Strasbaugh nCompass 7AB-II User manual

nCompass

(Model 7AB-II)

Automatic Edge Grinder

Operations and

Maintenance Manual

S T R A S B A U G H

825 Buckley Road

San Luis Obispo, California 93401

Phone: (805) 541-6424

Fax: (805) 541-6425

Copyright © 2002, 2003 by Strasbaugh. All rights reserved.

Document prepared by: Technical Publications Group

Operations and Maintenance Manual Introduction

Version 1.1-April 2003 1 -1

1

Introduction

•Overview of Manual

•Ordering Replacement Parts

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

1 -2Version 1.1 -April 2003

INTRODUCTION

Overview of Manual 3

Ordering Replacement Parts 4

Operations and Maintenance Manual Introduction

Version 1.1-April 2003 1 -3

INTRODUCTION

Your new machine will provide a long life of precision production and minimum

maintenance if the fundamentals of good operation are observed. This Operation and

Maintenance Manual describes safety, installation, operator functions, preventive

maintenance, and service for your Strasbaugh Model 7AB-II Automatic Edge Grinder.

OVERVIEW OF MANUAL

The Safety section provides detailed safety practices and information for your machine.

Safety guidelines and rules are listed to safely operate your machine. Safety graphics and

their meanings give the reasons for their placement on your machine. Read and observe

all safety labels carefully and completely. Please note that not all of the safety graphics

presented will appear on your machine. The lockout/tagout procedure has been provided

for you to copy and use when servicing your machine. Read the entire Safety section

before operating your machine!

The Installation, Operator Functions, and Maintenance sections of this manual present tips

and instructions for placing and operating your machine. The Installation portion of this

manual offers help for locating, lifting, moving, leveling, and connecting utilities to your

machine. The Operator Functions section provides information on using, adjusting, and

maintaining your machine.

The Machine Parts section makes it easy for you to order any parts from Strasbaugh

needed for your machine. The machine Assembly Drawings section provides detailed

drawings of your machine with all of the part numbers labeled. The Customer Parts list

provides the part item number, name, and quantity.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

1 -4Version 1.1 -April 2003

ORDERING REPLACEMENT PARTS

Engineering changes are occasionally made to improve the operation of the machine model.

This makes the precise matching of machines and parts important. Replacement part

orders can be facilitated easily by Strasbaugh when you provide the following information:

•machine name

•machine serial number

•replacement part item number

•replacement part name

•quantity required

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -1

2

Safety

•General Information

•Visual Hazard Alerts

•Interlocks -Safety Interlock Door Switches

•Waste Disposal

•Lockout Safety Procedures

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -2Version 1.1 -April 2003

SAFETY

Overview 3

General Information 4

Visual Hazard Alerts 6

Hazard Magnitude Levels 6

Three-Panel Alert Graphics 7

Power Interrupts and Interlocks 11

Emergency Off Button 11

Safety Interlock Door Switches 12

Waste Disposal 13

Electrical Disconnect 13

Lockout Safety Procedure 14

Lockout Procedure 15

Appendix to Lockout Safety Procedure 18

Training, Lockout/Tagout, per 29 CFR 1910.147 18

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -3

SAFETY

OVERVIEW

The safety information in this chapter is intended to provide for safe operation and

maintenance of Strasbaugh edge profiling equipment.

A checklist of basic safety instructions addresses general operation. The Visual

Hazard Alerts section explains the system of hazard alert graphics used on the

machines and in Strasbaugh manuals and on the machines themselves. The Power

Interrupts and Interlocks section explains machine motion shutdown and interlock

switches on access doors, followed by instructions on waste disposal, electrical

disconnect, and a detailed lockout safety procedure.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -4Version 1.1 -April 2003

GENERAL INFORMATION

Strasbaugh grinding machines are designed for safe operation. However, caution

must be exercised when operating this machine. Failure to adhere to these safety

instructions and to good safety practices in general may result in personal injury or in

damage to the machine. Hearing protection should not be necessary, since the 7AB-

II producesless than 70 db(A) sound pressure during normal operation.

It is the responsibility of the user to be sure that the machine is in safe operating

condition at all times. The user is also responsible for insuring that operators and

maintenance personnel follow approved operating and maintenance procedures. The

following is a list of safety instructions:

•Operating a machine with loose wafers inside is harmful to the machine and the

wafers. Always remove loose parts and obstructions before beginning

machine operation.

•DO NOT put hands or objects near the polishing head or drive mechanisms

while the machine is in motion unless it is absolutely necessary.

•Keep all guards and covers in place and in good repair.

•Interlocks and other safety circuits or devices may not be overridden except by

trained maintenance personnel using approved procedures. Operators must

not override interlocks or safety devices under any circumstances.

•Keep all control and electrical cabinet doors closed and latched.

•Disconnect power and padlock the power disconnect switch when servicing or

repairing the machine.

•DO NOT operate the machine without proper electrical grounding.

•DO NOT wear loose clothing that could be caught by machine parts in motion.

•Wear SAFETY GLASSES whenever working near moving machinery.

•Always heed visual hazard alert labels and messages.

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -5

•Recommendation Only: Avoid long-term exposure to low frequency

electromagnetic fields. The data concerning low-frequency electromagnetic

health effects is inconclusive, but a 1995 IEEE engineering publication

recommends “prudent avoidance” of prolonged and continuous exposure.

Maintenance personnel are advised to avoid standing at open power panel doors

for extended periods with the power on. Pregnant women, in particular, should

heed this advice. Closing power panel doors effectively shields all personnel

from any perceived hazardous fields. Studies have been and are being conducted

by the U. S. Department of Energy to determine what risks, if any, are posed by

low frequency electromagnetic field exposure.

•Always consult with your supervisor if your task or procedure is unclear or if

you believe that your assignment could result in unsafe conditions or equipment

damage.

REMEMBER:

The safe way is the best way.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -6Version 1.1 -April 2003

VISUAL HAZARD ALERTS

To aid in the safe operation of Strasbaugh machines, visual hazard alert graphics are placed

in appropriate locations throughout the manual and on the machines themselves. These

graphics alert users to the existence of pinch points, areas of potential entanglement, hot

surfaces, chemical and electrical hazards.

HAZARD MAGNITUDE LEVELS

The definitions of keywords (signal words) used to define hazard levels are shown

below:

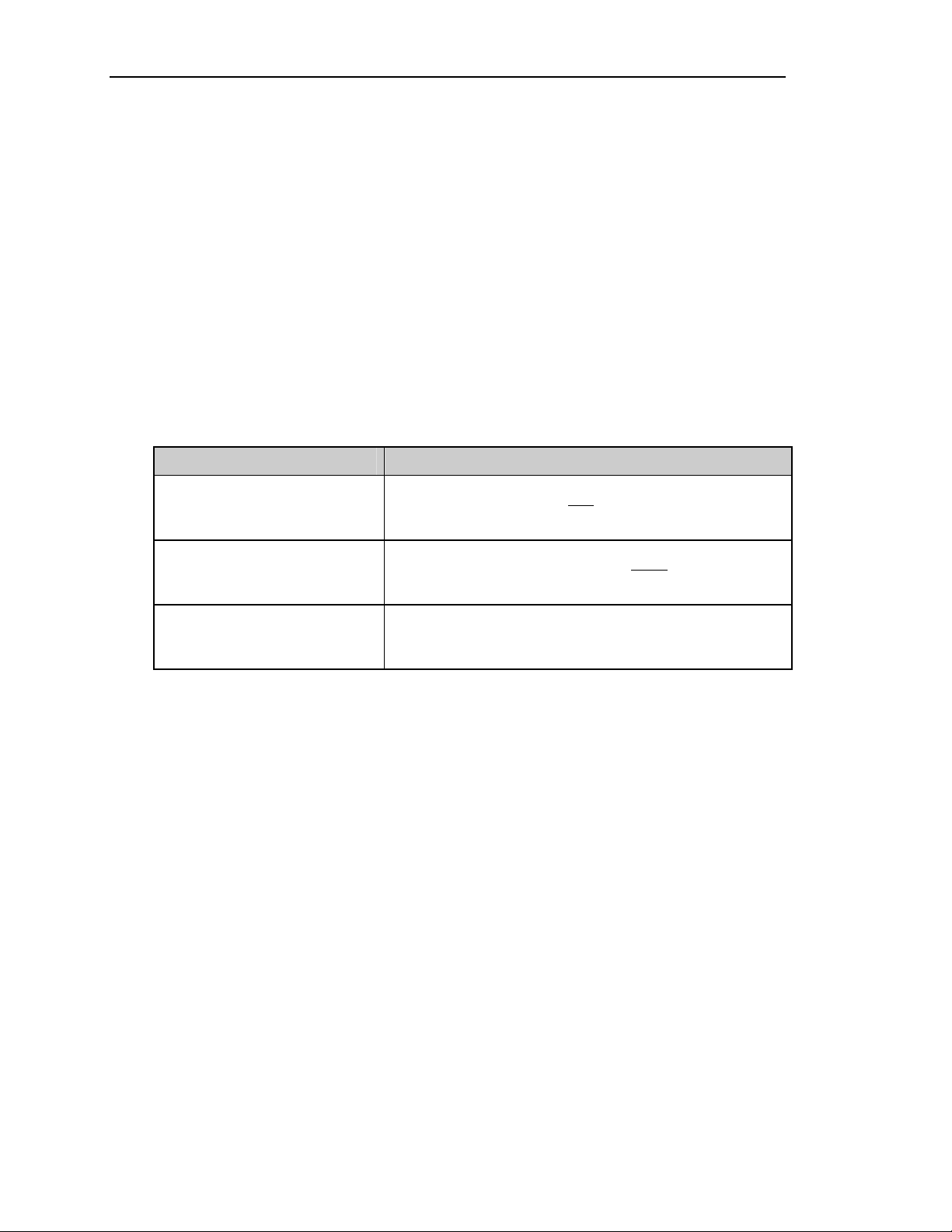

Keyword Definition

Danger

Immediate hazards which will result in severe personal

injury or death.

Warning

Hazards or unsafe practices which could result in severe

personal injury or death.

Caution

Hazards or unsafe practices that could result in minor

personal injury or in product or property damage.

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -7

THREE-PANEL ALERT GRAPHICS

The three-panel alert graphics used in Strasbaugh products consist of:

1. a keyword such as Danger, Warning, Caution (see table above)

2. a graphic hazard symbol and, typically,

3. a text box identifying the hazard, the result(s) of ignoring the hazard,

and instructions on avoiding the hazard.

Several representative graphic hazard symbols used in Strasbaugh manuals and on the

machines are presented below, together with information on when to be aware of the

hazard. For the purpose of avoiding injury, these labels are displayed in appropriate places

on the machines and in the operation and maintenance manuals. Although the text box

information is written for multiple machines, it may change as needed to identify

hazards in specific instances and provide more precise avoidance instructions.

Also note: The labels pictured here include common international symbols for various

hazards. Some labels may differ from these in their symbols.

CAREFULLY READ AND OBSERVE ALL CAUTIONS AND INSTRUCTIONS

ON HAZARD LABELS, BOTH ON THE MACHINES AND IN THE MANUAL

REFERENCES.

Note that some machines may not include all of the safety labels presented below. If you

do not see a safety label on your machine or see a safety label on the machine that is not

explained in this manual, please consult with your Safety Advisor, Supervisor, or

Strasbaugh for an explanation.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -8Version 1.1 -April 2003

Alert Graphic:

Symbol:

•Pinch Points

When to be Aware:

•whenever machine parts are moving.

•immediately before and during auto mode operation.

•immediately before and during manual operation.

Warning: Components may continue to move briefly after the process cycle is

completed.

Alert Graphic:

Symbol:

•Entanglement

When to be Aware:

•whenever machine parts are moving

•during maintenance and calibration procedures involving spindle rotation, table

rotation, conditioning brush rotation, or robot movement.

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -9

POWER INTERRUPTS AND INTERLOCKS

The Model 7AB’s safety systems include an Emergency Shutoff button (EMO), a

power disconnect interlock on the power cabinet, magnetic sensors on both hinged

access hatches and tool-operated latches on the remaining doors.

EMERGENCY OFF BUTTON

The fastest way to shut down the machine is to press the EMERGENCY OFF

button (EMO) on the main control panel. This red mushroom button with a yellow

collar is also an approved way to turn off the machine.

This button cuts off operational power to the entire machine, including the control

computer graphical user interface (GUI). The Power On light remains lit.

Operations cannot be restarted until the EMERGENCY OFF button is pulled or

twisted clockwise to the “out” position, and all other precautions, such as securing

all interlocked doors, are observed. The Machine On button on the main control

panel must then be pushed to restart the machine.

NOTE: You may lose any unsaved work on the system when the EMO

automatically powers down the control module. Any recipe or

parameter changes in process will be interrupted. To shut

down the machine for any extended period, save your work and

press the EMO.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -10 Version 1.1 -April 2003

Figure 2-1 Emergency Off Button

SAFETY SWITCHES AND DOOR LATCHES

The second safety shutoff system is on the main power cabinet door. The power

disconnect, to the upper right of the door, prevents opening the door without first

pushing the power disconnect lever to the off position. A medium flat-bladed

screwdriver must then be used in conjunction with the door handle in order to open

the door and permit access to the cabinet.

The third safety shutoff system consists of magnetic sensors on both the Send and

Receive hinged access covers that operate independently of the EMO system. These

sensors automatically stop all motion in either the Send or Receive cabinets

respectively, and work independently of each other. These are not technically

interlocks, since they do not actually lock the hinged access covers, and motion

resumes automatically when they are closed. With the exception of “door” #7,

which is bolted in place, the remaining doors have tool-operated latches to restrict

access. All of these safety systems and latches should be individually checked on a

weekly basis, and prior to machine use after a prolonged shutdown.

Machine power and machine air may be locked-out for safety and maintenance

purposes as described in the Energy Source Isolation section of this chapter.

Do not override safety equipment! To ensure the safety

of machine operators, check to make sure that the doors are

securely fastened before operating the machine.

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -11

WASTE DISPOSAL

The Model 7AB-II is designed to edge grind silicon wafers along with de-ionized water.

The Silicon-DI water waste mixture must be disposed of in a manner consistant with

applicable ordinances and regulations. Should any exotic or hazardous materials be used,

appropriate precautions should be taken not only during processing, but also during clean

up and disposal of any hazardous materials or waste.

Please Note: The 7AB was not designed to grind hazardous materials such as

Germanium or Gallium Arsenide and does not have an Exhaust Fail alarm.

For all chemicals and exotic or hazardous materials used with Strasbaugh machines:

•Know and prepare for any potential hazards relating to grinding materials other than

Silicon, including the need for additional exhaust and protective measures.

•Be aware of any personnel safety hazards. See chemical suppliers’ material safety

data sheets (MSDS).

•Be aware of local, state, and federal regulations regarding waste disposal. Consult

with your supervisor or company safety officer if there is any question.

ENERGY SOURCE ISOLATION

ATTENTION STRASBAUGH MACHINE OWNER!

Machine power and machine air may be locked-out for safety and maintenance purposes,

please see the Power Distribution and Plumbing Description chapters respectively for

specifics. Under certain circumstances the machine may require an additional electrical

disconnect appropriate for your machine power needs, which is not included unless

otherwise specified. For power disconnect information, please refer to the Power

Distribution chapter and consult your Strasbaugh representative if you have further

questions.

DECONTAMINATION AND

DECOMMISSION

At the end of the machine’s service life, it should be decontaminated in accordance with

SEMI standard S12-0298, dismantled and recycled in an appropriate manner. Any

hazardous materials used in machine processes over the life of the machine will determine

the extent of decontamination that may be necessary.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -12 Version 1.1 -April 2003

LOCKOUT SAFETY PROCEDURE

(Reproduce for shop copy. Fill-in specific data or check off as appropriate.)

EQUIPMENT LOCATION:

MACHINE SERIAL NUMBER:

MANUFACTURER:

STRASBAUGH

PROCEDURE AUTHORIZED BY:

DATE:

PHONE:

DEPARTMENT:

OSHA regulations state, "The procedures shall clearly and specifically outline the scope, purpose,

authorization, rules and techniques to be utilized for the control of hazardous energy, and the

means to enforce compliance, including but not limited to the following:

A. A specific statement of the intended use of the procedure.

B. Specific procedural steps for shutting down, isolating, blocking and securing machines or

equipment to control hazardous energy.

C. Specific procedural steps for the placement, removal and transfer of lockout devices or tagout

devices and the responsibility for them.

D. Specific requirements for testing a machine or equipment to determine and verify the

effectiveness of lockout devices, tagout devices, and other energy control measures.

SOURCES OF ENERGY FOR THIS EQUIPMENT:

Electrical 110 VAC. ___ Gas ___ Hydraulic ___

Electrical 208 VAC. ___ Chemical ___ Pneumatic (compressed air) _√_

Electrical 230 VAC. _√_ Thermal ___ Other (specify) __________ ___

Electrical 480 VAC. ___

STORED ENERGY (Remember energy can be stored!):

Raised Load ___ Air Tank ___ Coiled Springs ___

Chemical ___ Charged Capacitors _√_Hydraulic Pressure ___

Battery ___ Pneumatic Pressure _√_ Other (specify) __________ ___

MACHINE MAINTENANCE MANUAL:

See the machine maintenance manual(s) before attempting any activities for which this procedure

applies. The maintenance manual(s) are usually the best single source of information vital to the

understanding of the machine and hazards which may be present.

Operations and Maintenance Manual Safety

Version 1.1 -April 2003 2 -13

LOCKOUT PROCEDURE

• Per ANSI Z244.1-1982

• Lockout procedure for Strasbaugh Polishing, Lapping, Grinding, and Cutting Machines

PURPOSE

This procedure establishes the minimum requirements for lockout of energy sources

that could cause injury to personnel. All maintenance personnel, operators, and

machine owner employees shall comply with the procedure.

RESPONSIBILITY

The responsibility for seeing that this procedure is followed is binding upon all

machine maintenance personnel. All machine maintenance personnel shall be

instructed in the safety significance of the lockout procedure by the information

contained herein and instruction provided by the machine owner designated safety

personnel. Each new or transferred affected operator or maintenance person shall be

instructed accordingly in the purpose and use of the lockout procedure.

PREPARATION FOR LOCKOUT

Maintenance personnel authorized to perform lockout shall be certain as to which

switch, valve or other energy isolating devices apply to the equipment being locked

out. More than one energy source (electrical, mechanical, or others) may be

involved. Employees shall clarify the identification of questionable sources with

their supervisors. Before lockout commences, job authorization should be obtained.

Strasbaugh nCompass (Model 7AB-II) Automatic Edge Grinder

2 -14 Version 1.1 -April 2003

SEQUENCE OF LOCKOUT PROCEDURE

1. Notify all affected employees that a lockout is required and the reason

therefore.

2. If the equipment is operating, shut it down by the normal stopping procedure

(depress stop button, open toggle switch, etc.).

3. For each energy source, operate the switch, valve, or other energy isolating

device so that the energy source(s) (electrical, mechanical, hydraulic, etc.) is

disconnected or isolated from the equipment.

Stored energy, such as that in capacitors, springs, elevated machine members,

rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure,

etc., must also be dissipated or restrained by methods such as grounding,

repositioning, blocking, bleeding-down, etc.

4. Lockout the energy isolating devices with an assigned individual lock.

5. After ensuring that no personnel are exposed and as a check on having

disconnected the energy sources, operate the push button or other normal

operating controls to make certain the equipment will not operate.

CAUTION: Return operating controls to neutral position after the test.

6. The equipment is now locked out.

RESTORING EQUIPMENT TO SERVICE

1. When the job is complete and equipment is ready for testing or normal service,

check the equipment area to see that no one is exposed.

2. When equipment is all clear, remove all locks. The energy isolating devices

may be operated to restore energy to equipment.

Table of contents

Other Strasbaugh Grinder manuals

Popular Grinder manuals by other brands

MEISTER CRAFT

MEISTER CRAFT MSS 180 Operating instructions & safety hints

Go-On

Go-On WS 125/2 operating instructions

Far Tools

Far Tools XFB-Grinder2 Original manual translation

Lumberjack

Lumberjack AG820 Safety and operating manual

Worx Nitro

Worx Nitro WX813.X Series Original instructions

BLACK DECKER

BLACK DECKER BEG010 Original instructions