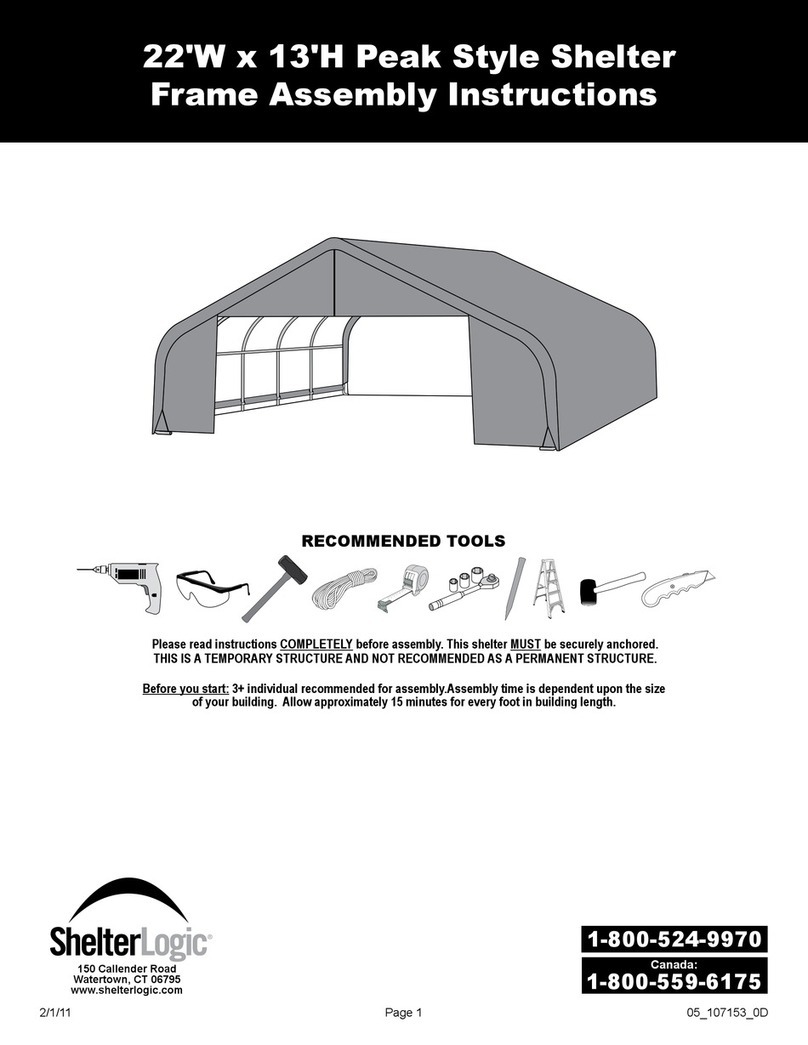

YOU MUST READ THIS DOCUMENT BEFORE YOU BEGIN TO ASSEMBLE THE SHELTER.

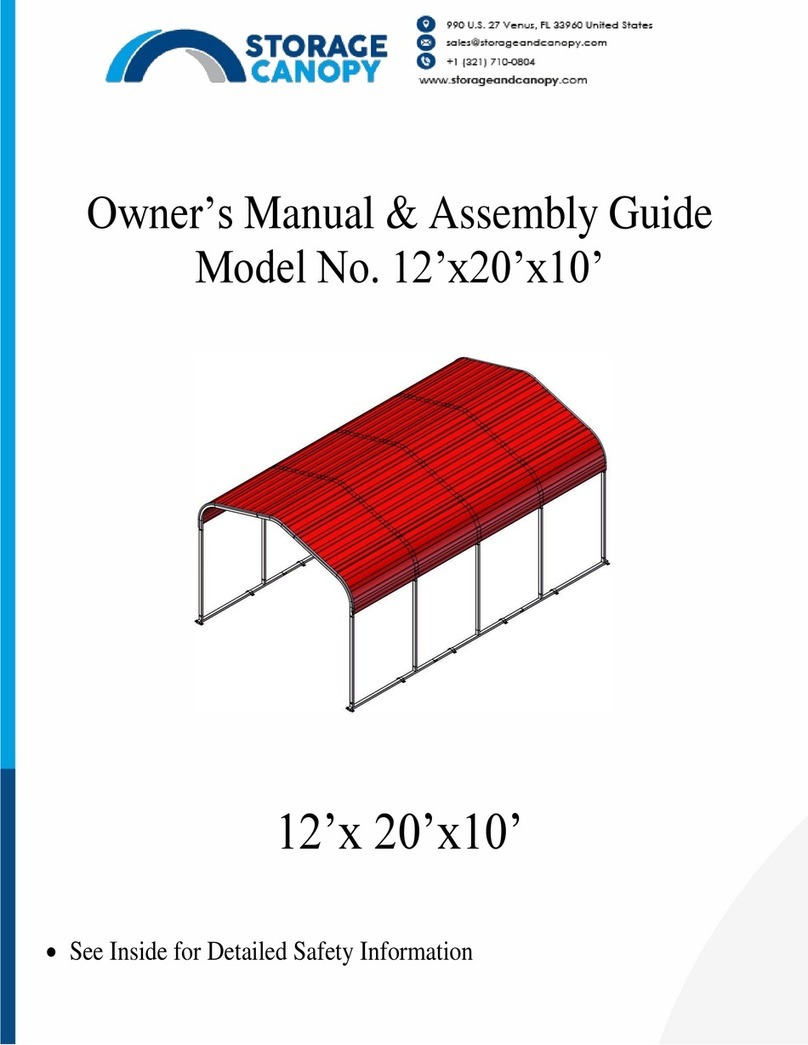

Thank you for purchasing our shelter. When properly assembled and maintained, this product will provide years

of reliable service. These instructions include helpful hints and important information needed to safely assemble

and properly maintain the shelter. Please read these instructions before you begin.

If you have any questions during the assembly, please contact local dealer for assistance.

SAFETY PRECAUTIONS

. Wear eye protection.

. Wear head protection

. Wear gloves when handling metal tubes

. Use a portable GFCI (Ground Fault Circuit Interrupter) when working with power tools and cords.

. Do not climb on the shelter or framing during or after construction.

. Do not occupy the shelter during high winds, tornadoes, or hurricanes.

. Provide adequate ventilation if the structure is enclosed.

. Do not store hazardous materials in the shelter.

. Provide proper ingress and egress to prevent entrapment.

ANCHORING INSTRUCTIONS

Prior to assembling this shelter, please read the MUST READ document included with the shipment.

WARNING: The anchor assembly is an integral part of the shelter construction. Improper anchoring may

cause shelter instability and failure of the structure. Failing to anchor the shelter properly will void the

manufacturer’s warranty and may cause serious injury and damage.

LOCATION

Choosing the proper location is an important step before you begin to assemble the structure.

The following suggestions and precautions will help you determine whether your selected location is the best

location.

. Never erect the structure under power lines.

. Identify whether underground cables and pipes are present before preparing the site or anchoring the

structure.

. Location should be away from structures that could cause snow to drift on or around the building

. Do not position the shelter where large loads such as snow and ice, large tree branches, or other overhead

obstacles could fall.

. Your shelter’s cover can be quickly removed and stored prior to severe weather conditions. If strong winds or

severe weather is forecast in your area, we recommend removal of cover.

SITE

After choosing a location, proper preparation of the site is essential. The following site characteristics will help

ensure the integrity of the structure.

. The support structure must be level to properly and safely erect and anchor the frame.

. Drainage: Water draining off the structure and from areas surrounding the site should drain away from the site

to prevent damage to the site, the structure, and contents of the structure.

WARNING: The individuals assembling this structure are responsible for designing and furnishing all

temporary bracing, shoring and support needed during the assembly process. For safety reasons, those who are

not familiar with recognized construction methods and techniques must seek the help of a qualified contractor.