23833A551 11/08/12

3

If raw sewage must be pumped in the home, use

outside basins that connect with pressure sewer

mains or gravity sewers, or run to septic tanks.

Basins can be used inside the home where extra

capacity sump pumps are required for water softeners

and wash water.

If an inside basin is used, it is usually installed at the

time of pouring the concrete floor.

Pumps can be installed in a compartment of septic

tanks for pumping to pressure sewer mains, gravity

sewers, leach fields, or evaporation mounds.

PROPER VENTING FOR BASINS

INSTALLED INSIDE

All inside sealed basins must have a 2" or 3" vent pipe

installed in accordance with local codes. Basins for

handling softener water, wash or drainage water do

not have to be sealed or vented.

Outside basins are usually of fiberglass and from 4 to

8 feet deep and have a sealed cover. Pump is usually

installed with a lift-out rail system so that pump can

be removed without disturbing the discharge piping.

The check valve comes out with pump for servicing.

Complete lift-out systems mounted in fiberglass

basins are available to meet customer specifications.

WARNING: Basin must be vented in accordance

with local plumbing codes. These pumps are not

designed for and CANNOT be installed in locations

classified as hazardous in accordance with the

National Electric Code ANSI/NFPA 70.

PIPING

Pumps are fitted with 2" or 3" female threaded pipe

flange. Galvanized or PVC plastic pipe can be used.

Plastic pipe is preferred for raw sewage or septic tank

effluent.

CHECK VALVES AND SHUT-OFF VALVES

All pumps must have check valves and shut-off valves

in the discharge line. Check valves must be flapper

type with outside spring or ball type. Shut-off valves

can be ball or gate type. Plastic construction for both

check or shut-off valves is preferred.

HOW TO SET CONTROLS FOR

SIMPLEX SYSTEMS

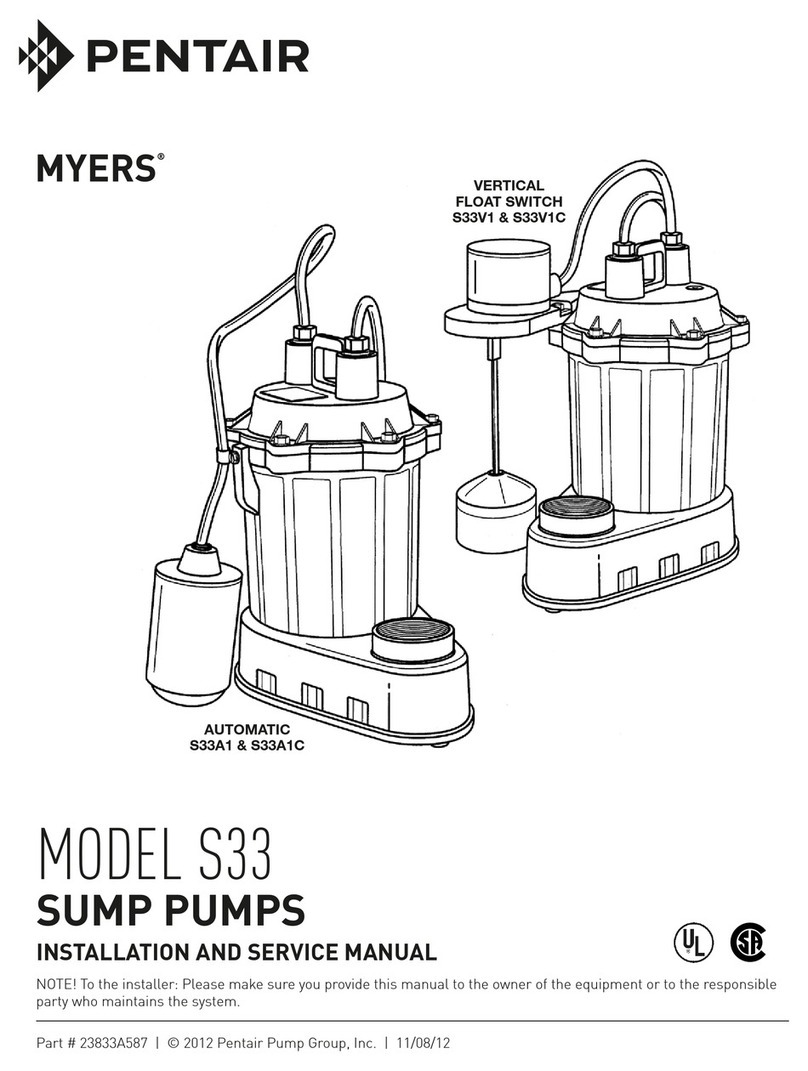

1. Automatic systems — These systems have the

float switches mounted on the pump, so pump is

installed in the basin and motor cord is plugged

into GROUNDED receptacle. For sealed basin

cover, power cord is brought through a split rubber

plug in the basin cover.

2. Where 2 float controls are used, the turn-on control

is set 3" to 6" above top of motor, and the turn-

off control is set about 6" to 8" above bottom of

basin. If a high level alarm control is used, it is set

about 6" above upper control. If basin depth will

not allow these settings, closer spacing can be

used.

3. Where ALC or AWS-1 (automatic wet systems)

controls are used, the displacement weights are

set so that turn-on weight is 4" to 6" above top

of motor and lower weight is set about 6" above

basin bottom.

HOW TO START SIMPLEX SYSTEMS

1. For single-phase pumps with MLC or MFLC

control, plug cords piggyback into receptacle and

run water into basin until pump starts. Allow pump

to make several on/off cycles. Leave power cord

plugged in.

If pump runs but does not pump it may be air

locked. Unplug cord and crack union in the

discharge line, then restart pump. This should vent

off any trapped air. Retighten union.

2. With 2 float controls turn on power at the control

box and run water into basin. When level gets

above top control, pump should start and continue

to pump until level drops to lower control, stopping

pump. Run pump through several cycles. If pump

runs but does not pump, check air lock. Leave

power on for automatic operation.

3. Where ALC or AWS-1 controls are used, plug in

cord or turn-on power and run water into basin.

When level is about halfway up on upper weight,

pump should start and run until level drops

until about half the lower weight is above water,

stopping pump.

For all cases if motor does not start when water level

is up, check for proper plug-in or that start switch is

on, or if fuse is blown.

ALWAYS HAVE ELECTRICIAN MAKE ELECTRICAL

CHECKS.

STARTING PUMP PIGGYBACK

(AUTOMATIC) USING MECHANICAL

SWITCH WITH SERIES PLUG –

SIMPLEX SYSTEM

1. These pumps have a mechanical (mercury-free)

float switch with a 20 ft. cord and a 115 volt or 230

volt series piggyback plug on 1/2 HP with switch

mounted to the pump. On 3/4, 1, and 2 HP, it

requires 20 ft. cord and 230 volt only.

2. Plug the switch cord plug into a proper voltage,

properly grounded outlet.