OPERATION

Troubleshooting

10 | Service-Bedienblende WWK 222/302/H www.stiebel-eltron.com

4. Troubleshooting

Problem Cause Remedy

No hot water is

available.

No power at the appli-

ance.

Check that the appliance

is connected to the power

supply.

A fuse/MCB in the fuse

box has blown/tripped.

Check whether the fuses/

MCBs in your fuse box have

blown/tripped. If required,

disconnect the appliance from

the power supply and replace

the fuses/reset the MCBs.

Contact your qualified cont-

ractor if the fuse/MCB blows/

trips again after the appliance

is re-connected to the power

supply.

The air intake or air

discharge of the appliance

is blocked.

Check the air intake grille and

air discharge grille for dirt

accumulations. Remove any

dirt (see the "Maintenance and

care" chapter).

The ambient tempera-

ture exceeds the upper

application limit (see

the "Specification/ Data

table" chapter). The ap-

pliance safety equipment

has responded and the

appliance has shut down

automatically.

Wait for the appliance to cool

down. Call a qualified contrac-

tor if the appliance does not

restart automatically.

The ambient tempe-

rature falls below the

lower application limit

(see the "Specification/

Data table" chapter). The

evaporator is being de-

frosted intermittently.

Wait until the appliance

restarts automatically.

The appliance is

not heating the

DHW cylinder

although the heat

pump symbol is

illuminated.

The compressor lockout

time has not yet elapsed.

Once the compressor has

been switched off, it will

only be switched back on

again after the 20minute

compressor lockout time

has elapsed.

The safety valve of

the cold water inlet

line is dripping.

These units are under

water mains pressure.

During the heat-up pro-

cess, expansion water will

drip from the safety valve.

Notify a qualified contractor if

water continues to drip when

heat-up has been completed.

The condensate

drain drips.

The surface temperature

of the evaporator is lower

than the dew point tem-

perature of the ambient

air. Condensate forms.

The amount of condensate

depends on the humidity level

of the ambient air.

The room tempera-

ture drops too low.

Operation of the appliance can

cause the room temperature

to fall by 1 to 3°C. If the room

temperature falls by more

than 5°C, check the room size

(see the "Specification/Data

table" chapter). Increasing the

room size by opening a door

to another room will remedy

this.

Service/fault sym-

bol is permanently

on.

See the "Fault codes"

chapter.

See the "Fault codes" chapter.

Problem Cause Remedy

Service/fault sym-

bol flashes and

the water does not

heat up.

See the "Fault codes"

chapter.

See the "Fault codes" chapter.

Defrost symbol is

shown.

The appliance is in defrost

mode.

No action required.

The heat pump

symbol is flashing.

There is a heat demand,

but the compressor is

locked out.

No action required. The com-

pressor restarts automatically

after the compressor lockout

time has elapsed. The com-

pressor lockout time lasts

20minutes once the compres-

sor has been shut down. The

symbol stops flashing auto-

matically.

The electric emer-

gency/booster

heater symbol is

flashing.

A temperature controller

has switched off the elec-

tric emergency/booster

heater during quick he-

at-up.

No action required. The ap-

pliance continues the quick

heat-up process using the

heat pump. The symbol stops

flashing when the controller

re-enables the electric emer-

gency/booster heater. The

symbol extinguishes when the

temperature throughout the

DHW cylinder reaches the set

temperature of 65°C.

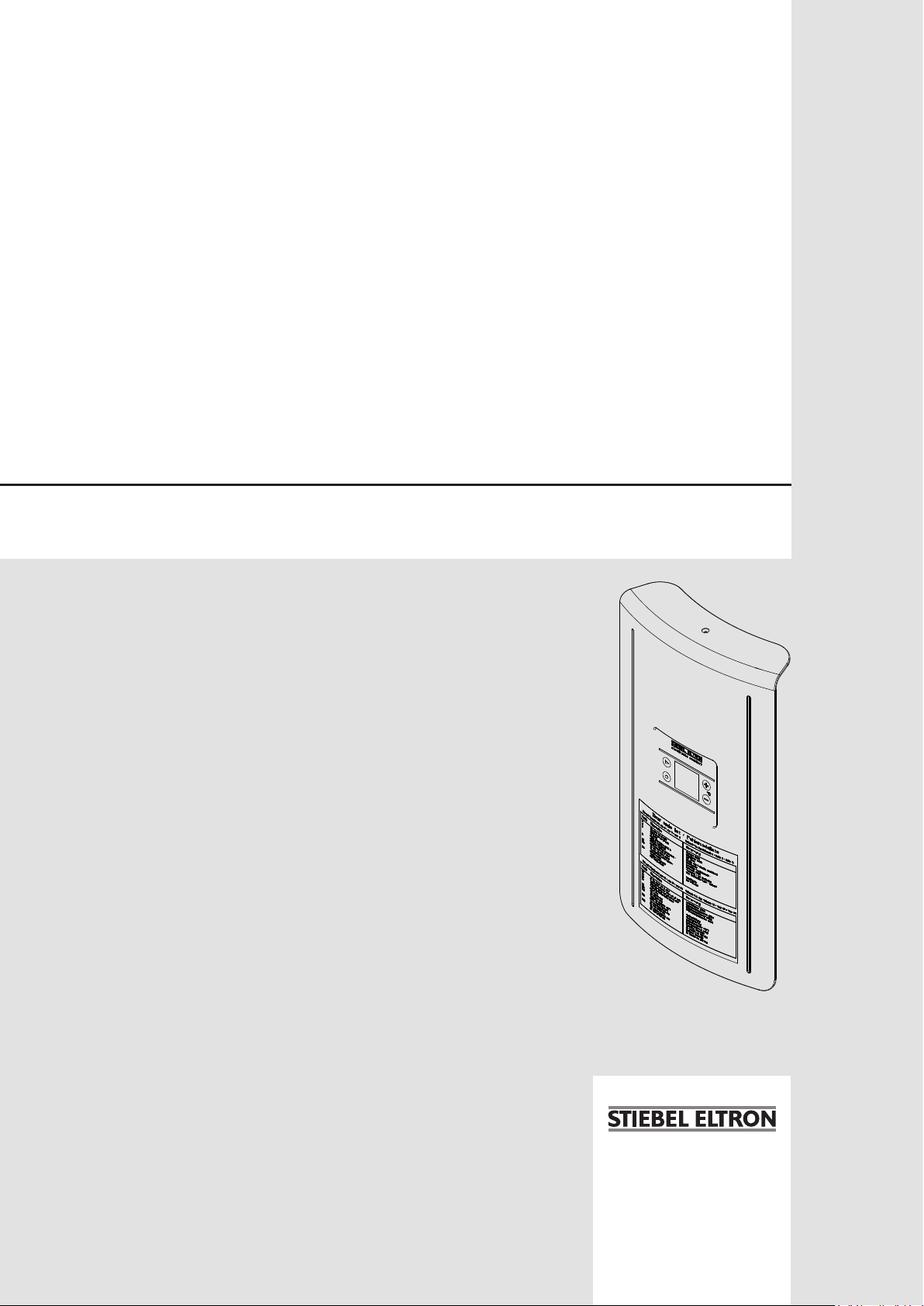

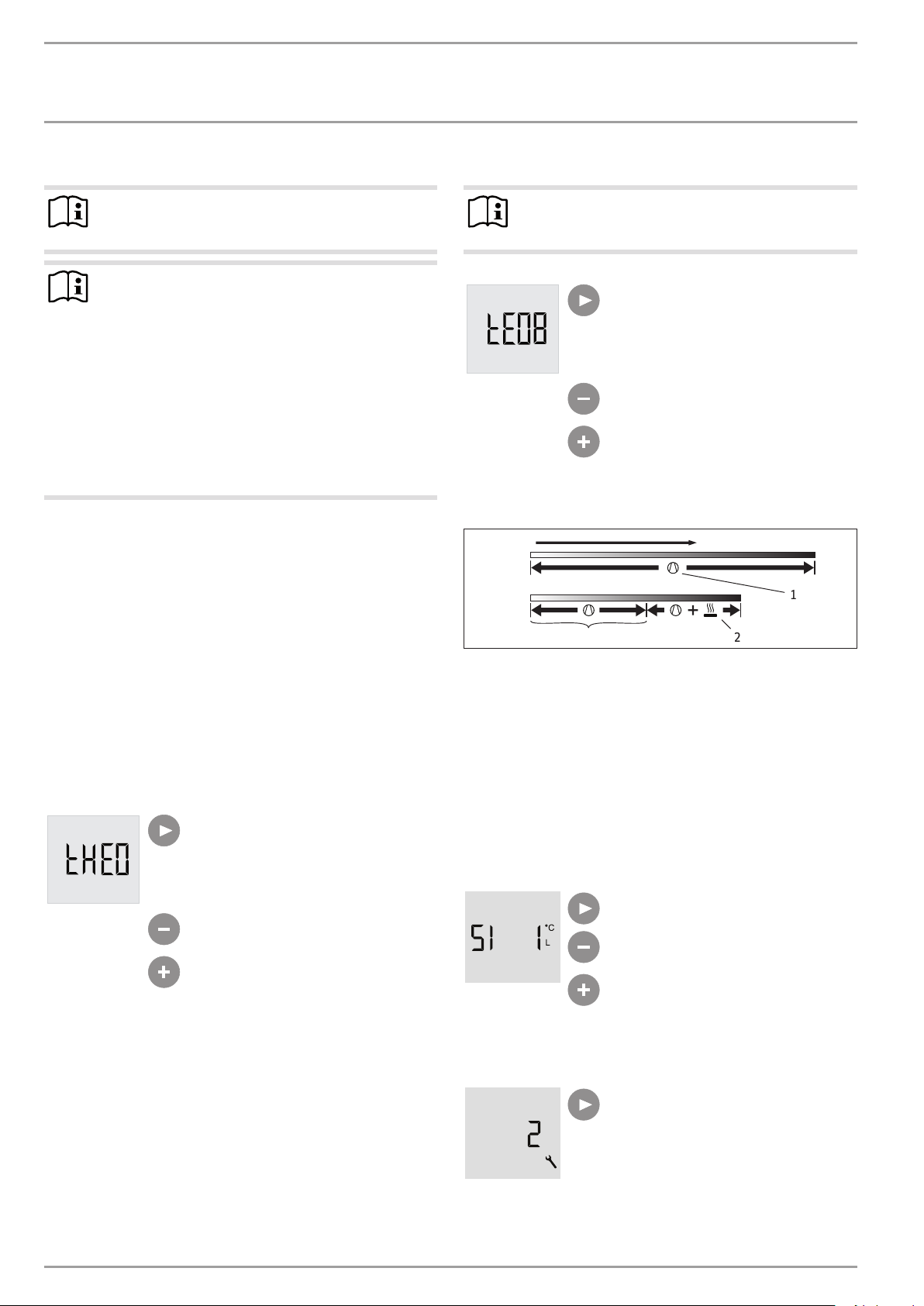

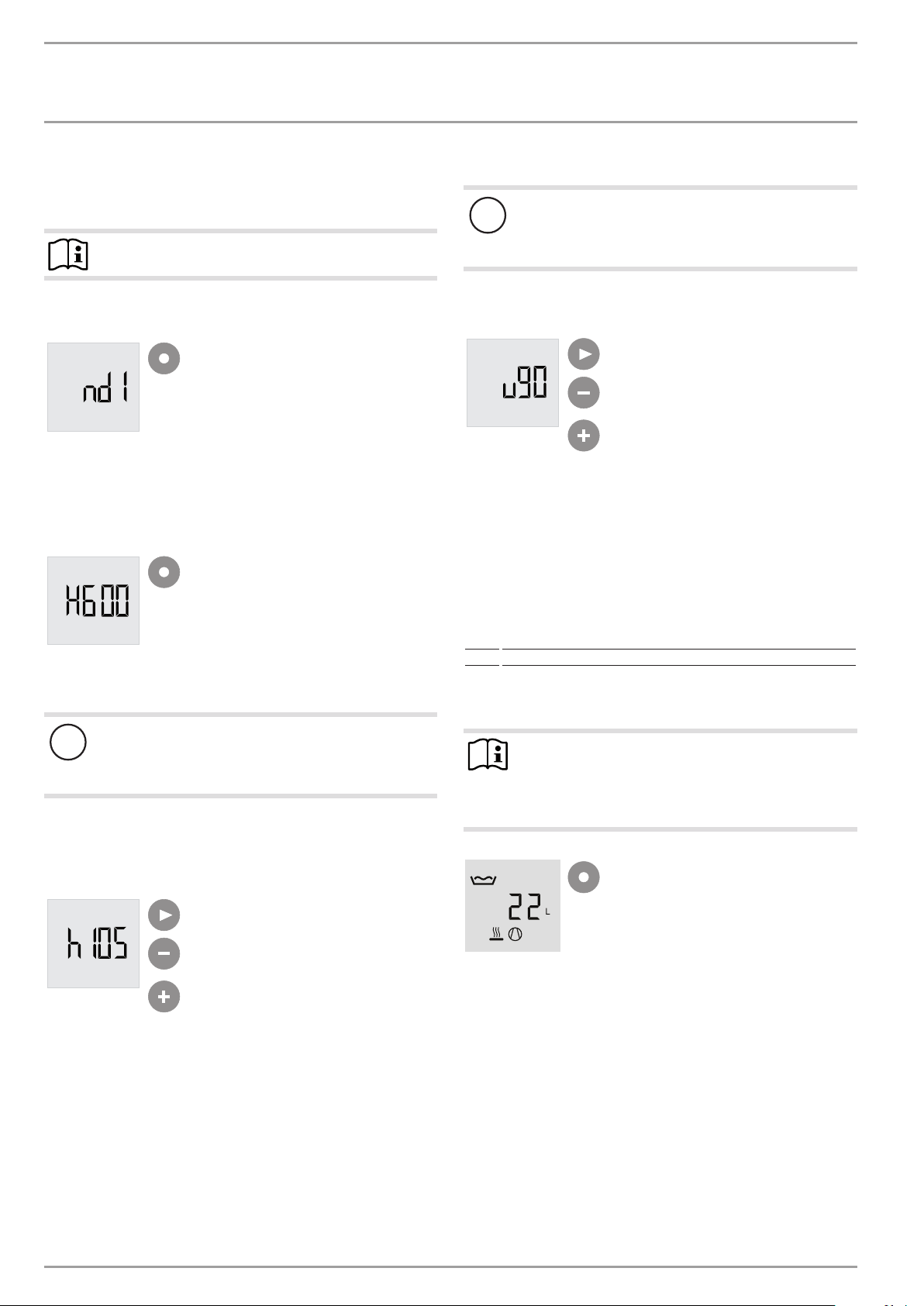

Fault code

You can call up a fault code if the Service/fault symbol is flashing

or continuously lit on the display.

Repeatedly press the "Menu" key until

the fault code is shown after set tempe-

rature2.

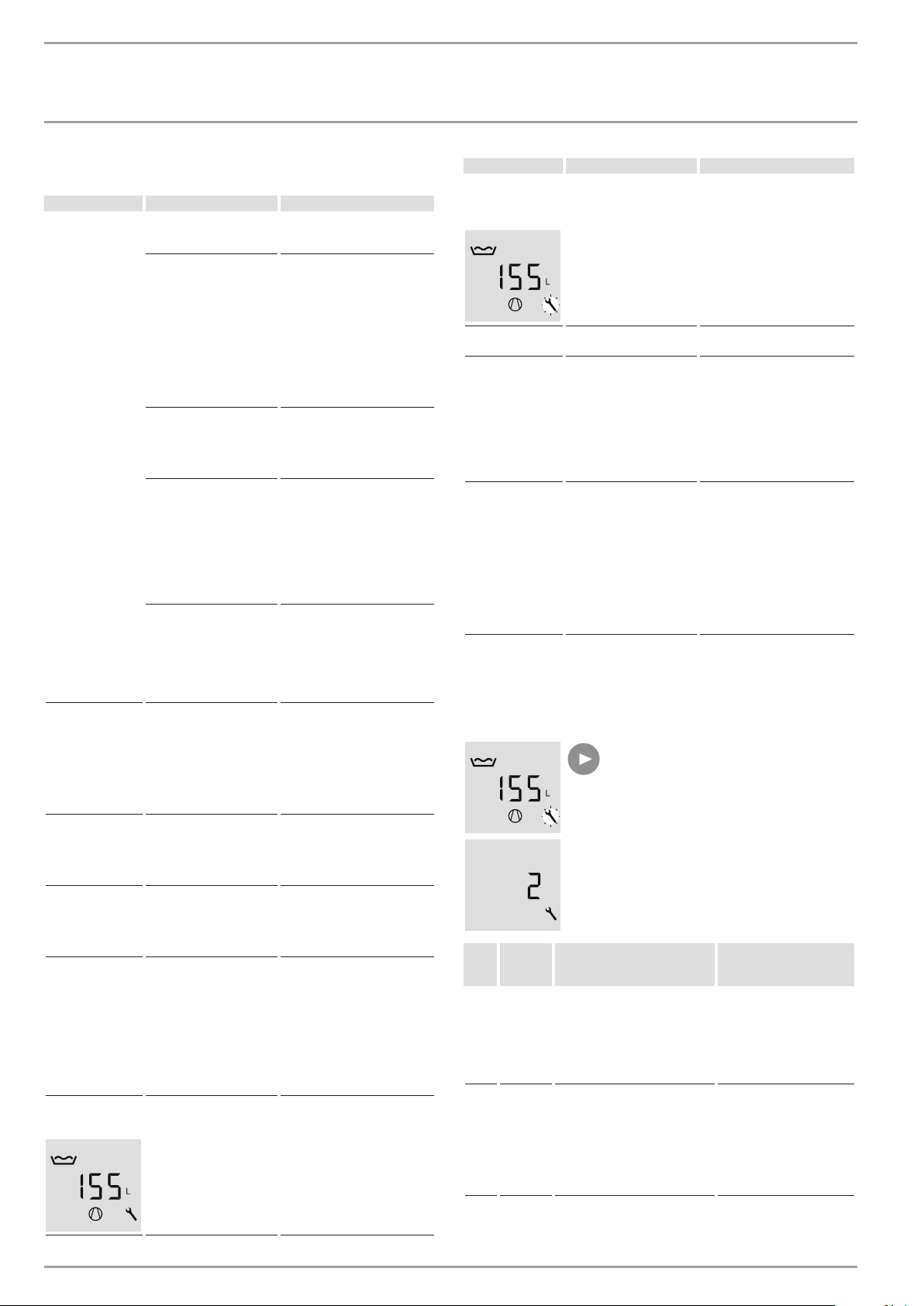

Fault code appears

Fault

code

Service/

fault

symbol

Fault description

Remedy

2

conti-

nuously

illumina-

ted

The sensor at the cylinder top is

faulty. The actual temperature

display changes over to the

integral sensor. The appliance

continues to deliver heat. The

amount of mixed water shown

is always less than 10 litres.

4

conti-

nuously

illumina-

ted

The integral sensor is faulty.

In the event of a faulty integral

sensor, the integral sensor is

set to the value of the sensor at

the cylinder top, and amount of

mixed water is calculated using

this value. The appliance conti-

nues to deliver heat.

We recommend installing

a replacement sensor. The

replacement sensor must

be activated in the appli-

ance menu.