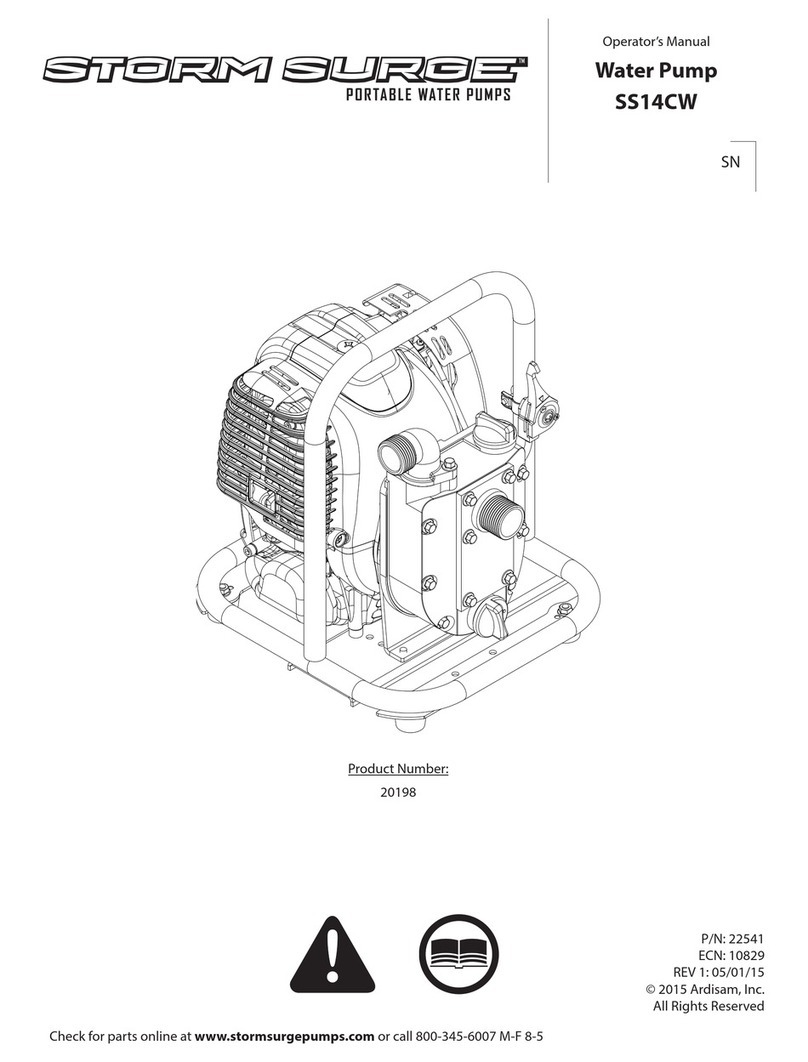

Operator’s Manual

SS20T and SS30T Water Pumps

Check for parts online at www.stormsurgepumps.com or call 800-345-6007 M-F 8-5

6

CAUTION

HOT GASES ARE A NORMAL BYPRODUCT OF A

FUNCTIONING CATALYTIC CONVERTER. FOLLOW

ALL SAFETY INSTRUCTIONS TO PREVENT BURNS

AND FIRES.

DO NOT ALTER OR MODIFY ENGINE:

NEVER ALTER OR MODIFY THE ENGINE FROM

THE FACTORY. SERIOUS INJURY OR DEATH MAY

OCCUR IF ENGINE IS MODIFIED OR ALTERED.

WHEN WORKING ON OR REPLACING PARTS FOR

THE ENGINE OR PRODUCT, YOU MUST ALWAYS

DISCONNECT SPARK PLUGWIRE FROMTHE SPARK

PLUG AND KEEP IT AWAY FROM THE SPARK PLUG.

USE EXTRA CARE IN HANDLING GASOLINE AND

OTHER FUELS. THEY ARE FLAMMABLE AND

VAPORS ARE EXPLOSIVE.

ENGINE SAFETY PRECAUTIONS

If your product comes with a separate engine manual, be

sure to read and follow all safety and warning precautions

outlined there, in addition to any in this manual.

Preventing Carbon Monoxide Poisoning:

• Always start and run engine outdoors. Do not start

or run engine in an enclosed area, even if doors or

windows are open.

• Never try to ventilate engine exhaust indoors. Carbon

monoxide can reach dangerous levels very quickly.

• Never run engine outdoors where exhaust fumes may

be pulled into a building.

• Never run engine outdoors in a poorly ventilated area

where the exhaust fumes may be trapped and not

easily taken away. (Examples include: in a large hole

or areas where hills surround your working area.)

• Never run engine in an enclosed or partially enclosed

area. (Examples include: buildings that are enclosed

on one or more sides, under tents, car ports or

basements.)

• Always run the engine with the exhaust and muer

pointed in the direction away from the operator.

• Always keep the throttle in the“slow”position when not

in use.

• Never point the exhaust muer towards anyone.

People should always be many feet away from the

operation of the engine and its attachments.

• Do not change the engine governor settings or over-

speed the engine.

WARNING

ENGINES GIVE OFF CARBON MONOXIDE, AN

ODORLESS, COLORLESS, POISONOUS GAS.

CARBON MONOXIDE MAY BE PRESENT EVEN IF

YOUDONOTSMELLORSEEANYENGINEEXHAUST.

BREATHING CARBON MONOXIDE CAN CAUSE

NAUSEA, FAINTING OR DEATH, IN ADDITION TO

DROWSINESS, DIZZINESS AND CONFUSION.

IF YOU EXPERIENCE ANY OF THESE SYMPTOMS,

SEEK FRESH AIR AND MEDICAL ATTENTION

IMMEDIATELY.

Gasoline Fires and Handling Fuel Safely

• When storing extra fuel be sure that it is in an

appropriate container and away from any re hazards.

• Prevent re and explosion caused by static electric

discharge. Use only nonmetal, portable fuel

containers approved by the Underwriter’s Laboratory

(U.L.) or the American Society for Testing & Materials

(ASTM).

• Always ll fuel tank outside in a well ventilated area.

Never ll your fuel tank with fuel indoors. (Examples

include: basement, garage, barn, shed, house, porch,

etc.) Never ll tank near appliances with pilot lights,

heaters, or other ignition sources. If the fuel has to be

drained, this should be done outdoors. The drained

fuel should be stored in a container specically

designed for fuel storage or it should be disposed of

carefully.

• Never remove the fuel cap or add fuel with the engine

running. Stop engine and allow to cool before lling.

• Do not smoke while handling fuel or operating pump.

• Never drain fuel from engine in an enclosed area.

• Always wipe up excess (spilled) fuel from engine

before starting. Clean up spilled fuel immediately.

If fuel is spilled, do not start the engine but move

product and fuel container from area. Clean up spilled

fuel and allow to evaporate and dry after wiping and

before starting.

• Allow fuel fumes/vapors to escape from the area

before starting engine.