BGA 862

Guide to Using this Service Manual

This service manual contains the necessary safety

information, exploded drawings and instructions for

diagnosis and repairs. The graphic elements used in this

manual have the following meanings:

Supplements to this service manual

Technical information bulletins supplement the service

manual until a revised edition is issued.

–Always refer to the latest edition of the relevant parts

list for the part numbers of any replacement parts.

–Use the part numbers to identify the tools in the

"STIHL Special Tools" manual.

–None of these documents may be passed to third

parties.

Interactive video tutorial

Interactive video tutorials may be used for repair

procedures. They can be opened from the service

manual.

Your computer must meet the following requirements:

–Active internet connection

–HTML5 compatible internet browser

2.1 Basic Safety Measures

–Never use defective machines, housings or

analyzers.

–Use only original STIHL spare parts, batteries,

chargers and analyzers.

–Never insert objects into the cooling slots of batteries,

chargers and analyzers.

–Never short the contacts of the battery, charger or

analyzer with metallic objects.

Observe the national safety regulations in the instruction

manual.

Always switch off the machine and remove the battery

before performing any repairs or transporting the

machine.

WARNING

To reduce the risk of serious injury and serious burns,

observe the following points before performing any

repairs:

2.2 Battery

WARNING

Risk of injury from fluid escaping from battery.

–Avoid contact with the skin and eyes.

–In the event of contact, rinse affected area thoroughly

with water.

–Seek medical advice.

NUse and store the battery only in a temperature range

from -10°C up to max. + 50°C (14°F up to

max. 120°F).

2.3 Charger, STIHL ADG 1 Battery Analyzer and

STIHL ADG 2 Analyzer

NDo not cover the unit.

NConnect the charger/analyzer only to a power supply

with the voltage and frequency specified on the rating

plate.

NUse and store only in a temperature range from 5°C

up to max. + 40°C (40°F up to max. 105°F).

NIn the event of smoke or fire, disconnect unit from the

wall outlet immediately.

NDo not operate the unit in a hazardous, easily

combustible location.

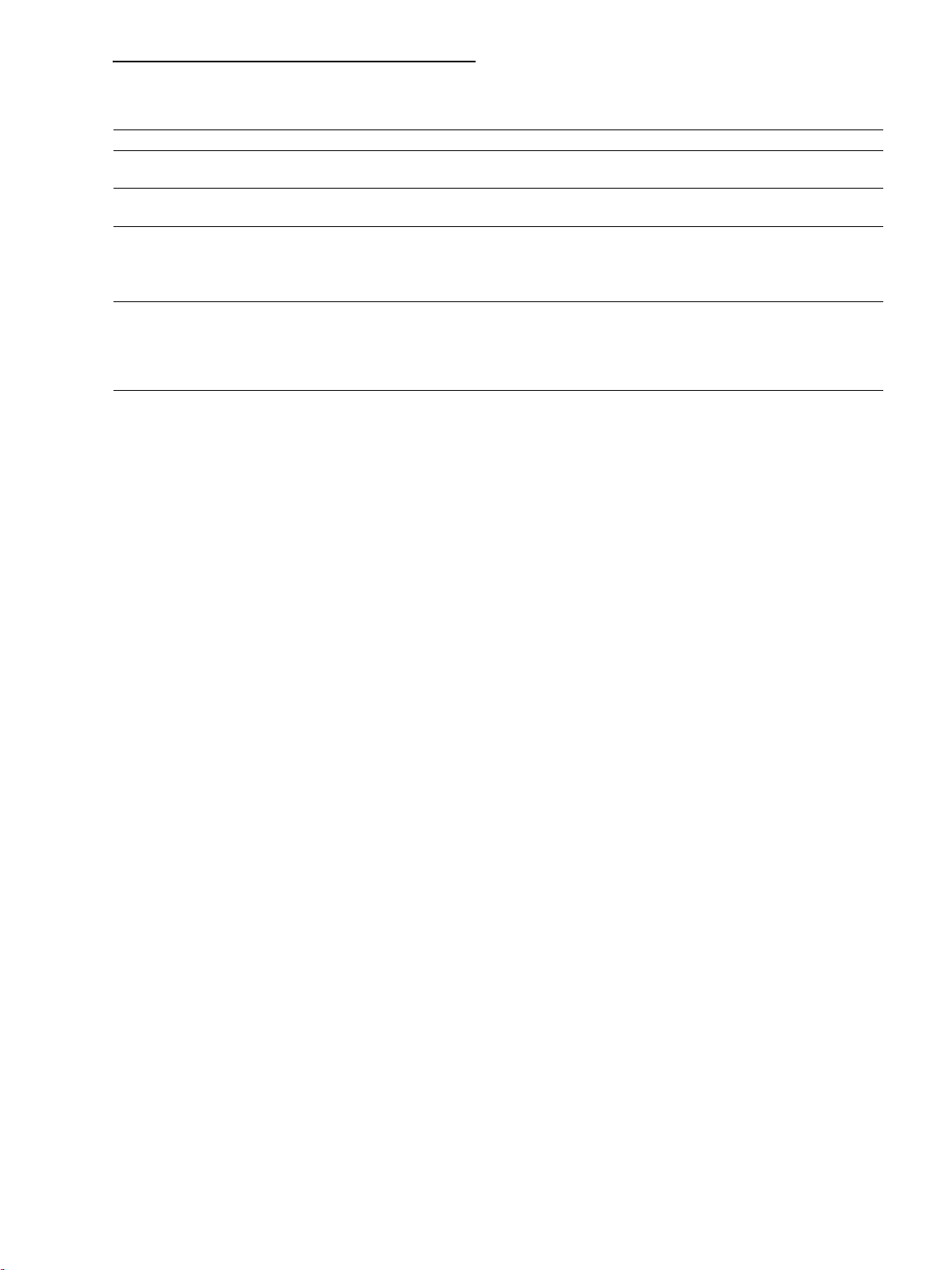

1 Safe diagnosis and repairs

Action to be taken

Reference to another chapter, i.e. chapter 3 in

this example

Interactive video tutorial available for this

chapter

Tighten screw to torque specified, i.e. 3 Nm in

this example

Tighten screw to torque specified, i.e. 5 Nm in

this example; then back it off 1 turn

counterclockwise

2 Safety Precautions

Always wear protective gloves when work-

ing on sharp or hot components.

Do not immerse the battery in liquids – this

may cause a malfunction or thermal reac-

tion – risk of explosion.

Protect from heat, fire and direct sunlight –

risk of explosion and fire.

Protect from dampness.

Use and store only indoors in dry

locations.