BR 800, BR 800 X

English

5

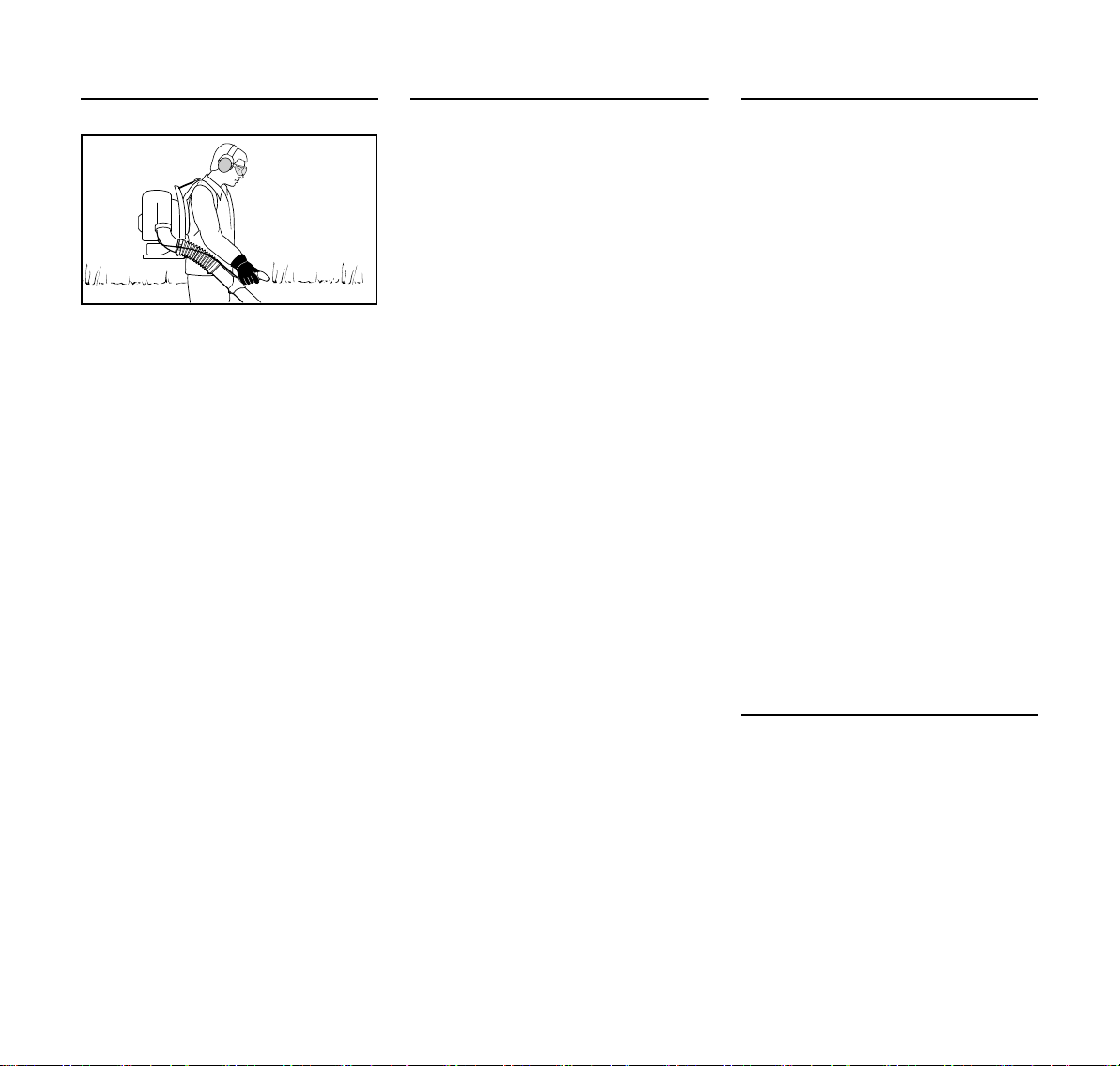

During Operation

In the event of impending danger or in

an emergency, switch off the engine

immediately by moving the setting lever

to STOP or 0.

To reduce the risk of injury from thrown

objects, do not allow any other persons

within 15 meters of your own position.

To reduce the risk of damage to

property, also maintain this distance

from other objects (vehicles, windows).

When blow-sweeping (in open ground

and gardens), watch out for small

animals to avoid harming them.

Never leave a running machine

unattended.

Take special care in slippery conditions

– damp, snow, ice,

on slopes and uneven ground.

Watch out for obstacles: Be careful of

refuse, tree stumps, roots and ditches

which could cause you to trip or stumble.

Never work on a ladder or any other

insecure support.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Stay alert so as not to endanger

others.

To reduce the risk of accidents, take a

break in good time to avoid tiredness or

exhaustion.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

To reduce the risk of accidents, stop

work immediately in the event of

nausea, headache, visual disturbances

(e.g. reduced field of vision), problems

with hearing, dizziness, deterioration in

ability to concentrate. Apart from other

possibilities, these symptoms may be

caused by an excessively high

concentration of exhaust gases in the

work area.

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Note that combustible fuel

vapor may escape from the fuel system.

If dust levels are very high, always wear

a suitable respirator.

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only when working.

After finishing work, put the unit down on

a level, non-flammable surface. To

reduce the risk of fire, do not put it down

near easily combustible materials (e.g.

wood chips, bark, dry grass, fuel).

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting Work". Check the fuel

system in particular for leaks and make

sure the safety devices are working

properly. Do not continue operating your

power tool if it is damaged. In case of

doubt, consult your servicing dealer.

Do not direct the air blast

towards bystanders or

animals since the air flow

can blow small objects at

great speed – risk of

injury.

Your power tool produces

toxic exhaust fumes as

soon as the engine is

running. These fumes

may be colorless and

odorless and contain

unburned hydrocarbons

and benzol. Never run

the engine indoors or in

poorly ventilated loca-

tions, even if your model

is equipped with a cata-

lytic converter.