- 3 -

FOREWORD ................................................................................................................................................... 4

TECHNICAL DATA ........................................................................................................................................ 5 - 8

Machine Specifications ........................................................................................................................... 6 - 7

Noise and Vibration Data ........................................................................................................................ 8

HEALTH & SAFETY ..................................................................................................................................... 9 - 15

Safety Use ............................................................................................................................................... 10

Safety Preca tions ................................................................................................................................... 11 - 15

OPERATION ................................................................................................................................................... 17 - 24

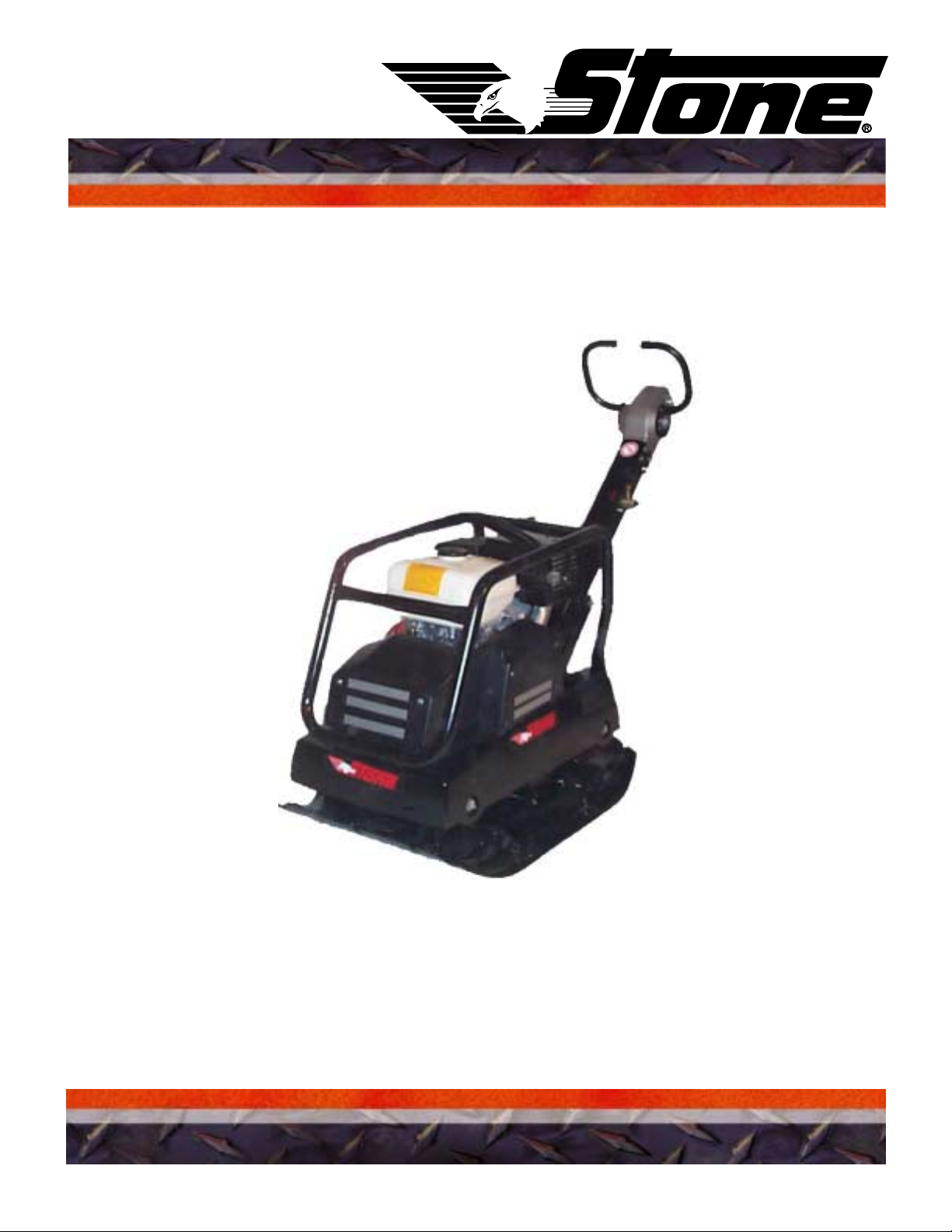

Description .............................................................................................................................................. 18

Improper Use .......................................................................................................................................... 18

Who Is Allowed To Operate The Machine? ........................................................................................... 18

Conversions And Modifications To The Machine .................................................................................. 18

Safety Information In The Operating And Maintenance Instr ctions ..................................................... 18

Transporting The Machine ...................................................................................................................... 19

Starting The Machine .............................................................................................................................. 19

Prior to starting................................................................................................................................ 19

Starting ............................................................................................................................................ 19

Starting with battery j mp leads ...................................................................................................... 19

Starting in enclosed spaces, t nnels, mines, or deep ditches ........................................................... 19

Machine Control ..................................................................................................................................... 20

Parking The Machine .............................................................................................................................. 20

Filling F el .............................................................................................................................................. 20

Maintenance and Repairs ........................................................................................................................ 20 - 21

Handling Batteries .................................................................................................................................. 21

Testing ..................................................................................................................................................... 21

Eq ipment Overview .............................................................................................................................. 21

Operating Control At The Tow-Bar ........................................................................................................ 21 - 22

Adj sting The Tow-Bar .......................................................................................................................... 22

Operating The Engine (Honda) ............................................................................................................... 22

Starting the engine ........................................................................................................................... 22

Operating The Engine (Hatz) .................................................................................................................. 23

Starting the engine ........................................................................................................................... 23

Switching off the engine .................................................................................................................. 23

Electric start (Hatz only) ................................................................................................................. 23

Switching off the engine .................................................................................................................. 23 - 24

Operation ................................................................................................................................................ 24

Loading And Transportation ................................................................................................................... 24

MAINTENANCE ............................................................................................................................................. 25 - 28

General Notes ......................................................................................................................................... 26

Maintenance Sched le ............................................................................................................................ 27

L brication Sched le .............................................................................................................................. 28

Alternative L be Oil Table ..................................................................................................................... 28

Maintenance Work (Honda Engine) ....................................................................................................... 29

Filing p with f el ........................................................................................................................... 29

Checking the engine oil level .......................................................................................................... 29

Cleaning the air filter element ......................................................................................................... 29

Maintenance Work (Hatz Engine)........................................................................................................... 30

Filling p with f el .......................................................................................................................... 30

Checking the engine oil level .......................................................................................................... 30

Cleaning the dry air filter ................................................................................................................ 30 - 31

Cleaning .................................................................................................................................................. 31

CALIFORNIA PROPOSITION 65 WARNING ........................................................................................... 35

TABLE of CONTENTS RP850G / RP850D