1

INDEX PRE-INSTALLATION INFO

The information in this document reflects products at the date of printing. Stern Engineering Ltd reserves the right, subject to all applicable laws, at any time, at its sole discretion,

and without notice, to discontinue or change the features, designs, materials and other specications of its products, and to either permanently or temporarily withdraw any of the

forgoing from the market. All information in this document is provided “as is” without warranty of any kind, either expressed or implied, including but not limited to any implied

warranties of merchantability, tness for a particular purpose, or non-infringement. Stern Engineering Ltd assumes no responsibility for errors or omissions in the information

presented in this document. In no event shall Stern Engineering Ltd be liable for any special, incidental, indirect or consequential damages of any kind, or any damages whatsoever

arising out of or in connection with the use or performance of this information. The tradenames, trademarks, logos and service marks presented in this document, including their

design, are the property of Stern Engineering Ltd or other third parties and you are not permitted to use them without the prior written consent of Stern Engineering Ltd or such

third party as may own them.

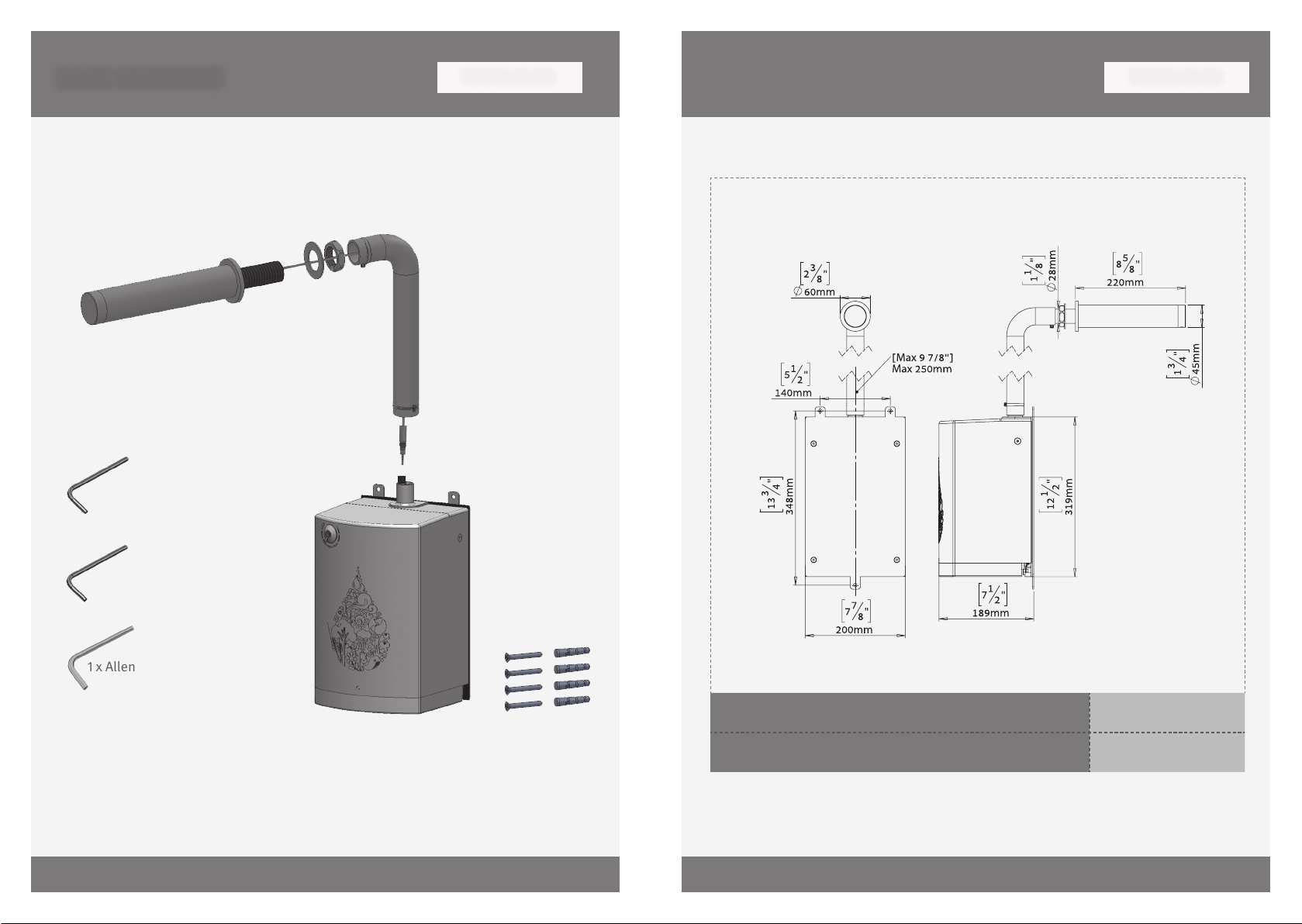

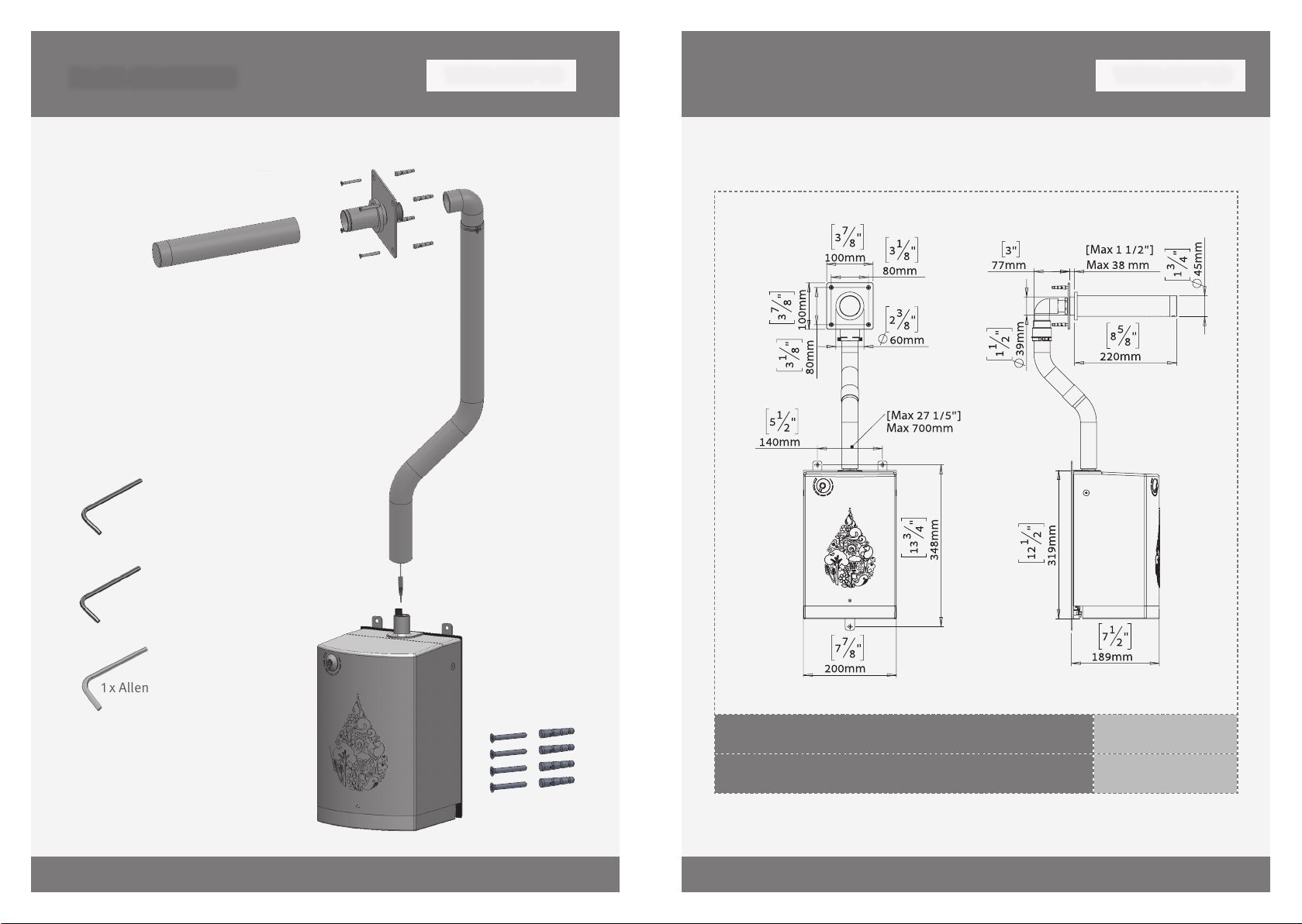

CHECK CONTENTS

Separate all parts from the packaging and check each part with the pack contents sec-

tion. Pay attention to the variations of the dierent models.

Make sure all parts are accounted for before discarding any packaging material.

If any parts are missing, do not attempt to install your electronic hand dryer until you

obtain the missing parts.

IMPORTANT

Wiring / installation of the appliance should be done according to AS/NZS

(Australian/New Zealand Wiring Rules).

WARNING

) To avoid reflection problems keep

a distance of more than mm.

between the sink and the spout.

) Model that have an infrared sensor

pointing down, are not intended to be

used together with a sink of a reflective

material such as stainless steel.

Min mm.

Bottom of the washbasin

PREINSTALLATION INFORMATION

INSTRUCTIONS FOR SAFE USE

TECHNICAL DATA ALL MODELS

PACK CONTENTS TUBULAR HD

TECHNICAL DATA TUBULAR HD

PACK CONTENTS TUBULAR DP HD

TECHNICAL DATA TUBULAR DP HD

PACK CONTENTS EVER HD

TECHNICAL DATA EVER HD

INSTALLATION

MAINTENANCE

SETTINGS ADJUSTMENT

LIMITED WARRANTY

TROUBLESHOOTING

SPARE PARTS LIST