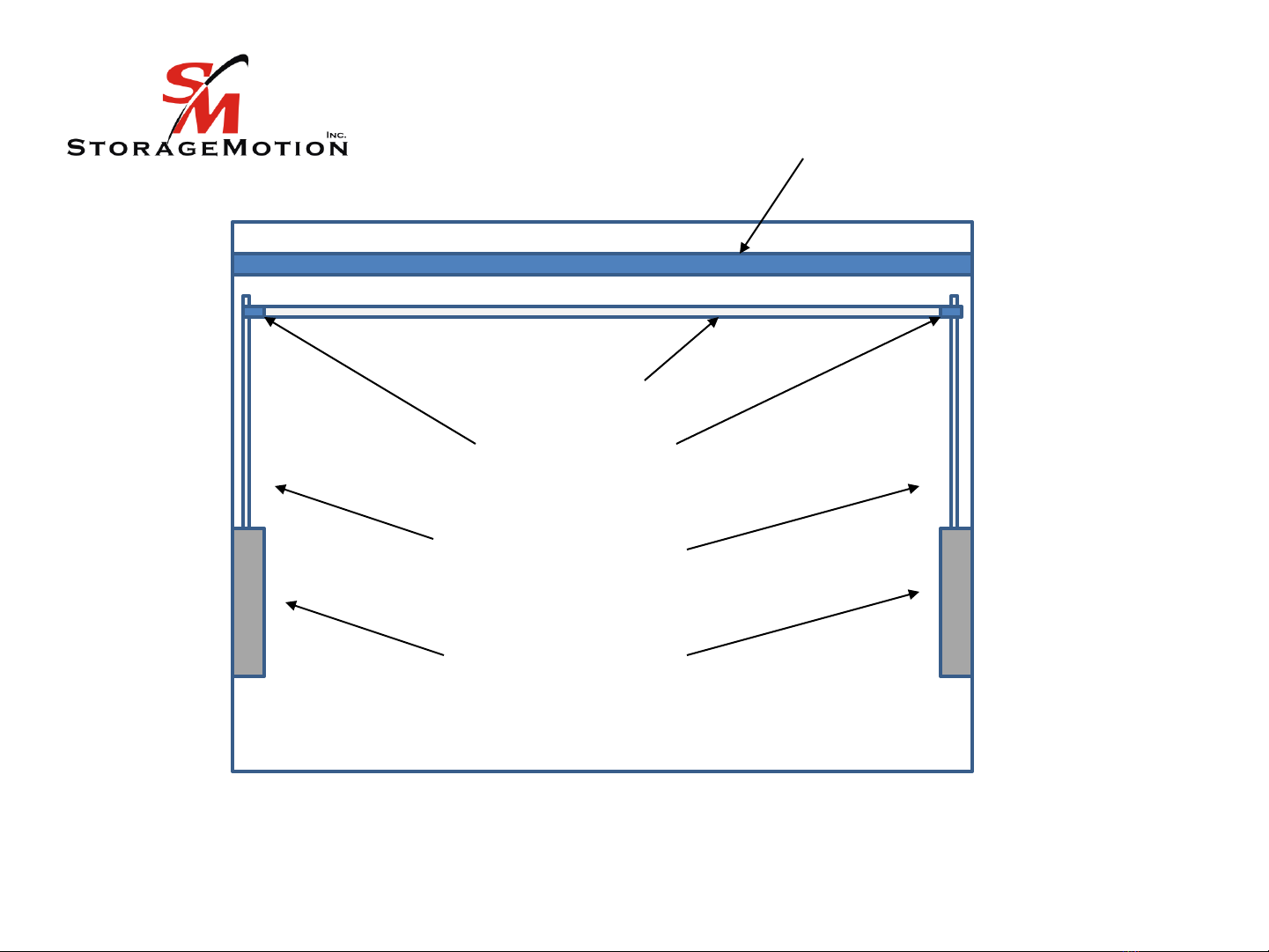

1. Attach LH and RH Mounting Box to the cabinet sides using the #4x20mm Flat Head Screws.

MAKE SURE THAT EACH SIDE IS PROPERLY ALIGNED WITH EACH OTHER. See Fig 1,2 and 3 and

photo 1 . The longer screws are to be used at the bottom of the mounting box.

2. Mount the telescoping clothes rail by attaching the side supports for the clothes rail using two

M8x35mm Screws . Use the hex key to loosely tighten.

3. Adjust the telescoping rail to proper length and twist to lock it. After adjusted to desired width

remove the side supports from step 2 and add the clothes pole. The main outer clothes pole

must be cut to the correct length before it is added. Re-tighten the M8 x35 Screws.

4. Lift the arms manually and ensure there is NO BINDING or scraping and that the arms move

freely at all times.

5. Measure the closet opening (see Fig 1 )The metal motor tube needs to be cut 1 1/2 inches less

than the closet opening(inside dimension). See photo 2 for where to hold the measuring tape.

Do not include the motor head when measuring the tube.

6. Insert right side end cap into the metal tube and place white round plastic idler bearing

onto right side end cap. Do not yet mount tube.

7. Mount right side strap with the strap clip and the small machine screw that is supplied. See

photo 3. Drill through the tube with 3/32 bit and attach the strap with the screw so that the

tape on the strap is directly across from the tape on the left side strap. This ensures that the

straps are the same length when lifting the rotating arms. Do not try to drill through the lifting

strap material as this is not necessary. The strap needs to be mounted about ¼ from the right

ed of the tube see Photo 4 ad the “X“ o the tape eeds to be agaist the otor tube so

that the strap clip on the other end is positioned correctly.

CONTACT PHONE - 704 746 3700

4