STM DITI10305610 User manual

WARNING: Read carefully and understand all

INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious

personal injury.

INTRODUCTION

The diesel transfer pump kit has been designed for the delivery of fuel from the drum & tanks in any situation.

This manual, apart from giving all necessary information on ordinary maintenance and supporting engineers

in failure detection and repair, should also give all the information’s needed to fully employ the capacity of

the machine, as well as to the user’s needs.

INSTALLATION

Electric connection should be done on a CEI standard socket provided with switch (so it isn’t live when the

connection is done) according to L.46/90 prescriptions.

DRUM PUMP KIT

User’s Manual

DITI10305610

DITI10305611

DITI10305619

DITI10307000

DITI10307207

1 of 7

2 of 7

PRELIMINARY INSPECTIONS

Before the power connection is done, verify the conductors aren’t live and general switches are off.

DISMANTLING AND DISPOSAL PROCEDURE

The metallic parts which the machine is mainly made of will be dismantled and sent to the steel mills. The

fuels in the tanks of the installation will be collected and sent to an authorized disposer. All plastic and

non-degradable material parts will be separately collected and sent to an authorized disposer or recycled.

SAFETY DEVICES

General Switch

It is placed on the motor body and allows the operator to set it on standby in a very short time. Once the

machine is stopped, the whole starting procedure can be repeated.

Harmful Functions

The noise from the machine is below 70 dB (A).

HARMFUL EMISSIONS

Steam emission is so reduced to result irrelevant.

FIRE PREVENTION

In case of fire never use water, but extinguishing powders charged with CO2 cat. A-B-C-D only, employing the

extinguishers placed next to the machine. Combustion of paints and plastic parts may produce toxic

emissions: use the normal precautions to be employed in case of fire (always refer to the security supervisor

of the place of installation).

FOR DC PUMP ONLY

ATTENTION!

1. Extreme operating conditions with working cycles longer than 30 minutes can cause the motor temperature

to rise, thus damaging the motor itself.

2. Each 30-minute working cycle should always be followed by a 30-minute power-off cooling phase.

3. MAXIMUM BY-PASSING TIME: 3 MINUTES.

4. DO NOT RUN DRY OVER 30 SECONDS.

NOTICE: THE VISION IS BUILT PAYING MAXIMUM CARE TO USER’S AND MAINTENANCE

ENGINEER’S SECURITY.

C. TECHNICAL DATA

PUMP

MODEL METER

MODEL Flow Rate ELECTRICAL POWER

Current Voltage(V) Frequency

10307000 Not Available 35/70LPM

9/18GPM DC 12/24 \

10305610 Not Available 56LPM/15GPM DC 12 \

10305611 Not Available 56LPM/15GPM DC 24 \

10305619 Not Available 56LPM/15GPM AC 230 50/60

10307207 Not Available 72LPM/19GPM AC 230 50/60

10305612 15111200 56LPM/15GPM AC 230 50/60

10307201 15111200 72LPM/19GPM AC 230 50/60

10307005 15111200 35/70LPM

9/18GPM DC 12/24 \

10305617 15111200 56LPM/15GPM DC 12 \

10305618 15111200 56LPM/15GPM DC 24 \

10306604 15111200 66LPM/18GPM AC 120 60

10308204 15111200 80LPM/22GPM AC 120 60

10306605 Not Available 66LPM18GPM AC 120 60

10308205 Not Available 90LPM/22GPM AC 120 60

PRECAUTIONS

During Diesel delivery always wear oil resistant and always wash hands with water and soap at the end.

Always cleanat once oil stains to avoid slips and/or pollution.

Use particular care with the zones next to the controls.

When cleaning, and specially when removing dust or waste, always wear suitable clothes, if possible use

aspirators only.Always use suitable clothes or protective devices. Never place hands or limbs under moving

parts.

SYSTEM DESCRIPTION

Functional Description

The diesel transfer system are hydraulic machine tools which feed with a given capacity (volume) of fluid in

the time unit, a collecting tank, sucking the liquid from an open surface feed tank; the allowed suction lift

(geodetic suction lift Hga) is also a specific characteristic of the pump. The system is composed by

complementary equipment, operating as whole to give a complete service:

Diesel pump

2M suction hose with filter

4M delivery hose

Dispensing nozzle

2” quick coupling

MACHINE DESCRIPTION

The diesel transfer unit has been designed and built according to the following standards:

Electric requirements: EN 60204-1 and EN 60529

Mechanical requirements: EN 292-1 and EN 292-2; EN 55081-2, EN 55011C/A

Other requirements 89/392 CEE

ALLOWED AND FORBIDDEN USE

Diesel transfer unit has been designed and built for DIESEL TRANSFER ONLYfrom reservoirs, tanks and

drums.

It is strictly forbidden to employ it to transfer liquids of different kind as gasoline, explosives and

corrosives (or flammable), alimentary liquids.

3 of 7

The machine isn’t designed for employment in the explosive environment.

Operating the pump is forbidden to children and disabled person.

It is forbidden to employ the unit next to flammable liquids (gasoline, alcohol, etc.).

It is forbidden the employment in closed environments in presence of gasoline, LPG, methane fuelled

vehicles.

TRANSPORT AND UNPACKING

Due to its weight and dimensions, the unit can easily be transported by hand. Control that the package is

good conditions and verify that the unit isn’t damaged. Each failure must be noticed in 10 days from receiving

the machine.

For correct unpacking carefully follow these instructions:

1. Place the case on the ground following the indications on the package.

2. Carefully open the case, remove the machine and place it on the ground or on a steady surface.

3. Control that the machine and its accessories aren’t damaged.

4. Firstly, connecting the pump and the flow meter by flange kit (provided in the carton), then install the nozzle

holder to the bottom of the pump. Take out the elbow and screw it on the outlet of the flow meter. For details,

pleaser refer to “M Diagram”

5. Connect the coupling, see Fig. 1. Connecting Coupling 2 with the spout of the drum or tank. Joint Coupling

1 with the inlet of the pump. Install the suction hose on the thread of the Coupling 1. Then joint coupling 1 to

coupling 2, tighten by screwing the screw.

6. Screw the delivery hose on the fitting of the flow meter and of the filling gun.

NOTE: FOR ALL ABOVE CONNETION, SCREWED IT TIGHTLY WITHOUT ANY LEAKAGE!

Fig. 1

USE AND STARTING

STARTING

Once the hoses are sealed, the feeding cable is connected and the filling gun is in rest position, the machine

can be started. After placing the hose into the tank and the gun into the filling hole, start the pump, gradually

release the lever and start Diesel transfer. Once the filling is done release the control of the gun and switch

the pump off. When the pump isn’t in use disconnect it.

FLOW METER

4 of 7

5 of 7

The flow meter shows how many litres of liquid were pumped by the unit. Be aware that this device is not

suitable to measure products for resale.

The mechanical flow meters indicate the partial (resettable) and total (no reset function) of the litres pumped.

Each time the instrument must be reset, turn the knob on the left of the unit until all zeroes are displayed.

Calibration

The meter used in the pumping unit is calibrated at the factory. Calibration is recommended upon initial use,

after disassembly or significant wear. Meter calibration can be easily changed with the procedure hereafter.

The proving container should be at least 50 litres.

Procedure:

Fill container to a know volume

Turn the calibration screw

+Clockwise to increase the number of liters counted

-Counterclockwise to decrease the number of liters counted

WARNINGS

1. The gunlock has been provided to make filling easier. It is forbidden to leave the gun unattended to avoid

overflow.

2. Don’t operate the machine if there is no liquid inside. Don’t start the pump before connecting suction and

delivery hoses.

3. Once the gun is closed switch the motor pump off as soon as possible. THE PUMP HAS TO WORK IN

BY-PASS CONDITION FOR SHORT PERIOD: MAXIMUM 3 MINUTES.

4. In case of current losses the pump should be switched off and the plug disconnected.

5. It is strictly forbidden to use the pump with wet hands, barefooted or dipped in water.

6. In case of blackout switch the pump off and disconnect the plug to avoid unexpected starts with liquid

overflow.

7. When transferring from open-air tanks, we suggest to place the machine as far as possible to avoid

sprays and sudden dips which may cause serious damage.

MAINTENANCE

Each kind of disassembly should always be carried out when the machine is stopped, the plug is

disconnected and after emptying the pump and the flow meter. For a better operation control every three

months that there isn’t any kind of debris in the flow meter filter.

OPERATIONAL PROBLEMS

ACCIDENTS CAUSES REMEDIES

The pump doesn’t work A) Jammed shaft

B) No electric feeding A) Disconnected the plug;

unscrew on the pump,

remove the pump body and

clean it inside. Control that

the shaft is now working

6 of 7

correctly. Reassemble the

pump.

B) Control that the plug is

correctly connected and that

the socket is live.

The pump works doesn’t deliver

liquid. A) The pump sucks air from the

suction hose.

B) Air inside the pump

A) Control the suction hose seal

on the pump. Verify that the

hose is completely immersed

into the liquid and free from

chokes.

B) Control that the filter is clean.

MECHANICAL RISKS

1. Mechanical parts subject to wear

The blades

The bearing

The rotor

These parts should be replaced with original spare parts by qualified personal only or in authorized service

centres.

2. Risks due to extreme temperatures

Remember that a very low temperature can freeze the Diesel inside the pump. This situation can cause

serious damage to the motor pump unit.

3. A very high temperature (about 45℃) may cause the plastic parts in the unit to expand. The unit should

thus be placed in a well-ventilated place and protected from the sun.

7 of 7

DIAGRAM & PRICE LIST

Part No. Component description Quantity Part No. Component

description Quantity

1 Outlet 1 8 O-ring 2

2 Nozzle 1 9 flange 1

3 Bolt M6 2 10 Nut M8 2

4 Nozzle base 1 11 Bolt M8 2

5 Nut M6 2 12 pump 1

6 Mechanical meter

(Optional)1 13 Quick Coupling 1

7 Elbow 1 14 Inlet 1

This manual suits for next models

4

Table of contents

Other STM Water Pump manuals

Popular Water Pump manuals by other brands

CAT Pumps

CAT Pumps 1530 Service manual

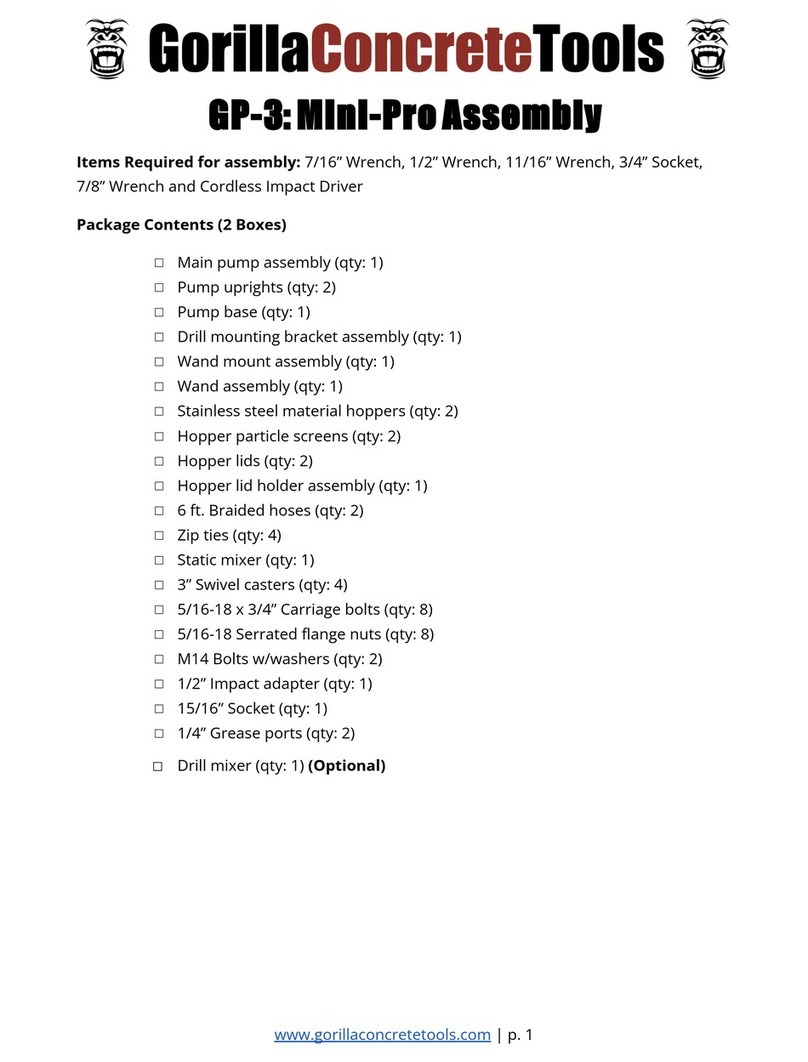

Gorilla Concrete Tools

Gorilla Concrete Tools GP-3 Mini-Pro Assembly

M&C

M&C MP Series instruction manual

Zoeller

Zoeller 105 installation instructions

Lippert Components

Lippert Components Duraself DS-600GSP-M owner's manual

Pentair

Pentair Myers WHR Series Installation and service manual

Silicon Solar

Silicon Solar AquaJet SPB50-801210D user manual

Craftsman

Craftsman 390.260293 owner's manual

Graco

Graco Dura-Flo A Series Instructions-parts list

Grundfos

Grundfos Geo-Flo MAGNA3 installation manual

Pentair

Pentair Hydromatic MPC Installation and service manual

Graco

Graco Husky 715 Instructions-parts list