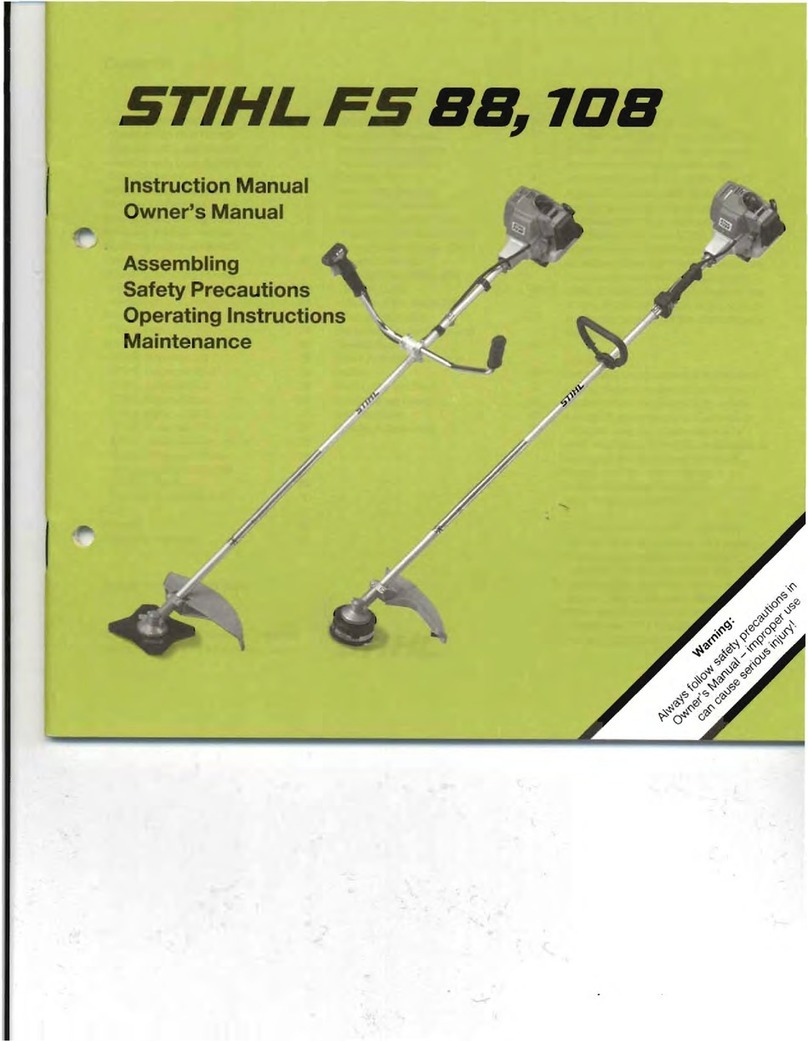

This service manual contains

detailed descriptions of all the

repair and servicing procedures

specific to this power tool series.

There are separate handbooks

for servicing procedures for stand-

ardized parts and assemblies that

are installed in several STIHL

power tool models. Reference is

made to these handbooks in the

appropriate chapters in this

manual.

Servicing procedures on the

carburetor are described in the

"Carburetors" handbook.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts

needed. Parts lists on microfiche

and CD-ROM are always more up

to date than printed lists.

A fault on the machine may have

several causes. To help locate the

fault, consult the troubleshooting

charts for all assemblies in the

"Standard Repairs, Troubleshoo-

ting" handbook.

Refer to the "Technical Informa-

tion" bulletins for engineering

changes which have been intro-

duced since publication of this

service manual. Technical informa-

tion bulletins also supplement the

parts list until a revised edition is

issued.

Special servicing tools mentioned

in the descriptions are listed in the

last chapter of this manual.

Use the part numbers to identify

the tools in the "STIHL Special

Tools" manual.

The manual lists all special

servicing tools currently available

from STIHL.

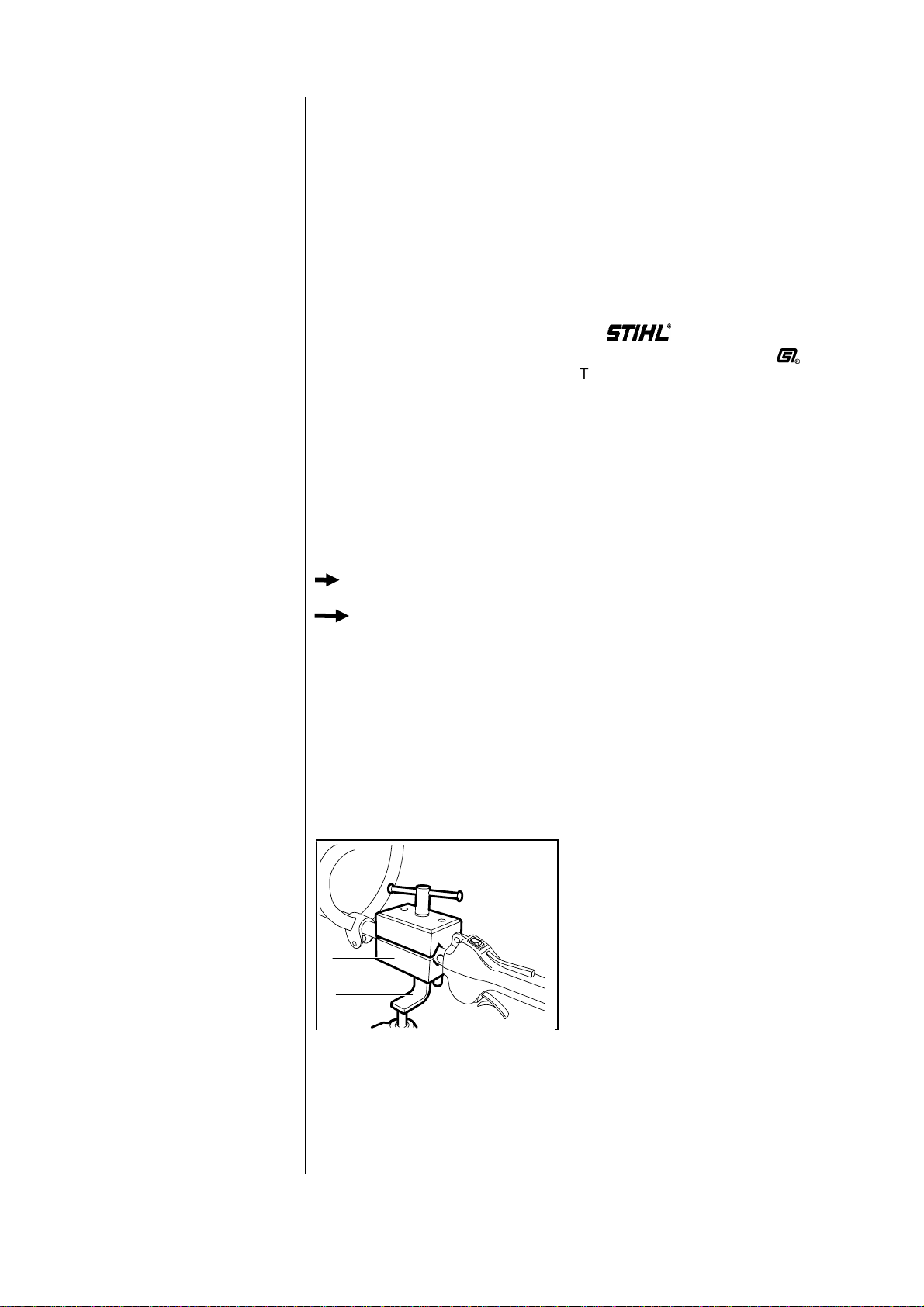

Symbols are included in the text

and pictures for greater clarity.

The meanings are as follows:

In the descriptions:

•= Actiontobetakenas

shown in the illustration

(above the text)

- = Action to be taken that

is not shown in the

illustration

(above the text)

In the illustrations:

= Pointer

= Direction of movement

Service manuals and all technical

information bulletins describing

engineering changes are intended

exclusively for the use of STIHL

servicing dealers. They must not

be passed to third parties.

Servicing and repairs are made

considerably easier if the machine

is mounted on assembly standard

(2) 5910 890 3100 with the aid of

clamp (1) 5910 890 8800.

Secure the clamp to the assembly

stand with two washers and two

M8 nuts.

The complete unit can then be

swivelled to the best position for

the ongoing repair and this leaves

both hands free.

Always use original STIHL

replacement parts.

They can be identified by the

STIHL part number,

the logo

and the STIHL parts symbol

(

The symbol may appear alone on

small parts.

2. INTRODUCTION

VA

232RA001

2

1

2FS 45