HSE 61, HSE 71, HSE 81

English

5

Do not leave the power tool outdoors in

the rain.

Your power tool is equipped with a

system designed to quickly stop the

cutting blades – they come to an

immediate standstill as soon as you

release the trigger switch or the switch

lever, or the auxiliary switch.

Check this function at regular, frequent

intervals. Do not operate the machine if

the cutting blades continue to run after

switching off – risk of injury! Contact a

dealer.

Take special care in slippery conditions

– damp, snow, ice, on slopes or uneven

ground!

Clear away fallen branches, scrub and

cuttings.

Watch out for obstacles such as tree

stumps, roots – risk of tripping or

stumbling!

When working at heights:

–Always use a lift bucket

–Never use the machine while

standing on a ladder or in a tree

–never work in an insecure standing

position

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

Take breaks when you start getting tired

or feeling fatigue – risk of accidents!

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Proceed with caution, do not put

others in danger.

The gear head becomes hot during

operation. To reduce the risk of burn

injury, do not touch the gear housing!

If the machine is subjected to unusually

high loads for which it was not designed

(e.g., heavy impact or a fall), always

check that it is in good condition before

continuing work - refer also to the

chapter "Before starting work". Make

sure the safety devices are working

properly. Never use a power tool that is

no longer safe to operate. In case of

doubt, contact a dealer.

Inspect the hedge and work area to

avoid damaging the cutting blades:

–Remove stones, rocks, pieces of

metal and other solid objects

–When working close to the ground,

make sure that no sand, grit or

stones get between the cutting

blades

–Take particular care when cutting

hedges next to or against wire

fences

Do not touch electric power lines – never

cut through electric power lines – risk of

electrocution!

If the hedge is very dusty or dirty, spray

the cutting blades with STIHL resin

solvent from time to time during cutting.

This will significantly reduce blade

friction, the aggressive effects of sap

and the build-up of dirt particles.

The dust that occurs during operation

may be harmful to health. Wear a dust

mask in case of dust formation.

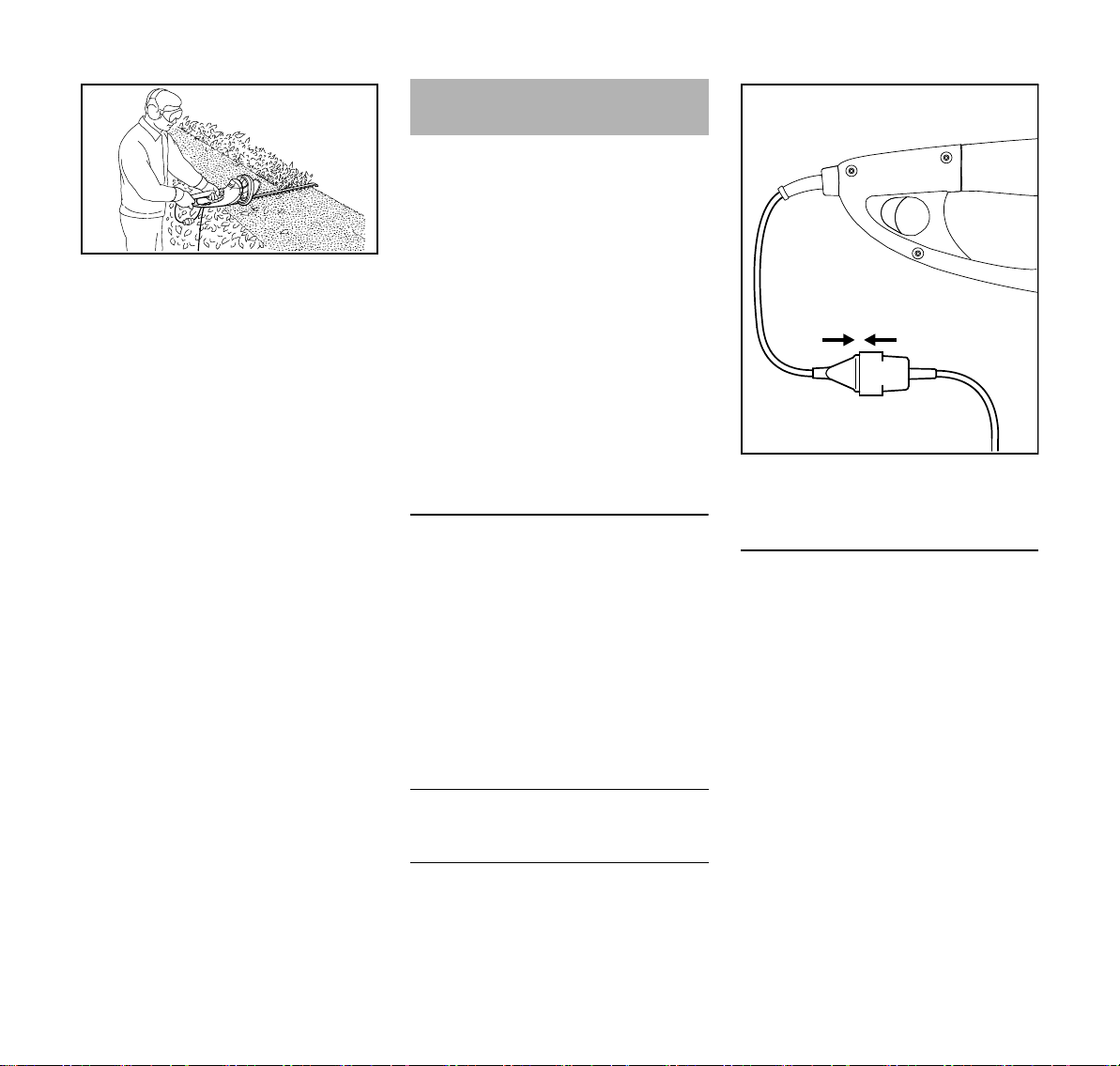

Never jerk the power cord to disconnect

it from the wall outlet. To unplug, grasp

the plug, not the cord.

Avoid damage to the power supply cord.

Do not drive over it, pinch or tug it.

Position the connecting and extension

cords correctly:

–Do not chafe on edges, pointed or

sharp objects

–don't trap or squeeze the cord in or

under doors or windows

–If cords are twisted – unplug the

power tool and straighten them out

–Always avoid contact with the

cutting attachment

–always completely unfurl the

connecting cord from the cable reel

to avoid risk of fire due to

overheating

Before leaving the power tool

unattended: Switch it off and disconnect

the plug from the power supply.

Do not touch the cutting

blades.while the engine

is running. If the cutting

blades become jammed

by thick branches or

other obstructions, switch

off immediately and dis-

connect the plug from the

power supply before

attempting to free the

blades.

If the power cord is dam-

aged, immediately

disconnect the plug from

the wall outlet to avoid

the risk of electric shock.