Stollmann BlueMod+C11/G2 Series Application guide

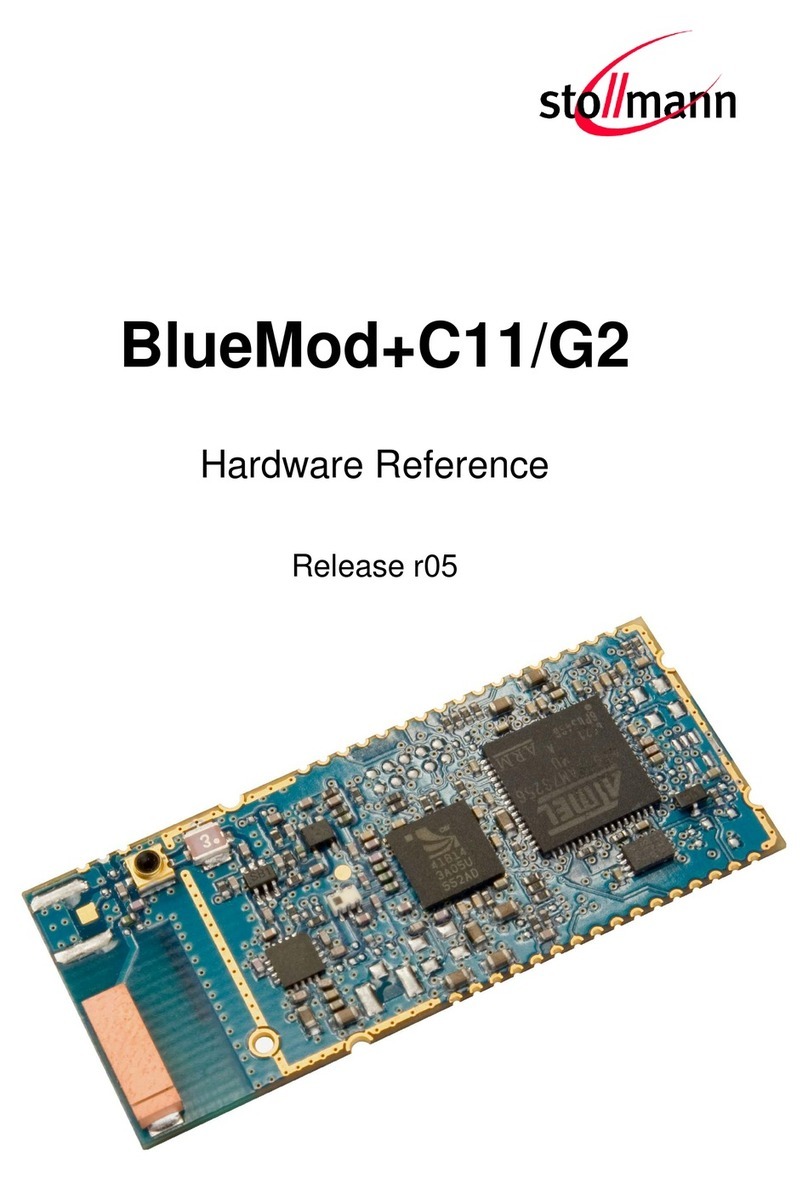

BlueMod+C11/G2

Hardware Reference

Release r09

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 2 of 54

Note

This product was developed for the purpose of communication. It is intended solely

for our clients for integration into their own technical products after careful examina-

tion by experienced technical personnel for its suitability for the intended purpose.

The product was not developed for or intended for use in any specific customer ap-

plication. It may have to be adapted to the specific intended modalities of use or

even replaced by other components in order to ensure flawless function in the re-

spective areas of application. Performance data (range, power requirements, foot-

print, etc.) may depend on the operating environment, the area of application, the

configuration, and method of control, as well as on other conditions of use; these

may deviate from the technical specifications, the Design Guide specifications, or

other product documentation. The actual performance characteristics can be deter-

mined only by measurements subsequent to integration in the target environment.

Variations in the performance data of mass-produced devices may occur due to

individual differences between such devices. Product samples were tested in a ref-

erence environment for compliance with the legal requirements applicable to the

reference environment. No representation is made regarding the compliance with

legal, regulatory, or other requirements in other environments. No representation

can be made and no warranty can be assumed regarding the suitability of the prod-

uct for a specific purpose. Stollmann reserves the right to make changes to the

product without prior notice or to replace the product with a successor model. Of

course, any changes to the product for which we have entered into a supply agree-

ment with our customers will be made only if, and only to the extent that, such

changes can reasonably be expected to be acceptable to our customers. No general

commitment will be made regarding periods of availability; these must be subject to

individual agreement. All agreements are subject to our Terms and Conditions for

Deliveries and Payments, a copy of which is available from Stollmann.

Trademarks

The Bluetooth®word mark and logos are owned by the Bluetooth SIG, Inc.. The

NFC word mark and logos are owned by the NFC Forum. Any use of such marks by

Stollmann E+V GmbH is under license. Other trademarks and trade names are

those of their respective owners.

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 3 of 54

Table of contents

1Introduction .......................................................................................................6

1.1 Feature Summary.........................................................................................7

1.2 Applications ..................................................................................................7

2Block Diagram...................................................................................................8

3Application Interface..........................................................................................9

3.1 Power Supply................................................................................................9

3.2 Power-up slew-rate.....................................................................................10

3.3 Power-On-Reset.........................................................................................11

3.4 Serial Interface............................................................................................11

3.4.1 Baudrate Deviation .............................................................................12

3.4.2 RS-485 Support..................................................................................13

3.5 GPIO Interface............................................................................................15

3.6 Alternate GPIO/IO Functions ......................................................................15

3.6.1 Master/Slave SPI Interface..................................................................16

3.6.2 Synchronous Serial Interface..............................................................16

3.6.3 Multi Channel PWM Controller............................................................17

3.6.4 Analog to Digital Converter .................................................................17

3.7 Bluetooth Radio Interface............................................................................18

3.8 JTAG ..........................................................................................................18

4Pin Description................................................................................................19

4.1 Pin Numbering............................................................................................19

4.2 Pin Description............................................................................................20

4.2.1 General Pin Description......................................................................20

4.2.2 Application Specific Pin Description ....................................................21

4.2.2.1 SPP Configuration........................................................................21

5Electrical Characteristics .................................................................................22

5.1 Absolute Maximum Ratings ........................................................................22

5.2 Environmental Requirements......................................................................22

5.3 Operating Conditions ..................................................................................23

5.3.1 RF and Supply Connections................................................................23

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 4 of 54

5.3.2 GPIO, JTAG; Serial IF and Test Pins..................................................24

5.3.3 USB Pins ............................................................................................24

5.4 Power consumption and power down modes..............................................24

5.4.1 SPP configuration...............................................................................25

5.4.1.1 Deep Sleep state..........................................................................25

5.4.1.2 Power down state.........................................................................25

5.4.1.3 Idle state.......................................................................................25

5.4.1.4 Power Consumption .....................................................................26

5.5 RF performance..........................................................................................27

5.5.1 Antenna-Gain and Radiation-Pattern ..................................................29

5.6 Power-up Time ...........................................................................................30

5.7 Wake-up Time ............................................................................................30

6Mechanical Characteristics..............................................................................31

6.1 Dimensions.................................................................................................31

6.2 Connectors .................................................................................................31

6.3 Recommended Land Pattern......................................................................32

6.4 Soldering Temperature-Time Profile (for lead-free re-flow soldering)..........33

6.5 Housing Guidelines.....................................................................................34

6.6 Antenna Issues...........................................................................................35

6.7 Safety Guidelines........................................................................................37

7Approvals/Certifications...................................................................................38

7.1 EC Declaration of conformity ......................................................................38

7.2 FCC Grant ..................................................................................................39

7.3 IC Grant......................................................................................................40

7.4 FCC Compliance and FCC Statement ........................................................41

7.4.1 Caution ...............................................................................................41

7.4.2 FCC Warning......................................................................................41

7.4.3 RF-exposure Statement......................................................................42

7.4.4 Labelling and re-test requirements for the End Product.......................42

7.5 Japanese Certification ................................................................................43

7.6 Taiwanese NCC Certification......................................................................45

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 5 of 54

7.6.1 NCC Certificate...................................................................................45

7.6.2 NCC Warning in Chinese....................................................................45

7.7 Bluetooth Qualification................................................................................46

7.8 RoHS Declaration.......................................................................................47

8Related Documents.........................................................................................48

9Packing ...........................................................................................................49

9.1 Package Label............................................................................................50

10 Ordering Information........................................................................................51

11 History.............................................................................................................52

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 6 of 54

1 Introduction

This Hardware Reference Guide documents how BlueMod+C11/G2 can be integrat-

ed into customer systems.

It addresses developers of hardware environments for BlueMod+C11/G2.

For detailed information about software interfaces refer to the software reference

manual.

For the latest version of this document please check the following URL:

http://www.stollmann.de/en/modules/bluetooth-products/bluemod-c11g2/

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 7 of 54

1.1 Feature Summary

•Bluetooth specification V2.0+EDR

•EDR compliant with V2.0 of specification for 2Mbps and 3Mbps modulation

modes

•Full Speed Bluetooth Operation with Full Piconet Support

•Scatternet Support

•Complete Co-location and Co-existence with 802.11 (AWMA, AFH and SFH)

•Fast Connection Setup

•RF output power class 1 with power control

•Supply Voltage 3.0V to 3.6V

•Internal crystal oscillator (26 MHz BC04 and 14,7456MHz for ARM7)

•Full Bluetooth data rate up to 2178 kbps asymmetric

•Support for very low-power modes (sleep and deep sleep)

•Full 8- to 128-bit encryption

•High sensitivity design ( -87 dBm typ.)

•Extra ARM7TDMI CPU for embedded profiles and/or application software

•Up to 17 GPIO lines

•USB 2.0 Full Speed Device Interface

•Master/Slave SPI

•Synchronous Serial Controller

•PWM Controller

•10 bit A/D Converter

•Power control

•5V tolerant I/Os

•-40°C to +85°C industrial operating temperature range

•RoHS Compliant

1.2 Applications

BlueMod+C11/G2 can be used in different applications.

Available applications are

•Bluetooth SPP

•BlueCluster Adhoc Networking

Please refer the software reference and interface specifications for further infor-

mation.

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 8 of 54

2 Block Diagram

ARM7

CPU

AT91SAM7S

256k

FLASH

64k

SRAM

Bluetooth

BC04-ROM

+3V3

EXT-RES#

RS-232 (TTL)

BlueMod+C11/G2

Class1

PA

HCI

SingleChip

+3V3-PA

GPIO

USB 2.0 FS

JTAG

TEST

Fig. 1 Block Diagram

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 9 of 54

3 Application Interface

3.1 Power Supply

The BlueMod+C11/G2 has two power supply rails, which always should be kept on

the same voltage level. Although we recommend using two different power rails, it is

as well possible to feed both rail from a single supply.

Pin # Signal Usage

C-13 3V3 Supply for digital and low power RF circuitry,

C-16 3V3-PA Supply for RF Amplifier

C-14 GND Reference Supply

C-15 GND Reference Supply

The pin order is made such that on the customer hardware directly at the pins of

each supply pair pins (C-13/C14) and pins (C-16/C-15) a 10uF X5R ceramic capaci-

tor with for example a 1206 footprint can be placed for decoupling. It is recommend-

ed to add further smaller value ceramic capacitors. These values depend on noise

frequencies on the supply rail. The following picture shows a sample layout with two

linear regulators in SOT23-5 housings and various capacitors in SMT shapes 0402,

0805 and 1206.

Fig. 2 Sample Layout Power Supply

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 10 of 54

Each supply rail should be fed with 3,3V, Range 3,0V to 3,6V incl. noise, low noise

from a linear regulator with fast transient response. Stollmann suggest using two

pcs.

TOREX: XC6204B332MR

regulators, so that the fast current transients of the class1 RF power amplifier do not

interfere with sensitive PLL circuitry of the low power RF circuitry.

For layout guidelines please see sample implementation Stollmann reference design

BlueMod+Eval/C11/G2.

Excessive noise or too slow current transient response on the supply rails may have

an impact on the RF performance.

3.2 Power-up slew-rate

The Power up slew-rate for the BlueMod+C11/G2 must be more then 6V/ms for

proper startup of the AT91SAM7S Controller used on the BlueMod+C11/G2.

Figure 3 shows an example circuit for a power supply. The Output Voltage of the

Regulator is enabled by the Threshold Voltage of a RESET-Circuit, when VCC

Startup ramp reaches a valid Voltage.

Vin

RESET

Enable

Vout

TOREX: XC6204B332MR

VCC 3V3

Vth ~ 2.8 - 3.3V

Figure 3 power supply example circuit

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 11 of 54

3.3 Power-On-Reset

The BlueMod+C11/G2 is equipped with circuitry for generating Power-On Reset and

to provide under-voltage supervision. An integrated circuit type Maxim DS1818R

provides this functionality.

A reset is generated if the 3.3V supply rail including noise falls below 2,8V to 2,97V.

Via Pin A-1 an external reset can be generated by holding EXT-RES# at ≤ 0.3V for

≥10ms. A 74LVC14 Schmitt Trigger gate with a 1kR5/10nF low-pass filter at the

input is implemented to avoid false reset pulse recognition due to EMC effects.

If EXT-RES# is not used, it may be left open or tied to VCC.

3.4 Serial Interface

The interface functionally corresponds to the norm V.24 / RS-232 but has TTL-level.

•Transmission speeds 300 bps – 921600 bps (asynchronous)

•Character representation: 7 to 9 Bit, even, odd, mark, space or no Parity, 1, 1.5

or 2 stop bits

•Half duplex or full duplex

•Hardware flow-control (RTS/CTS)

Note: All signals of the serial interface are named according to the EIA232 DCE

definition.

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 12 of 54

3.4.1 Baudrate Deviation

The following table shows the deviation in percent of the standard data rates. The

deviation is caused by the inaccuracy of the crystal oscillator.

Data Rate (bits/s) Deviation (%)

300

±0.5

600

1200

2400

4800

9600

19200

38400

57600

115200

230400

460800

921600

Note: The total deviation of sender and receiver shall not exceed 2.5 % to prevent

loss of data.

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 13 of 54

3.4.2 RS-485 Support

For RS-485 support the serial interface has to be connected to an external Trans-

ceiver, we suggest the MAX3491E from Maxim Integrated Products, due to it sup-

ports full duplex transmissions.

UART_RX

UART_TX

BlueMod+C11/G2

Connections in Full Duplex Mode

D

R

RO

RE

DI

DE

GND

A

B

Z

Y

VCC GND

2

3

4

5

14 6,7

9

10

11

12

+

+3,3V

MAX3491E

UART_CTS

GND

UART_RX

UART_TX

BlueMod+C11/G2

Connections in Half Duplex Mode

D

R

RO

RE

DI

DE

GND

A

B

Z

Y

VCC GND

2

3

4

5

14 6,7

9

10

11

12

+

+3,3V

MAX3491E

UART_CTS

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 14 of 54

CTS

Tbd

b

y

tes

max

Tbd

TXD

RTS

Tbd

h t

Tbd

S

RXD

Figure 4. UART Timing Diagram

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 15 of 54

3.5 GPIO Interface

All user signals, except for EXT-RES#, which is routed via an Schmitt Trigger gate,

are connected directly to port pins of the ATMEL AT91SAM7S256 CPU. Except for

JTAG, USB signals DP, DM and GPIO(4,10), no additional pull-up or down resistors

are implemented, so that the I/O characteristics of the ATMEL CPU apply. These

are

•3V3 logic 5V tolerant

•VIL max = 0.8V, VIH min = 2.0V, VIH max = 5.5V

•VOH min = VCC – 0.4V @ IO= 8mA, VOL < 0.4V @ IO= 8mA

•LED’s can be driven directly on specific GPIO lines when Iostays below 8mA

and the specific GPIO line is specified for Iomax = 8mA.

All current consumption data in this document are given with IO(GPIO) = 0mA

See chapter 5 Electrical Characteristics for detailed information.

•All I/O signals except USB, GPIO(4) with 47k5 pull-down, GPIO(10) with 10k

pull-up and JTAG each with 100k pull-up except for TDO are connected directly

from the AT91SAM7S pins to the user accessible stamp pins. Therefore, the

electrical characteristics of the I/O pins are programmable in regard to direction,

pull-up resistor, function, push-pull or open drain. Please see specific applica-

tion software documentation for details. After reset, all GPIOs have pull-ups ac-

tivated. GPIO10, GPIO8 and TXD have 50kR to 300kR pull-ups, all other I/Os

have 5kR to 20kR pull-ups

•In reference to the ATMEL AT01SAM7S256 Errata Sheet 6173B-ATARM item

no. 18, the on-chip pull-up resistors on all GPIO pins, except for GPIO[8,10,16]

pull to min. (VDD -0,65V) rsp. to max. (VDD -0,45V). VDD is 3,0V to 3,6V. Use

of ext. pull-ups on open inputs is recommended.

3.6 Alternate GPIO/IO Functions

Application specific GPIO or IO pins can be programmed to alternate functions.

Then pin function and direction are fixed for the activated function block. Many

GPIOs are used by the SPP application. See chapter SPP Configuration. Probably

some of them can be released for use by other function blocks. Co-functionality of

blocks has to be carefully considered, because pin multiplexing possibilities are lim-

ited by the ATMEL AT91SAM7S CPU and using a function block often causes that

other function blocks can’t be used at the same time. Please refer to the ATMEL

data sheet AT91SAM7Sxxx Rev. F for complete information. The possibilities de-

picted in the following chapters are a subset only.

The following function blocks may be usable on the BlueMod+C11/G2:

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 16 of 54

3.6.1 Master/Slave SPI Interface

Pin # GPIO#

IO Name Alternative

Signal Name Description Direction

Master Slave

A5 GPIO1 MISO Master In Slave Out IN OUT

A4 GPIO0 MOSI Master Out Slave In OUT IN

A3 GPIO3 SPCK Serial Clock OUT IN

A6 GPIO2 NPCS0 Peripheral. Chip Select OUT IN

Clock polarity and phase are programmable. The chip select signal is low active.

3.6.2 Synchronous Serial Interface

The Synchronous Serial Interface is capable of handling the protocols I2S, Short

Frame Sync, Long Frame Sync and other Telecom protocols. Receiver and trans-

mitter do act independently. Due to multiplexing interdependencies, the SSC is only

available with the Transmitter clock signal TK used for both directions if the UART IF

is enabled..

Pin # GPIO#

IO Name Alternative

Signal Name Description Direction

Case 1 Case 2

A16 GPIO16 RF Receiver Frame Sync IN OUT

A12 GPIO10 RD Receiver Data IN IN

C7 TXD RK Receiver Clock IN OUT

A13 GPIO7 TF Transmitter Frame Sync IN OUT

A11 GPIO8 TD Transmitter Data OUT OUT

A14 GPIO9 TK Transmitter Clock IN OUT

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 17 of 54

3.6.3 Multi Channel PWM Controller

Each PWM channel can be programmed individually in regard to IO pin assignment

and PWM functionality. Therefore, PWM application designers can choose a proper

channel and pin for their application with the chance not to interfere with other nec-

essary interfaces.

Pin # GPIO#

IO Name Alternative

Signal Name Description Direction

A6 GPIO2 PWM0 PWM Waveform Out CH0 OUT

C9 GPIO5 PWM0 PWM Waveform Out CH0 OUT

C5 /CTS PWM1 PWM Waveform Out CH1 OUT

A5 GPIO1 PWM1 PWM Waveform Out CH1 OUT

C2 GPIO15 PWM1 PWM Waveform Out CH1 OUT

C4 /RTS PWM2 PWM Waveform Out CH2 OUT

A4 GPIO0 PWM2 PWM Waveform Out CH2 OUT

C8 GPIO6 PWM2 PWM Waveform Out CH2 OUT

A3 GPIO3 PWM3 PWM Waveform Out CH3 OUT

3.6.4 Analog to Digital Converter

Three ADC channels with 8 to 10bit resolution in reference to 1.8V are available. A

wide range of trigger sources and programmable S&H timing are available.

Pin # GPIO#

IO Name Alternative

Signal Name Description Direction

A16 GPIO16 AD3 ADC channel

3 In ana-

logue

A12 GPIO10 AD0 ADC channel

0 In ana-

logue

A11 GPIO8 AD1 ADC channel

1 In ana-

logue

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 18 of 54

3.7 Bluetooth Radio Interface

The BlueMod+C11/G2 offers three population variants for the antenna

1) The BlueMod+C11/G2/AI variant presents an integrated ceramic antenna.

Pins A-26 and A28 shall always be connected directly to the reference GND plane

3) The BlueMod+C11/G2/AP variant presents a 50Ω impedance antenna interface

on pin A-27 with adjacent GND pins A-26 and A-28. In this case Pin A-26 and A28

shall be connected directly to the reference GND plane. Signal routing of the RF

signal on customer PCB has to be implemented with 50R micro-strip line technique.

If the antenna performance does not meet your requirements or you need antenna

support, please contact Stollmann.

3.8 JTAG

For software development purposes a JTAG interface, connected to the ATMEL

MCU is available.

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 19 of 54

4 Pin Description

The BlueMod+C11/G2 module is soldered on customers PCB via stamp pins locat-

ed on the module PCB edges.

4.1 Pin Numbering

Top View

BlueMod+C11/G2

Hardware Reference

Release r09 www.stollmann.de Page 20 of 54

4.2 Pin Description

4.2.1 General Pin Description

Pin Signal Type Ac-

tive Description

A1 /EXT_RES I-PU L Reset low active internal 47k pull-up

A2 GPIO11 (DTXD) I/O-PU General Purpose IO – Debug Uart Output

A3 GPIO3 I/O-PU General Purpose IO

A4 GPIO0 I/O-PU General Purpose IO

A5 GPIO1 I/O-PU General Purpose IO

A6 GPIO2 I/O-PU General Purpose IO

A7 ATDO O JTAG test data output

A8 ATCK I-PU JTAG clock

A9 ATMS I-PU JTAG mode select

A10 ATDI I-PU JTAG test data input

A11 GPIO8 I/O-PU General Purpose IO

A12 GPIO10 I/O-PU General Purpose IO - internal 10k pull-up

A13 GPIO7 I/O-PU General Purpose IO

A14 GPIO9 I/O-PU General Purpose IO

A15 GPIO12 (DRXD) I/O-PU General Purpose IO – Debug Uart Input

A16 GPIO16 I/O-PU General Purpose IO

A17 reserved do not connect-

A26 ANT_GND Antenna ground, connect directly to plane

A27 ANT 50 Ohm Rx/Tx connection to antenna

A28 ANT_GND Antenna ground, connect directly to plane

C1 GPIO14 I/O-PU General Purpose IO

C2 GPIO15 I/O-PU General Purpose IO

C3 GPIO13 I/O-PU General Purpose IO

C4 /RTS I-PU L Request to send

C5 /CTS O L Clear to send

C6 RXD O Receive Data

C7 TXD I-PU Transmit Data

C8 GPIO6 I/O-PU General Purpose IO

C9 GPIO5 I/O-PU General Purpose IO

C10 GPIO4 I/O-PD General Purpose IO - internal 47k pull-down

C11 USB_DM I/O USB D-, Data pin

C12 USB_DP I/O USB D+, Data pin

C13 VCC P +3.3V Power digital and low power RF

C14 GND P GND

C15 GND P GND

C16 VCC P +3.3V Power RF amplifier

Type: PU – pulled up on Module; PD pulled down on Module

Notes: General) Pull-up resistor on module pulls to min. (VDD -0,65V) to max. (VDD -0,45V)

VDD is 3,0V to 3,6V. Use of ext. pull-ups on open inputs is recommended

Other manuals for BlueMod+C11/G2 Series

1

Table of contents

Other Stollmann Microcontroller manuals

Popular Microcontroller manuals by other brands

Microchip Technology

Microchip Technology SAM Series Troubleshooting Checklist

Infineon

Infineon TC2X5 user manual

Espressif

Espressif ESP32-C6-DevKitC-1 user guide

Infineon

Infineon FX3 EZ-USB DEMO_FX3_LVDS_CAM01 manual

Huawei

Huawei ViewPoint 8650C Series user guide

Texas Instruments

Texas Instruments Serial Programming Adapter MSP430 user guide