Danfoss 176F6617 User manual

Other Danfoss Servo Drive manuals

Danfoss

Danfoss VLT 6002-6011 User manual

Danfoss

Danfoss VLT FC 103 User manual

Danfoss

Danfoss VLT series Operating instructions

Danfoss

Danfoss VLT ISD 410 User manual

Danfoss

Danfoss VLT AQUA Drive FC 200 Operating instructions

Danfoss

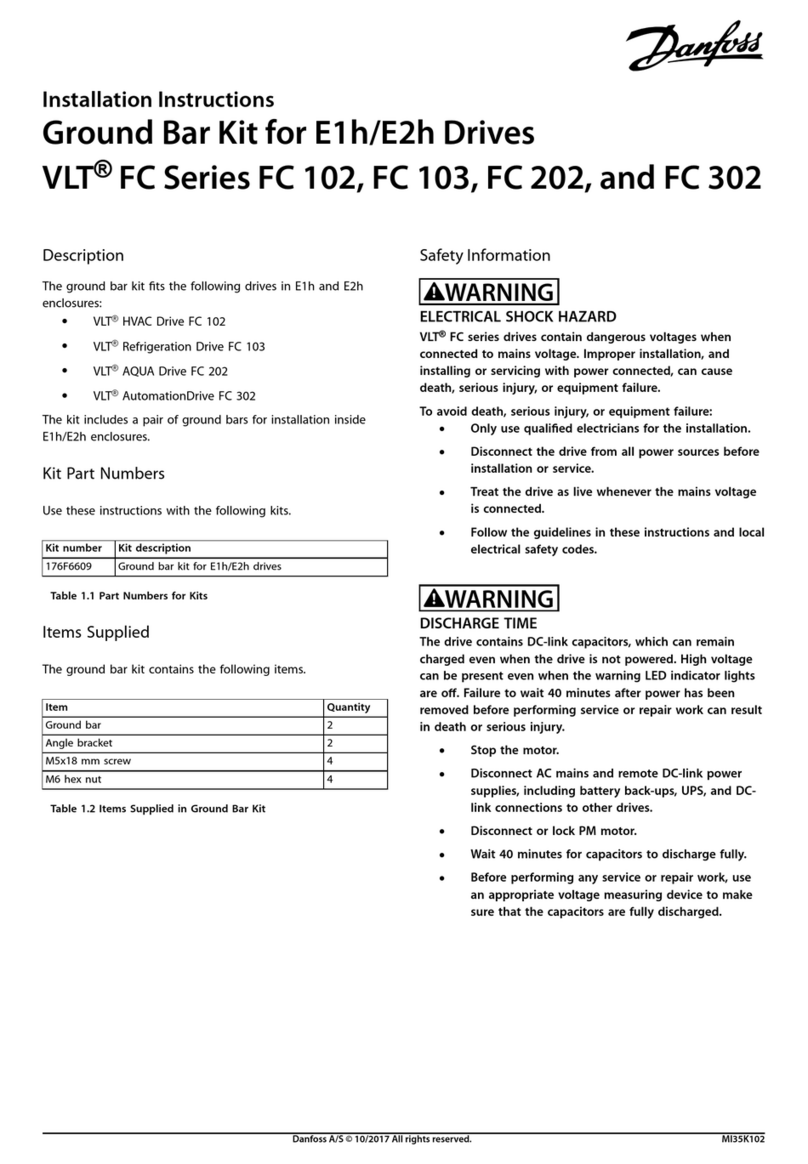

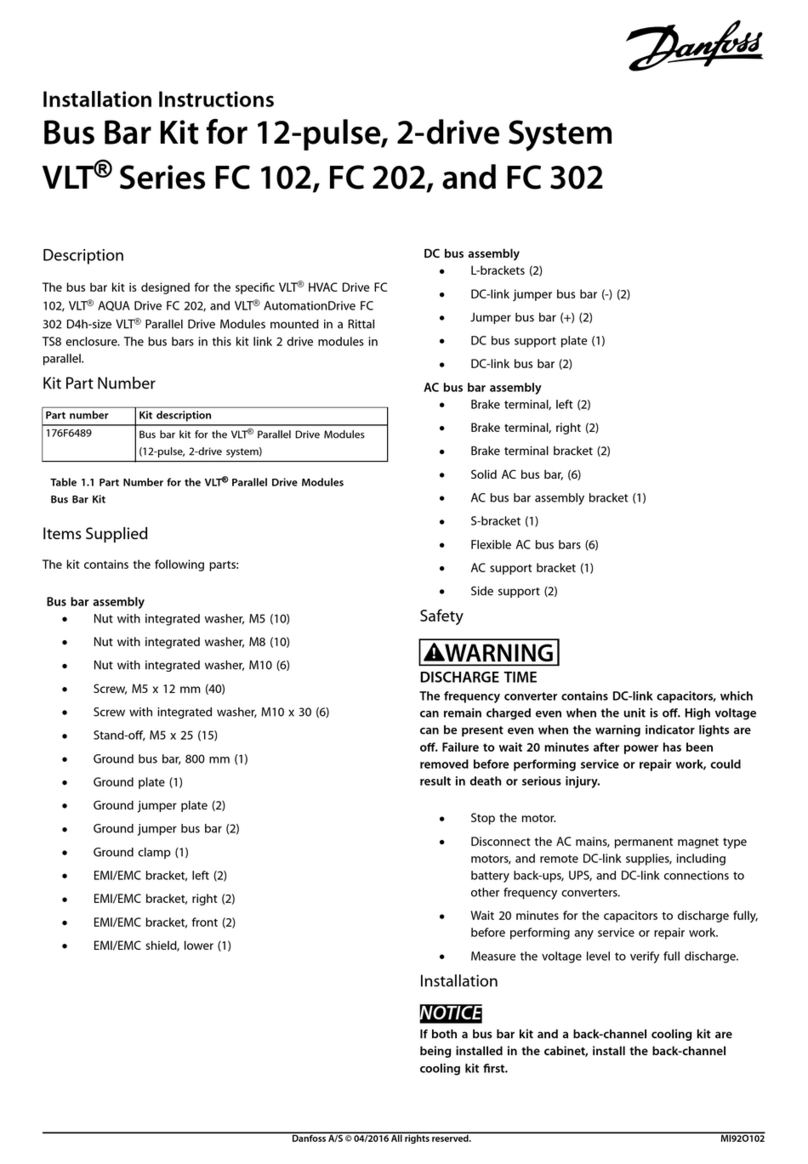

Danfoss 176F6489 User manual

Danfoss

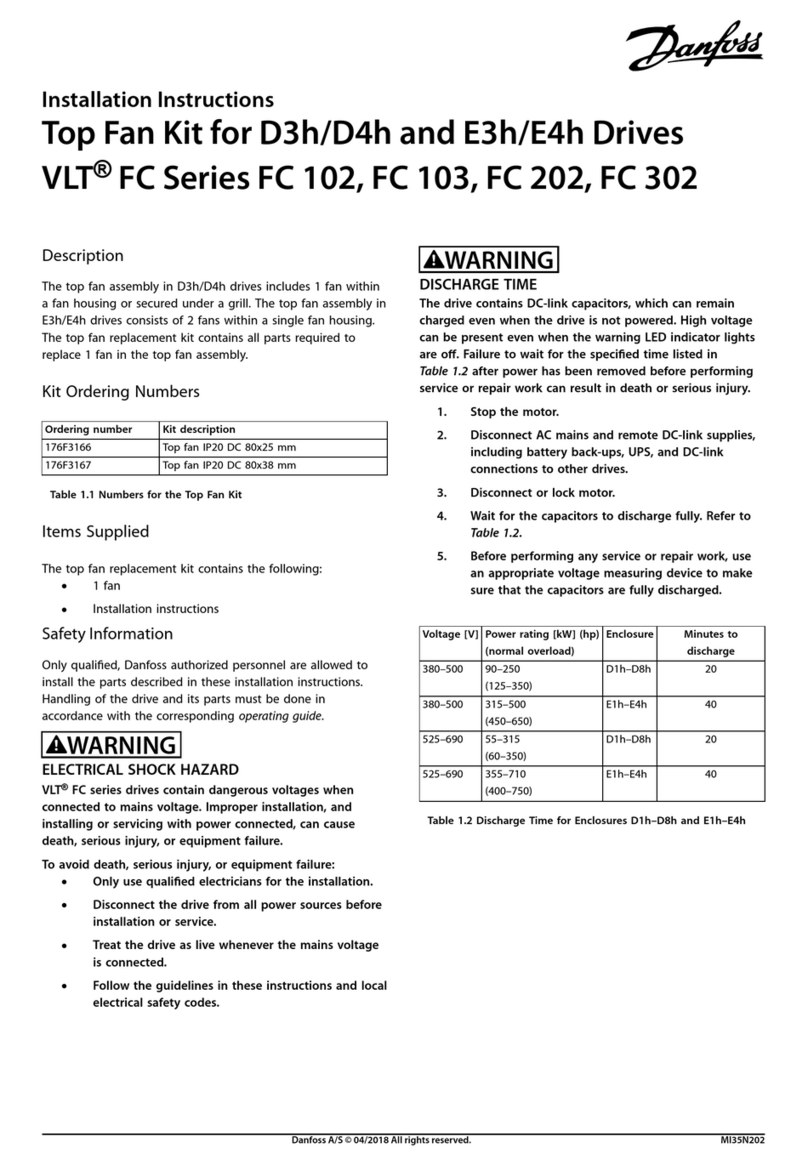

Danfoss 176F3166 User manual

Danfoss

Danfoss VLT Integrated Servo Drive ISD 510 System User manual

Danfoss

Danfoss 176F6764 User manual

Danfoss

Danfoss 176F6619 User manual

Danfoss

Danfoss 176F6494 User manual

Danfoss

Danfoss 176F6491 User manual

Danfoss

Danfoss VLT Integrated Servo Drive ISD 510 System Guide

Danfoss

Danfoss AME 25 User manual

Danfoss

Danfoss VLT ISD Connection Box User manual

Danfoss

Danfoss AMV 655 User manual

Danfoss

Danfoss 176F6748 User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 Guide

Danfoss

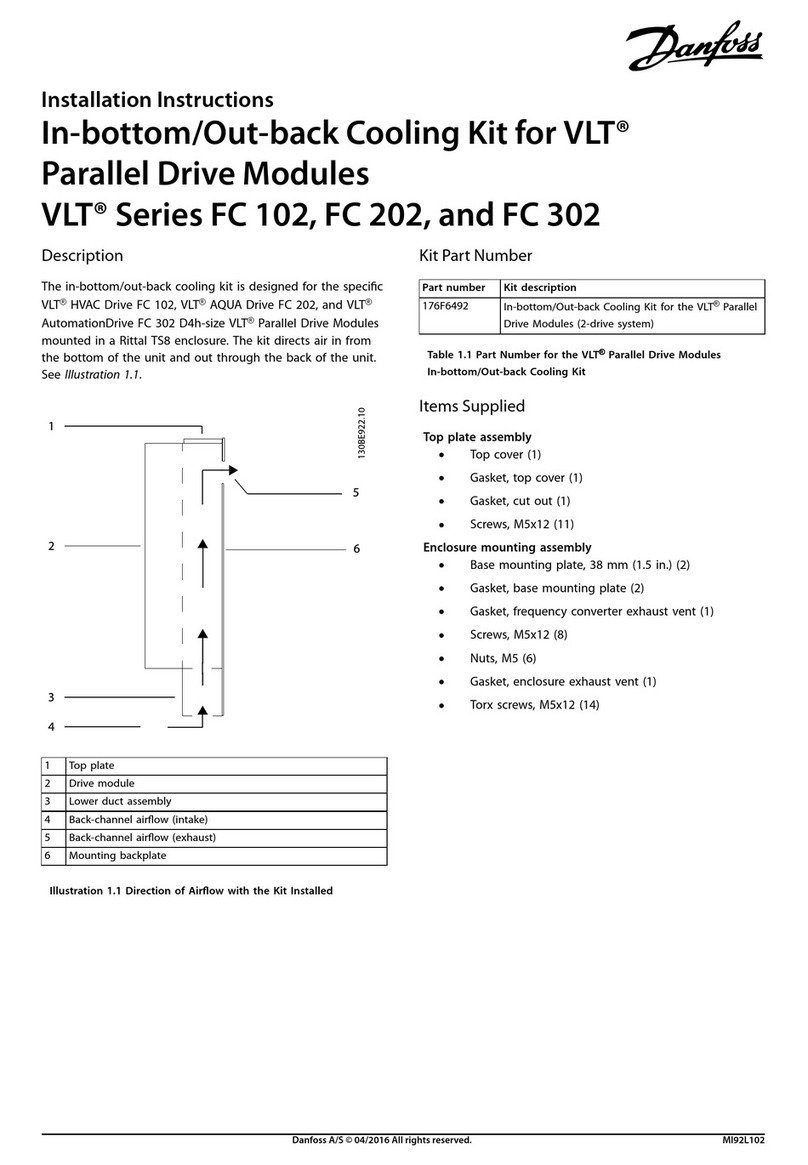

Danfoss 176F6492 User manual

Danfoss

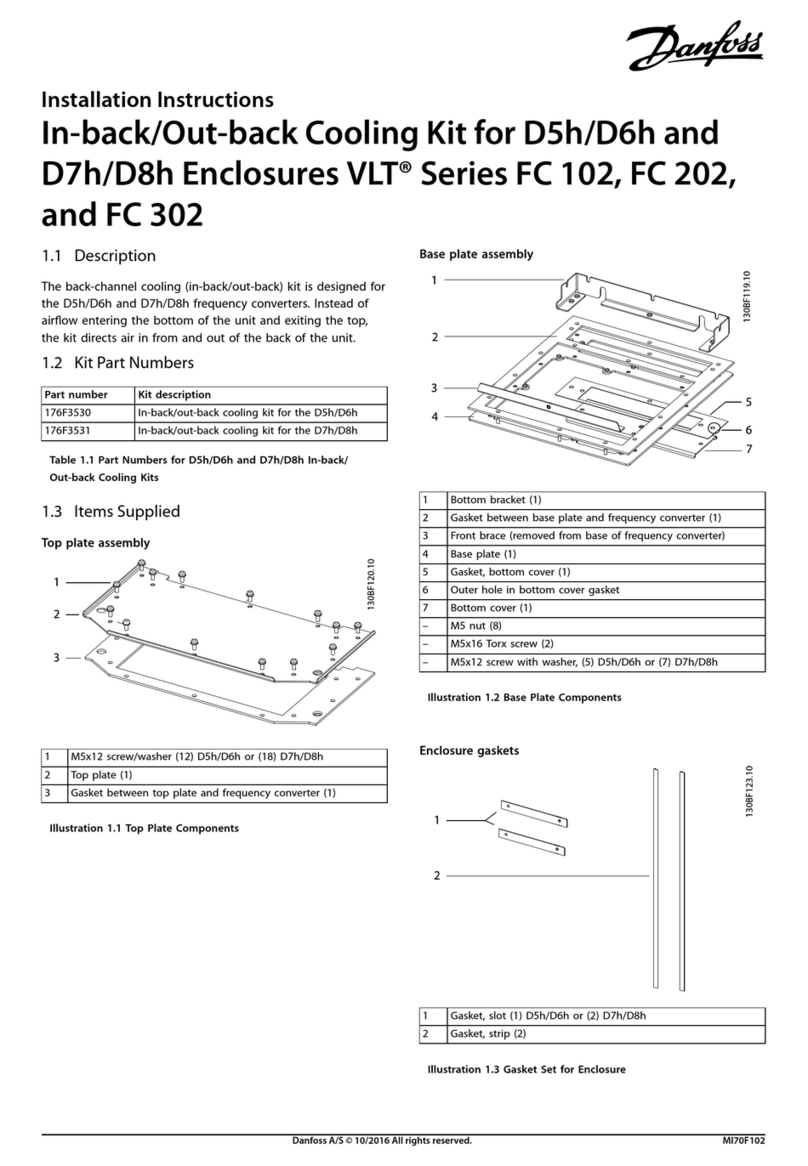

Danfoss 176F3530 User manual