594 TITAN

HYDRAULIC PRESSURE TEST PUMP

MADE IN USA

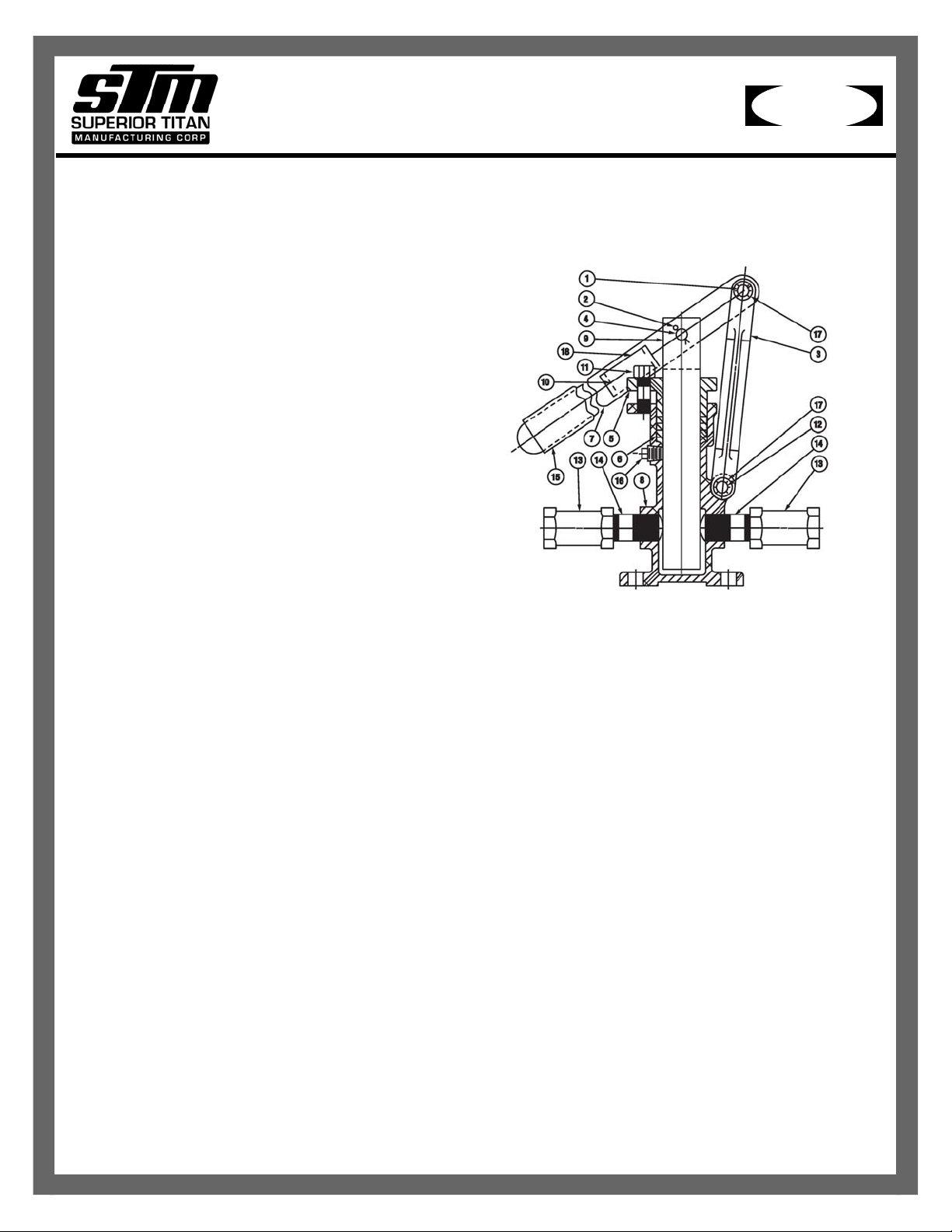

Recommended Procedure to Change out Packing

on the 594 TITAN Hydraulic Pressure Test Pump

1) Disconnect Lever (7) from Plunger (9).

2) Remove Packing Gland (5) and set aside.

3) Remove all five rings of old packing (a picking

tool or flat head screw driver works).

4) Clean any dirt or debris from the packing box

housing area (a solvent works well).

5) Dry out the packing box housing with a clean

cloth.

6) Install five each new rings of Gland Packing (6),

P/N TI2 06-0008272.

a) Install each ring of packing so that the “joints”

are offset 90 degrees from one another.

7) Reassemble pump in reverse order.

LIMITED WARRANTY

Note:

The plunger needs to be installed before installing new packing. This allows the packing to wrap around

the plunger. The packing gland can be used to press the packing into the stuffing box.

Superior Titan Manufacturing Corp. (STM Corp) warrants its 594 TITAN Hydraulic Test Pump to be free

of defects in parts and workmanship for a period of two (2) years from date of manufacture. Failures

due to normal “wear and tear”, misapplication, or abuse will be excluded from warranty coverage.

Product being claimed for warranty must be returned to the factory “freight prepaid”. Contact your dis-

tributor for a “Return Authorization” number prior to shipment. Any pump being returned which has

been handling chemicals, fuels, or any liquid other than fresh clean water, must be accompanied by the

appropriate MSDS paperwork.

Product returned for warranty claim will be inspected by our warranty team and a decision will be

made. Decisions made by STM Corp are at its sole discretion and are final. Repaired or replacement

product will be shipped freight prepaid to the INCOTERMS point of the original sale.

STM Corp accepts no liability for extenuating charges relating to a pump’s failure such as labor, time

lost, damage to other equipment, etc. Any damage incurred to goods in transit must be handled with

the corresponding carrier.

5407 N Haverhill Road, Suite 345, West Palm Beach, FL 33407 USA

T: 561-340-1685 - www.superiortitanmfgcorp.com