Stober EZ User manual

Operating manual

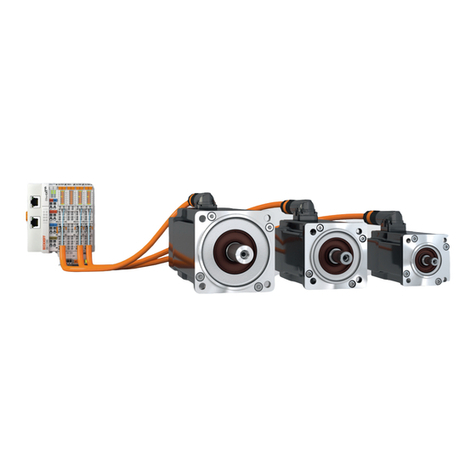

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

107/2015

WE KEEP THINGS MOVING

ID 442581_en.03

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

These operating instructions contain information about the

transport, installation and commissioning of STOBER EZ,

EZF, EZH, EZHD, EZHP synchronous servo motors and EZS,

EZM synchronous servo motors for screw drive.

For further details, see catalogs SMS-EZ (ID 442212) and

EZS/EZM synchronous servo motors for screw drive (ID

442416).

In the event of any unclear points, we recommend that you

contact STÖBER with the model designation and serial

number, or have the installation and maintenance work

carried out by a STÖBER service partner.

1 Operation in accordance with its

intended use

Synchronous servo motors must be used exclusively for

operating machines and systems together with servo

inverters.

Stay within the limits defined by the technical data.

Do not use synchronous servo motors in potentially explosive

atmospheres.

For reasons of operational safety, motors may only be used

for the single application for which they were projected.

Any overload on the drives is considered unintended use.

The information and instructions in these operating

instructions must be precisely followed to ensure that claims

submitted under the warranty will be honored. If modifications

are made to motors, warranty claims will be rendered void.

Comply with the safety instructions in these operating

instructions and in all supplementary documents for the

synchronous servo motor and other components such as

gear units and servo inverters.

2 Technical data

The technical data for synchronous servo motors, geared

motors and servo inverters that are used is indicated on the

relevant nameplates.

Acceleration / shock load in operation:

The following value for the shock load indicates the value up

to which the motor can be operated without loss of

functionality: 50 m/s² (5 g), 6 ms (maximum value as per DIN

EN 60068-2-27).

Brace the motor connection cable close to the motor so that

vibrations of the cable are not transferred to the motor.

When connecting the motors to drive units such as gear units

or pumps, take into consideration the permissible shock loads

and tilting torques of the units.

NOTICE

Damage to the motor.

XPrevent undue force on the motor such as impact, shock,

pressure or high acceleration.

Designs: IMB5, IMV1, IMV3

(DIN EN 60034-7)

Protection class: EZ, EZF, EZHD: IP56

EZHP: IP56 / IP66 (option)

EZH: IP54

EZS, EZM: IP40

(DIN EN 60529)

Protection class: I

Thermal class: 155 (F) (DIN EN 60034 / VDE 0530)

155 °C, heating ∆T = 100 K

Surrounding

temperature:

-15 °C to +40 °C (with water cooling +5

°C to +40 °C)

Installation altitude: up to 1000 meters above sea level

Cooling: For IC 410 convection cooling;

or optional IC 416 convection cooling

with forced ventilation (DIN EN 60034-

6), see 2.4.1;

or optionally for water cooling in the A-

side motor flange, see 2.4.2

Surface: Black matte as per RAL 9005

Please note! Repainting will change

the thermal properties and therefore

the performance limits of synchronous

servo motors.

Vibration intensity: as per DIN EN 60034-14 degree N

(half wedge balancing for shafts with

key).

Winding: Connection wires: U (U1) - black, V

(V1) - blue, W (W1) - red.

Connection

method:

see motor connection diagrams

Information

If brakes are installed, the holding torques may

be reduced by the shock load!

Operating manual

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

2

ID 442581_en.03

WE KEEP THINGS MOVING

07/2015

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

2.1 Thermal winding protection

Synchronous servo motors are equipped with a thermistor

(PTC thermistor) in the standard configuration. You can

optionally select the KTY 84-130 as thermal winding

protection.

Make note of the information specified in the SMS-EZ catalog

and in the commissioning instructions for the servo inverter.

CAUTION!

Overheating of the motor!

If the thermal winding protection is not connected, the motor

may overheat as a result.

Possible consequences: destruction of the motor, danger of

fire.

XYou must also take precautions to ensure that no hazard

could occur after the thermal winding protection has

responded and the motor has then cooled off by

unintentional automatic switching on of the motor again!

Always connect to the thermal winding protection. If the

thermal winding protection is not connected, the warranty is

rendered void!

2.1.1 Thermal winding protection PTC

NOTICE

The PTC thermistor is a low-voltage sensor with max. 7.5

VDC connection voltage.

Higher voltages will cause the thermistor and motor winding

to be destroyed.

Always connect to the thermistor. If the drive controller has no

option for PTC evaluation, appropriate triggering devices

must be used for this purpose.

2.1.2 Thermal winding protection KTY

(optional)

Synchronous servo motors can optionally be equipped with a

temperature-dependent KTY 84-130 resistor as a

temperature sensor in a winding. On the KTY the resistance

changes in proportion to the temperature of the winding.

The continuous sensor current icont = 2mA.

NOTICE

When making the KTY connection make certain the

polarity is correct! The installed KTY protects the

synchronous servo motors against overload only to a

limited degree. For this reason the I2t monitoring

parameter should be set to "WARNING".

XAvoid currents >4mA in the KTY circuit, as these could

result in excessively high self-heating of the temperature

sensor and damage to its insulation and to the motor

winding.

CAUTION!

ESD/EGB safety information

This product contains components that can be damaged or

destroyed by electrostatic discharges.

XAlways avoid directly touching the pin contacts with your

fingers!

2.2 Encoder systems

Synchronous servo motors have an encoder system

integrated into the motor for motor commutation and

recording of position. Two-pole resolvers are possible as well

as absolute encoders in various versions.

Note the relevant motor connection diagram and the details

on the motor nameplate. The encoder systems have been set

to the respective servo inverters in the factory.

WARNING!

Changes to the factory settings of encoder systems may

result in uncontrolled startup or vibrating movements of

the motor shaft.

XTherefore the factory settings must not be changed.

CAUTION!

ESD/EGB safety information

This product contains components that can be damaged or

destroyed by electrostatic discharges.

XAlways avoid directly touching the pin contacts with your

fingers!

Operating manual

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

307/2015

WE KEEP THINGS MOVING

ID 442581_en.03

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

2.3 Holding brake (optional)

A brake with permanent magnet excitation can be installed to

serve as a holding brake.

Power supply: 24 VDC ± 5 % smoothed.

The air gap of the brakes cannot be readjusted.

CAUTION!

An incorrect connection can cause the brake and motor

to be destroyed.

XPlease note when connecting the brake the associated

motor connection plan.

2.3.1 Brakes on gravity-loaded vertical axes

WARNING!

Unintentional lowering or falling of unsecured gravity-

loaded vertical axes can lead to serious personal injuries

or even death!

XThe holding brake of the motor does not provide

adequate safety for person in the hazardous area around

gravity-loaded vertical axes. Therefore the machine

manufacturer must take additional measures to minimize

risks (for example by providing a mechanical

substructure for maintenance work).

Check brake functionality for gravity-loaded vertical axes by

performing a cyclic brake test. To do this load the brake with

1.3 times the load torque. Make certain while doing this that

the suspended load of the vertical axis is already exerting

torque on the motor when it is at a standstill. Take this into

consideration when supplying power to the motor.

2.3.2 Testing holding brake

After making the connection check functionality and measure

the holding torque of the holding brake.

Please note, that the brake types are not defined as working

brakes. Therefore braking from full speed during emergency

stops (power failure or dangerous situations) and braking

while setup mode is active are only permitted within the

defined limits. For further details refer to catalog SMS-EZ.

To ensure that the brakes receive the full braking torque, they

are ground according to a special grinding cycles after final

assembly of the motors. If a brake is not required to exert any

friction over an extended period of time, the friction factor may

change as a result. This can occur due to accumulations of

flash rust or vapors resulting from the high motor

temperature. Slight material distortion may also occur as a

result of major fluctuations in temperature. All of these factors

affect the braking torque.

If the brake does not exhibit the required braking torque, it

must be reground.

To do this, drive the motor as well at max. 20 rpm. Release

and close the brake once per second so that the motor is

required to work against the closed brake for about 0.7

seconds. After about 20 cycles perform the process in the

reverse direction of rotation. In some circumstances you may

need to perform this process several times until the nominal

holding torque of the brake has been reestablished. If the

braking torque has not been reestablished after the grinding

process is repeated four times, other factors may also be

responsible (for example reaching the wear limit). Options for

automatically integrating a grinding routine, if available, are

described in the documentation for the relevant servo inverter

2.4 Motor cooling

CAUTION!

Overheating of the motor!

Reduced cooling, for example due to accumulation of dirt or

fan failure, will cause the motor to overheat, thereby resulting

in damage and/or destruction of the winding.

XTherefore check the functionality of the external fan

during commissioning and at regular intervals thereafter.

2.4.1 Forced-air cooling (optional)

External ventilation is optional and can also be retrofitted due

to the modular layout. This makes it possible to optimize

drives subsequently. Technical data can be found on the

nameplate and in the SMS-EZ catalog in the Motor section.

2.4.2 Water cooling (optional)

NOTICE

Material damage!

To prevent damage to the synchronous servo motor or your

machine, please observe the following:

XComply with the coolant specifications described in this

chapter.

XThe nominal data for synchronous servo motors with

water cooling refers to water as a coolant. If another

coolant is used, you will have to determine the nominal

data again.

XCoolant with fresh water from the public supply grid with

coolants, lubricants or cutting agents from the machining

process is not permitted.

XIf the temperature of the coolant is lower than the

surrounding temperature, interrupt the supply of coolant

when the motor is stopped for extended times to prevent

condensation water from forming.

Cooling circuit specification

Information

The brake must only be tested at a motor speed

of max. 20 rpm!

Feature Description

Coolant Water

Temperature at

inlet

+5 °C to +40 °C (max. 5 K below the

surrounding temperature)

Cooling circuit Closed, with recooling unit

Cleanliness Clear, with no suspended matter or dirt

(use particle filter ≤100 μm if necessary)

pH value 6.5 – 7.5

Hardness 1.43 – 2.5 mmol/l

Operating manual

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

4

ID 442581_en.03

WE KEEP THINGS MOVING

07/2015

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

3 Safety information

Also follow the instructions in the operating manuals as well

as applicable national, local and system-specific

requirements.

WARNING!

- Danger of electrical shock if unpainted parts conducting

voltage are touched.

- Moving and rotating parts can cause injuries

- Touching the gear unit and motor housing may cause

burns (surface temperatures of over 100°C are possible)

XThe machine manufacturer must provide suitable

protective measures. The connector or terminal box

cover of the motor must remain closed during operation.

All work on the drive must only be performed when no

current is present.

WARNING!

Incorrect operation, improper use, insufficient maintenance or

unauthorized removal of required covers can result in severe

injuries or material damage!

3.1 Personnel requirements

All work on the electrical equipment of the drive units must be

performed by qualified electricians. Installation, maintenance

and repairs of mechanical parts must be performed by fitters,

industrial mechanics or persons with comparable

qualifications.

3.2 In the event of disruptions

NOTICE

Changes compared to normal operation indicate that the

function has been impaired. This includes:

- Higher power consumption, temperatures or vibrations

- unusual noises or odors

- Leaks on the gear unit

- Monitoring devices responding

XIf any of these occur shut down the machine as quickly as

possible and notify the responsible qualified specialist

without delay.

NOTICE

The heat produced while a motor is in operation must be

dissipated into the surrounding air as efficiently as

possible.

Reduced heat dissipation is frequently the reason why

temperature monitoring devices respond.

Accumulations of dirt reduce the performance of the

motor.

XTherefore remove dirt that has settled on the surface of

the motor regularly.

3.3 Safety during installation and

maintenance

NOTICE

Damage to the motor.

XPrevent undue force on the motor such as impact, shock,

pressure or high acceleration.

WARNING!

Risk of injury due to moving parts.

XThe machine manufacturer must provide suitable

protective measures for personnel who must work in the

travel range of a motor within a system or machine,

especially under raised loads.

3.4 Safe function and EMC of the drive

system

The drive controller, cable and motor must be matched to

each other. Each product has specific electrical properties in

and of itself that may affect other products. Unsuitable

matches can therefore result in impermissibly high voltage

peaks on the motor or drive controller, which could destroy

the motor and cause malfunctions in the system. Legal

requirements for EMC (electromagnetic compatibility) must

also be observed.

STÖBER offers a product line of matching cables to ensure

this with suitable shielding technology and cable layout for the

power connection and the various encoder systems.

Using other connection cables and drive controllers may

result in voiding of any claims made under the warranty.

Salinity NaCl < 100 ppm, demineralized

Anticorrosive Maximum percentage 25 %,

neutral relative to AlCuMgPb F38, GG-

220HB

Operating

pressure

≤3.5 bar (provide a pressure relief valve in

the supply line)

Flow rate EZ4 – EZ5: 6 l/min ( 4.5 l/min)

EZ7 – EZ8: 7.5 l/min ( 5.0 l/min)

Feature Description

Operating manual

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

507/2015

WE KEEP THINGS MOVING

ID 442581_en.03

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

3.5 EZF, EZH, EZHD, EZHP synchronous

servo motors

NOTICE

The hollow shaft of the motors moves in relation to the

supply elements passing though during operation.

XThe supply elements must be protected so they do not

scrape against the hollow shaft.

CAUTION!

The hollow shaft can heat up to 100°C in operation.

XObserve the temperature for the supply elements that

pass through.

3.6 Servo spindle motors EZS/EZM

NOTICE

Destruction of the spindle system!

Removing the spindle shaft from the spindle nut will cause the

system to be destroyed and will void the warranty.

XNever remove the spindle shaft from the spindle nut!

WARNING!

Risk of injury due to moving parts!

Make certain before commissioning that

Xthe spindle shaft and motor are installed in the machine

before you place the drive in operation.

Xno persons will be endangered by the axial movement of

the spindle shaft or slide.

Xno one touches the spindle shaft by coming in physical

contact with it.

WARNING!

Crushing due to contact with the spindle shaft!

Turning the spindle shaft manually with your hand can lead to

crushing injuries.

XNever turn the spindle shaft manually.

CAUTION!

When EZM synchronous servo motors for screw drives

are in operation the spindle shaft moves axially in

reference to the motor.

XFix the spindle shaft in place and install it in the machine.

XScrew the motor together with the machine or moving

slide.

XMake certain there are no objects in the axial movement

range of the slide or spindle shaft.

4 Transport, storage and

preservation

The motors must not be exposed to acceleration levels or

working times of more than 300 m/s² (30 g) as an individual

shock load during transport as per EN 60 068-2-27. The

values for operation apply to long-term shock loads.

When transporting the motors make certain not to damage

the shafts and bearings with impacts.

The motors may only be stored in enclosed, dry rooms.

Storage in open air areas with a roof is only permitted for brief

periods. Protect the motors from all damaging environmental

effects and mechanical damage.

If you will be storing or transporting the system in which a

synchronous servo motor with water cooling is installed below

+3 °C, drain the water completely out of the cooling circuit in

advance.

Avoid extreme temperature fluctuations with high relative

humidity when the motors are being stored temporarily to

prevent formation of water from condensation. If long-term

storage is planned, protect the bare parts of the motor against

corrosion. Before placing a motor in operation again, have the

winding checked for its insulation resistance by an electrical

specialist.

Do not use the fan cover for transport or storage of the

motors. For transport, use the eyebolts on the motors,

together with suitable slings.

Eyebolts are provided only for lifting the motor without

additional attachments. When you remove the eyebolts after

installation, the threaded holes must be permanently closed

corresponding to the protection type of the motors.

Operating manual

EZ, EZF, EZH, EZHD, EZHP synchronous servo motors / EZS, EZM synchronous servo

motors for screw drive

6

ID 442581_en.03

WE KEEP THINGS MOVING

07/2015

en

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

www.stober.com

GERMANY

Tel.: ++49 7231 582-0

5 Mounting

Completely remove all corrosion protection on the shaft ends

prior to installation.

NOTICE

The lip seals of the shaft seal rings can be damaged by

the use of solvents.

XWhen removing the corrosion protection, make sure that

the lip seals of the shaft seal rings do not come into

contact with solvents.

Tab. 5-1: Assembly information for clamping units

6 Commissioning

Electrical connections provided by the customer must comply

with applicable regulations.

Note:

The electrical connection diagram and safety regulations are

with the delivery documents of the motor. Comply exactly with

the information and safety regulations therein.

WARNING!

Danger of injury from moving parts.

Before commissioning the drive unit, ensure that...

Xno one will be endangered by startup of the machine.

Xall protective guards and safety equipment have been

properly installed, also for a test run!

Xthe drive unit is not blocked.

Xthe brakes have been bled.

Xthe direction of rotation is correct.

Xcomponents mounted on the power take-off end are

sufficiently secured against centrifugal force (e.g. fitting

keys, coupling elements, etc.)

7 Maintenance

7.1 Servo spindle motors EZS/EZM

Axial angular ball bearings are installed on the A-side in the

EZS and EZM motors that directly absorb the threaded

spindle forces. These axial angular ball bearings are greased

with lithium soap grease GA28 at the factory. Under certain

application conditions, for example after a prolonged

downtime or for high humidity, relubrication may be required.

Mineral-based grease is suitable for relubrication, for

example Arcanol Multitop.

Protect the threaded spindle against dirt.

8 Troubleshooting

In the event of a malfunction of the drive unit, call the

STÖBER service department at 07231 582-1190 (-1191, -

1224, -1225) in order to locate the nearest STÖBER service

partner for further action.

In urgent cases outside of normal business hours, you

can call the STÖBER 24-hour service hotline at 01805

786323 / 01805 STOEBER

9 Spare parts

Include the following when ordering replacement parts:

– item no. of the part according to the replacement parts lis

– model designation according to the rating plate

– serial number according to rating plate

You can reach the STÖBER replacement parts service by

phone: 07231 582-1190 (-1191, -1224, -1225), or fax: 07231

582-1010.

Important notice: The replacement parts lists are not

assembly instructions! They are not binding for assembly of

the gear unit. Use only original replacement parts from

Stöber. Otherwise we will provide no guarantee and will

assume no liability for resulting damages!

10 Disposal

This product contains recyclable materials. Observe local

applicable regulations for disposal.

Mount the threaded spindle on the EZS motor:

1. Degrease the threaded spindle in the area where it

comes into contact with the clamping unit.

2. Insert the threaded spindle through the clamping set in

the hole of the motor shaft.

3. The wrench size and the tightening torque that

corresponds to the size of your EZS motor can be found

in the table Tab. 5-1:

4. Tighten the hexagonal screws of the clamping unit

successively in several tightening sequences (approx. 1/

4 revolution per sequence) properly with a torque

wrench until all of them are tightened to the prescribed

tightening torque. Make sure that both spring washers lie

parallel to each other (maximum permitted deviation 0.2

mm).

EZS5 EZS7

Thread M5 M6

Strength class 8.8 10.9

Wrench size [mm] 8 10

Tightening torque [Nm] 5 12

This manual suits for next models

6

Table of contents

Other Stober Servo Drive manuals

Popular Servo Drive manuals by other brands

Allen-Bradley

Allen-Bradley Kinetix 350 user manual

Servo Dynamics

Servo Dynamics 1224-BL user guide

Rockwell Automation

Rockwell Automation Reliance electric GV3000/SE installation manual

Mitsubishi

Mitsubishi MELDAS HS Series Specifications and Instruction Manual

Beckhoff

Beckhoff AM8100 Series operating instructions

Festo

Festo CMMT-AS Series Translation of the original instructions