StoneAge SA 1900 User manual

AIR POWERED ROTARY

WATERBLAST TOOL

SA 1900 and 1909

OPERATION AND MAINTENANCE

MANUAL

466 S. Skylane Dr. Durango, Colorado 81303 (970) 259-2869 Phone (970) 259-2868 Fax

www.stoneagetools.com [email protected]

05/04

TABLE OF CONTENTS

1.0 INTRODUCTION

2.0 SAFETY WARNING

3.0 DESCRIPTION

4.0 PARTS LIST

5.0 ASSEMBLY DRAWINGS

6.0 MAINTENANCE

7.0 WARRANTY

APPENDIX

A. AIR MOTOR

B. WATER SWIVEL

1.0 INTRODUCTION

This manual was prepared to provide the operator with the basic information needed to operate and

service this equipment. The operating recommendations in the manual will ensure that you receive

satisfactory performance. All operating personnel responsible for the care of this equipment should be

familiar with the information in this manual.

If you have any questions or problems with this equipment, please contact the distributor you obtained the

product from, or the manufacturer:

StoneAge, Inc.

466 S. Skylane Dr.

Durango, CO 81303

970-259-2869 Phone 970-259-2868 Fax

www.stoneagetools.com

2.0 SAFETY WARNING

Operations with high pressure water can be potentially dangerous if caution is not exercised. Please read

and follow all of these instructions, in addition to the guidelines in the WJTA Recommended Practices

handbook.

2.1 Only competent and trained persons should operate this equipment.

2.2 Do not exceed the maximum operating pressure specified for any component in a system.

2.3 This equipment should always be used with an operator controlled dump mechanism to

release the high pressure water.

2.4 The immediate work area should be marked off to keep out untrained persons.

2.5 All personnel in the area should wear eye and hearing protection, as well as other

protective clothing in accordance with specific conditions.

2.6 Inspect the equipment for visible signs of deterioration, damage, or improper assembly.

Do not operate until repaired. Make sure all threaded connections are tight and leak free.

2.7 Check to see that all control functions work properly before going to high pressure.

2.8 If it is necessary to have a person work near the cleaning jets, then it is this person who

should have control of the pressure dump mechanism.

2.9 The tool should be securely supported. Strong back thrust is created by waterjets and

these forces can become unbalanced if a nozzle should become plugged.

3.0 DESCRIPTION

The SA 1900/1909 is an air powered rotary tool for high pressure fluids use. It can apply the power of

water jets to drilling or cleaning jobs.

The tool is designed to be used with all common waterblast pumps and compressed air systems. The unit

consists of two main components: the air motor and the water swivel. The tool can be used with all

standard lace rods and nozzle tips. Special cutting bits with jets are available.

3.1 WATER SWIVEL

The MODEL HI high pressure water swivel is constructed of hardened stainless steel. Two longwearing

high pressure seals offer many hours of leak-free operation. The unit is easy to work on, no special

equipment or adjustments are necessary. The swivel can handle 20/18 gpm of flow, respectively for the

SA 1900/1909, with only 400 psi of pressure loss (Cv = 1.0/.9 respectively) at a working pressure up to

15,000/22,000 psi, respectively. The input port for the SA 1900 is 3/8 NPT female. The input port for the

SA 1909 is female Autoclave Engineering 9/16 High Pressure, with an adapter to female 9/16 Medium

Pressure.

The output shaft for the SA 1900 is male 3/8 NPT thread. Adaptors for the SA 1900 are available to fit

standard lance rods. The output shaft for the SA 1909 is male, Autoclave Engineering 9/16 High

Pressure. Adapters for the SA 1909 are available to fit 1/4, 3/8, and 9/16 Medium Pressure lances.

LANCE LANCE ADAPTOR COLLET

SIZE O.D. THREAD PART NUMBER PART NUMBER

1/4 tubing .250 1/4-28 SA 056-S4 GP 075-250

3/8 tubing .375 1/8 npt SA 056-P6--P2 GP 075-375

1/8 pipe .405 1/8 npt SA 056-P6--P2 GP 075-406

1/4 pipe .540 1/4 npt SA 056-P6--P4 GP 075-546

9/16 tubing .562 1/4 npt SA 056-P6--P4 GP 075-562

LANCE SIZE COUPLER FITTING COLLAR

1/4 AF 073-MP4MP9 AF 072-MP4 AF 071-MP4

3/8 AF 073-MP6MP9 AF 072-MP6 AF 071-MP6

9/16 AF 073-MP9MP9 AF 072-MP9 AF 071-MP9

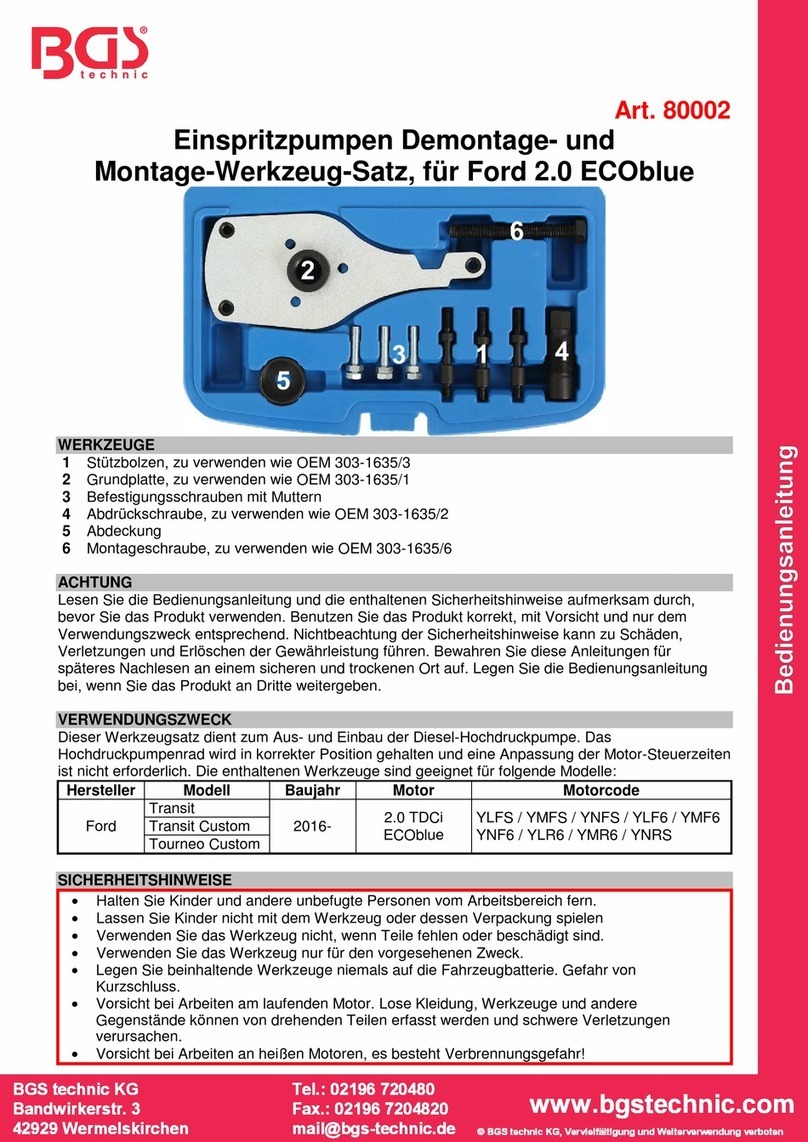

4.0 PARTS LIST

SA 1900

Part # Description Qty

SA 019 AIR MOTOR 1

SA 040 SIOUX COUPLER 1

HI P6-P6 HI-P ASSEMBLY 1

SA 056 P6-S4 LANCE ADAPT 1/4 OD Optional

SA 056-P6--P2 LANCE ADAPT 1/8 Pipe 1

SA 056-P6-P4 LANCE ADAPT 1/4 Pipe Optional

GP 075-X COLLET (X denotes size) 1

GP 076 NUT 1

HI 061 OVERHAUL KIT Optional

SA 1909

Part # Description Qty

SA 019 AIR MOTOR 1

SA 040 SIOUX COUPLER 1

HI-MP9MP9 HI-MP9 ASSEMBLY 1

AF 073-MP4MP9

LANCE CPLR 1/4 MP Tubing Optional

AF 073-MP6MP9

LANCE CPLR 3/8 MP Tubing 1

AF 073-MP9MP9 LANCE CPLR 9/16 MP Tubing Optional

AF 072-MP4 ANTV GLAND 1/4 MP Optional

AF 072-MP6 ANTV GLAND 3/8 MP 1

AF 072-MP9 ANTV GLAND 9/16 MP Optional

HI 060 SERVICE KIT 1

HI 061 OVERHAUL KIT Optional

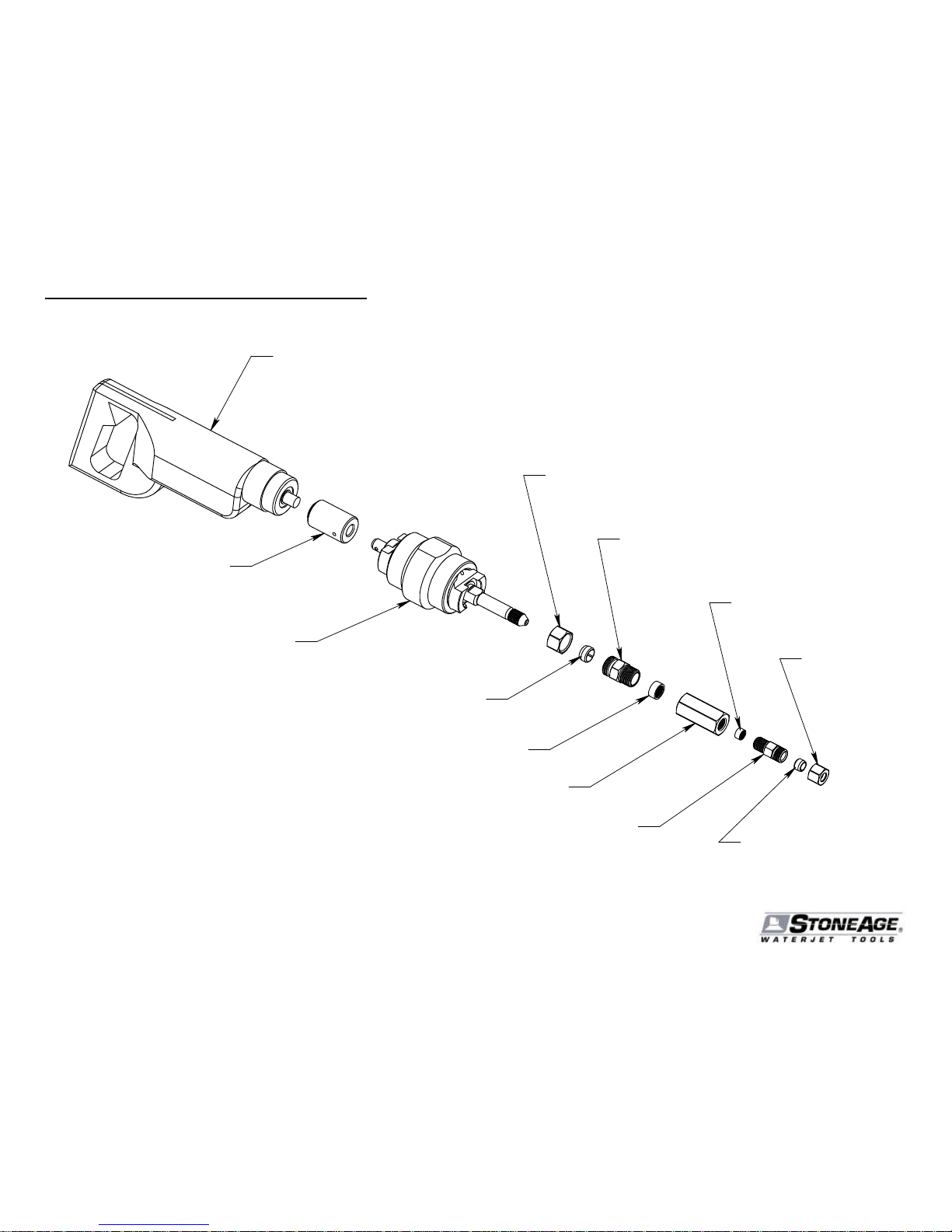

-

SA 019 AIR MOTOR

SA 040 SHAFT COUPLING

HI-P6P6 ASSEMBLY

SA 056-P6-P4 LANCE ADAPTOR

GP 075-XXX COLLET

GP 076 COLLET NUT

12/06

5.0 SA 1900 EXPLODED ASSEMBLY DRAWING

SA 019 AIR MOTOR

SA 040 SHAFT COUPLING

HI-MP9MP9 ASSEMBLY

AF 072-MP9 GLAND NUT

AF 072-MP9 GLAND COLLET

AF 072-MP9 GLAND BODY

AF 071-MP9 COLLAR

AF 073-MP6MP9 LANCE COUPLER

AF 071-MP6 COLLAR

AF 072-MP6 GLAND BODY AF 072-MP6 GLAND COLLET

AF 072-MP6 GLAND NUT

12/06

5.1 SA 1909 EXPLODED ASSEMBLY DRAWING

6.0 MAINTENANCE

This tool has been designed to require a minimum amount of attention by the operator. However, some

guidelines should be followed to obtain top performance and a long, useful life.

This tool is capable of fairly high rpm, but it is recommended that a valve be installed in the airline to

regulate the top speed. For many applications lower rpm may improve performance. It will definitely be

easier on the motor and swivel.

6.1 AIR MOTOR

1. The air supply should be filtered and use a line oiler to supply lubrication.

2. For added protection when preparing to store the tools, pour a few ounces of oil or diesel directly into

the port and run briefly.

3. Keep the control handle clean and working properly.

4. Always blow out the airline before connecting hardware.

Repairs to the air drill are straight forward and require only standard metric wrenches. The most common

problems are worn and sticking vanes. Clean all components and lubricate thoroughly before

reassembling.

Refer to the appendix for more detailed information.

6.2 WATER SWIVEL

1. Grease the bearings regularly. Every few hours of operation inject enough to cause some grease to

push out past the retainer washer.

2. Periodically check the shaft collar and end nuts to be sure they are tight. Any looseness may cause a

premature seal or bearing failure.

3. The high pressure seals may leak occasionally but heal themselves during continued use. The seals

do not fail abruptly and can be used for several hours even after continuous leaking begins. As long as

the leak is tolerable the swivel can be operated without fear of damaging it.

4. Keep all connections clean and flush out the supply hoses before connecting to the swivel.

Refer to the appendix for more detailed information.

7.0 LIMITED WARRANTY

StoneAge, Inc. warrants to the extent herein provided the products of its own manufacture against defects

in material and workmanship under normal use and service for which the products were designed for a

period of six months after shipment from the factory. If such products should fail through defect in

workmanship or material and specific written notice of failure is made within six months after date of

shipment from factory, StoneAge, Inc. will either repair or replace any such items, F.O.B. its factory without

charge. StoneAge, Inc. shall not be liable for expense incurred in repairs or alterations made outside the

factory without the proper and prior authorization. StoneAge, Inc. shall have the option of requiring the

return of the defective products to its factory, with transportation charges prepaid, to establish the claim.

StoneAge, Inc. shall in no event be held liable for damages or delay resulting from or arising out of

defective products nor for consequential damages or otherwise except for repair or replacement of items

of defective material or workmanship aforesaid.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE AND NEITHER

ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR STONEAGE, INC. ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF ITS PRODUCTS. THIS WARRANTY SHALL NOT

APPLY TO PRODUCTS OR ANY PARTS THEREOF WHICH HAVE BEEN SUBJECT TO ACCIDENT,

NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. STONEAGE, INC. MAKES NO WARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES, PARTS OR PRODUCTS NOT MANUFACTURED BY

STONEAGE, INC.

Table of contents