Watch out for obstacles: Be careful of refuse,

tree stumps, roots and ditches which could

cause you to trip or stumble

Do not work on a ladder or in unstable locations.

Be particularly alert and cautious when wearing

hearing protection because your ability to hear

warnings (shouts, alarms, etc.) is restricted.

Work calmly and carefully – in daylight conditions

and only when visibility is good. Proceed with

caution, do not put others in danger.

Take breaks when you start getting tired or feel‐

ing fatigue – risk of accidents!

Mufflers with catalytic converters can become

especially hot.

Your power tool produces toxic

exhaust fumes as soon as the engine

is running. These gases may be odor‐

less and invisible and may contain

unburned hydrocarbons and ben‐

zene. Never run the engine indoors or

in poorly ventilated locations, even if

your model is equipped with a cata‐

lytic converter.

To reduce the risk of serious or fatal injury from

breathing toxic fumes, ensure proper ventilation

when working in trenches, hollows or other con‐

fined locations.

Stop work immediately if you start suffering from

nausea, headaches, impaired vision (e.g. your

field of vision gets smaller), impaired hearing,

dizziness, or impaired concentration – these

symptoms may possibly be the result of too-high

exhaust gas concentration – Risk of accidents!

To reduce the risk of fire, do not smoke while

operating or standing near your power tool. Com‐

bustible fuel vapor may escape from the fuel sys‐

tem.

Always wear a dust mask if dust is generated.

Operate your power tool so that it produces a

minimum of noise and emissions – do not run the

engine unnecessarily, accelerate the engine only

when working.

After work, place the machine on a level, non-

flammable surface. Do not place the machine

near easily flammable materials (e.g. wood

chips, bark, dry grass, fuel) – risk of fire!

If the machine was exposed to a load for which it

was not designed (e.g. heavy impact or a fall),

always check that it is in good condition before

continuing work – see also "Before Starting".

Check in particular that the fuel system has no

leaks and the safety equipment is fully operative.

Do not continue operating your power tool if it is

damaged. In case of doubt, contact a dealer.

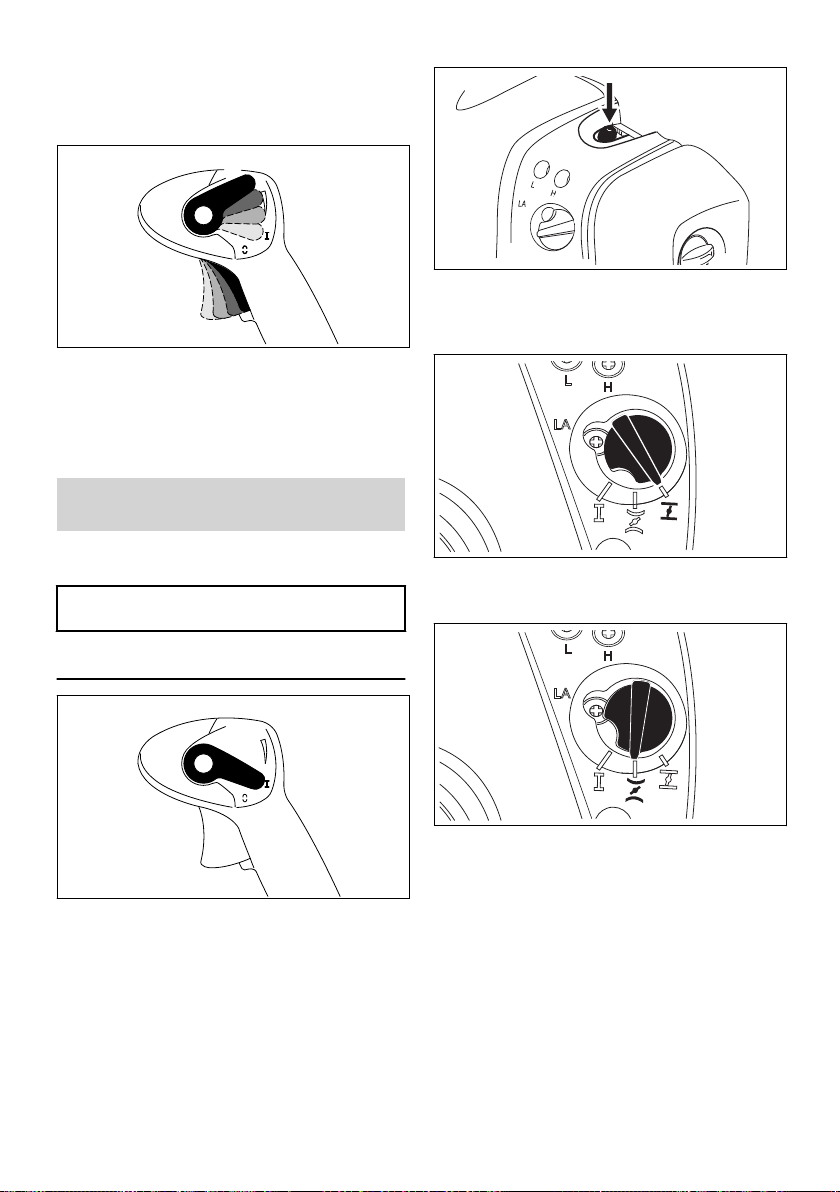

2.10 Using the blower

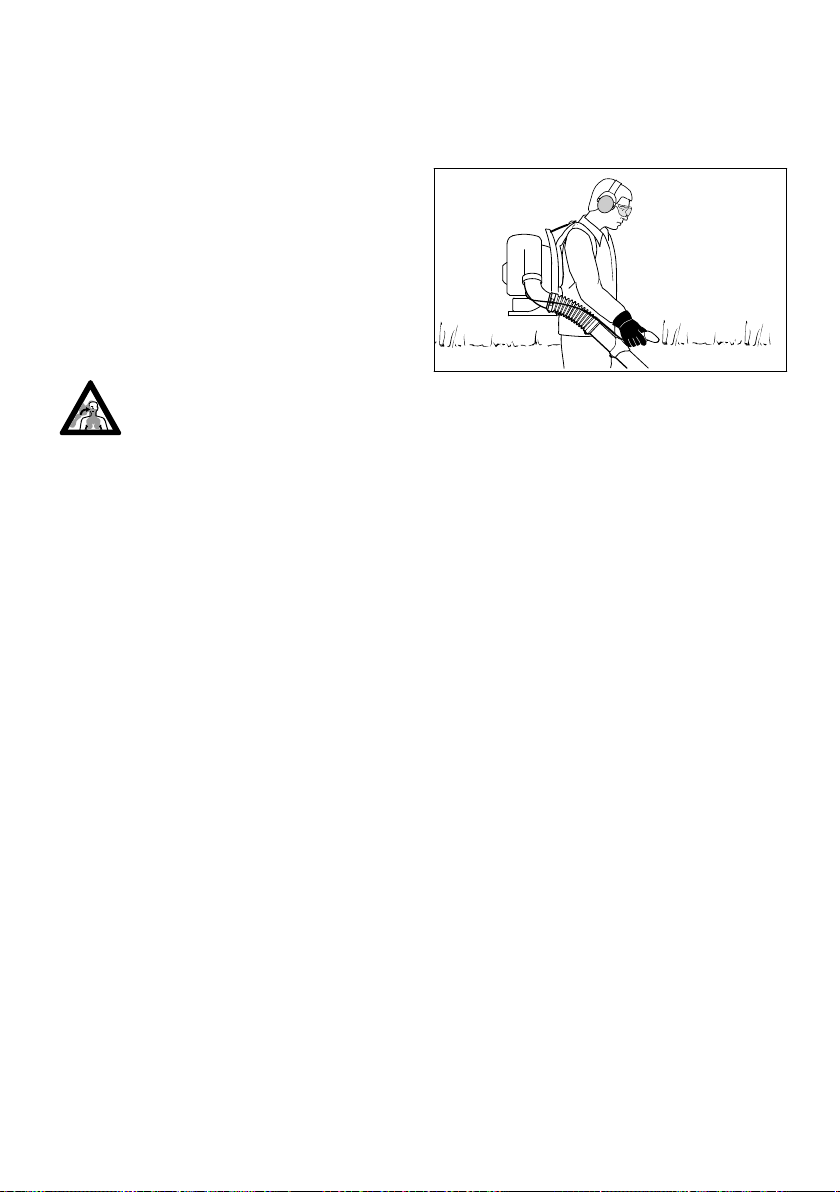

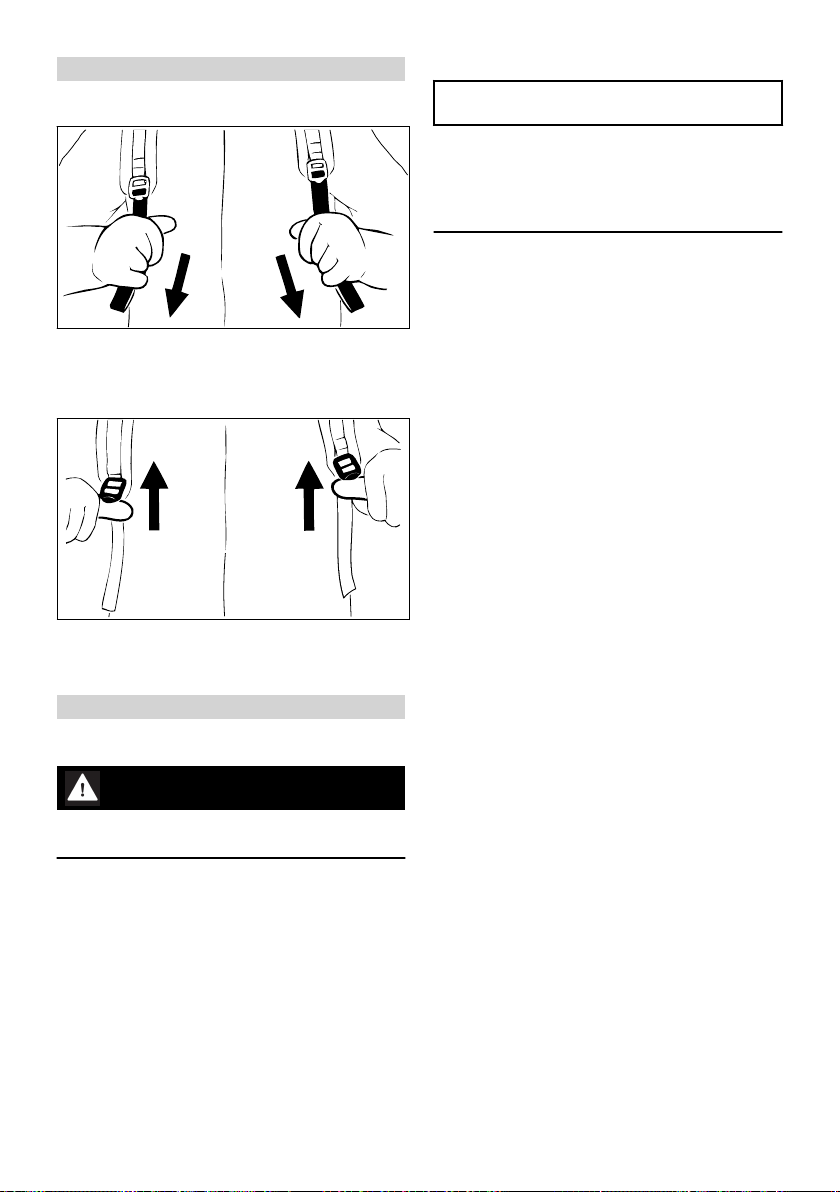

The unit is carried as a backpack. Hold and con‐

trol the blower tube with your right hand on the

control handle.

Work only slowly, moving in a forwards direction

– always observe the discharge area of the

blower tube – do not move backwards – risk of

tripping!

Always shut off the engine before taking the

machine off your back.

2.11 Working Technique

To minimize blowing time, use a rake and broom

to loosen dirt particles before you start blowing.

–If necessary, dampen the surface to be

cleaned in order to avoid creating too much

dust.

–Do not blow particles in the direction of

bystanders, in particular in the direction of chil‐

dren, pets, open windows or freshly washed

vehicles. Take special care in such situations.

–Remove the blow-swept debris in rubbish bins

– do not blow it onto the neighbor's land.

–Operate your power tool at reasonable times

only – not early in the morning, late at night or

during midday rest periods when people could

be disturbed. Observe local rest periods.

–Operate blowers at the lowest engine speed

necessary to accomplish the task.

–Check your blower before starting work. Pay

special attention to the muffler, air intakes and

air filter.

2.12 Vibrations

Prolonged use of the power tool may result in

vibration-induced circulation problems in the

hands (whitefinger disease).

2 Safety Precautions and Working Techniques English

0458-455-0121-D 5