P 1548 EN13 RE 01 3

Contents

1Introduction ..................................................................................................... 5

1.1 About this operating and maintenance manual .......................................... 5

1.2 Symbols in this operating and maintenance manual.................................. 5

2Use.................................................................................................................. 6

2.1 Intended use............................................................................................... 6

2.2 Improper use .............................................................................................. 6

3Safety instructions .......................................................................................... 7

3.1 General safety instructions ......................................................................... 7

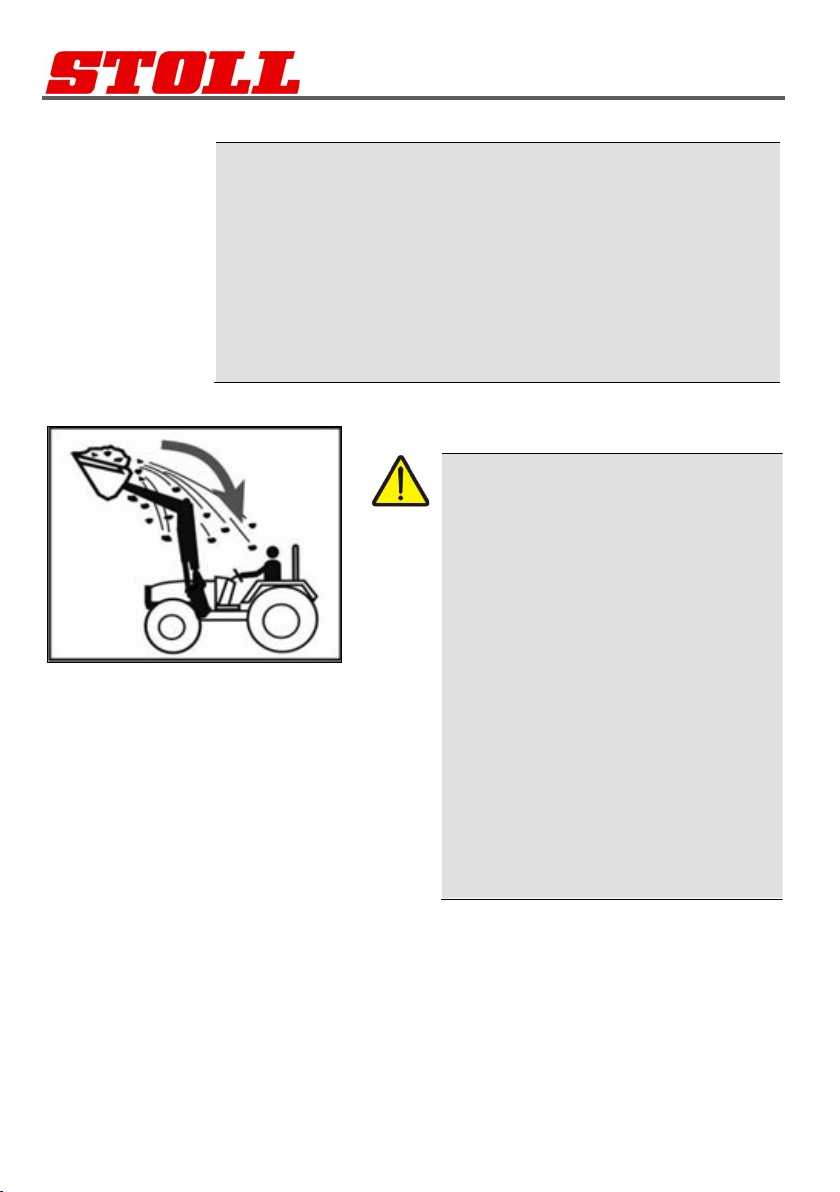

3.2 Safe handling of front loader tools.............................................................. 7

3.3 Special safety instructions for the wrapped bale handler......................... 12

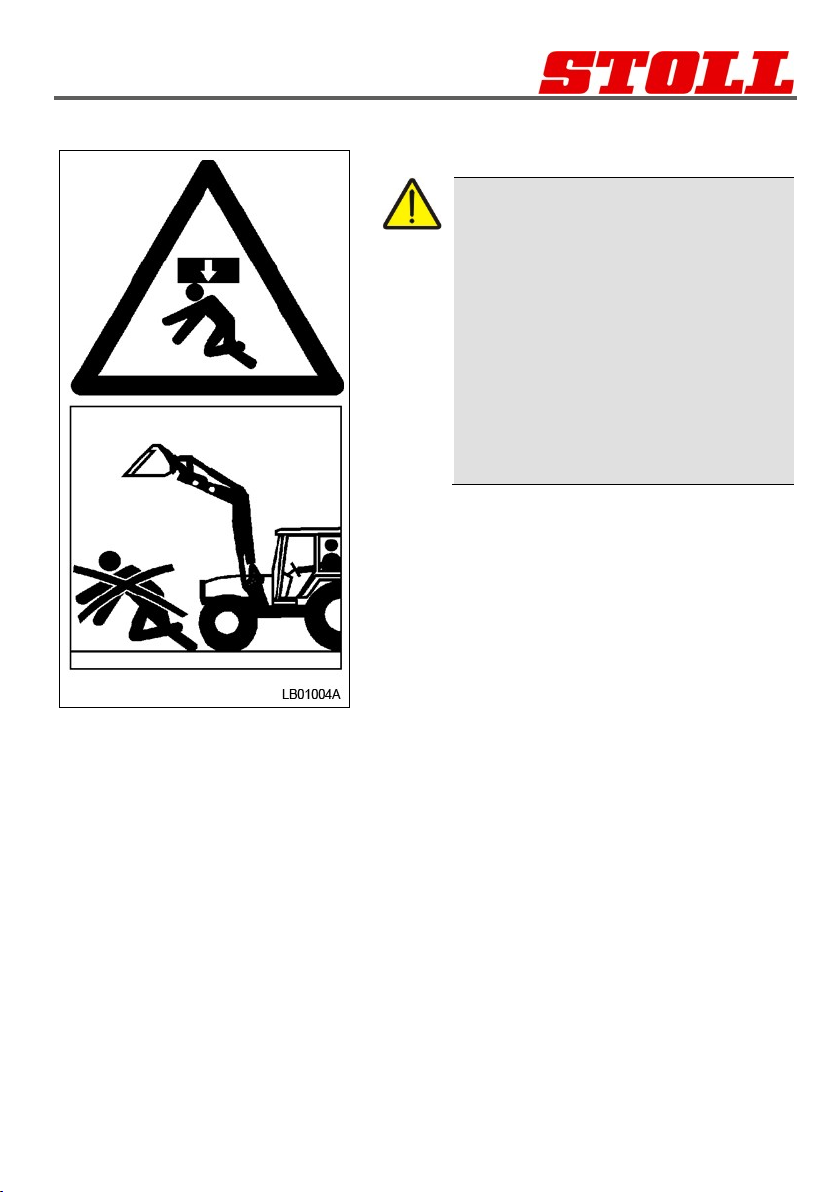

3.4 Safety labels ............................................................................................. 12

3.5 Position of the safety labels...................................................................... 14

4Description of the wrapped bale handler ...................................................... 15

4.1 Construction ............................................................................................. 15

4.2 General information .................................................................................. 16

4.3 Startup ...................................................................................................... 16

5Maintenance ................................................................................................. 18

5.1 Safety instructions .................................................................................... 18

5.1 Screw connections ................................................................................... 18

5.2 Hydraulics................................................................................................. 20

5.3 Regular maintenance work....................................................................... 20

6Declaration of Conformity ............................................................................. 21

7Notes............................................................................................................. 22