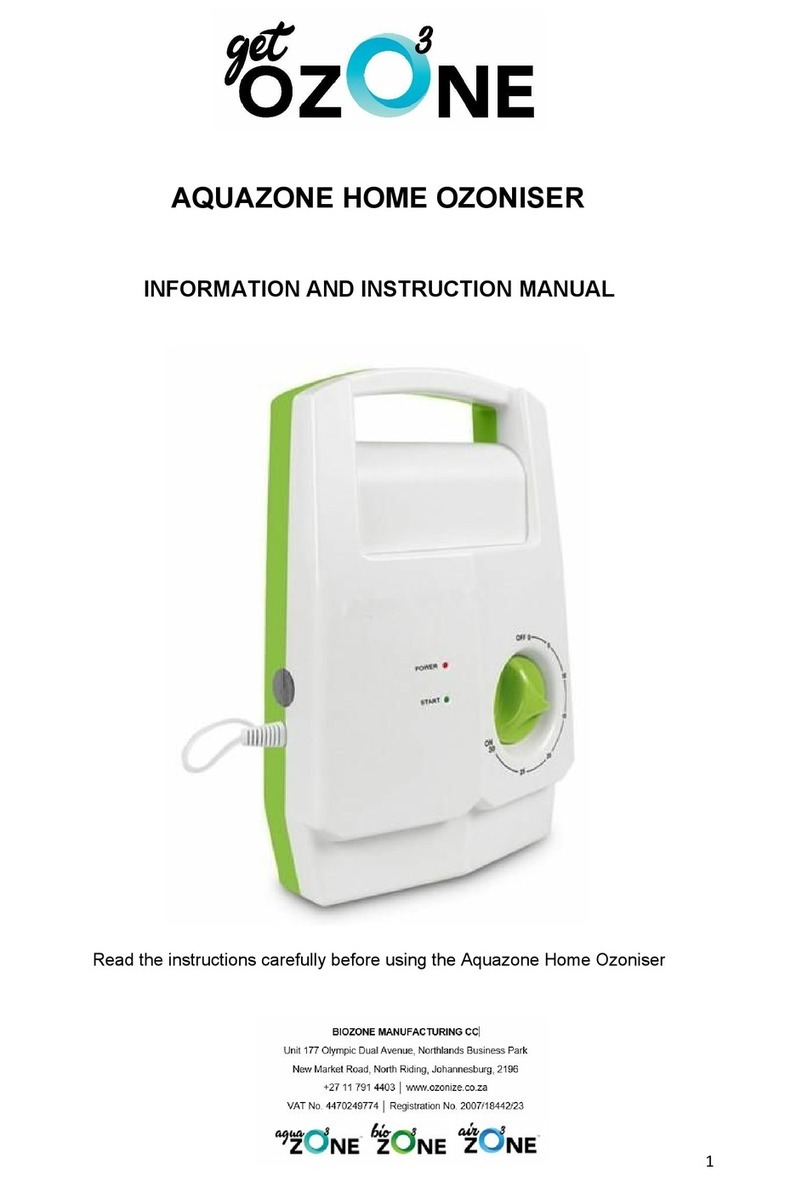

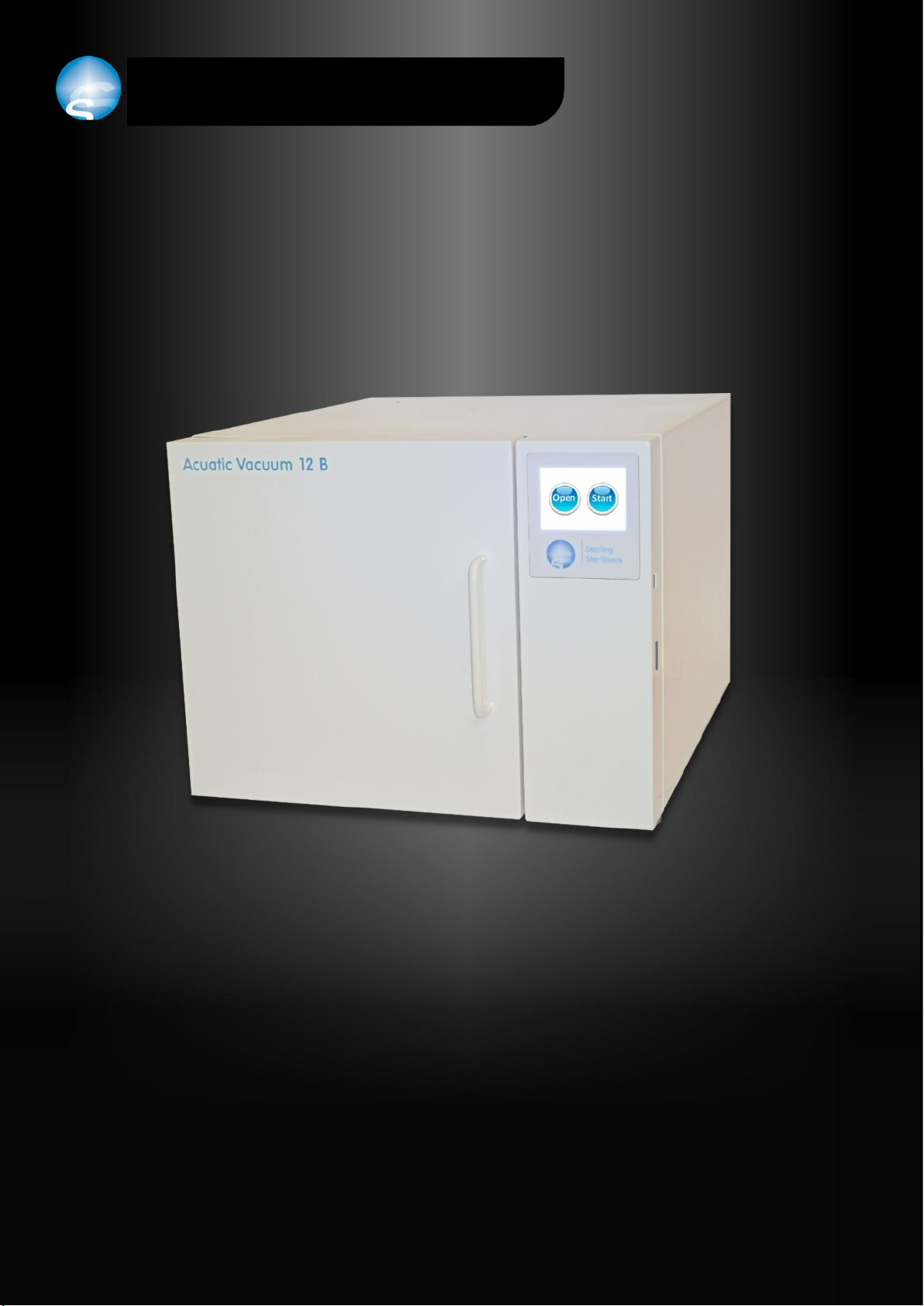

Sterling Sterilisers Acuatic Vacuum 12 B User manual

Sterling Sterilisers

Acuatic Vacuum 12 B

User Instructions

Read these Instructions before using the Steriliser

Please take time to read these instructions before using the steriliser for the first time, then keep them in a safe

convenient place for future reference.

After Sales Service

Sterling Sterilisers staff are available to provide verbal advice and assistance by phone during normal office hours and

to answer written queries by post or email. For further information visit www.sterlingsterilisers.com

Symbol Explanation

Acuatic Vacuum steriliser

020 3289 9916

Sterling Sterilisers Ltd

Wenta Business Centre

Colne Way

Watford WD24 7ND

sales@sterlingsterilisers.com

This symbol confirms that the Acuatic Vacuum steriliser complies with Council Directive 93/42/EEC

concerning medical devices as amended by Directive 98/79/EC, Directive 2000/70/EC, Directive

2001/104/EC and Regulation (EC) No 1882/2003. 0086 indicates that the Notified Body employed to

check conformation with the above is BSI.

This symbol indicates that the number next to it is the serial number of the steriliser.

This symbol indicates that the information next to it is the date of manufacture and the name and

address of the manufacturer.

This symbol indicates that the user should read the User Instructions.

This symbol indicates that in order to comply with EU Directive 2002/96/EC for Waste Electrical and

Electronic Equipment (WEEE) the steriliser should be returned to Sterling Sterilisers or disposed of at

an appropriate facility at the end of its working life in order to enable recovery and recycling in an

environmentally sound manner.

This symbol is used to highlight the fact that there are specific warnings or precautions associated with

the steriliser that the reader should be aware of.

Copyright © 2012. Sterling Sterilisers Ltd. All trademarks or registered trademarks are the property of Sterling Sterilisers Ltd

User Instructions

Acuatic Vacuum steriliser

Introduction

Features ...................................................................1

Parts Supplied ...................................................................1

Guarantee ..................................................................1

Pressure Vessel ..................................................................1

Contents

Illustration

Illustration ...................................................................2

Cycle Charts ...................................................................2

Safety

General Safety ..................................................................3

Safety Features ..................................................................3

Ambient Conditions ..................................................................3

Processing Limitations ..................................................................3

Care and Data Logger

Daily Maintenance ..................................................................4

Daily Testing ..................................................................4

Weekly Testing .................................................................4

Servicing ..................................................................4

Annual Inspection .................................................................4

Annual Testing .................................................................4

Getting Started

Getting Started ...................................................................5

Filling .................................................................5

Water Quality .................................................................5

Draining .................................................................5

Options .................................................................5

Operation

Stand By ................................................................6

Instrument Preparation ..................................................................6

Starting a Cycle .................................................................6

Processing ..................................................................6

Cycle Completion .................................................................6

Error Messages .................................................................6

Securilog Data Logger

Securilog Data logger ................................................................7

Installing the application ..............................................................7

Importing cycle data ..............................................................7

Reading cycle data ..............................................................7

Securilog SD memory card ..............................................................8

Thank you for choosing the Acuatic Vacuum 12 B steriliser from Sterling Sterilisers. We are confident that you have

purchased the finest steriliser of its type which will provide you with many years of efficient, reliable service.

Features

Fast - cycle times are between 12 and 35 minutes from start to finish not including drying - dependent on cycle

choice and loading

Simple to use - easy to understand colour touch screen display

Easy close and easy open door - push to close with vacuum assistance, touch button opening

Inbuilt Securilog data logger - to encrypt and record cycle details onto a memory card

Separate internal clean and used water reservoirs - water is only used once per cycle to ensure cleanliness

Easy to service and maintain - keeps downtime and maintenance costs to a minimum

No internal heating element - makes for easy cleaning of the chamber

N-type cycle - a fast, non vacuum cycle for solid unwrapped instruments

B-type cycle - a vacuum cycle for solid, hollow, tubular or porous loads, wrapped or unwrapped, pouched or not

Low energy consumption per cycle - keeps running costs to a minimum

Low water consumption per cycle - keeps water production or purchase costs to a minimum

No rust construction - structural parts are manufactured from stainless steel or aluminium

Impossible to overheat - innovative engineering eliminates downtime due to overheating

Easy water fill - just pour into the filling spout

Clean water auto fill - connects to an external water supply for automatic filling

Easy water drain - simple plug in drain hose

Used water auto drain - connect a tube to the rear of the steriliser for automatic draining

Self monitoring - an automatic control system continuously monitors cycle parameters to ensure effective, reliable

and complete sterilisation

Parts Supplied with the Acuatic Vacuum steriliser

These instructions

Four trays, tray rack and tray handle

Two drain tubes

Drying rack if the steriliser is supplied for use in the dental market

SD memory card and USB adaptor

Guarantee

No other steriliser manufacturer offers the security and assurance of a guarantee quite like the onesupplied by Sterling

Sterilisers. We're so confident in the quality and reliability of our product that each of our distributors provide a one

year parts and labour guarantee and a five year, fully transferable, unlimited usage parts guarantee. For full details of

the guarantee see www.sterlingsterilisers.com .

Pressure Vessel

The parts of the steriliser that are subject to steam pressure comply with the Pressure Systems Safety Regulations

2000.

1

Acuatic Vacuum steriliser

Introduction

2

Acuatic Vacuum steriliser Illustration

ABCD

E

F

G

N-type

-1

0

2

Pressure (bar)

138°C

134°C

Air removal

and heating

1

Time

Sterilising

Drying

138°C

134°C

-1

0

2

Pressure (bar)

1

Time

Air removal

and heating

Drying

Sterilising

B-type

A- door seal

B-chamber with tray rack and trays

C-water filling spout

D- touch screen display

E-clean water drain

F- used water drain

G-data logger

Cycle Charts

Pressure/time graphs are shown below for both N-type and B-type cycles.

Table of contents