STIF VIGIBELT TOUCH ATEX (II 2 D) User manual

INSTRUCTION MANUAL VIGIBELT®TOUCH ATEX (II 2 D) GB –1/4

www.stifnet.com - VER. 01/16 - N° DOC BE0455041

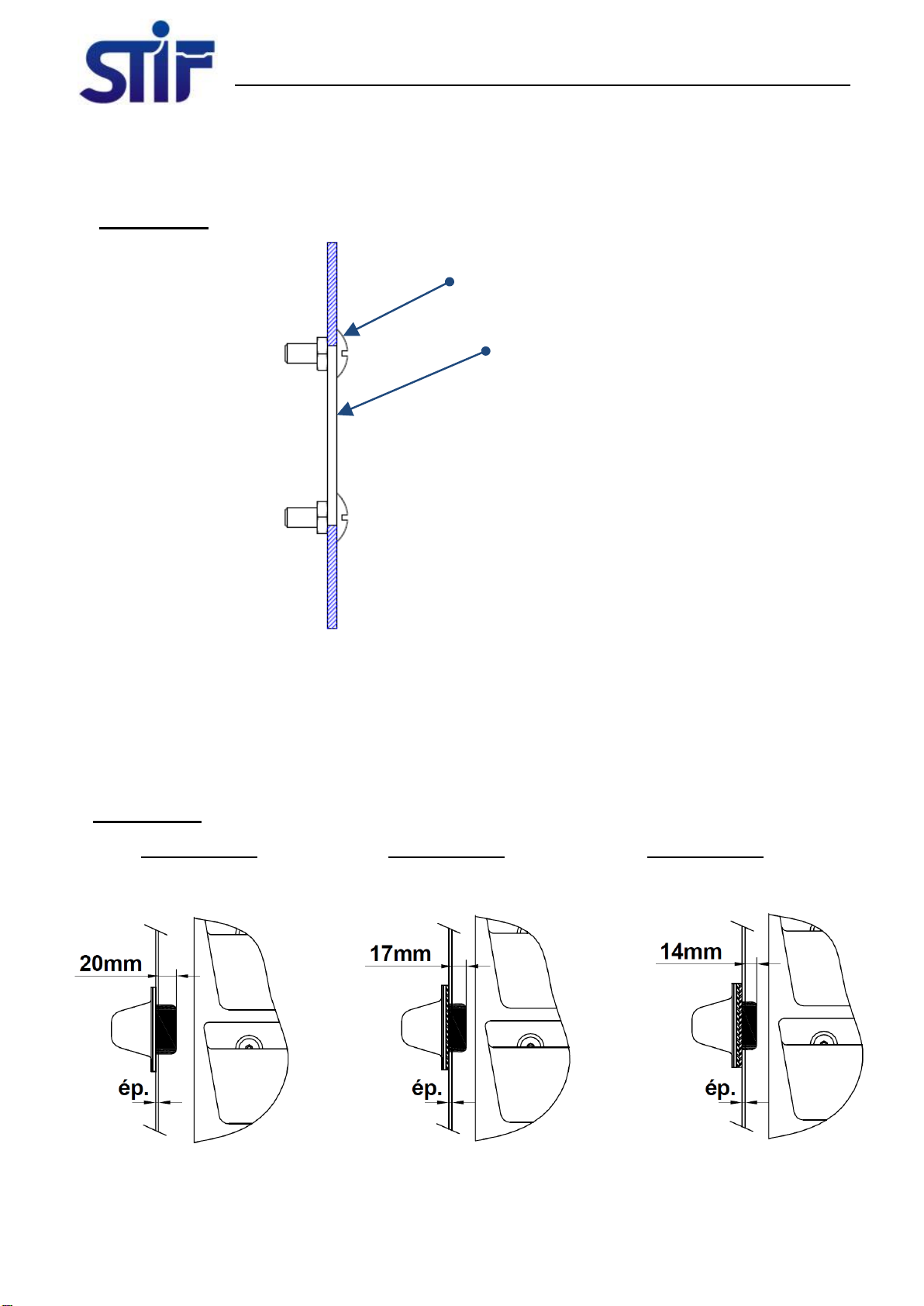

FUNCTION

- The VIGIBELT®TOUCH is a lateral movement sensor that detects run-out of elevator belts or conveyor belts, and

at the same time the run-out of the lift pulley. It reacts to the pressure of the belt coming into contact with the front

face of the sensor. Baffle plates are usually fitted opposite each other, preferably on the upward leg close to the

pulleys for elevators, and on the load bearing side close to the drums for conveyors.

The sensors can be connected directly to a PLC, or for absolutely safety, to an independent "monitoring M-JET”

central unit. The electrical circuit can control an alarm or a machine shut down.

- For elevators more than 20 meters long, we recommend fitting the head with a second VIGIBELT®TOUCH kit, still

on the upward leg.

- The sensors trigger when the belt applies a force of approximately 5 daN.

DESCRIPTION

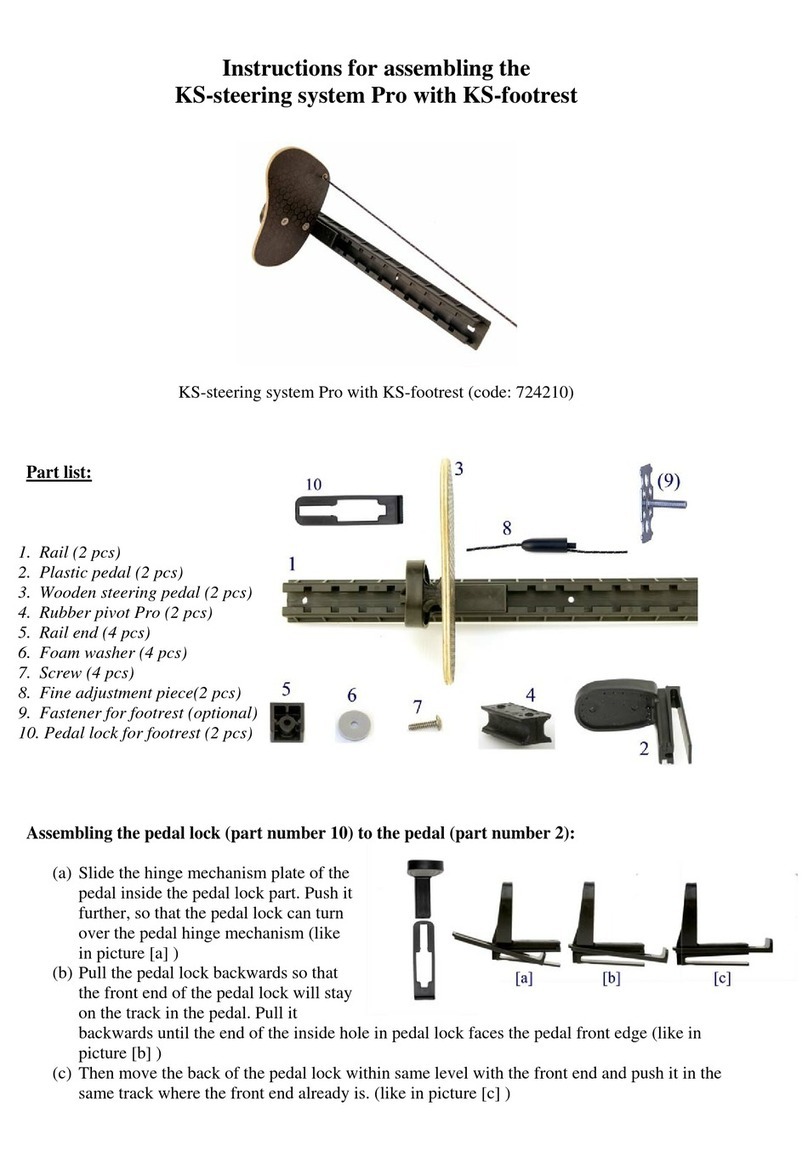

- The VIGIBELT®TOUCH kit comprises two sensors, four elastomer spacers (3mm NBR) and the fastenings (M6).

Composition :

PRECAUTIONS

The VIGIBELT®TOUCH must be installed, connected and put into service by competent personnel. The personnel

should be qualified electricians and know the regulations and requirements concerning the installation of these

appliances, especially when installed in ATEX areas.

- Carry out a study prior to the electrical connection of the VIGIBELT®TOUCH sensors (standardised electrical

diagram, PLC control, electricity supply and protection).

- Define the sensing distance between the belt and the elevator shaft (confirmation of the triggering distance by the

person in charge of the site).

- Before any installation or intervention on the VIGIBELT®TOUCH, it is essential to make sure that the bucket

elevator is shut down (intervention warning to be posted on the machine).

- When the VIGIBELT®TOUCH is dismantled, the user should ensure that the appliance is scrapped properly and

that the components are passed to the appropriate specialist collection centres according to their nature (stainless

steel, electrical equipment, seals, etc.).

Z.A. de la lande - 49170 Saint-Georges-sur-Loire - France

Siège social, achats et usine : tél.: +33 2 41 72 16 80 - Fax +33 2 41 72 16 85

Service commercial France Export : tél.: +33 2 41 72 16 82 - Fax +33 2 41 39 32 12

Email : sales@stifnet.com - Site internet : www.stifnet.com

SAS au capital de 800 000 € - R.C.S. Angers B 328 876 503 - 84B12 APE 2511Z - N° TVA FR 35 328 876 503

2x VIGIBELT®TOUCH

4x elastomer spacers (th.3mm)

8x mounting bolts (M6)

23mm

INSTRUCTION MANUAL VIGIBELT®TOUCH ATEX (II 2 D) GB –2/4

www.stifnet.com - VER. 01/16 - N° DOC BE0455041

INSTALLATION

1) Make two symmetrical round openings on each side of the up shaft of an elevator (56mm dia. + 4 7mm dia. holes

on a PCD of 72mm): DIagram-A

Diagram A

On a conveyor belt position the VIGIBELT®

TOUCH sensors on the load carrying side close to

the axis of the drum and the belt.

On a bucket elevator position the VIGIBELT® TOUCH

sensors on the upward leg close to the axis of the

pulleys and the belt.

Make the 56mm opening

on the belt axis

sangle

Belt

INSTRUCTION MANUAL VIGIBELT®TOUCH ATEX (II 2 D) GB –3/4

www.stifnet.com - VER. 01/16 - N° DOC BE0455041

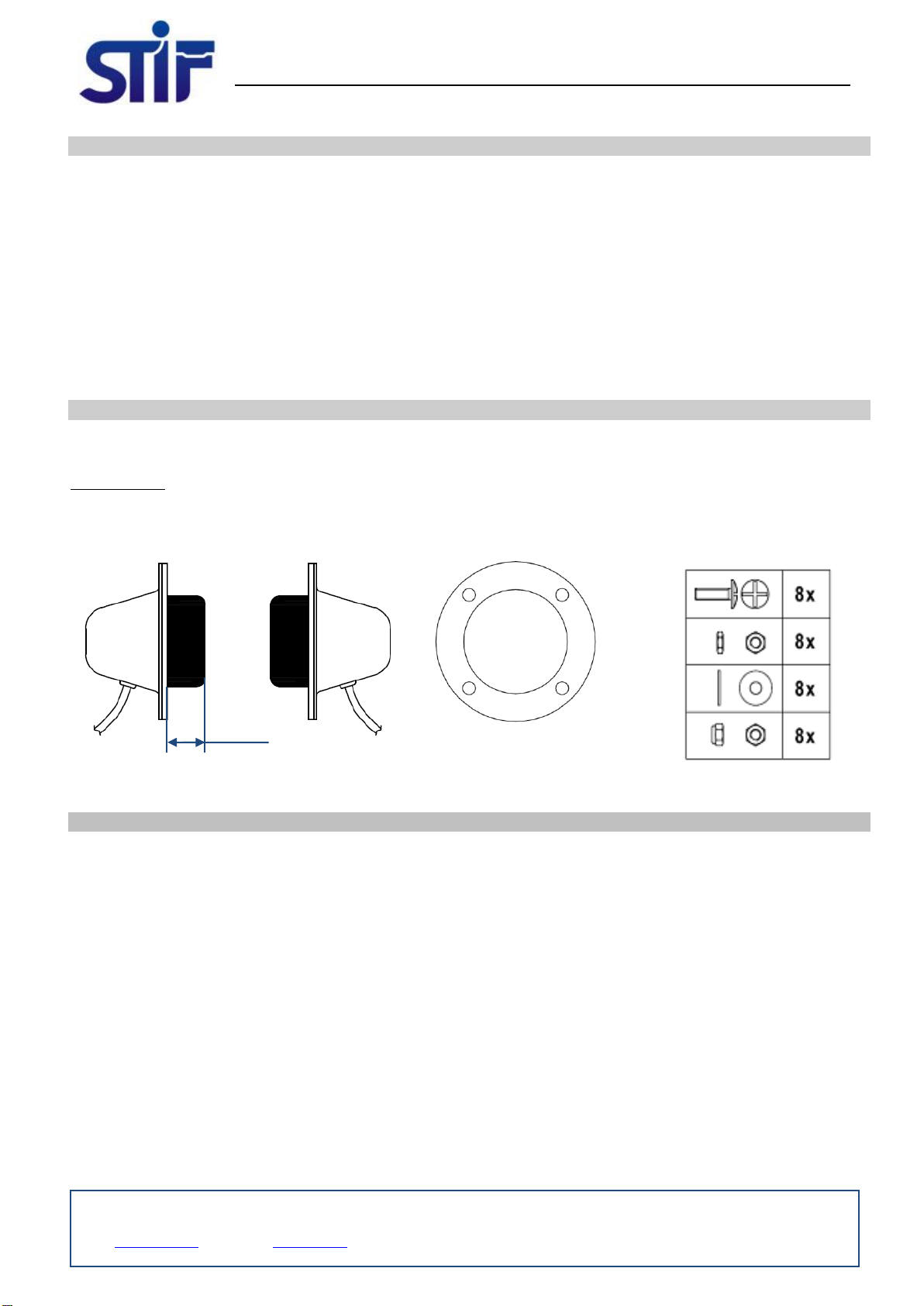

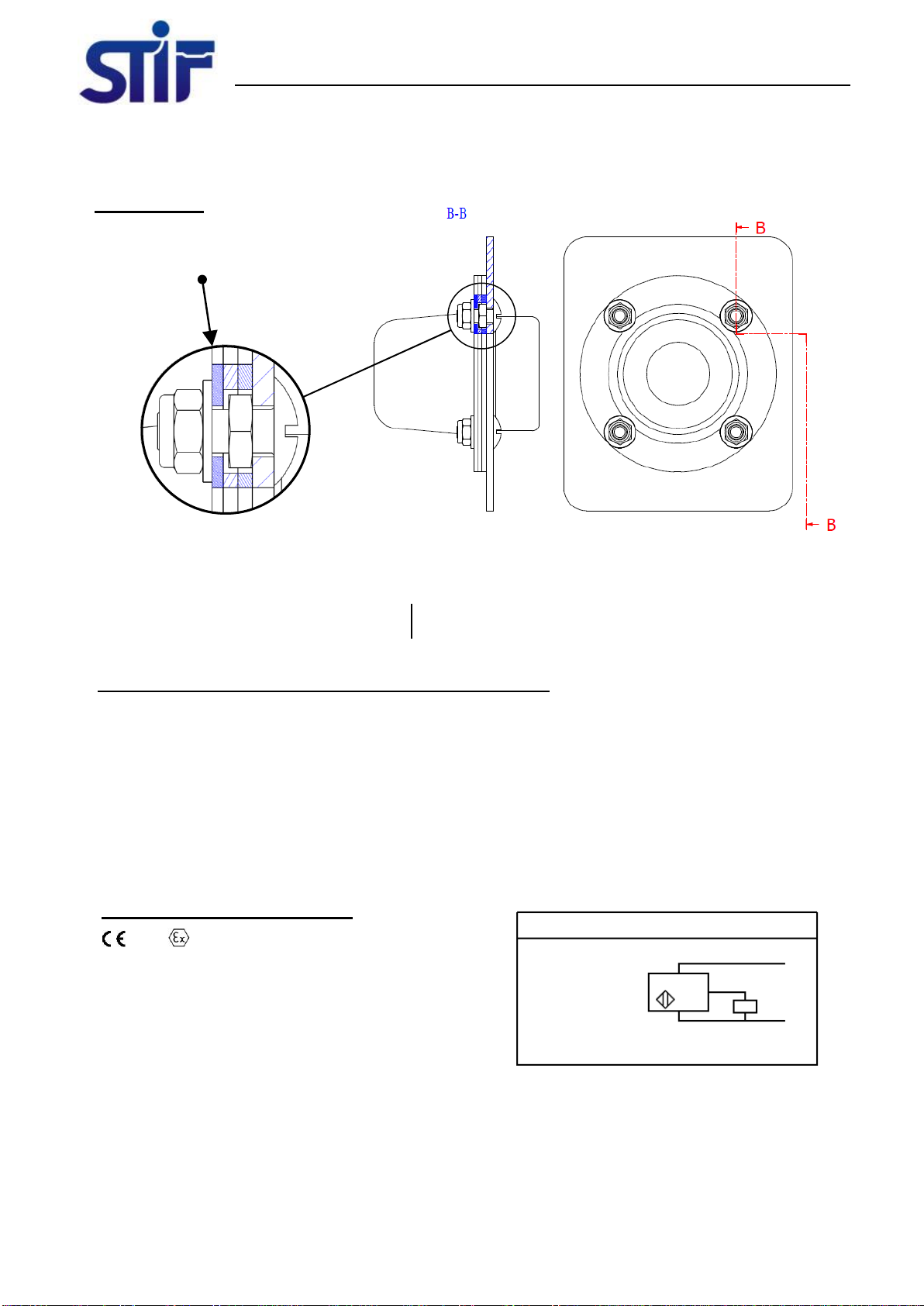

2) Fit the M6 pan head screws with the low nuts on the shaft (torque 6 N.m): Biagram-B.

3) Adjust the triggering distance of the VIGIBELT®TOUCH sensors. This distance is the dimension between the

inside face of the elevator and the contact face of the sensor.

To achieve this, three detection adjustments are possible, diagram-C:

No 1 - Sensor with no additional spacer, elevator thickness (e.g.: 3mm), i.e. a distance of 20mm

No 2 - Sensor with one additional spacer, elevator thickness (e.g.: 3mm), i.e. a distance of 17mm

No 3 - Sensor with two additional spacers, elevator thickness (e.g.: 3mm), i.e. a distance of 14mm

Diagram B

On the inside face of the shaft

Fit pan head screws + low nuts

Diagram C

Adjustment no 1

Distance of 20mm,

With no additional spacer

Adjustment no 2

Distance of 17mm,

with one additional spacer

Adjustment no 3

Distance of 14mm,

with two additional spacers

INSTRUCTION MANUAL VIGIBELT®TOUCH ATEX (II 2 D) GB –4/4

www.stifnet.com - VER. 01/16 - N° DOC BE0455041

4) Position the VIGIBELT®TOUCH sensors on the openings and tighten the M6 locknuts (torque 4 N.m) according

to Diagram-D.

5) Connect the VIGIBELT®TOUCH sensors according to the electrical diagrams:

NC sensor = positive safety, continuous sensor function monitoring

Loss of the signal indicates a problem of Belt run-out

Wiring open circuit

6) After completing the mechanical and electrical installation of the VIGIBELT®TOUCH sensors, you should check

each sensor to make sure that they are all working. To do this, trigger each sensor by pressing its contact face.

This simulation serves to confirm that the fault information is transmitted to the monitoring system (monitoring M-

JET, supervisor PLC).

VIGIBELT®TOUCH for area ATEX 21 (II 2 D) - 55KVT72616TE

- Connection by cable: 10 m (3 wires)

- Rated supply voltage: 12 to 24V DC

- Voltage limits (incl.wave): 10 to 36V DC

- Switching capacity in mA: <= 100 mA

with protection against overloads and short-circuits

- Protection - IP67 according to IEC 60529

- Temp: -20° C < Ta < 60° C

Connection diagram - 3 wires

Wire colours

BN = Brown

BU = Blue

BK = Black

PVC cable - 10m; 3x0.34mm²

BN

BK

BU

+

-

NC/PNP

Diagram D

Fix the VIGIBELT®TOUCH sensor

with the washers and locknuts

Inside sensor - XS7E1A1PBL10EX

0080 II 2 D –Ex tb IIIC T90° C Db IP67

INERIS 06ATEX0065X

- Do not disconnect when energized

- Prevent from dust deposits

- EU Declaration of Conformity Nr/S1A42203_03

- Technical document Nr/S1A41508_00

Table of contents

Popular Accessories manuals by other brands

Lightolier

Lightolier D14 specification

Craftsman

Craftsman 509344 owner's manual

Samsung

Samsung SIP-1201DD user manual

Byron

Byron B002E quick start guide

PCB Piezotronics

PCB Piezotronics 106M131 Installation and operating manual

Motorisation+

Motorisation+ SAFEDUO Instructions and warnings for installation and use