STF-Filtros FMA-6000 User manual

Sistemas de Filtradoy Tratamiento de FluidosS.A.

Pol. Industrial La ArmenteraParc. 86

22400 Monzón (Huesca) Tel.974 401933 Fax. 974 417809

www.stf-filtros.com · e-mail: info@stf-filtros.com

FMA – 6000

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

Ref: 6000/CPF/400/VM

2

TABLE OF CONTENTS

INTRODUCTION....................................................................................................................3

SAFETY INSTRUCTIONS.....................................................................................................4

TECHNICAL SPECIFICATIONS...........................................................................................5

HEAD LOSS CHART…………………………………………………………………………….10

RECOMMENDED INSTALLATION DIMENSIONS AND DESIGN………………………….12

INSTALLATION AND START-UP INSTRUCTIONS...........................................................12

INSTALLATION DIAGRAM .................................................................................................14

MASTER PANEL PERFORMANCE....................................................................................14

PRESSURE DIFFERENTIAL REGULATION .....................................................................24

EXPLOSION DIAGRAM .....................................................................................................26

HYDRAULIC LAYOUT.........................................................................................................31

ELECTRIC PANEL ..............................................................................................................32

ELECTRIC LAYOUTS .........................................................................................................33

PREVENTIVE MAINTENANCE SCHEDULE......................................................................38

REFERENCES…………………...……………...……………………………………………….39

3

INTRODUCTION

GENERAL

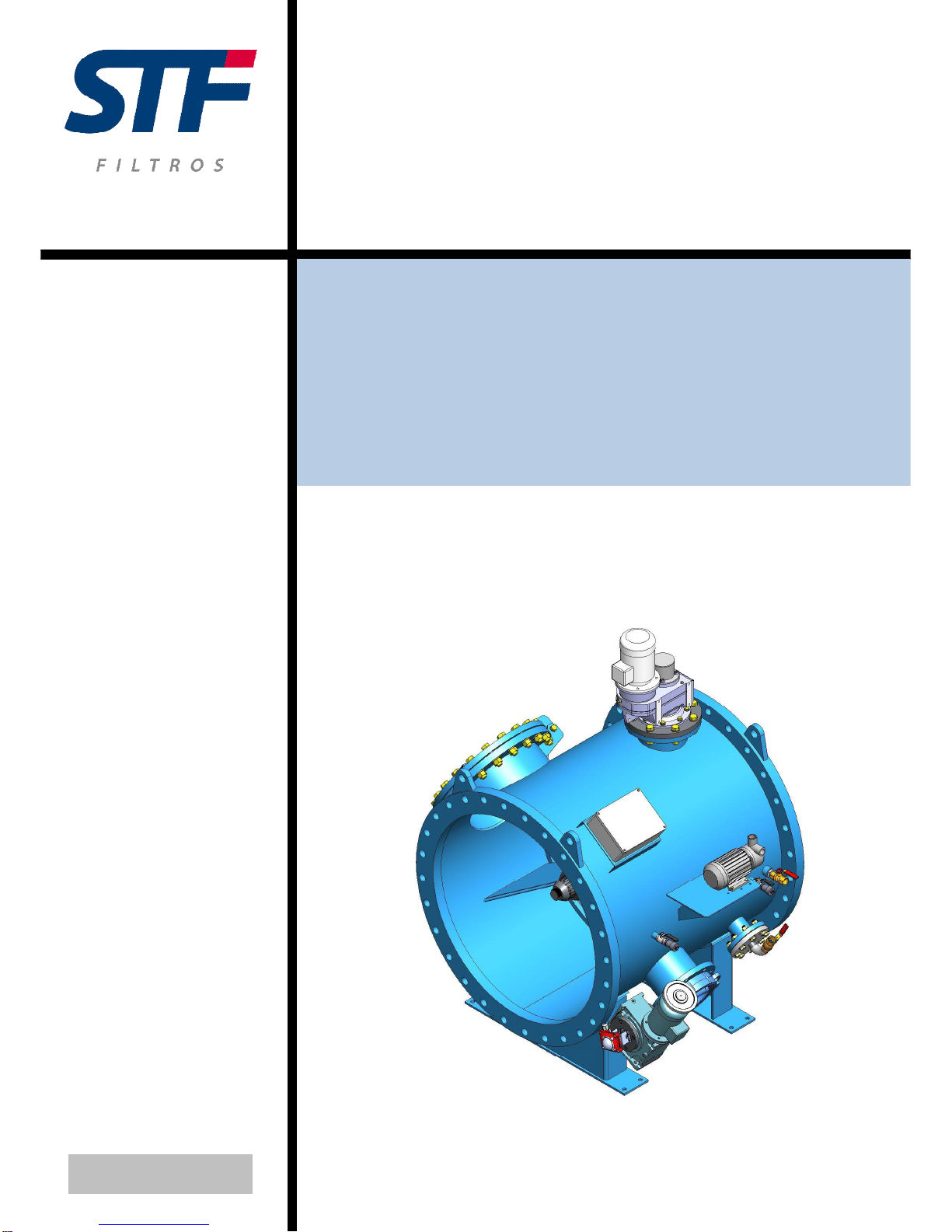

STF filtros congratulates you on the acquisition of the FMA 6000 self backwashing automatic filters.

This filter joins the STF filters wide range for agricullture, water treatment, sewage treatment plants and

other industrial use. All the products manufactured by STF-FILTROS are easy to install, use and maintain

and no special knowledge is required to operate them.

WARRANTY

The product has a two-year warranty from the moment of acquisition.

Follow this manual instructions to operate and maintain the filter.

Mechanical damages or any other damages caused by incorrect use are excluded fromwarranty.

The warranty gets also cancelled in case that no original spares are used.

4

SAFETY INSTRUCTIONS

1. Prior to installation or filter operation, read carefully this manual.

2. Please note, the filters enters into a backflushing mode automatically, without prior warning.

3. Non authorized modifications or changes on the equipment are permitted.

4. Filter installation should be performed so as to avoid direct water splashing on the electrical

components.

5. Take correct precautions when raising and placing the equipment so that no damages are

produced.

6. Make sure to leave enough clearance so as to enable easy access for future treatments and safe

maintenance operations.

7. It is necessary to place a shut-off valve in the collector before the equipment to make the

maintenance easier.

8. Make sure that the equipment is operating at a correct working pressure.

9. Disconnect the filter from power supply before maintenance or treatment.

10. Never switch on the equipment without placing all the safety elements.

11. Don’t carry out a differente maintenance different from the indicated in this manual.

12. Use only original spare pieces.

5

TECHNICAL SPECIFICATIONS

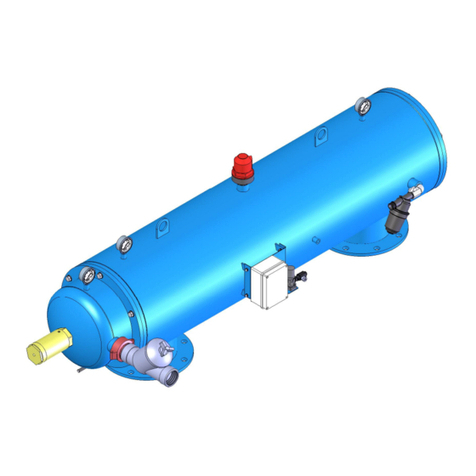

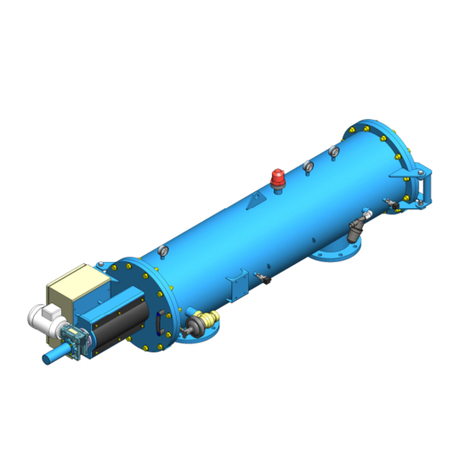

Equipment general description

The filter is composed of a metallic body, gear crown, main drain, opening valve (backwashing),

a pump for injecting clean water to the nozzles and a geared motor for rotation crown and measure and

control elements running. The filtering element is a special screen, fixed to the rotation crown, for filtering

all kinds of dirt particles, with a hydrodynamic profile that provides low head loss and reduces

turbulences, reduces head losses and avoiddirt particles accumulation.

All the materials are top-quality, in all the mechanic elements that are in contact with water it is

used stainless steel orsimilar. The filter body is made of carbon steel. The mechanic elements are in the

“clean water” side (water under the screen) in such a way that no foreign object can affect its performing

or deterioration.

FMA-6000 filters fit directly to the pipe by means of flanges, as it was one more element of the

pipe. Only the electric and control elements require installation.

It is a self backwashing automatic filter that has minimum maintenance and low consumption.

Performance

Water goes through the rotative screen and all the dirt particles bigger than the screen holes get

filtered. When the default pressure differential, backwashing starts, this is made area by area, collecting

waste materials to be expelled to the exterior.

The backwashing cycle starts when the default differential pressure is detected on both sides of

the screen. At that moment, the crown starts spinning until an area is placed just in the backwashing

chamber and then the backwashing valve is opened and the pump for water is started for water flooding

through the nozzles, from the “clean water” screen side.A screen exhaustive backwashing is obtained by

means of these nozzles. The backwashing valve stays open during the backwashing pre-set time and

then it closes. The crown moves on to the following area and the opening and closing the backwashing

valve and the water flooding pump cycle starts again.

6

When the sector is placed in the backwash chamber, this remains watertight due to the nylon

bristles, for this reason, when the backwashing valve is opened, water flows through the filtration screen

in the opposite sense than the filtration process which means an important saving in backwashing water

consumption.

An electronic system protects mechanically the equipment. It is composed of an electronictorque

limiter, a progressive starting system and a crown position electronic control.

In the case that any foreign object blocks the screen rotation, the system inverts the rotation

alternatively until the foreign object is removed. In case it is too big, it will be extracted manually. An

alarm signal will turn on if any system failure occurs.

Performance

FIRST STARTING UP:

The pipe has to be object-free. The filter rotation has to be initiated before there is water flow in

the pipe.

COMMON PERFORMANCE:

When water flows through the filter, the dirt particles that are bigger than the filtration degree get

retained on the screen. These particles produce an increase on the differential pressure. If this differential

is not larger than 0.8 m.c.a, the filter backwashes according to the default time interval (8 hours,

variable). If the the scale 0.8 m.c.a. is not exceeded, the differential pressure system detects the same

one and the backwashing cycle starts.

7

Maintenance

The FMA-6000 filter has only a mobile piece and it is accesible from outside. The rest of the

mobile pieces like engines and external valves are easily accesible. The rest of the maintenance is

based on visual inspections and greasing.

The necessary spare pieces change according to the dust quantity, sand and number of

backwashing cycles.

Screen technical characteristics

The “Double Diamond” screen is composed of quality AISI-316 electrowelded angle frames

arranged 90º between the longitudinal and the transversal angle frames. The particles retention angle

frames are rhombus-shaped so that water flow is possible (decrease head loss). This rhombus shape

makes screen backwashing easier by means of reducing backwashing time.

Backwashing cycle

Backwashing time cycle is 90 seconds, from which, during 54 seconds the backwashing valve is

open (including valve opening and closing time). For this reason, the backwashing consumption is quite

reduced (if the factory worker does not manipulate the default times).

Remove the thick particles from the crown

In case the filtering crown is blocked with any thick element, this will get unblocked automatically.

There is an electronic torque limiter in the system that detects when the crown is making more effort than

the effort that there is on the design, then the screen changes its spin direction (backwashing just in the

opposite direction).

If the crown gets blocked again, it will invert the spinning direction. If the blocking element could

not become detached from the filter after several spinning direction changes, then a manual intervention

would be carried out (opening the inlet and extracting manually the element that is stuck).

Head loss

Head loss for nominal flow is 0,4 m.c.a. (head loss is made with clean water).

8

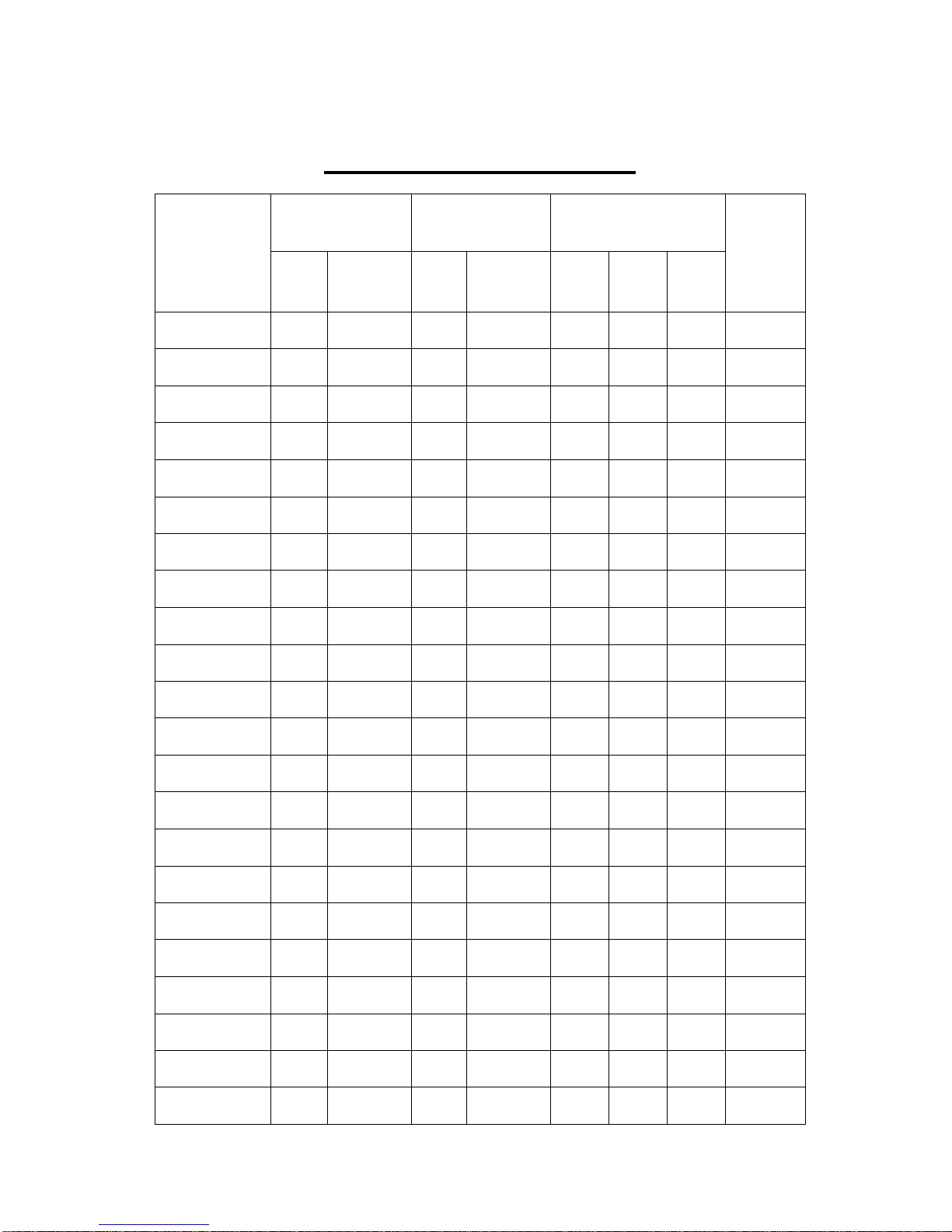

TECHNICAL SPECIFICATIONS

Connection inlet/

outlet Drainage

connection Nominal flow m3/s

Model

DN Inches DN Inches Screen

1 x 1

Screen

1,5 x

1,5

Screen

2 x 2

Installed

power

capacity

FMA - 6016 400 16" 80 3" 0.089 0.13 0.17 1.48 Kw

FMA- 6020 500 20" 100 4" 0.13 0.19 0.36 1.48 Kw

FMA - 6024 600 24" 125 5" 0.2 0.3 0.56 1.68 Kw

FMA- 6028 700 28" 150 6" 0.31 0.45 0.65 1.75 Kw

FMA- 6032 800 32" 150 6" 0.43 0.63 0.92 1.83 Kw

FMA- 6036 900 36" 200 8" 0.61 0.89 1.25 2.1 Kw

FMA- 6040 1000 40" 200 8" 0.78 1.14 1.53 2.57 Kw

FMA- 6044 1100 44" 200 8" 0.97 1.42 1.75 2.8 Kw

FMA- 6048 1200 48" 250 10" 1.16 1.69 2.22 3.35 Kw

FMA- 6052 1300 52" 250 10" 1.3 1.9 2.5 3.5 Kw

FMA - 6056 1400 56" 300 12" 1.61 2,35 3.33 3.7 Kw

FMA- 6060 1500 60" 300 12" 1.95 2.85 3.89 4.1 Kw

FMA - 6064 1600 64" 300 12" 2.33 3.4 4.17 4.3 Kw

FMA- 6068 1700 68" 350 14" 2.57 3.75 4.72 4.7 Kw

FMA- 6072 1800 72" 350 14" 2.83 4.14 5.14 5.2 Kw

FMA- 6076 1900 76" 400 16" 3.25 4.75 5.56 5.5 Kw

FMA - 6080 2000 80" 400 16" 3.7 5.41 6.67 6 Kw

FMA- 6088 2200 88" 450 18" 4.42 6.45 7,78 6.2 Kw

FMA - 6096 2400 96" 500 20" 5.14 7.5 8.89 6.38 Kw

FMA- 6104 2600 104" 500 20" 5.75 8.39 11.1 6.72 Kw

FMA - 6112 2800 112" 500 20" 6.54 9.55 13.06 7.1 Kw

FMA - 6120 3000 120" 600 24" 7.1 10.3 14.44 7.25 Kw

9

HEAD LOSS CHART

Screen 2 x 2 Double Diamond

Screen 1,5 x 1,5 Double Diamond

FMA - 6016 FMA - 6020 FMA - 6024 FMA - 6028 FMA - 6032 FMA - 6036

FMA - 6040 FMA - 6044 FMA - 6048 FMA - 6052 FMA - 6056 FMA - 6060

FMA - 6064 FMA - 6068 FMA - 6072 FMA - 6076 FMA - 6080 FMA - 6088

FMA - 6096 FMA - 6104 FMA - 6112 FMA - 6120

10

11

RECOMMENDED INSTALLATION DIMENSIONS AND DESIGN

It is advisable to assemble a motorized butterfly valve together with a dismantling joint, previous to the

filter. This is necessary in order to cut the water supply to the installation, in case of filter alarm or

preventive maintenance.

Shut

-

off

valve

Dismantling

joint

Filter

FMA

-

6000

Drain

pipe

Minimum 1% slope

CORRECT

1% slope downwards

INCORRECT

The pipe gets blocked up with

heavy solids.

12

START-UP AND FIRST OPERATION

1. Make sure that water flood direction coincides with the arrows indicated on the equipment.

2. A backflow valve has to be installed if it is foreseen reflux in the filter in order to protect the

device from water hammer. STF is not responsible for any damages occurred on the

equipment, in case of water hammers or pressures superior to the maximum design

pressure.

3. Butterfly valves have to be placed in the filter inlet and outlet to drain off the pipe and carry out

the maintenance. (The outlet butterfly valve will depend on the equipment placement in the

installation).

4. Disconnect the equipment.

5. Turn the circuit breakers to ON.

6. The equipment is already adjusted to operate correctly, (0.8 m.c.a pressure differential; 8 hours

between safety backwashings).

7. The pipe has to be object-free. The filter rotation has to be started before there is water flow in

the pipe.

8. Backwash manually when filling in the installation, until the pipe is pressurized completely.

13

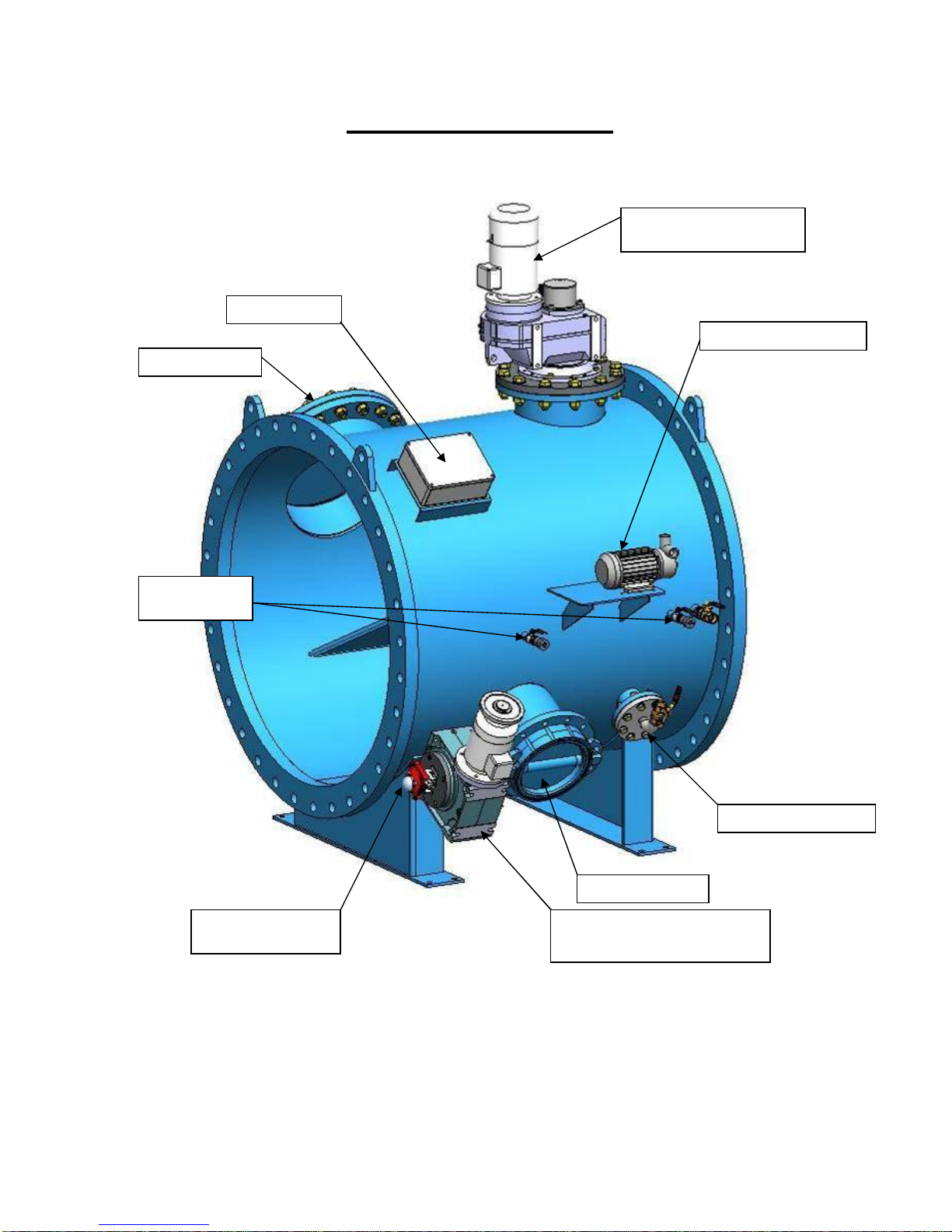

INSTALLATION DIAGRAM

Terminal block

Motorized reduction

gear

crown

Injection pump

Backwashing valve motorize

d

reduction gear

Backwashing valve

Limit switch

Backwashing valve

Injection manifold

Pressure

transducers

Man hole

14

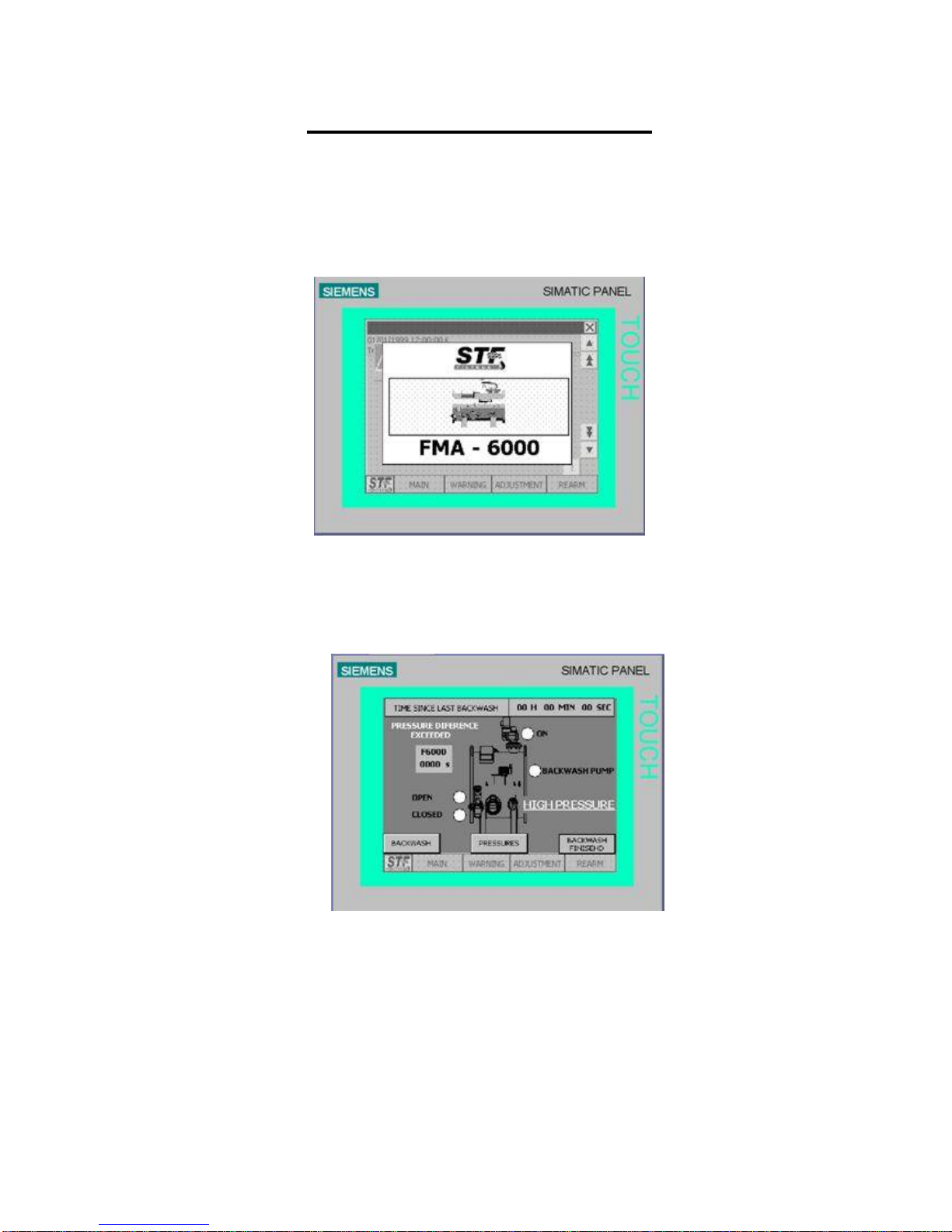

MASTER PANEL PERFORMANCE

The control panel of the self backwashing FMA-6000 is controlled from a touch screen that allows you to

control and modify the equipment parameters.

STARTUP SCREEN (1)

Touch the STARTUP SCREEN to have access to the MAIN MENU screen.

MAIN MENU SCREEN(2)

On the main menu screen, time since the last backwashing filter appears on the screen besides the

backwashing time if its in the middle of the backwashingprocess.

The drain valve operation LEDS, the backwashing pump operation LEDS and the crown gear motor

during the backwashing process appear in the filter diagram.

When the default pressure difference on the PRESSURE screen (4) is reached, the legend “ EXCEEDED

15

PRESSURE DIFFERENCE” will appear on the screen. Besides this, in case of pressure excess, the

legend “OVERPRESSURE” will be indicated.

If an alarm goes on or there is an operation failure, a triangle warning symbol will appear on the screen.

MENUS ACCESS:

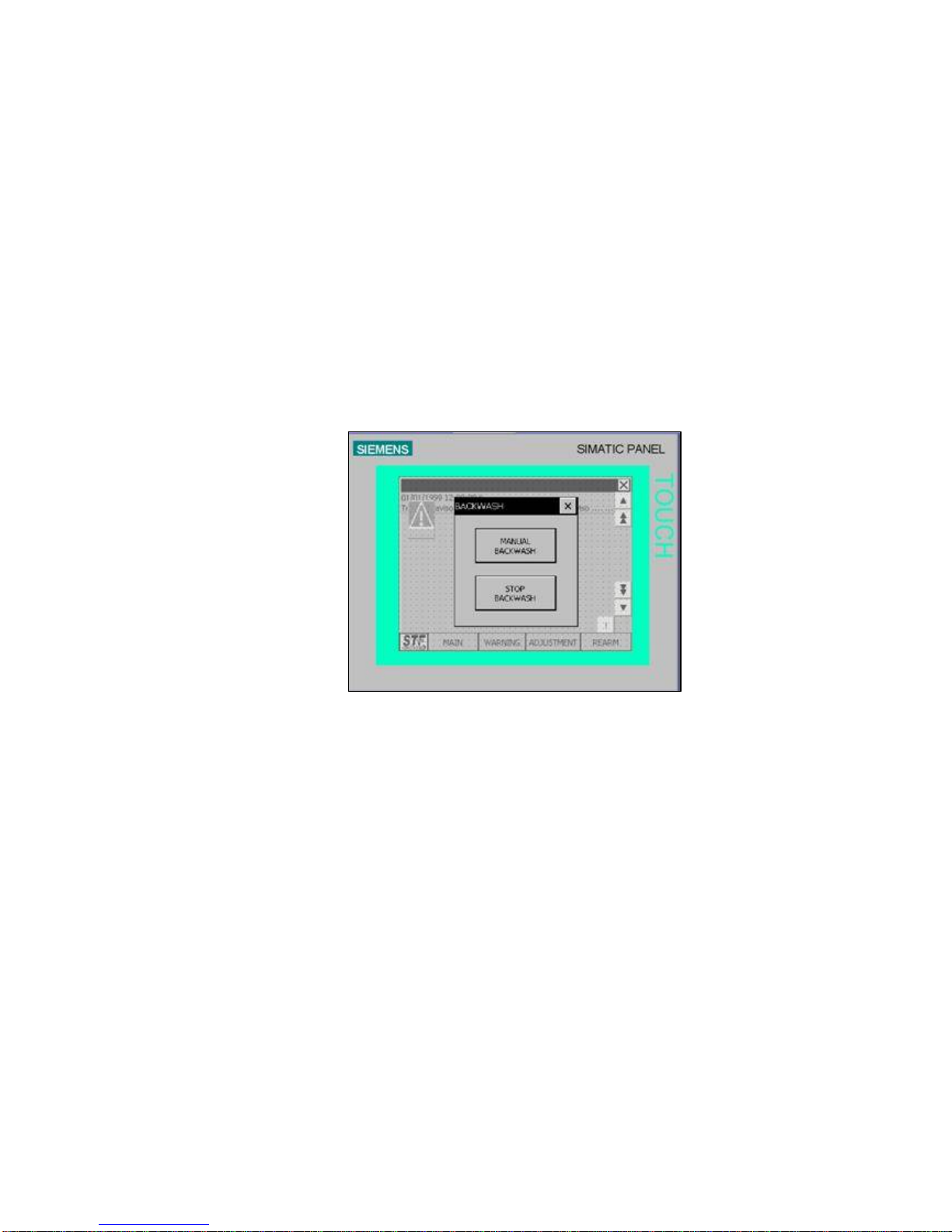

-INSTALLATION BACKWASHING(3): This screen allows you to start the backwashing

manually by pressing the STOP WASHING button, in this way the backwashing process

is stopped, the drain valve closes, the backwashing pump stops and the crown rotation

stops.

If you press X it returns to the previous screen (2).

-BACKWASHINGS CARRIED OUT(4): This screen allows you to look up the

backwashings number that have been carried out in the equipment according to the

causes: If it has been manually (by means of the manual backwashing button),

automatically (because of pressure differential) or because of time. Besides this, the

total accumulated time is also indicated. Accumulated backwashings can not be deleted

and also the number of total backwashings that the equipment carries out between the

STF maintenance processes is indicated. Only STF personnel can turn this value to

zero.

If you press X it returns to the previous screen(2).

If you press BACKWASHINGS RESET the updating screen will appear.

16

-PRESSURES (5): This screen allows you to look up both the inlet and the outlet

pressure. Besides the real time pressure differential in water column pressure. In the last

variable “set point pressure difference” it allows us to select to what pressure differential

we want to start a backwashing. The alarm value for overpressure is the value at which

the overpressure alarm will be indicated.

17

The menu, which is common to all the screens, appears at the bottom of the screen. It this menu it is

possible to have access to:

WARNINGS screen (7)

ADJUSTMENTS screen (10)

REARM screen (11)

18

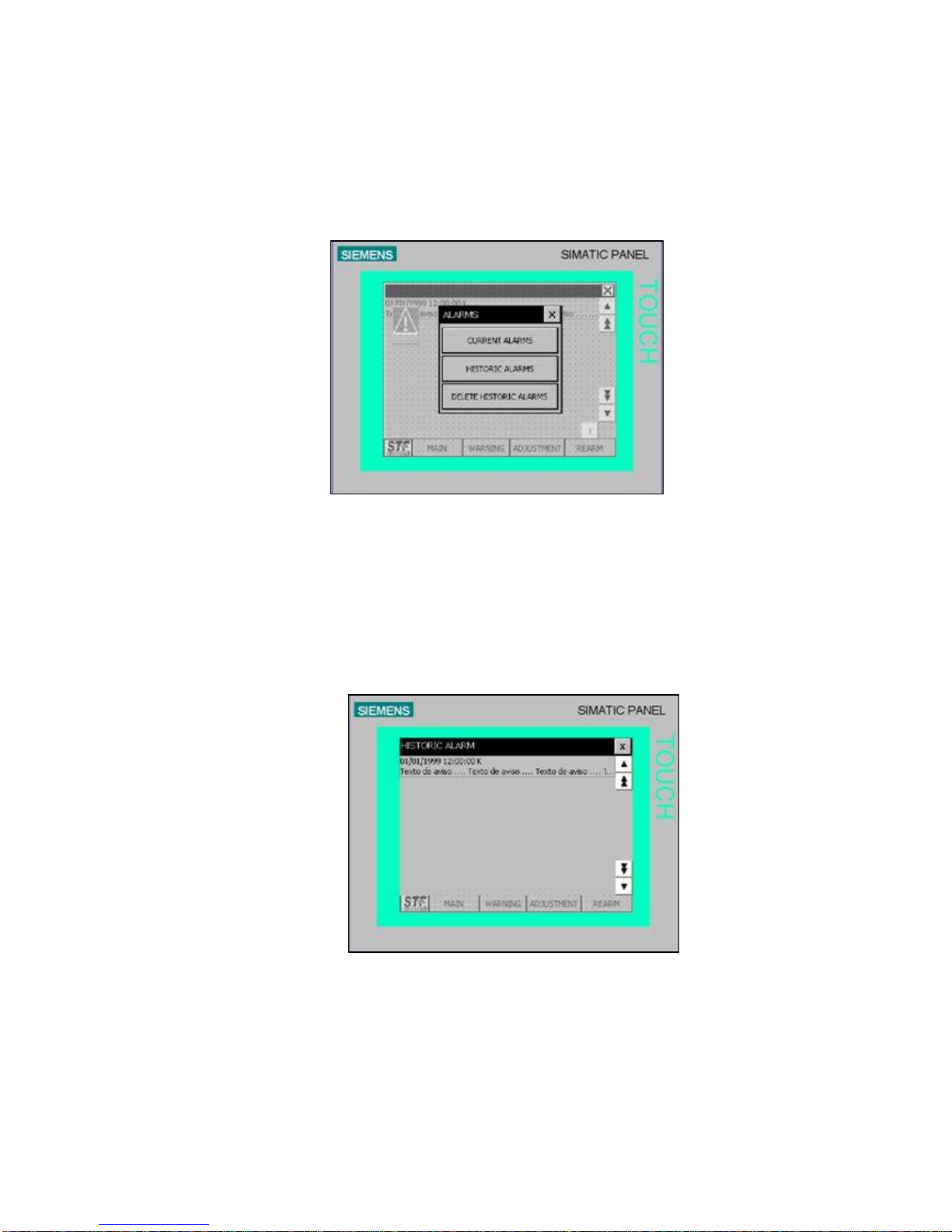

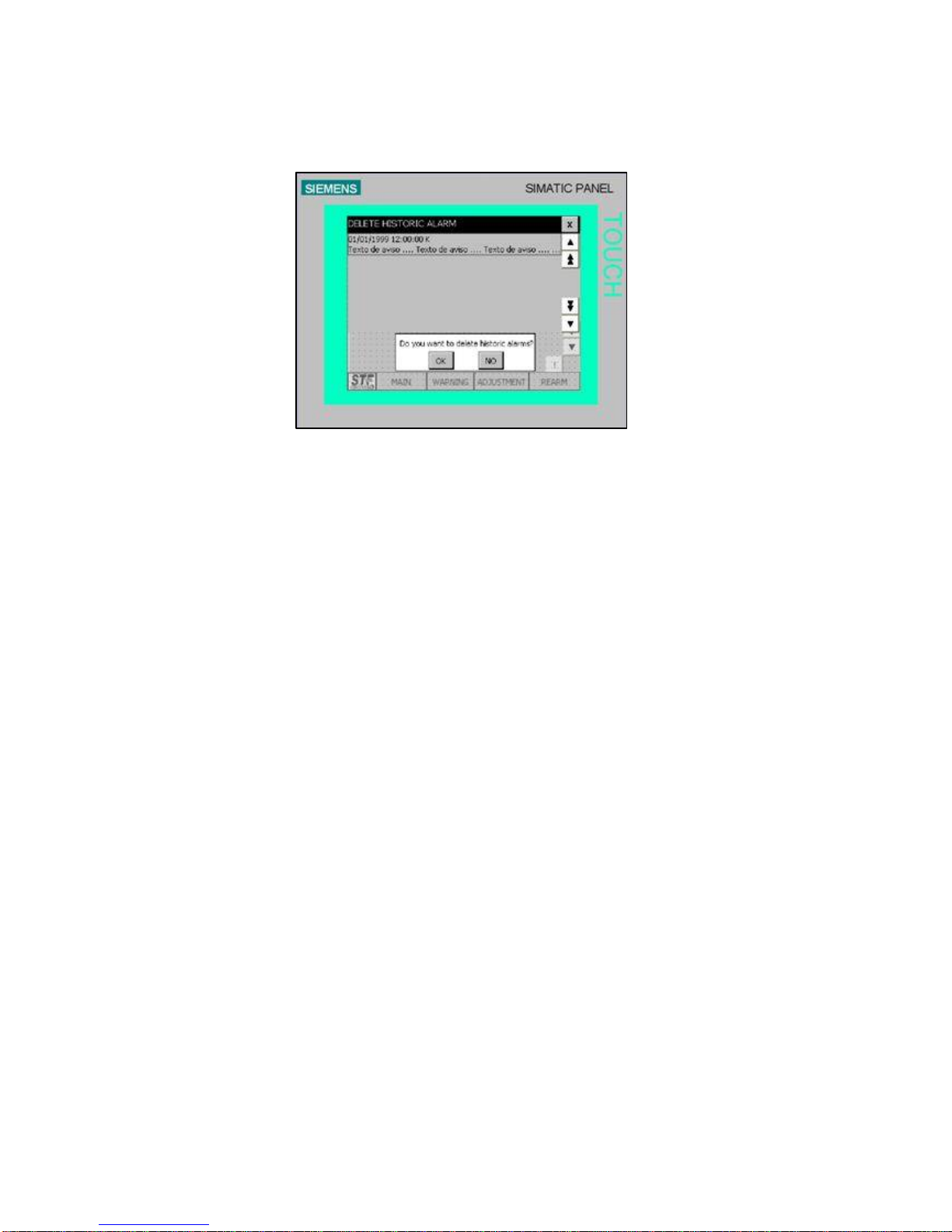

WARNINGS (7)

In the warnings menu, we can select the option to check the current alarms, to see the warnings record

since the the last updating and to delete the alarm record.

If you press X it returns to the previous screen.

The ALARMS screen indicates the actual warnings that are still to be corrected in the installation,

indicating the warning reason and the moment when they occurred.

The list is updated to check if the error has been corrected with the right inferior key. The blue triangle will

appear on the menu screen if there is an active warning.

19

The alarms record screen indicates all the warnings that have appeared since the last deletion. If we

push DELETE THE ALARMS RECORD the option to delete all the no active warnings will appear.

When the programmer makes the consecutive backwashings indicated in the parameter

“CONSECUTIVE BACKWASHINGS ALARM” with no continuity, the safety device that stops the

backwashing will activate. The text (2) “ALARM” will appear on the screen in the inferior right hand side

and on the alarm screen. The legend: CONSECUTIVE BACKWASHINGS ALARMwill appear.

This alarm indicates that the pressure switch sends a continuous signal to the electric panel, this can be

due to a pressure switch failure, to the fact that it has got blocked or to dust excess.

Unblock the pressure switch and press the REARM button to cancel the alarm.

20

ADJUSTMENTS(10)

screen (10) allows you to configurate the installation parameters, the filter operating times and to adjust

the touch screen.

CONFIGURATION (11):

The CONFIGURATION screen allows you to adjust the backwashing process modifying several

parameters such as delay time, pressure difference to start backwashing, opening and closing the

backwashing collector butterfly as well as the continuous backwashing time.

Pressing the “PRESSURE ADJUSTMENTS” touch button it is possible to have access to the pressure

adjustments screen where the pressure parameters are modified.

Table of contents

Other STF-Filtros Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Evoqua

Evoqua DEFENDER SP-27-48-487 Operation & maintenance manual

Wayde King Water Filtration

Wayde King Water Filtration Platinum Series owner's manual

San Dy

San Dy SDW-1800 instruction manual

3B Filters

3B Filters 8500 Series Service instructions

Waterwise

Waterwise Waterwise 1600 Use & care guide

Eureka Forbes

Eureka Forbes Aquaguard Aquasure Smart Plus RO+UV+MTDS user manual