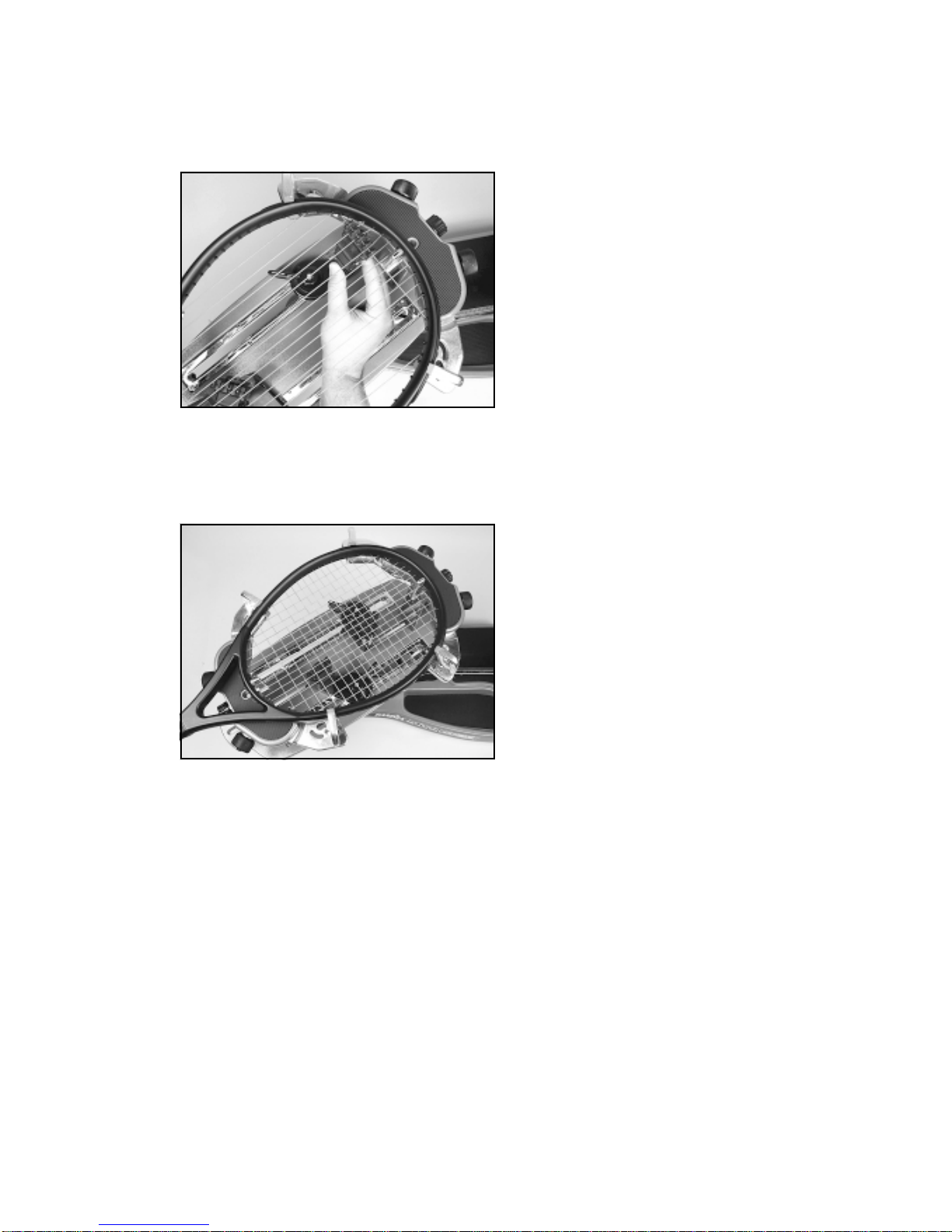

Clamps are of a dual action design where

as the clamp head and clamp base operate indepen-

dently of one another.

Toclampastring,lifttheclampheadandplacethestring

between the jaws and depress the clamp head lever to

secure the string. The clamping pressure applied to the

string should be adjusted to provide sufficient pressure

tosecurethestringwhensubjectedtothedesiredpulling

tension. The diamond coated gripper plates provide for

increased friction between the clamps and the string to

allow for reduced clamping pressure while securing and

holding the string under tension.

Note:Ifthestringslipsinthestringclampwhiletensioning,

adjust the gap between the clamp jaws per the instruc-

tions on page 13.

STRINGING THE FRAME

Travel Stop

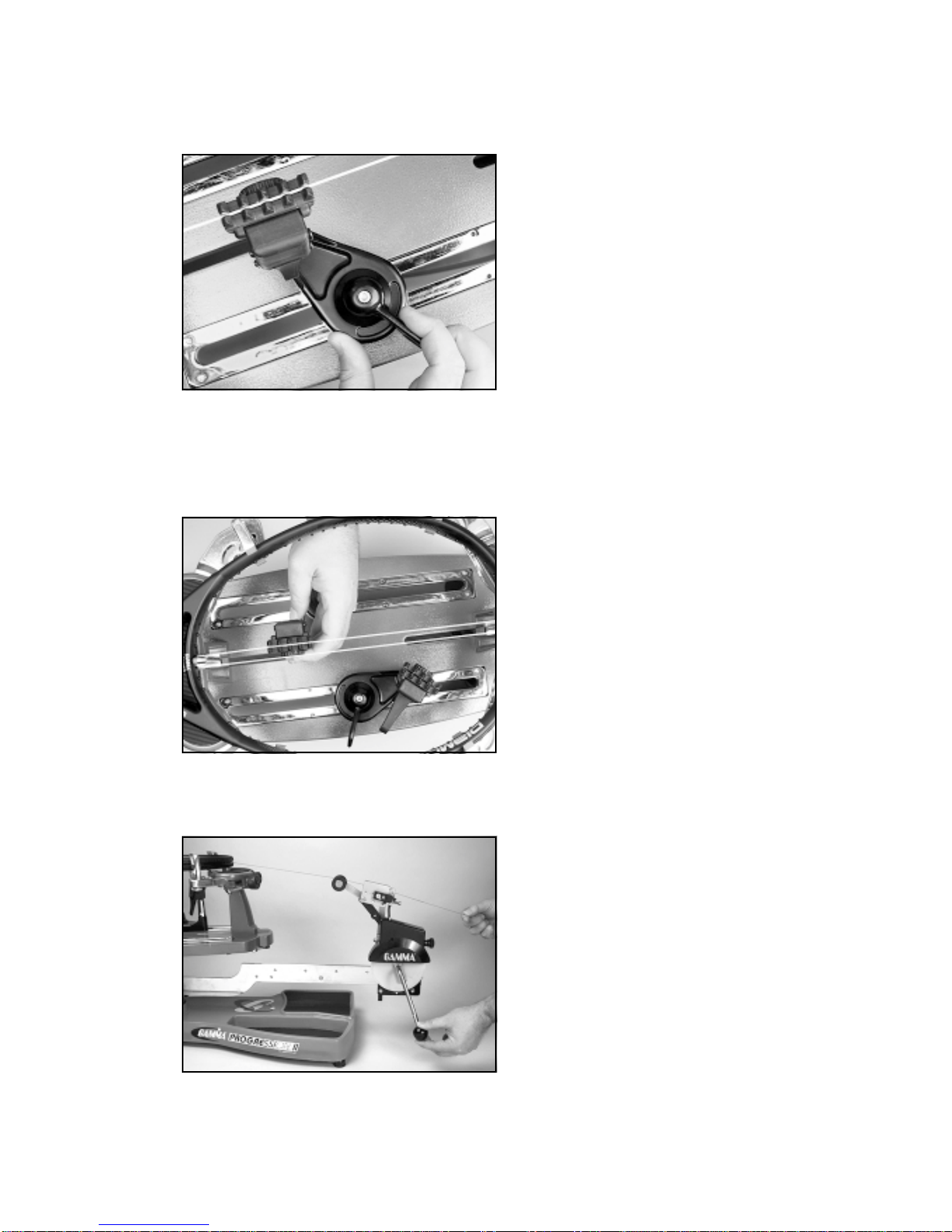

Setting Tension

The Progression STII utilizes a rotary adjusting knob

along with a linear tension scale to indicate the tension

setting. The scale is divided into 3 lb increments and

each 1/3 turn of the tension knob changes tension by 1

lb. To set the desired tension, rotate the tension knob

and align the mark on the spring guide with the desired

tension setting on the scale. When the “0” mark on the

knobaligns withthe line onthe knobsupport the tension

willbethatindicatedonthescale.Toincreasetensionby

1 or 2 lbs turn the knob counterclockwise until the “1” or

“2” mark on the knob aligns with the line on the knob

support.Todecrease tension by1or 2 lbs,turntheknob

clockwiseuntil the“2”or“1” mark on the knob aligns with

the line on the knob support.

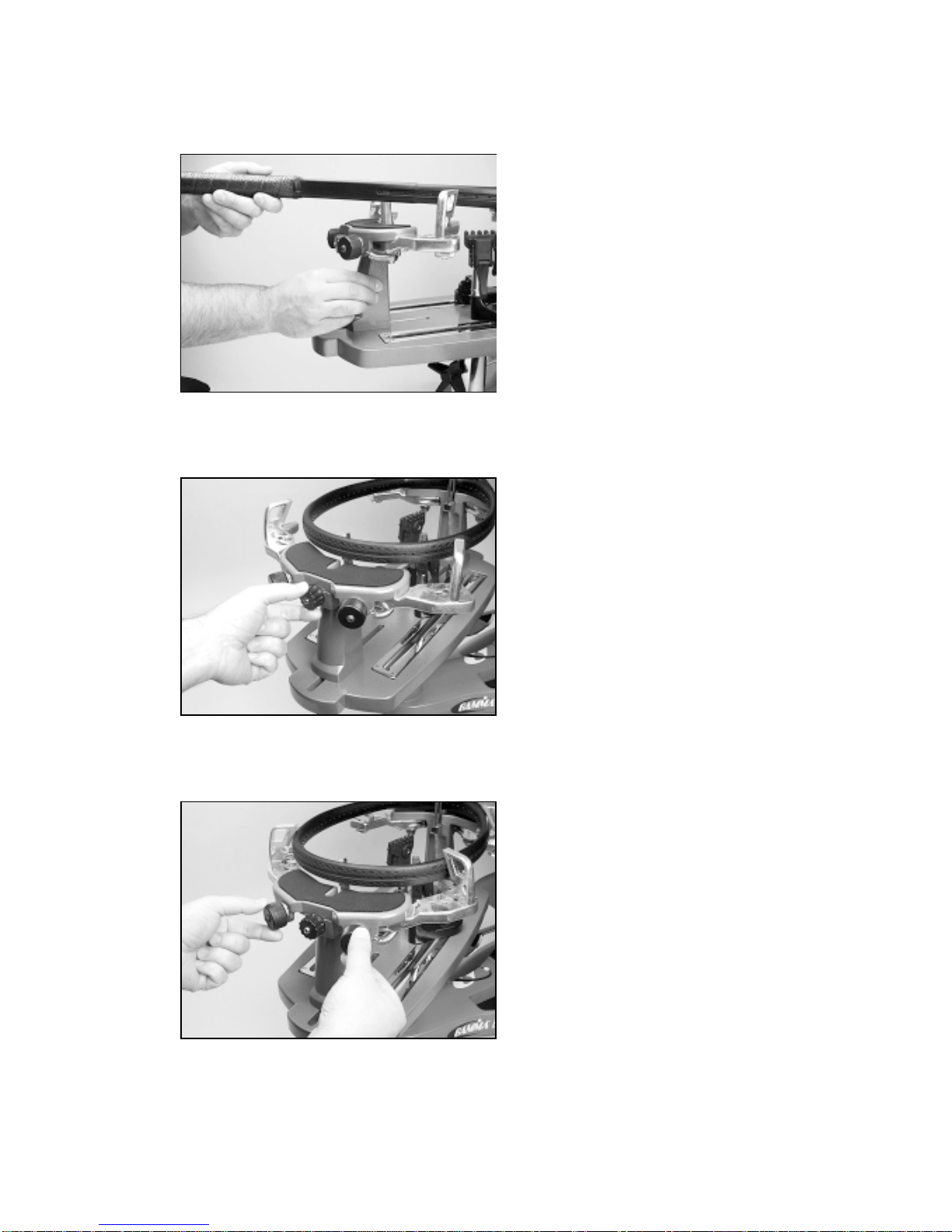

Tensioner Travel Stop

The tensioner bar is equipped with a tensioner travel

stop to limit travel of the tensioner along the bar and

prevent contact between the tensioner and the racquet

mounting system while stringing. The travel stop is

locatedaboutmidpointalongthetensionerbarbelowthe

gear track.

To disengage the stop, pull and hold the knob, rotate 90

degrees and release. To engage the stop, repeat the

above procedure until the travel stop pin protrudes

beyond the opposite surface of the tensioner bar.