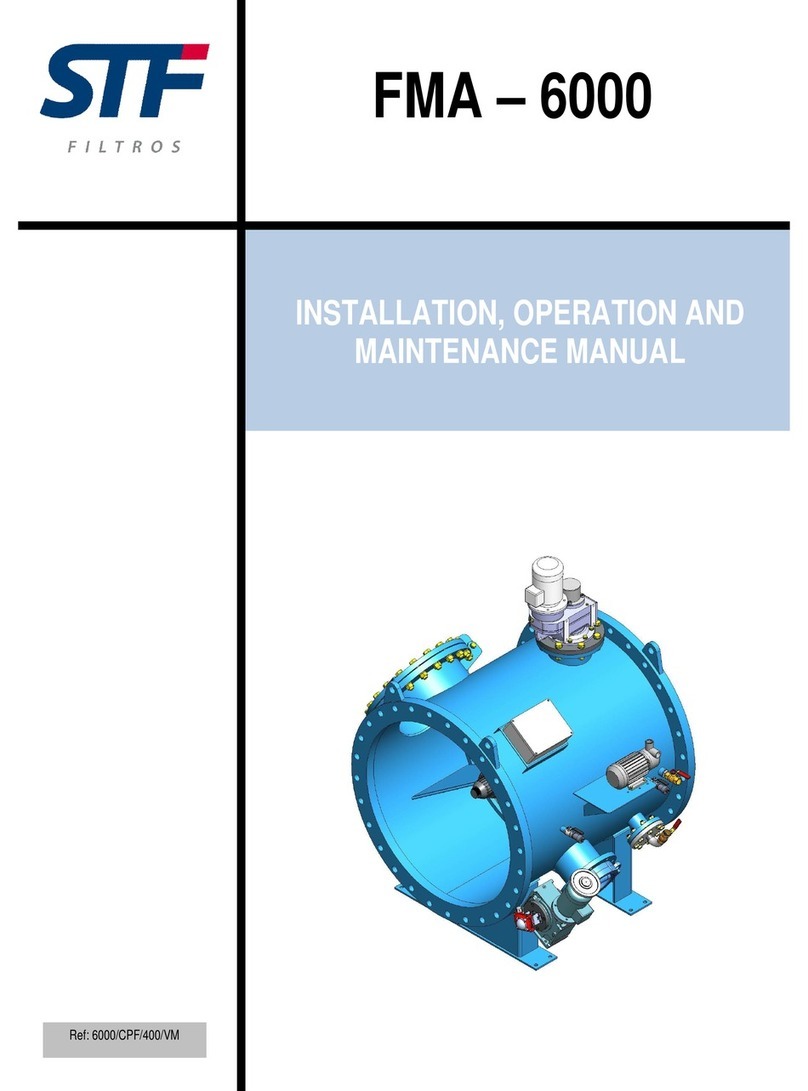

STF-Filtros FMA-3000 User manual

Table of contents

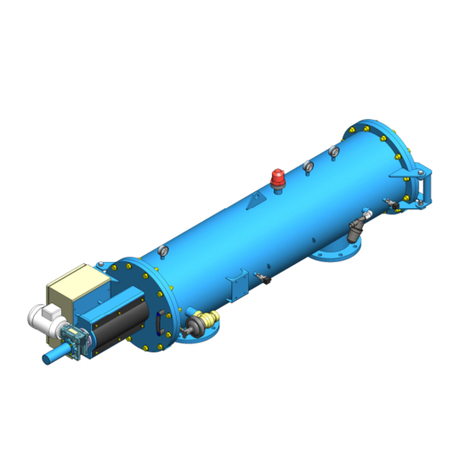

Other STF-Filtros Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Survivor Filter

Survivor Filter L600 instruction manual

Philips

Philips AWP2950/03 user manual

PureEffect

PureEffect ULTRA-UC-DISINFECT manual

Dometic

Dometic RO400 Service manual

Aquasana

Aquasana AQ-4501 Installation instructions and service guide

Grundfos

Grundfos AQpure Installation and operating instructions

HYTECON

HYTECON HYPRO WATER user manual

Graco

Graco 25M212 Instructions - parts

King Technology

King Technology 01-01-7820 instruction manual

MURSATT

MURSATT Digital 48 Installation and operation manual

GE

GE Profile PNRQ21LBN Owner's manual and installation

Barnstead

Barnstead EASYpure II UV 1302 Series Operation manual and parts list

Oasis Clearwater

Oasis Clearwater 3000 Series owner's manual

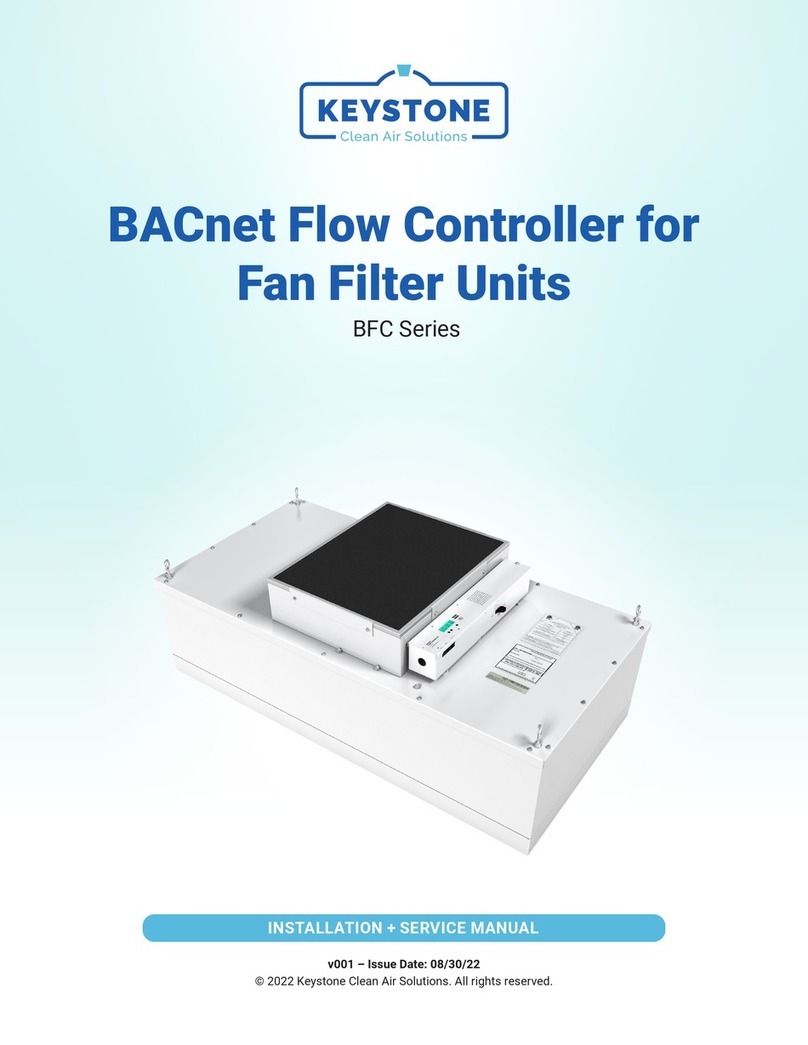

Keystone

Keystone BFC Series Installation and service manual

Intex

Intex 26669EG owner's manual

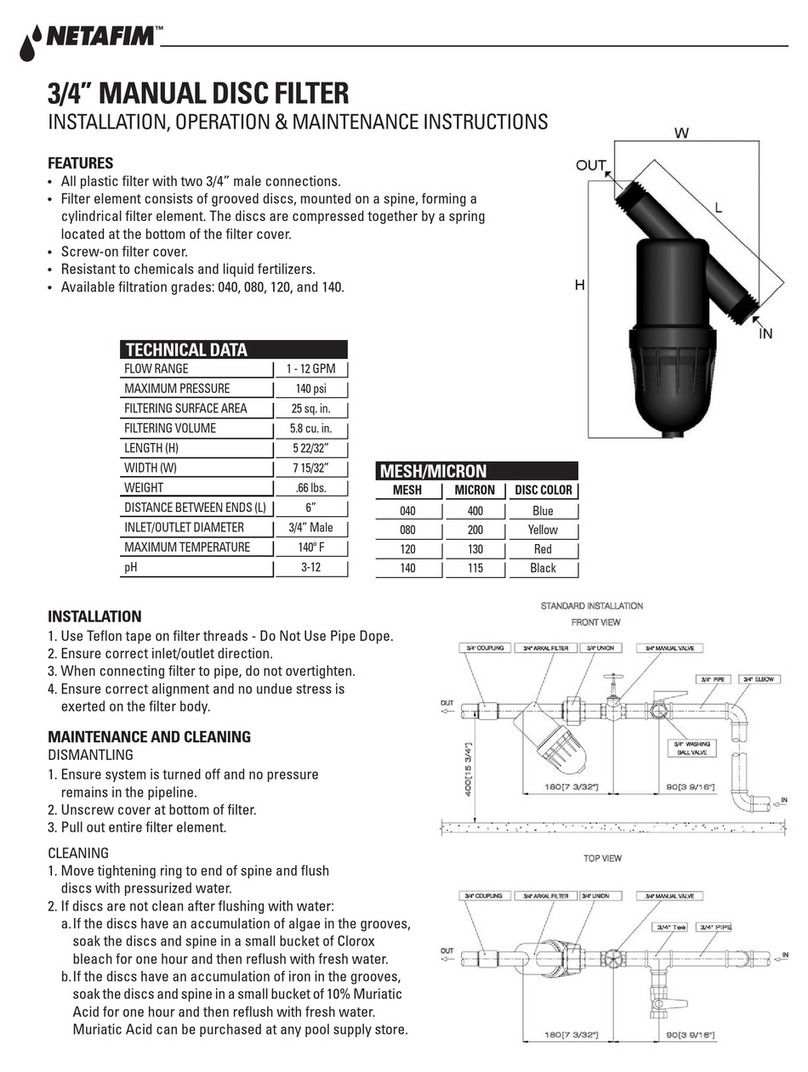

Netafim

Netafim 25AP46 Series Installation, operation & maintenance instructions

Autek

Autek QF-1A instructions

Sea Recovery

Sea Recovery SRC Aqua Matic 450-1 owner's manual