F. INITIAL START-UP

The pumps are self-priming and, therefore, able to draw oil from the tank even when the suction hose is

empty on start-up.

The priming height (distance between the surface of the oil and the inlet opening) must not exceed 2.5

meters

ATTENTION!

Wetting the pump. Before starting the pump, wet the inside of the pump body with oil through the inlet and

outlet openings.

If the pump is already installed, the operation can be performed by removing the cover of the chamber filling

the internal chamber with oil and placing the cover again, paying attention to the O-ring seal.

In the priming phase the pump must blow the air that was initially present in the tubing into the line, therefore,

it is necessary to keep the delivery open.

When the tube is filled with oil, the purging phase is concluded.

ATTENTION!

If a foot valve was not installed, install the pump in a position so that oil is always present in the gear

chamber.

If the foot-valve seal is not perfectly tight, the suction tube may be emptied and the operation of initial

start-up described above must be repeated.

The priming phase may last from several seconds to a few minutes, depending on the characteristics of the

system.

If this phase is excessively prolonged, stop the pump and verify:

zThat the pump is not running completely ”dry”

zThat the suction hose guarantees against air infiltration and is correctly immersed in the fluid to be

drawn

zThat the filter in the suction circuit, if any, is nit blocked

zThat the delivery hose allows for the easy evacuation of the air

zThat the priming height is not greater than 2.5 meters

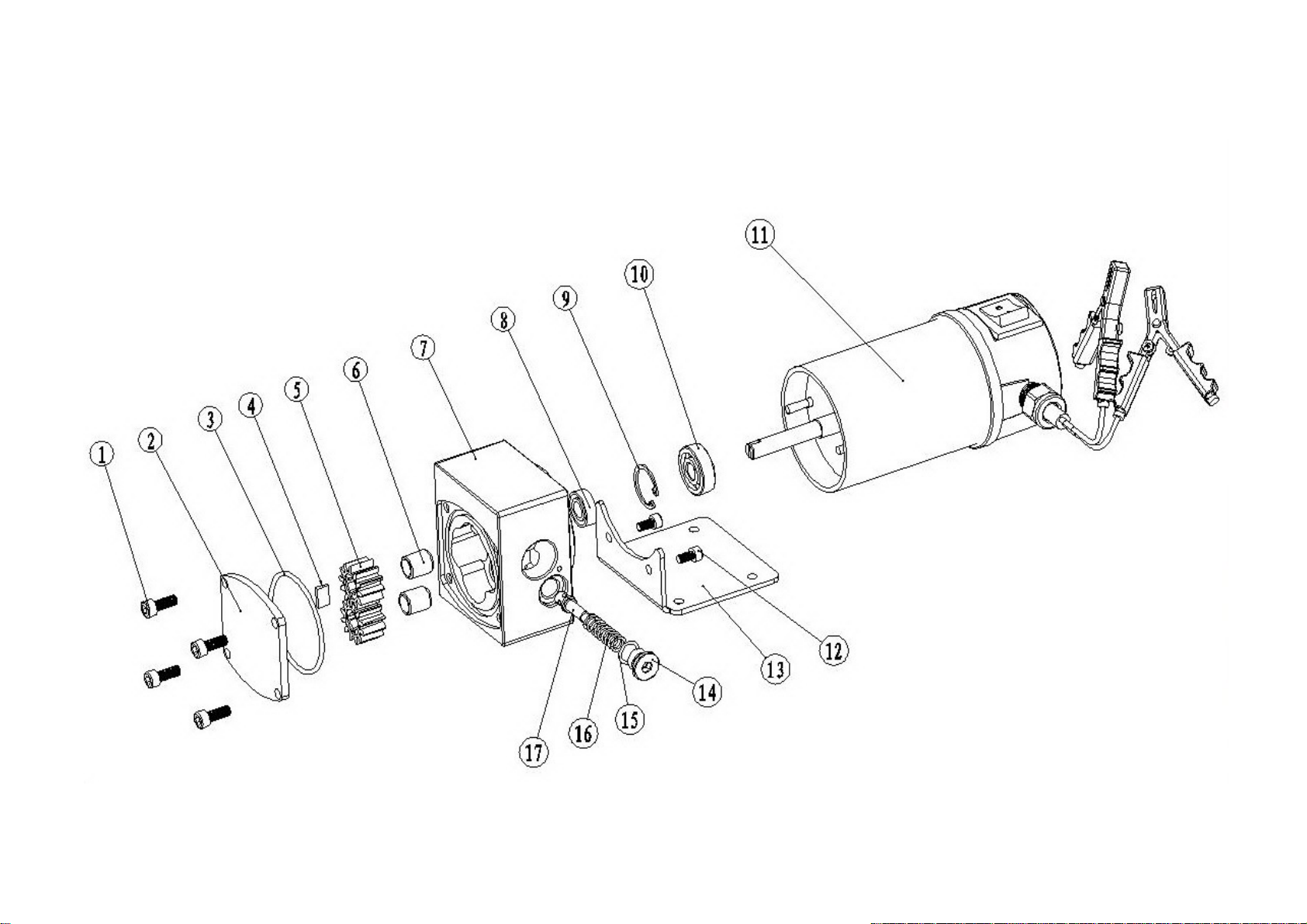

zThe exact rotation direction of the motor: it must be in a counter-clockwise considering the motor from

pos. 1 of the exploded diagram.

When priming has occurred, after reattaching the delivery nozzle, verify that the pump is functioning within

the expected ranges, possibly checking:

that under conditions of maximum flow the energy drawn by the motor falls within the values indicated on the

label

G. DAILY USE

NO particular preliminary operation is required for every day use of these pumps.

zBefore starting the pump, make sure that the ultimate shut-off device (delivery nozzle or line valve) is

closed. If the delivery has no shut-off device (free delivery), make sure that it is correctly positioned and

appropriately attached to the delivery tank.

zMake sure that the tank is filled with a quantity of oil greater than the quantity to be supplied (running

dry could damage the pump)

zTurn the on-switch present on some pump models or the start/stop switch installed on the electrical

power line

zOpen the delivery valve or activate the delivery nozzle, gripping it securely