Stewart Filmscreen CVM User manual

Producers of Professional Projection Screens

OWNERS MANUAL

CVM Control

Printed in U.S.A. ©2019 Stewart Filmscreen Corporation

Stewart Filmscreen reserves the right to make changes to the product specified in this document.

Sizes and specifications subject to change without notice at Manufacturer’s discretion. From time to time, this

document is updated. Current versions of documentation are posted on the Stewart Filmscreen website at:

www.stewartfilmscreen.com

CVM Control

OWNERS MANUAL

Contents

About CVM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keypads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

STI Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CVM Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Stewart Filmscreen

ABOUT CVM

About CVM

The Stewart CVM masking / screen controller is a bi-directional device capable of controlling multiple

motors while providing instant recall of pre-selected viewing settings. It can be controlled by a

dedicated wired keypad, serial communication, remote IR or IP (Internet Protocol). There are many 3rd

party serial drivers available; AMX, Crestron, Control4, Elan, On Controls, RTI, etc.

The CVM board electrically operates by an on board universal power supply that automatically accepts

100 to 240 VAC input. Only connect / match same voltage motors for your designated power input.

Mounting

Secure the CVM control box to a location near the Stewart screen. The encoder signaling cables are

length sensitive and therefore the control set must reside near the screen. The factory has pre-wired the

motors and encoder lines to the control box. DO NOT CUT, SPLICE OR LENGTHEN THESE CABLES. Do

not coil the excess encoder cables as this could lead to EMI. Also, avoid placing encoder cables directly

adjacent to motor’s AC power leads (do not use cable ties).

Power Up & First Time Testing

For some Stewart framed masking products, do not attach the main screen to the frame until you have

run all the cabling and tested the masking motors.

After the frame or screen housing has been installed, connect all encoder wires as needed. The factory

has installed colored Molex connectors on each white AC motor cable. Simply match these colors with

the same colored Ethernet cables and plug into the appropriate motor encoder. Improperly connected

encoder leads will cause faulty control of the motors. Also at this time make sure the wired keypad is

connected as well as any 3rd party control leads or IP Ethernet cables.

Plug in the CVM’s main AC power cord and wait approximately 30 seconds before sending any

commands. This time frame allows the controller to perform an internal status check. The on board red,

green & blue LEDs will cycle and when ready for normal operation you will see a steady blinking blue LED.

If you are using serial or IP control, this blinking LED will be green.

At this time you can begin to operate the CVM control system. For enhanced testing, control and bi-

directional feedback, use the Pilot application software thru the IP port.

CVM Control 5

KEYPADS

Wired 11-Button Keypad

the dedicated CVM keypad is the quickest way to test, operate and control the masking motors. You

can easily overwrite the preset masking positions / presets directly from the keypad. The keypad also

contains the IR receiver should IR control be utilized. The supplied connection cable is a 4 conductor

cable terminated with RJ-25 plugs. This factory cable must be replaced if the keypad is to reside at

mounted positions further away from the CVM control box. Use CAT5e or 6e shielded cables for runs

exceeding 80 ft. We advise placing this keypad in a convenient location as it can be used to quickly

test the motors / control system should 3rd party or other control inputs be non-operational. The key-

pad’s RJ-25 input port (powered) is located in the middle of the switching side of the CVM. The RJ-25

port (non-powered) directly to its right is reserved for daisy-chaining other CVM devices.

Ctrl 1 & Ctrl 2 Buttons

You will find the four long horizontal buttons on the keypad to manually operate the motor panels or

screen. Ctrl 1 operates Channel A of the CVM. This will typically be a screen, left panel or top horizontal

panel. Ctrl 2 operates Channel B of the CVM which is typically a right panel or bottom horizontal panel.

In the event of an electric screen, this would control the horizontal masking panel. When you press and

release a Ctrl button the motor will activate and run until it finally hits its internal stopping limit. At any

time during the motor’s operation, a second press of the Ctrl button will execute a stop. This makes it

easy to adjust the screen or panels when setting preset positions. Should the motor only run in small

increments and then stop after you have depressed a Ctrl button, this indicates an encoder signal fault.

The encoder signal is not reaching the CVM so therefore re-check the signal cables and make sure they

did not get crossed.

6 Stewart Filmscreen

PRESETS

The top 6 buttons on the keypad are the presets. They are stenciled as image aspect ratios however it

is best to think of them as positions 1 thru 6. You can assign any aspect ratio to any of the 6 buttons. You

can even have your own custom settings on User 1 & 2. Additional settings (up to 24 total) can be uti-

lized through use of IP control.

How to record a preset

Use the Ctrl 1 & 2 buttons to position the screen and or masking panels to a desired stopping position.

Then hold down one of the six preset buttons for 4 seconds. You will hear a slight beep sound com-

ing from the keypad. This indicates that you have successfully over-written or stored this new preset.

Please remember there are “no factory default” settings in the CVM control system. Now whenever this

button is pressed, given the screen or panels are at a different location, the motors will return to this

preset.

* Button (Director’s Choice, WallMask)

The button on the lower right corner of the keypad is a panel select button on four motor masking

products. If you press & release this button, you will now have independent control of the vertical side

panels (CVM slave board). If you position these panels and wait a few seconds, the CVM will auto-

matically return the keypad to operate the Master board (top & bottom horizontal panels). The Master

board operates the top & bottom horizontal panels and the Slave board operates the vertical side pan-

els. If you are controlling the vertical side panels, you can go back to the Master board with a second

press of the * button.

CVM Control 7

PRESETS CONTINUED

* Button (ElectriMask)

On some Stewart masking products, this button will also perform an All Home command at which time

all motors will move to their retracted position. On screens with trapdoors, the door will automatically

close once the screen and panel have fully retracted.

Keypad Backlight

To turn on the keypad’s blue back light, simply hold down Ctrl 1 Up button for 4 seconds. Hold down

Ctrl 1 Down button for 4 seconds to turn off the back light. You will hear a slight beep which signifies the

action has been completed.

Hand Held IR Remote (12 buttons)

The included hand held IR remote works in very similar fashion as the wired keypad except for storing

presets. To store or overwrite a preset, move the screen or panels to a desired position and then press

and release the blue Program button. Next press whichever preset you want and now that new setting

will be recorded.

8 Stewart Filmscreen

PRESETS CONTINUED

Alternate Communication / Low Voltage Inputs

IP (Internet Protocol) is highly advisable especially for locations where the control run exceeds 75 ft.

IP control runs can go up to 400 ft. IP is also advantageous in the event the user requires more presets

and wishes to monitor via bi-directional feedback. We suggest using Standard Ethernet cables for this

purpose and for excessive runs, shielded cable will yield best results. The CVM’s IP port is a standard

RJ-45 port located on the far right end of the board. If you will be using serial communication, use the

RJ-45 port located on the left side of the board adjacent to the STI Phoenix block.

When making any switching connections on the CVM we always advise removing AC power before in-

serting plugs. In this manner the switching circuit is protected from possible voltage spikes. Hot Swap-

ping input cables should never be attempted for this reason.

Serial communication is also highly popular and there are many 3rd party drivers that have been written

for the CVM controller. Avoid using runs over 75ft. in length. The CVM serial input requires a special

pinout and therefore off the shelf Ethernet cables will not provide proper connectivity. See the pinout

below. Also, serial communication parameters can be found on page 13.

CVM Control 9

STI INPUTS

STI – Screen Trigger Input

The CVM can also be controlled via external trigger sources. These trigger signals typically come from

video projectors but can also be sent via 3rd party I/O relays. In these situations the closed relay is send-

ing the trigger signal moving the system to preset #2. When a second trigger signal is sent, the system

moves over to preset # 1. The operating range of the CVM trigger input is +3 to + 12 VDC covering just

about any available trigger source.

STI Phoenix block connections

Pin 1 – located on the right = trigger ground (neg. voltage)

Pin 2 -- +12 vdc trigger signal moves panels to preset #2.

Pin 3 – +12 vdc trigger signal moves panels to preset #1

Pin 4 – not used

CVM control inputs

STI Block – Pin 1 RJ-45 Serial Port RJ-25 Keypad RJ-25 CS Bus RJ-45 IP control

10 Stewart Filmscreen

CVM INPUTS

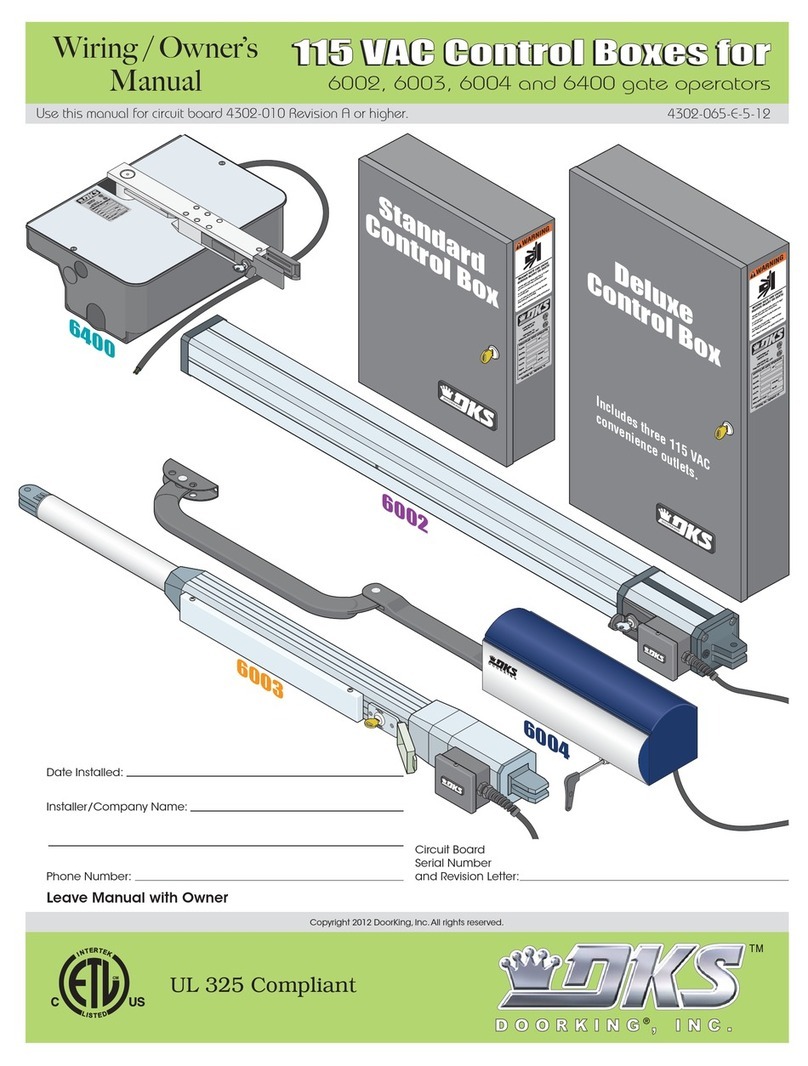

Channel A & B Motor Connections & Encoder Cables – Channel A is blue, Channel B is red

Phoenix connectors attach to the motor’s high voltage leads & then snap into board’s terminals

Channel C in photo is not in use.

Unused RJ-45 port in photo is for unspecified usage – Do Not connect – leave it open

High Voltage motor lead connections: White = Neutral, Black – Down, Red – Up . Can be shortend if

needed.

AC power input: White – Neutral, Black – Hot Line

Blue blinking LED indicates wired CVM keypad connected & operating the system.

Green blinking LED signifies serial or IP control.

CVM Control 11

CVM INPUTS CONTINUED

IP Control with Pilot Software

Internet Protocol control of the CVM is quickly obtained with Pilot software application. Use a standard RJ-

45 Ethernet cable to connect the CVM to a network switcher while running the Pilot software on a laptop or

PC. The following examples on page 12 are the Syntax commands used for both serial and IP control. When

you visit the Converging Systems Website to obtain the Pilot software use:

Login: csidealer & Password: 4212color

CVM is listed as IMC-300MKII at this site

IP Control from Network

IP control from your network is easily obtained by connecting a standard RJ-45 Ethernet cable from your

network switcher to the IP port on the CVM board. You can use Hyper Link, Putty or Pilot as the operating

program. At that time the CVM will auto assign its IP address and you can begin sending the Syntax control

commands. These commands are located on page 13 for your convenience.

1. To find the CVM IP address on your PC or laptop – click on Network

2. You then locate: e-IMC (Screen Control) under other devices – left click to open

3. IP address will self-populate in the browser

4. And the Stewart Web page will appear – then click on Settings tab

5. Hit Restart and you should hear the relays click in the CVM. The Syntax commands should now

be operational (Page 13)

6. If commands do not operate CVM make sure Telnet is enabled with correct user name and password.

12 Stewart Filmscreen

APPENDIX

CVM Control 13

COMMANDS SERIAL

Baud rate 19200

Parity N

Valid Data 8

Stop Bit 1

Hand Shaking None

Serial Communication Parameters

Set up your serial communication software (from your AMX, Crestron, or other automation system) with

the following serial communication parameters. These parameters cannot be changed within the CVM

or IBT-100 serial converter.

14 Stewart Filmscreen

COMMANDS

Command Function

#1.1.1.MOTOR=UP; Ch. A motor up

#1.1.2.MOTOR=UP; Ch. B motor up

#1.1.3.MOTOR=UP; Ch. C motor up

#1.1.4.MOTOR=UP; Ch. D motor up

#1.1.1.MOTOR=DOWN; Ch. A motor down

#1.1.2.MOTOR=DOWN; Ch. B motor down

#1.1.3.MOTOR=DOWN; Ch. C motor down

#1.1.4.MOTOR=DOWN; Ch. D motor down

#1.1.1.MOTOR=STOP; Ch. A motor stop

#1.1.2.MOTOR=STOP; Ch. B motor stop

#1.1.3.MOTOR=STOP; Ch. C motor stop

#1.1.4.MOTOR=STOP; Ch. D motor stop

#1.1.0.MOTOR=STOP; Stops all motors

#1.1.0.MOTOR=RECALL,X; Moves all motors to preset X (x = 1 to 24)

#1.1.0.MOTOR=STORE,X; Stores current position as preset X (x = 1 to 24)

#1.1.0.MOTOR=RETRACT; All motors move to “Home” position

Query Mode

#1.1.1.Motor.Position=?; Shows Ch. A motor’s position as %

#1.1.2.MOTOR.POSITION=?; Shows Ch. B motor’s position as %

#1.1.3.MOTOR.POSITION=?; Shows Ch. C motor’s position as %

#1.1.4.MOTOR.POSITION=?; Shows Ch. D motor’s position as %

www.stewartfilmscreen.com

1161 W. Sepulveda Blvd., Torrance CA 90502 USA l 800.762.4999 l Tel: 310.784.5300 l Fax: 310.326.6870 l Email: request@stewartfilmscreen.com

©2019 Stewart Filmscreen. Specifications are subject to change without notice.

xxx

Table of contents

Popular Controllers manuals by other brands

LinMot

LinMot E1100-CO Data Sheet & Installation Guide

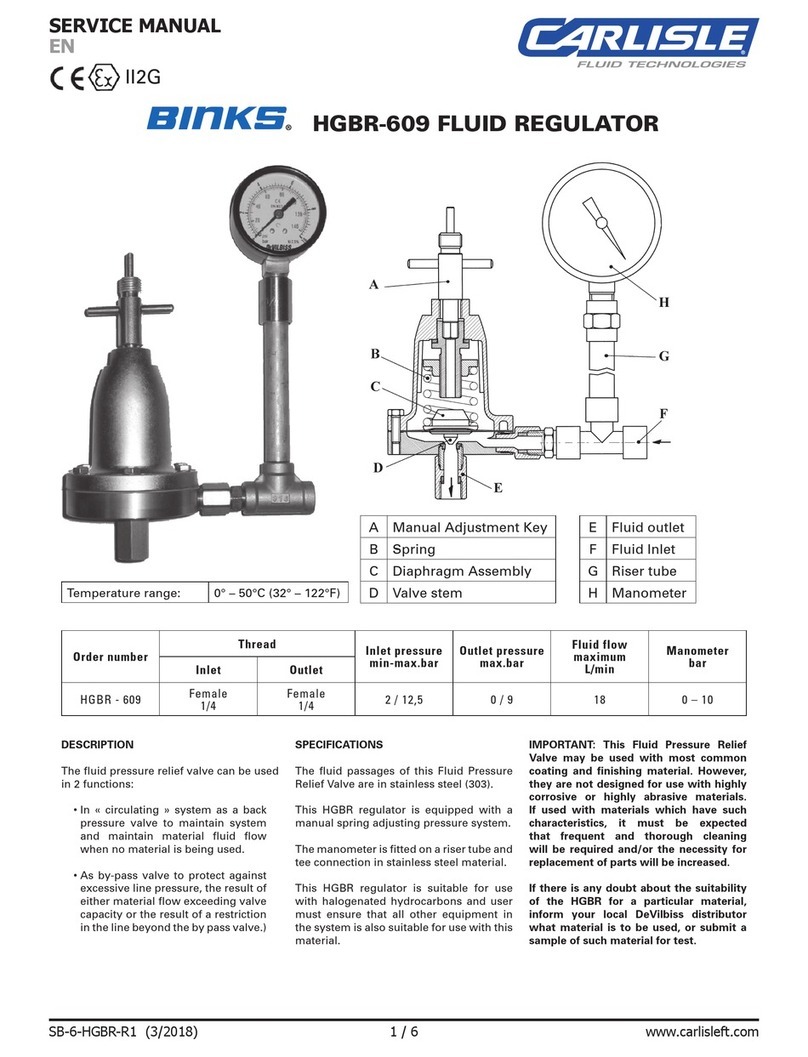

Binks

Binks HGBR-609 Service manual

Mitsubishi Electric

Mitsubishi Electric FX3U-64DP-M installation manual

Flex-a-Lite

Flex-a-Lite 31163 installation instructions

National Instruments

National Instruments PCI-7342 user manual

SolaStat

SolaStat AlphaStat-Plus installation guide