STM DPA25090 User manual

Instruction Manual

WARNING:

Read carefully and understand all INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious personal injury.

Save these instructions in a safe place and on hand so that they can be read when required.

Keep these instructions to assist in future servicing.

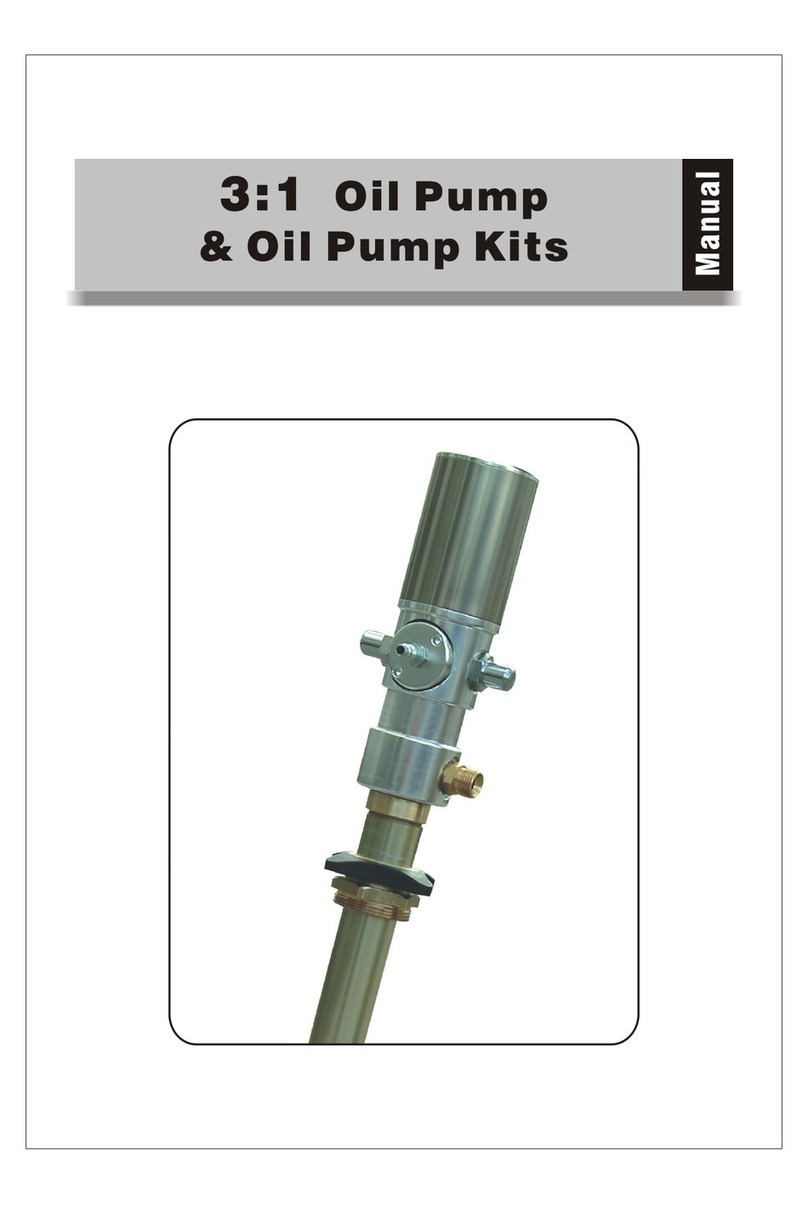

Air-operated Double Diaphragm Pump

DPA25090

GENERAL SAFETY REGULATIONS

WARNING: The warnings, cautions, and instructions

discussed in this instruction manual cannot cover all

possible conditions or situations that could occur. It

must be understood by the operator that common

sense and caution are factors that cannot be built into

this product, but must be supplied by the operator.

1. Keep the work area clean and dry. Damp or wet work areas can result in

injury.

2. Keep children away from work area. Do not allow children to handle this

product.

3. Use the right tool for the job. Do not attempt to force small equipment to do

the work of larger industrial equipment. There are certain applications for

which this equipment was designed. It will do the job better and more safely

at the capacity for which it was intended. Do not modify this equipment, and

do not use this equipment for a purpose for which it was not intended.

4. Check for damaged parts. Before using this product, carefully check that it

will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product.

Replace damaged or worn parts immediately.

5. Do not overreach. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etc.

6. DO NOT use the equipment when tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating this

equipment may result in serious personal injury.

TECHNICAL DETAILS

TECHNICAL

DETAILS

EXPLODED AND

PARTS LIST

MAINTENANCE

TROUBLE

SHOOTING OPERATING

INSTRUCTIONS AIR AND LUBE

REQUIREMENTS GENERAL

DESCRIPTION

OPERATING AND

SAFETY PRECAUTIONS

Model No.

DPA25090

Inlet/

Outlet Air Inlet Flow Rate Max. Air

Inlet/Outlet

Pressure

Max.

Diameter

Solid

Pump

Body Membrane

1" 1/4" 24GPM/90LPM 115PSI/8BAR 1/8" Aluminum Nitrile

100

75

50

25

20

15

10

5

876543210

Working Pressure(Bar)

Flow Rate(L/min)

Air Comsumption(M

3

/h)

Flow Rate

Air Comsumption

DIMENSIONAL DATA

10.82" / 275mm 8.0" / 203mm

8.05" / 204.5mm

5.90" / 150mm

7.57" / 192.5mm

6" / 0.23mm

13.22" / 336mm

TECHNICAL

DETAILS

EXPLODED AND

PARTS LIST

MAINTENANCE

TROUBLE

SHOOTING OPERATING

INSTRUCTIONS AIR AND LUBE

REQUIREMENTS GENERAL

DESCRIPTION

OPERATING AND

SAFETY PRECAUTIONS

OPERATING AND SAFETY PRECAUTIONS

READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND

PROPERTY DAMAGE.

WARNING! EXCESSIVE AIR PRESSURE. Can cause personal injury, pump

damage or property damage.

• Do not exceed the maximum inlet air pressure as stated on the pump model plate.

•

Be sure material hoses and other components are able to withstand fluid pressures developed

by this pump. Check all hoses for damage or wear. Be certain dispensing device is clean and

in proper working condition.

WARNING! STATIC SPARK. Can cause explosion resulting in severe injury or

death. Ground pump and pumping system.

• Spark can ignite flammable material and vapors.

• The pumping system and object being sprayed must be grounded when it is pumping,

flushing, recirculating or spraying flammable materials such as paints, solvents, lacquers etc.

or used in a location where surrounding atmosphere is conducive to spontaneous combus-

tion. Ground the dispensing valve or device, containers, hoses and any object to which

material is being pumped.

• Use the pump grounding screw terminal provided. Connect a suitable ground wire to a good

earth ground source.

• Secure pump, connections and all contact points to avoid vibration and generation of contact

or static spark.

• Consult local building codes and electrical codes for specific grounding requirements.

• After grounding, periodically verify continuity of electrical path to ground. Test with an

ohmmeter from each component (e.g., hoses, pump, clamps, container, spray gun, etc.) to

ground to insure continuity. Ohmmeter should show 100 ohms or less.

• Use proper ventilation.

• Keep inflammables away from heat, open flames and sparks.

• Keep containers closed when not in use.

WARNING! Pump exhaust may contain contaminants. Can cause severe injury.

Pipe exhaust away from work area and personnel.

• In the event of a diaphragm rupture material can be forced out of the air exhaust muffler.

• Pipe the exhaust to a safe remote location when pumping hazardous or inflammable

materials.

WARNING! HAZARDOUS PRESSURE. Can result in serious injury or property

damage. Do not service or clean pump, hoses or dispensing valve while the

system is pressurized.

WARNING! EXPLOSION HAZARD. Models containing aluminum wetted parts

cannot be used with III. -Trichloroethane, Methylene Chloride or other Halogenat-

ed Hydrocarbon solvents which may react and explode.

CAUTION! Verify the chemical compatibility of the pump wetted parts and the

substance being pumped, flushed or recirculated.

CAUTION! Do not use the pump for the structural support of the piping system.

Be certain the system components are properly supported to prevent stress on

the pump parts.

CAUTION! Prevent unnecessary damage to the pump. Do not allow pump to

operate when out of material for long periods of time.

Disconnect air line from pump when system sits idle for long periods of time.

GENERAL DESCRIPTION

• The diaphragm pump offer high volume delivery even at low air pressure.

• Air-operated double diaphragm pumps utilize a pressure differential in the air chambers to

alternately create suction and positive fluid pressure in the fluid chambers, ball check insure a

positive flow of fluid.

• Pump cycling will begin as air pressure is applied and it will continue to pump and keep up with

the demand. It will build and maintain line pressure and will stop cycling once maximum line

pressure is reached (dispensing device closed) and will resume pumping as needed.

AIR AND LUBE REQUIREMENTS

WARNING! EXCESSIVE AIR PRESSURE. Can cause pump damage, personal

injury or property damage.

• The air delivery pipe should be big enough to ensure the air needed.

• Air pressure not exceed 115 PSI (8 BAR).

• Afilter capable of filtering out particles larger than 50 microns should be used on the air supply.

There is no lubrication required other than the O-ring lubricant which is applied during

assembly or repair.

• If lubricated air is present, make sure that is compatible with the O-rings in the air motor

section of the pump.

OPERATING INSTRUCTIONS

• Always flush the pump with a solvent compatible with the material being pumped if the material

being pumped is subject to “setting up” when not in use for a period of time.

• Disconnect the air supply from the pump if it is to be inactive for a few hours.

• Disconnect the air supply from the pump if it is not in use.

• The material supply tubing should not be too small or restrictive. Be sure not to use hose which

might collapse.

• When the diaphragm pump is used in a forced-feed (flooded inlet) situation, it is recommended

that a “Check Valve” be installed at the air inlet.

• Secure the diaphragm pump legs to a suitable surface to insure against damage by vibration.

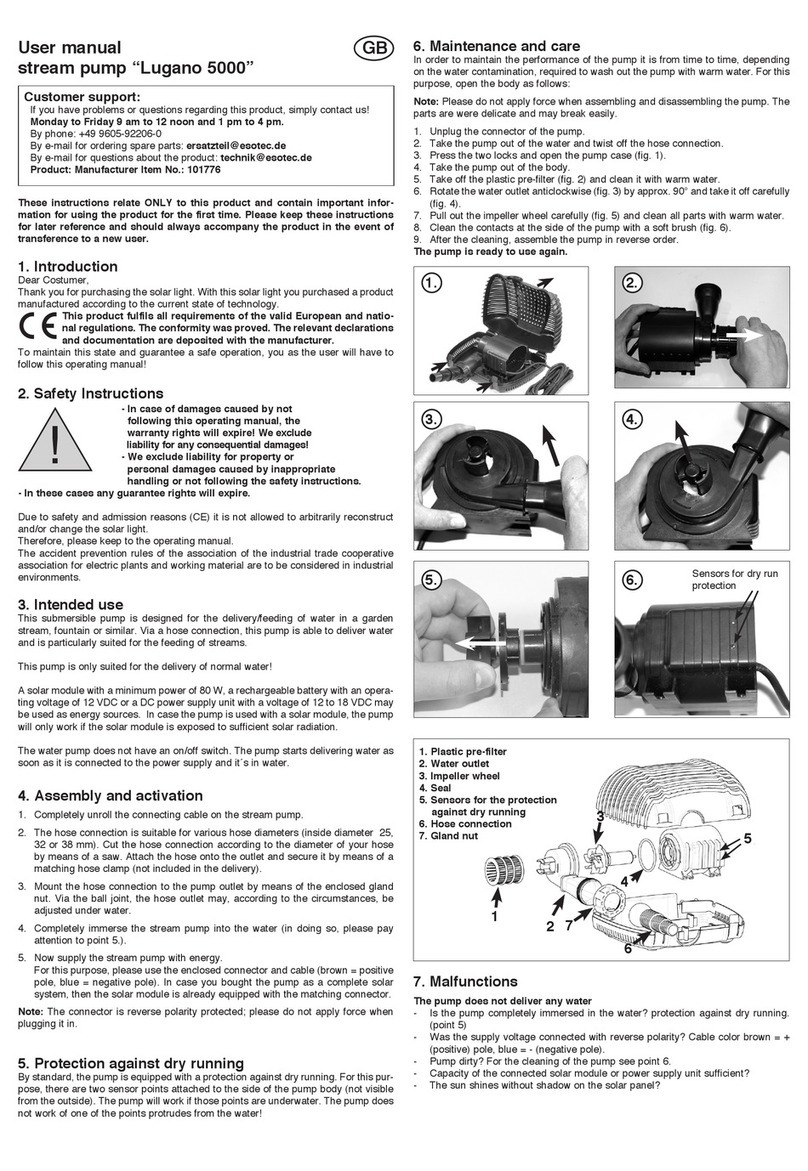

MAINTENANCE

• Provide a clean work surface to protect sensitive internal moving parts from contamination

from dirt and foreign matter during service disassembly and reassembly.

• Keep good records of service activity and include pump in preventive maintenance program.

• Before disassembling, empty captured material in the outlet manifold by turning the pump

upside down to drain material from the pump.

TROUBLE SHOOTING

Product discharged from exhaust outlet.

• Check for diaphragm rupture

• Check tightness of diaphragm

Air bubbles in product discharge.

• Check connections of suction plumbing

• Check O-rings between intake manifold

and fluid caps

• Check tightness of diaphragm nut

Low output volume, erratic flow, or no flow.

• Check air supply

• Check for plugged outlet hose

• Check for kinked (restrictive) or collapsed inlet

material hose

• Check if there is leakage for the connection.

These must be air tight

• Inspect the pump for solid objects logged in

the diaphragm chamber or the seat area

TECHNICAL

DETAILS

EXPLODED AND

PARTS LIST

MAINTENANCE

TROUBLE

SHOOTING OPERATING

INSTRUCTIONS AIR AND LUBE

REQUIREMENTS GENERAL

DESCRIPTION

OPERATING AND

SAFETY PRECAUTIONS

TECHNICAL

DETAILS

EXPLODED AND

PARTS LIST

MAINTENANCE

TROUBLE

SHOOTING OPERATING

INSTRUCTIONS AIR AND LUBE

REQUIREMENTS GENERAL

DESCRIPTION

OPERATING AND

SAFETY PRECAUTIONS

EXPLODED AND PARTS LIST

FLUID SECTION FOR SERIES: DPA25090

Part No.

1

2

*3

*4

*5

*6

7

8

*9

10

*11

Description

Hex-bolt

Discharge Manifold

Valve Cover

Valve Ball

Valve Seat

O-ring(37.77*2.62)

Hex-bolt

Hex-bolt

O-ring(17.17*1.78)

Liquid Chamber Plate

Diaphragm

Q’ty

8

2

2

4

4

4

16

2

2

2

2

Part No.

12

13

14

15

16

17

18

*19

20

21

Description

Air Chamber Plate

Screw

Air Chamber

Bracket

Screw

Air Motor Assembly

Nut

O-ring(94.92*2.62)

Plug

Pump cover

Q’ty

2

12

2

2

1

1

16

2

2

2

Note: The Part No. with “*”are the wearing parts

TECHNICAL

DETAILS

EXPLODED AND

PARTS LIST

MAINTENANCE

TROUBLE

SHOOTING OPERATING

INSTRUCTIONS AIR AND LUBE

REQUIREMENTS GENERAL

DESCRIPTION

OPERATING AND

SAFETY PRECAUTIONS

EXPLODED AND PARTS LIST

AIR MOTOR SECTION

Part No.

1

2

3

4

5

6

*7

8

9

*10

*11

Description

Hex-bolt M6X20

Press board

Seal for press board

Spacer

Spacer

Spacer

O-ring 20.35X1.78

Hex bolt M5X12

Gasket

Seal for gasket

Washe

Q’ty

4

1

1

4

5

2

6

8

2

2

2

Part No.

12

*13

14

*15

16

*17

18

*19

20

*21

Description

Major Valve

O-ring 9.93X2.62

Sleeve

O-ring 20.35X1.78

Retaining Ring 25

O-ring 7.1X2.65

Pilot Valve

O-ring 6.86X1.78

Muffler 3/8"

O-ring 15.60X1.78

Q’ty

1

5

1

3

1

2

1

5

1

2

1234567

8

9 10 11

121316

14 15

171819

20

21

Note: The Part No. with “*”are the wearing parts

Table of contents

Other STM Water Pump manuals

Popular Water Pump manuals by other brands

Zwilling

Zwilling Fresh & Save Vacuum Storage System operating instructions

Franklin Electric

Franklin Electric TurfBOSS TB15CI owner's manual

LEYBOLD

LEYBOLD Sogevac NEO D 16 Original instruction manual

Nira

Nira 6B VITON Instruction and maintenance manual

KSB

KSB Amarex KRT Installation & operating manual

LEYBOLD

LEYBOLD ECODRY plus 25 operating instructions