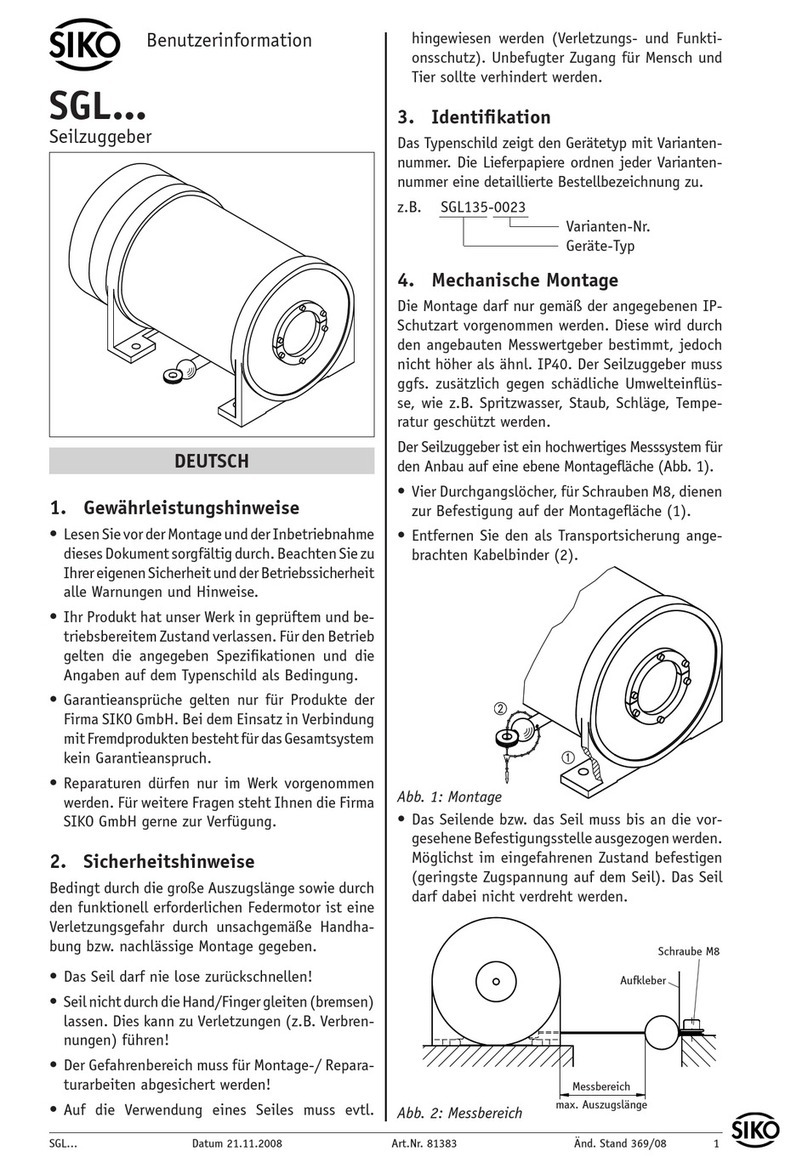

Strasbaugh nTellect 7AF User manual

nTellect

(Model 7AF)

Wafer Grinder

Operations and

Maintenance Manual

S T R A S B A U G H

825 Buckley Road

San Luis Obispo, California 93401

Phone (805) 541-6424

Fax: (805) 541-6425

Copyright © 1998, 2002-2004 by Strasbaugh. All rights reserved.

Document prepared by: Technical Publications Group

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -1

TABLE OF CONTENTS

CHAPTER 1 -INTRODUCTION

About this Manual 3

Contents and Purpose 3

Update Sections 3

Document Conventions 4

Touch Screen 4

Control Panel 4

At the PC Keyboard 5

Step-By-Step Instructions 5

About the Machine 6

Mechanical Components 6

Electrical Distribution and Control 7

Safety 9

General Operation 9

Visual Hazard Alerts 10

Hazard Magnitude Levels 10

Three-Panel Alert Graphics 10

Sprayer Use 13

Safety Interlock Door Switches 13

Guarantee/Warranty Certificate 14

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -2Version 1.2 -June 2004

CHAPTER 2 -INSTALLATION

Overview 3

Step 1 -Unpacking/Inspection 4

Preparation for Installation 5

Step 2 -Machine Placement 6

For Manufacturing Locations with a Wide Access Door 7

(70 Inches or Greater) 7

For Manufacturing Locations with a Narrow Access Door 8

(Greater than 50 Inches but Less than 70 Inches) 8

Step 3 -Leveling the Two Machine Sections 9

Summary 9

A. Grinding Area Cabinet Base Leveling Procedure 10

Leveling Feet 10

Leveling Procedure 10

B. Handling Area Cabinet Base Leveling Procedure 16

Leveling Casters 16

Leveling Procedure 16

Step 4 -Utility Requirements 20

Step 5 -Connecting Utilities to External Sources 21

Electrical 23

Clean Dry Air 24

Vacuum 24

Vacuum Clean Dry Air 25

De-Ionized Water 25

Industrial Waste 26

Exhaust 26

Air Bearing Spindle Motor Cooling Water In/Out 26

Step 6 -Initial alignments -Completing the Installation 27

Initial Adjustments -Grinding Area 27

Initial Adjustments -Handling Area 28

Robot Software Calibration Procedures 28

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -3

CHAPTER 3 -PHYSICAL DESCRIPTION

Overview 3

Cabinetry 4

Door Numbering System 4

Service Doors (Doors 7, 8 , 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, and 21) 4

Disconnect Enclosure Door (Door 20) 4

Operator Doors (Doors 5 and 6) 5

Cassette Turrets (Doors 1, 2, 3, and 4) 5

Interlock Safety Switches 5

Machine Views 7

Subassemblies 15

Grinding Area 16

Wafer Handling Area 17

Control Panel and Emergency Off Buttons 18

Control Panel 18

Emergency Off Buttons 19

Control Computer 20

Monitor -Touch Screen 20

Keyboard 20

To Plug in the Keyboard: 20

Frequently Used Keys 21

User Interface 22

Menu Tree 22

Main Menu 23

Home Machine Menu 24

Grind Cycle Menu 25

Edit Recipes (Wafer Recipes) Menu 26

Wheel and Chuck (Truing and Dressing) Recipes Menu 27

Dress Cycle Menu 28

Machine Maintenance Menu 29

Output Control/Input Status Menu 30

Machine (Calibration) Setup Entry Menu 31

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -4Version 1.2 -June 2004

CHAPTER 4 -MECHANICAL DESCRIPTION

Overview 3

Grinding Area 3

Bridge Assembly 3

Spindle Assemblies 4

Coarse/Fine Spindles 4

Left/Right Work Chucks 5

Air Bearing Spindles 5

Left/Right Digital Measurement Probes 6

Left/Right Conditioning Arms 6

Wafer Handling Area 7

Robot 7

Pre-Aligner 8

Spin-Rinse Station 9

Send 1, Send 2, Receive 1, Receive 2 Cassette Access Turret Assemblies 9

CHAPTER 5 -CONTROL SYSTEM DESCRIPTION

Control Computer3

Servo Control 3

Servo Amplifier 5

I/O and Interface System 6

Robot and Controller, 7

Pre-Aligner, and Controller 7

Digital Measurement Probes 8

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -5

CHAPTER 6 -POWER DISTRIBUTION

Introduction 3

AC Distribution 3

DC Distribution 4

Power Up 4

Interlocks 6

CHAPTER 7 -PLUMBING DESCRIPTION

Clean Dry Air System 4

Vacuum System 5

Water System 6

Exhaust System 7

Drain System 7

CHAPTER 8 -OPERATOR FUNCTIONS

Overview 4

Menus Used in Basic Operation 6

Menu Tree 6

The Main Menu 7

The Home Machine Menu 9

The Grind Cycle Menu 15

The Dress Cycle Menu 19

Auto Grind Cycle Sequence 23

Event Sequence 24

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -6Version 1.2 -June 2004

Basic Operation 26

Summary 26

Problems and Error Messages 26

1 -Powering Up 27

2 -Homing the Machine 30

Check for Obstructions and Display the Home Machine menu 31

Home the Machine Automatically 32

Home Individual Servos Manually 34

3 -Checking Utilities 36

4 -Referencing the Chucks 37

5 -Running an Automatic Grind Cycle 42

Display the Grind Cycle menu 43

Select the Desired Recipe and Grind 43

Compare the Stored Recipe Values with the Parameter Values Received from the Process Supervisor 45

Prepare the Cassettes and Start the Cycle 47

While the Cycle Is Running, Monitor the Status Screen Display Values 49

If There’s a Problem, Halt (Interrupt) or Stop (Cancel) the Cycle 51

When the Last Wafer Has Been Processed 52

Truing and Dressing the Grind Wheels and Work Chucks 53

Display the Dress Cycle Menu 54

Grind Wheel Dressing and Truing 57

Select the Wheel and the Treatment Desired 57

Compare the Stored Recipe Values with the Parameter Values Received from the Process Supervisor 58

Start the Cycle 60

While the Cycle Is Running, Monitor the Status Screen Display Values 61

If There's a Problem, Stop (Cancel) the Cycle 62

When the Start Cycle and Stop Cycle Buttons Begin to Flash 62

Chuck Dressing and Truing 63

Select the Chuck and the Treatment Desired 63

Compare the Stored Recipe Values with the Parameter Values Received from the Process Supervisor 64

Start the Cycle 65

While the Cycle Is Running, Monitor the Status Screen Display Values 66

If There’s a Problem, Stop (Cancel) the Cycle 67

When the Start Cycle and Stop Cycle Buttons Begin to Flash 67

Using the Probes 68

Raising and Lowering the Probes 68

Referencing the Probes 70

Measuring the Thickness of an Item on the Work Chuck 73

Operator Daily Preventive Maintenance Schedule 75

Light Tower Operation 77

Idle: Green Flashing, No Alarm Sounds 77

Running: Green Steady, No Alarm Sounds 77

Needs Assistance: Yellow Flashing, Alarm Sounds 78

Needs Assistance, Acknowledged: Yellow Steady, No Alarm Sounds 78

Fault: Red Flashing, Alarm Sounds 79

Fault, Acknowledged: Red Steady, No Alarm Sounds 80

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -7

CHAPTER 9 -MACHINE SETUP

Overview 3

Wafer Recipes Menu 5

Grinding Sequence 7

Recipe Parameter Settings and Information Available at the Wafer Recipes Menu 9

Coarse and Fine Grind Recipe Steps and Parameters 9

Wafer Parameters 12

Estimated Throughput in Wafers Per Hour 12

Example Recipes 13

Choices Available at the Wafer Recipes Menu 14

Using the Wafer Recipes Menu 16

Summary 16

Step 1 -Select the Name of the Recipe 16

Step 2 -Enter the Coarse Grind Data 17

Step 3 -Enter the Fine Grind Data 18

Step 4 -Set the Wafer Parameters 18

Step 5 -Quit and Save Changes 19

Wheel and Chuck Recipes Menu 20

Recipe Parameter Settings and Information Available at the Wheel and Chuck Recipes Menu 23

Dress and True Recipe Steps and Parameters 23

Fine Wheel Parameters 24

Grind Wheel Example Recipes 25

Work Chuck Example Recipes 26

Choices Available at the Wheel and Chuck Recipes Menu 27

Using the Wheel and Chuck Recipes Menu 29

Summary 29

Step 1 -Select the Name of the Recipe 29

Step 2 -Enter the Dress and True Recipe Data 30

Step 3 -Quit and Save Changes 32

Pre-Aligner Second Flat Sensing -OPTION 32

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -8Version 1.2 -June 2004

CHAPTER 10 -PREVENTIVE MAINTENANCE

SCHEDULES

Overview 3

Daily

Preventive Maintenance Schedule 4

7-Day or 5,000 Wafers

Preventive Maintenance Schedule 7

30-Day or 20,000 Wafers

Preventive Maintenance Schedule 11

180-Day or 80,000 Wafers

Preventive Maintenance Schedule 12

365-Day or 160,000 Wafers

Preventive Maintenance Schedule 14

CHAPTER 11-MECHANICAL MAINTENANCE

PROCEDURES

Overview 4

Manual Control of Assemblies 6

Menus Used in the Mechanical Maintenance Procedures 6

Manual Movement of the Bridge with Machine Power OFF 7

Initial Alignments 8

Grinding Area 8

Summary 9

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -9

I. Before You Begin 10

II. Level the Horizontal Rails of the Bed 15

III.Level the Lower Left and Right Spindle Assemblies 19

IV. Mount the Fringe Plates to the Lower Spindle Assemblies and Adjust 28

V. Adjust Upper Spindle Assemblies to Positions Parallel with Lower Right Spindle 34

VI. Adjust Lower Left Spindle Assembly Parallel to Upper Spindle Assemblies 43

VII. Bridge Left/Right Travel Proximity Sensor Adjustments 48

VIII. Spindle Z Travel Proximity Sensor Adjustments 61

IX. When Grinding Area Initial Adjustments are Successful 68

Handling Area 69

Summary 69

I. Before You Begin 70

II. Level the Robot 72

III. Level the Robot End Effector 74

IV. Align the Pre-Aligner with the Robot 79

V. Align the Spin-rinse Station with the Robot 84

VI. Level the Four Cassette Platforms (Turrets) 92

VII. Adjust the Bed to a Position Parallel to the Robot 109

VIII. When Grinding Area and Handling Area Initial Alignments are Complete 114

Bridge 115

Horizontal Travel Belt Adjustment 115

Spindles 118

Z Travel Belt Adjustment 118

Changing the Grind Wheels 120

Changing the Work Chucks 127

Digital Measurement Probes 134

Assembly Height Adjustments 134

Robot 140

Pre-aligner 141

Spin-Rinse Station 142

Spin-Rinse Motor Drive Belt Adjustment 142

Spin-Rinse Chuck Up/Down Cylinder Reed Switch Adjustments 144

Cassette Turrets 149

Rotary Actuator Sensor Load/Robot Position Adjustments 149

A. Before You Begin 149

Load Position 150

B. Check All Four Turret Switches and Record Results 150

C. Adjust the Load Position Sensors 152

D. Test the New Positioning 153

Robot Position 153

E. Check All Four Turret Sensors and Record Results 153

F. Adjust the Robot Position Sensors 155

G. Test the New Positioning 156

H. When Satisfactory Adjustment Is Achieved 156

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -10 Version 1.2 -June 2004

CHAPTER 12-SOFTWARE CALIBRATION

PROCEDURES

Overview 3

Menus Used in Maintenance and Calibration 4

Machine Maintenance Menu 4

Information Available at the Maintenance Menu 5

Choices Available at the Machine Maintenance Menu 7

Using the Machine Maintenance Menu's Manual Controls -An Example 14

Output Control / Input Status Menu 16

Information and Choices Available at the Output Control/Input Status Menu 17

Using the Output Control/Input Status Menu's Manual Controls -An Example 24

Machine (Calibration) Setup Entry Menu 26

Information and Choices Available at the Machine Setup Entry Menu 28

Using the Machine Setup Entry Menu -An Example 30

Robot (and Pre-Aligner) Setup and Calibration 32

Robot Coordinates 32

Robot (and Pre-Aligner) Commands 33

Robot / Cassette Turret Position Calibration 38

Theta 38

Radius 39

Z-Axis 40

Setting and Saving the New Coordinates 42

Work and Spin Chuck Home Index Calibration 43

Machines with Home Index Hardware Installed 44

Machines Without Home Index Hardware Installed 44

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -11

CHAPTER 13 -PNEUMATIC ADJUSTMENTS

Overview 3

Clean Dry Air 5

Incoming Clean Dry Air 6

Left/Right Grind Chamber Seals 7

Left/Right Chuck Conditioning Arms Up 8

Left/Right Chuck Conditioning Arms Engage 13

Left/Right Chuck Conditioning Arms Brush Rotation 13

Left/Right Chuck Conditioning Arms Downforce 14

Automatic Lubricator 14

Send 1 Cassette Turret Rotary Actuator 15

Send 2 Cassette Turret Rotary Actuator 18

Receive 1 Cassette Turret Rotary Actuator 19

Receive 2 Cassette Turret Rotary Actuator 20

Left/Right Measurement Probes 21

Spin Station Spindle Up/Down 22

Spin Station Lid Up/Down 25

Spin Station Brush Arm Park 28

Robot Flipper 29

Lower (Work Chuck) Air Bearing Spindles 32

Upper (Grind Wheel) Air Bearing Spindles 32

Turret Hydraulic Accumulator Reservoirs 33

Vacuum 34

Left/Right Grind Chamber Seal Vacuum 34

Left/Right Work Chuck Vacuum 34

Pre-aligner Vacuum 35

Rinse Spin Chuck Vacuum 35

Robot End Effector Vacuum 35

D.I. Water 36

Left Work Chuck Cutting Water 36

Right Work Chuck Cutting Water 40

Left/Right Work Chuck D.I. Water Backflush 41

Spin Station Wafer Clean 46

Blow Off 47

Left/Right Work Chuck Air Blow Off 47

Spin Station Wafer Blow Off 48

Robot End Effector Blow Off 48

Spindle Cooling Water for the Four Air Bearing Spindles 49

Coarse Spindle Cooling Water 49

Fine Spindle Cooling Water 51

Left (Work Chuck) Spindle Cooling Water 52

Right (Work Chuck) Spindle Cooling Water 53

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -12 Version 1.2 -June 2004

CHAPTER 14 -TROUBLESHOOTING

Overview 4

Messages Displayed on the Control Computer Screen Take Precedence! 4

Assumption 4

Work and Spin Chuck Homing Hardware 5

Machine Operation Checkout 6

Normal Operating Conditions and Strategies for Maintaining Them 8

Grind Force 8

Motor Current 8

Probe 8

Manual Dressing and Truing 9

Automatic Dressing and Truing 9

Visual Wafer Inspection -Identifying and Correcting Six Grind Process Problems 10

Fault Messages 14

Air Pressure (PSI) 15

Coarse Spindle PSI 15

Fine Spindle PSI 15

Left Chuck PSI 15

Right Chuck PSI 15

Cassettes 15

Cross Slot/Cassette 15

New Receive Cassette 15

New Send Cassette 15

Chucks 16

Rotational Home 16

Left Chuck Home 16

Right Chuck Home 16

Conditioning Arm Position 16

Left Condition Arm 16

Right Condition Arm 17

Coolant 17

Left Chuck Coolant 17

Right Chuck Coolant 17

Counterbalance 17

Counterbalance 17

Doors and Panels 18

Operator Door Open 18

Service Panels Open 18

Exhaust—IMPORTANT SAFETY INFORMATION! 18

Exhaust Fail 18

Force 18

Coarse Force Limit 18

Fine Force Limit 19

Grind Abort 20

Grind Abort: Unsafe! 20

Grind Seal 21

Left Grind Seal 21

Right Grind Seal 21

Operations and Maintenance Manual Table of Contents

Version 1.2 -June 2004 TOC -13

Grind Wheel 21

Coarse Wheel is Down 21

Fine Wheel is Down 21

Load Cell 22

Coarse Z Load Cell 22

Fine Z Load Cell 22

Prealigner 22

Prealigner Error 22

Probes 23

Left Probe 23

Right Probe 23

Left Probe is Down 23

Right Probe is Down 23

Reference 24

Bad Reference 24

Robot Communication 24

Robot Communication 24

Service Panel: Abort 24

Service Panel: Abort 24

Servo 25

Bridge Servo 25

Coarse Z Servo 25

Fine Z Servo 25

Left Chuck Servo 25

Right Chuck Servo 26

Robot Servo 26

Spin Station Servo 26

Coarse Spindle Servo 26

Fine Spindle Servo 27

Servo Water 27

Coarse Servo H20 27

Fine Servo H20 27

LT Chuck Servo H20 27

RT Chuck Servo H20 27

Spin Station 28

Spin Chuck Up/Down 28

Spin Lid Up/Down 28

Spin Station Home 28

Thickness 28

Thickness Limit 28

Turrets 29

Hand Close Turrets 29

Vacuum 29

Aligner Vacuum (Prealigner) 29

Left Chuck Vacuum 29

Left Chuck VacAbort 29

Right Chuck Vacuum 30

Right Chuck VacAbort 30

Robot Chuck Vacuum 30

Spin Station Vacuum 30

Strasbaugh nTellect (Model 7AF) Wafer Grinder

TOC -14 Version 1.2 -June 2004

CHAPTER 15-SOFTWARE AND CONTROL COMPUTER

MAINTENANCE

Overview 3

Messages Displayed on the Control Computer Screen Take Precedence! 3

Assumption 3

Backup and Recovery 4

Software Version Required 4

Backup 4

Restore 5

Protecting Recipe Files--Temporary Security Measures 7

Software Version Required 7

Protecting Recipes 7

Removing Protection from Recipes 8

Grind Data Files 9

File Structure 9

Example of a Grind Data File 10

Operation 11

Operation and Maintenance Manual Model 7AF Wafer Grinder

Appendices

Appendix A Calibration Variables Listing

Appendix B Engineering Drawings (bound under separate cover)

Appendix C Customer Parts List

Appendix D Electrical Input/Output System Address List

Appendix E Vacuum Station

Appendix F Maintenance Log Sheets

Appendix G Manufacturers' Documentation Sheets

Version 1.2 - June 2004 TOC - 13

Strasbaugh Table of Contents

List of Figures

Figure 2-1 Top View of Wafer Handling Section with

References to Procedure Steps 2-18

Figure 2-2 Side View Detail of Alignment Leg and Its

Adjacent Caster 2-19

Figure 2-3 Utility Connections 2-23

Figure 3-1 Model 7AF Wafer Grinder - Front View 3-7

Figure 3-2 Left Side View 3-9

Figure 3-3 Right Side View 3-11

Figure 3-4 Rear View 3-13

Figure 3-5 Wafer Grinder Subassemblies 3-15

Figure 3-6 Control Panel 3-18

Figure 3-7 Menu Tree 3-22

Figure 3-8 Main Menu 3-23

Figure 3-9 Home Machine Menu 3-24

Figure 3-9 Grind Cycle Menu 3-25

Figure 3-11 Edit Recipes (Wafer Recipes) Menu 3-26

Figure 3-12 Wheel and Chuck Recipes Menu 3-27

Figure 3-13 Dress Cycle Menu 3-28

Figure 3-14 Machine Maintenance Menu 3-29

Figure 3-15 Output Control/Input Status Menu 3-30

Figure 3-16 Machine Setup Entry Menu 3-31

Figure 8-1 Menu Tree 8-5

Figure 8-2 Main Menu 8-6

Figure 8-3 Home Machine Menu 8-8

Figure 8-4 Grind Cycle Menu 8-14

Figure 8-5 Dress Cycle Menu 8-19

Figure 8-6 Main Menu at Power Up 8-28

Figure 8-7 Home Machine Menu 8-30

Figure 8-8 Grind Cycle Menu 8-42

Figure 8-9 Example of a Coarse Grind Recipe 8-44

Figure 8-10 Example of a Fine Grind Recipe 8-45

Figure 8-11 Dress Cycle Menu 8-53

Figure 8-12 Example of a Coarse Wheel Dressing Recipe 8-57

Figure 8-13 Example of a Fine Wheel Dressing Recipe 8-57

Figure 8-14 Example of a Coarse Wheel Truing Recipe 8-58

Figure 8-15 Example of a Fine Wheel Truing Recipe 8-58

TOC - 16 Version 1.2 - June 2004

Operation and Maintenance Manual Model 7AF Wafer Grinder

Figure 8-16 Example of a Work Chuck Dressing Recipe 8-63

Figure 8-17 Example of a Work Chuck Truing Recipe 8-63

Figure 9-1 Wafer Recipes Menu 9-6

Figure 9-2 Wheel and Chuck Recipes Menu 9-21

Figure 11-1 Lower Spindle Side to Side Adjustment 11-20

Figure 11-2 Lower Spindle Front to Rear Adjustment 11-22

Figure 11-3 Sketch of Stacking Pattern for Spring Washers

Used with the Fringe Plate Tools 11-27

Figure 11-4 Upper Spindle Probe Reading Points 11-35

Figure 11-5 Upper Spindle Side to Side Adjustment 11-36

Figure 11-6 Upper Spindle Front to Rear Adjustment 11-37

Figure 12-1 Machine Maintenance Menu 12-5

Figure 12-2 Output Control / Input Status Menu 12-18

Figure 12-3 Machine Setup Entry Menu 12-29

Figure 12-4 Top View of Robot Theta Positioning at

Cassette Turret 12-40

Figure 12-5 Top View of Radial Positioning of Robot 12-41

Figure 12-6 Top View of Z-Axis Positioning of Robot 12-42

Figure 14-1 Wafer Surface Finish Examples 14-11

Figure 14-2 Cross-Hatching on the Wafer Edge 14-12

Figure 14-3 Blue-Blacking or Burning 14-12

Figure 14-4 Circular Marks Around Center of Wafer 14-13Figure 14-5 Cross-Hatching at the Center of the Wafer 14-13

Figure 14-6 Chatter Marks on the Wafer Edge 14-14

Figure 14-7 Star Crack 14-14

Figure 15-1 Grind Data Transfer to Diskette 15-12

Version 1.2 - June 2004 TOC - 17

Strasbaugh Table of Contents

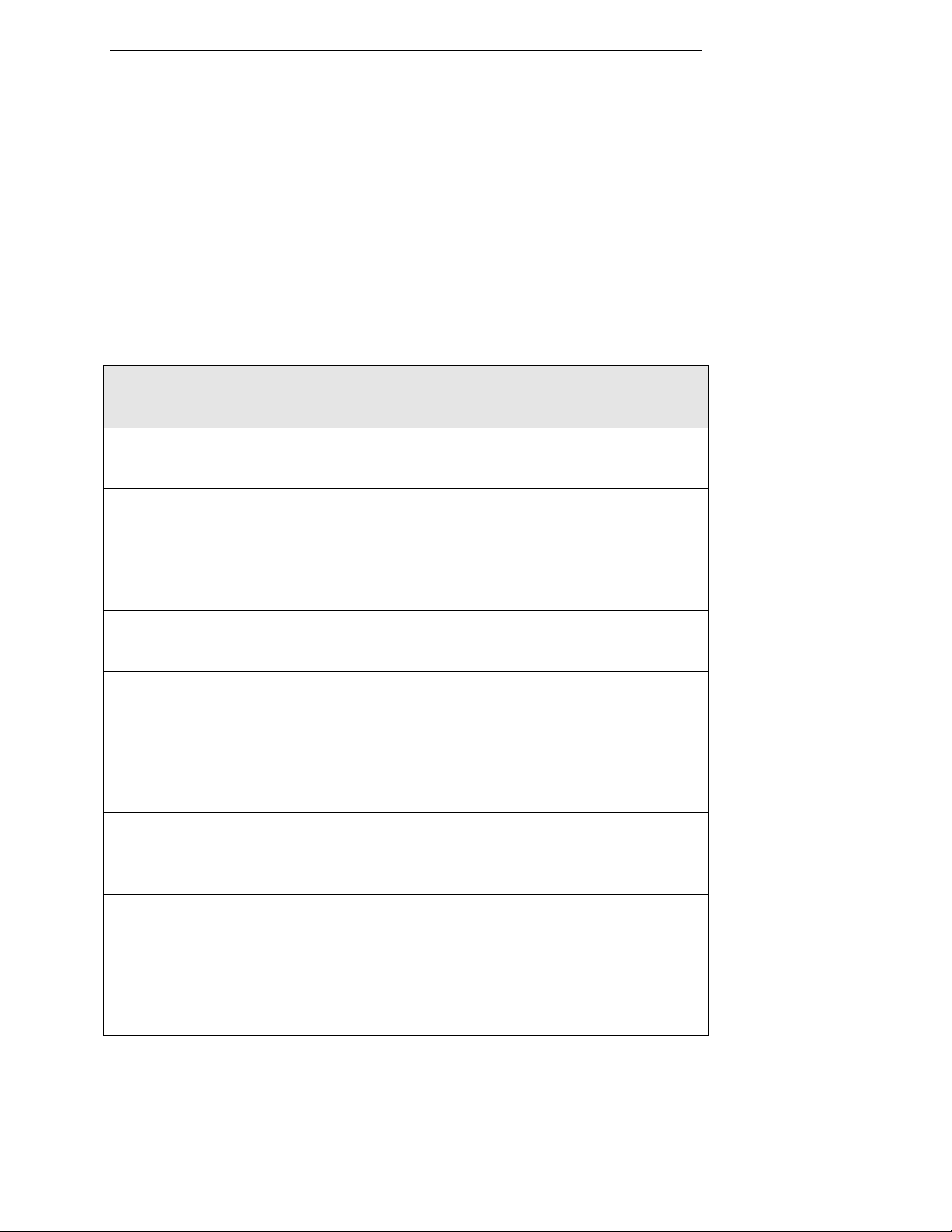

Menu Information Locator

The table below lists the 7AF software menus alphabetically together

with the location(s) in the Operation and Maintenance manual at

which detailed information for each may be found.

Menu Where to Find Details - Manual

Location(s)

DRESS CYCLE MENU • Ch. 8 - Operator Functions

GRIND CYCLE MENU • Ch. 8 - Operator Functions

HOME (MACHINE) MENU • Ch. 8 - Operator Functions

MACHINE MAINTENANCE MENU • Ch. 12 - Software Calibration

MACHINE (CALIBRATION) SETUP

ENTRY MENU • Ch. 12 - Software Calibration

MAIN MENU • Ch. 8 - Operator Functions

OUTPUT CONTROL/INPUT STATUS

MENU • Ch. 12 - Software Calibration

WAFER RECIPES MENU • Ch. 9 - Machine Setup

WHEEL AND CHUCK RECIPES

MENU • Ch. 9 - Machine Setup

TOC - 18 Version 1.2 - June 2004

Table of contents

Other Strasbaugh Industrial Equipment manuals