HL 91 K

English

6

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Take care not to endanger other

people.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

If you feel sick, have a headache, vision

problems (e.g., your field of vision gets

smaller), hearing problems, dizziness or

inability to concentrate, stop work

immediately. Such symptoms may be

caused by an excessively high

concentration of exhaust emissions –

risk of accident!

Keep the noise and exhaust emissions

to a minimum – do not let the engine run

unnecessarily and only open the throttle

when actually working.

No smoking when working with or near

the machine – risk of fire! Combustible

fuel vapor may escape from the fuel

system.

Dust, fumes and smoke produced while

working may be hazardous to health.

Wear respiratory protection in the

presence of major dust or smoke.

If the machine has been exposed to

stress due to improper use (e.g. forceful

impact from a blow or fall), test the

machine for safe-to-operate condition

before continuing work, in every case –

see also "Before start-up". Check the

fuel system for leaks and make sure the

safety devices are working properly. Do

not continue operating a machine which

is damaged. In case of doubt, have the

unit checked by your servicing dealer.

Do not work with the throttle trigger in

the starting throttle position – in that

position of the throttle trigger, the engine

speed cannot be controlled.

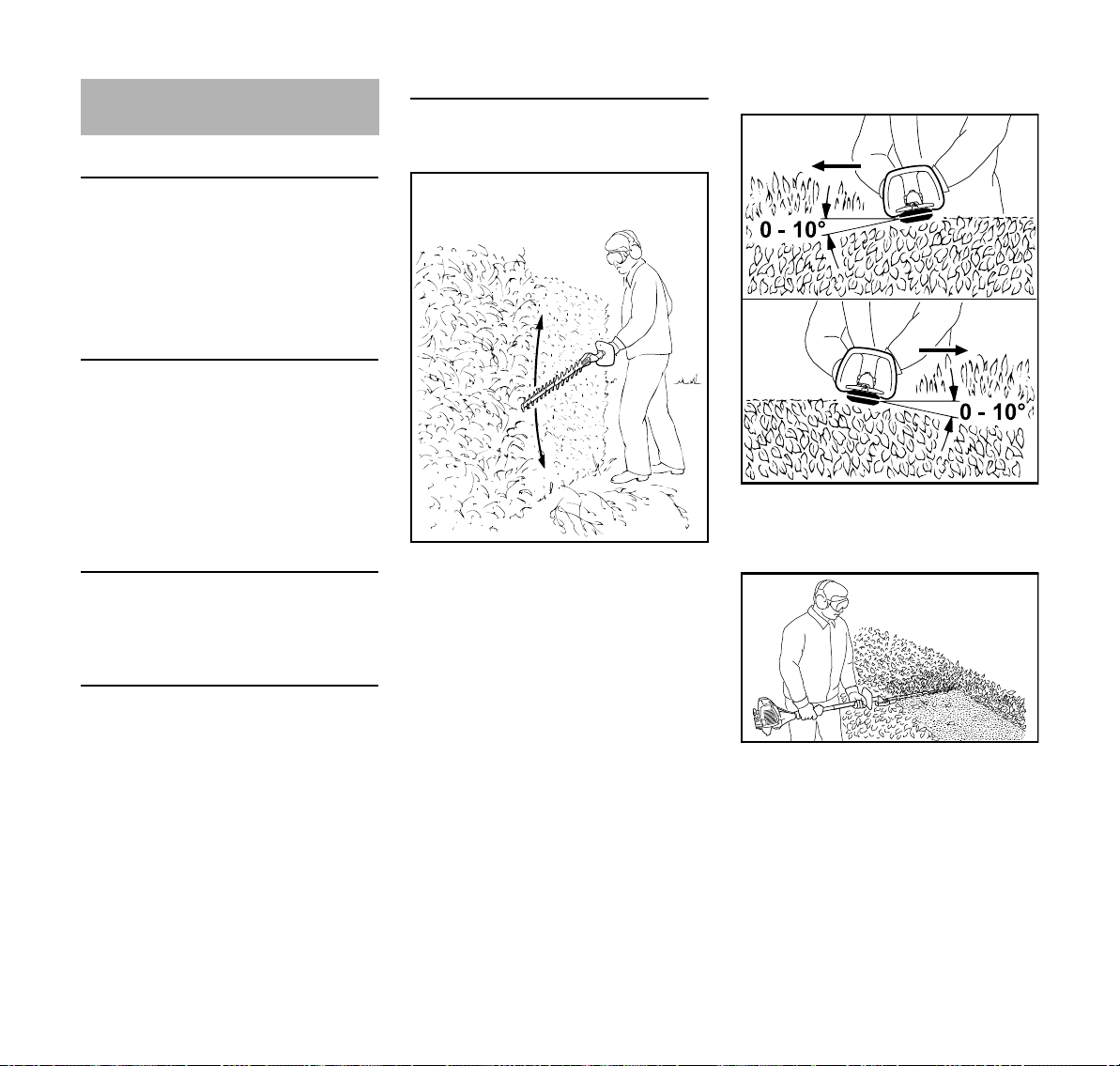

Inspect the hedge and work area to

avoid damaging the cutting blades:

–Remove stones, rocks, pieces of

metal and other solid objects

–When working close to the ground,

make sure that no sand, grit or

stones get between the blades

–Take particular care when cutting

hedges next to or against wire

fences

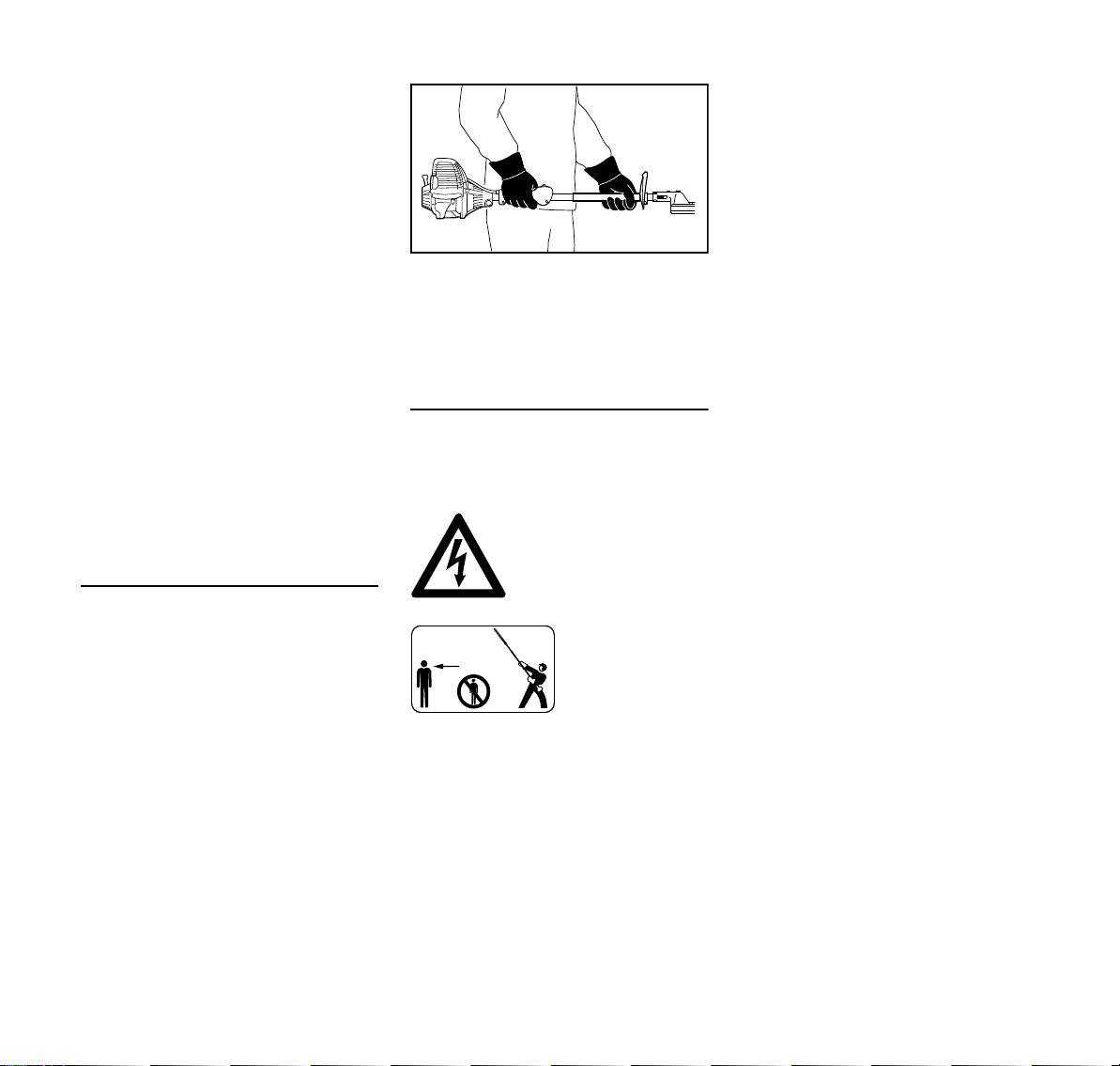

Do not touch electric power lines – never

cut through electric power lines – risk of

electrocution!

Opening the throttle when the blades are

jammed increases the load and reduces

the working speed of the engine. The

constant slipping of the clutch causes

overheating and damage to important

components (e.g. clutch, plastic housing

parts) – thus e.g. due to the blade

moving during idling – risk of injury!

If the hedge is very dusty or dirty, spray

the blades with STIHL resin solvent from

time to time during cutting. This helps

reduce blade friction as well as the

aggressive effects of sap and the build-

up of dirt particles.

Before leaving the machine unattended:

Switch off engine.

Check the cutting blades at regular short

intervals during operation or

immediately if there is a noticeable

change in cutting behavior:

–Switch off engine

–Wait for cutting blades to come to a

standstill

–Check condition and tightness; look

for cracks

–Check sharpness

Always clean plant residue, chips,

leaves and excess lubricant off the

engine and muffler – risk of fire!

Your power tool produces

toxic exhaust fumes as

soon as the engine starts

running. These gases

may be colorless and

odorless and may contain

unburnt hydrocarbons

and benzene. Never use

the machine indoors or in

poorly ventilated areas –

even if your model is

equipped with a catalytic

converter.

The gearbox becomes

hot during operation.

Never touch the gear

housing – risk of burns!

Do not touch the cutting

blades while the engine is

running. If the cutting

blades become jammed

by an object, switch off

the engine immediately

before attempting to

remove the object – risk

of injury!