TLV V1 Series User manual

Manufacturer:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511 JAPAN

Tel: [81]-(0)79 - 422 - 1122 Fax: [81]-(0)79 - 422 - 0112

V1/V2 Series

Safety Considerations

Specifications

•

Read this section carefully before use and be sure to follow the instructions.

•

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve opening/closing should be carried out only

by trained maintenance personnel.

•

The precautions listed in this manual are designed to ensure safety and prevent equipment damage and personal injury.

For situations that may occur as a result of erroneous handling, three different types of cautionary items are used to indicate

•

The three types of cautionary items above are very important for safety: be sure to observe all of them as they relate to

installation, use, maintenance, and repair. Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbol

CAUTION

Install properly and DO NOT use this product outside the recommended operating pressure,

temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or malfunctions that may lead to

serious accidents. Local regulations may restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct contact with product outlets.

Failure to do so may result in burns or other injury from the discharge of fluids.

When disassembling or removing the product, wait until the internal pressure equals

atmospheric pressure and the surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under pressure may lead to discharge of

fluids, causing burns, other injuries or damage.

Do not use excessive force when connecting threaded pipes to the product.

Over-tightening may cause breakage leading to fluid discharge, which may cause burns or other injury.

Do not stand on or apply body weight to the handwheel.

The handwheel may break, resulting in injury or other accidents.

Do not carry the product by its handwheel

The handwheel may turn causing the balance to shift and the product to be dropped, resulting in injury

or other accidents.

Installation & Operational Consideration

CAUTION

*1

Maximum Allowable Pressure (PMA) and Maximum Allowable Temperature (TMA) are PRESSURE

SHELL DESIGN CONDITIONS for trap station only, NOT OPERATING CONDITIONS.

*2

For trap station only; further restricted by mounted trap unit.

(1 MPa = 10.197 kg/cm2)

Important

This product connects to TLV QuickTrap series trap

units. For the connection procedure and the installation

procedure, see the instruction manual included with the

trap unit, and make sure to work safely.

Name

Inlet/Outlet Valve

Body Material

Size

Applicable Fluid

Appearance

Flow Diagram

Flow Direction

Blowdown Valve

Test Valve

Right or Left

or

or

or

or

Right

●

Left

●

Only at the inlet side

Free Float Steam Trap

S3, S5, S5H, S3-K, S5-K

Disc Type Steam Trap

P32

P46UC

Thermostatic Steam Trap

L5, L21, L32, L5-C, L21-C, L32-C

X1

Inlet/outlet side

TRAP STATION

SUS304

15, 20 mm (1/2, 3/4 in)

4.6 MPaG (650 psig) / 425 °C (800 °F)

4.6 MPaG (650 psig) / 425 °C (800 °F)

Steam, Condensate

Other trap units may be applicable. Contact TLV for QuickTrap models not listed.

TRAP STATION

CAUTION

: Indicates that there is a possibility of injury or equipment/product damage

Copyright 2021 by TLV CO., LTD. All rights reserved.

C

○

When operating the blowdown/test valve, stand to the side well clear of the outlet to avoid contact with

internal fluids that will be discharged. Operate the valve slowly and surely, taking care to avoid the area

from which internal fluids are discharged and any fluids deflected off piping or the ground etc.

Failure to do so may result in burns or other injury.

Do not tighten the BD2 valve or the BD2 valve seat in excess of the appropriate tightening torque.

Over-tightening may cause breakage to threaded portions, which may cause burns, other injuries or

damage.

Do not excessively loosen the BD2 valve when opening the blowdown/test valve.

The valve stopper pin installed to prevent the BD2 valve from being removed may break and internal

pressure may result in the BD2 valve being blown off, leading to injuries, damage and fluid discharge,

causing burns.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, reading to fluid discharge, which may cause

burns or other injury.

Always wear eye protection and heat-resistant gloves when operating the blowdown/test valve.

Failure to do so may result in burns or other injury.

Before installing the product, blow out the piping to remove any piping scraps, dirt, oil and scale.

Failure to do so may lead to early clogging due to an initial heavy load of foreign material in the piping.

Do not remove the product from its box or protective covering until just prior to installation.

Remove any plugs or seals just prior to installation.

The protective covers keep damage causing foreign material out of the product.

Do not use a wire-brush or other hard devices to clean the screen.

Doing so may damage or detach the meshed screen.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, reading to fluid discharge, which may cause burns or other injury.

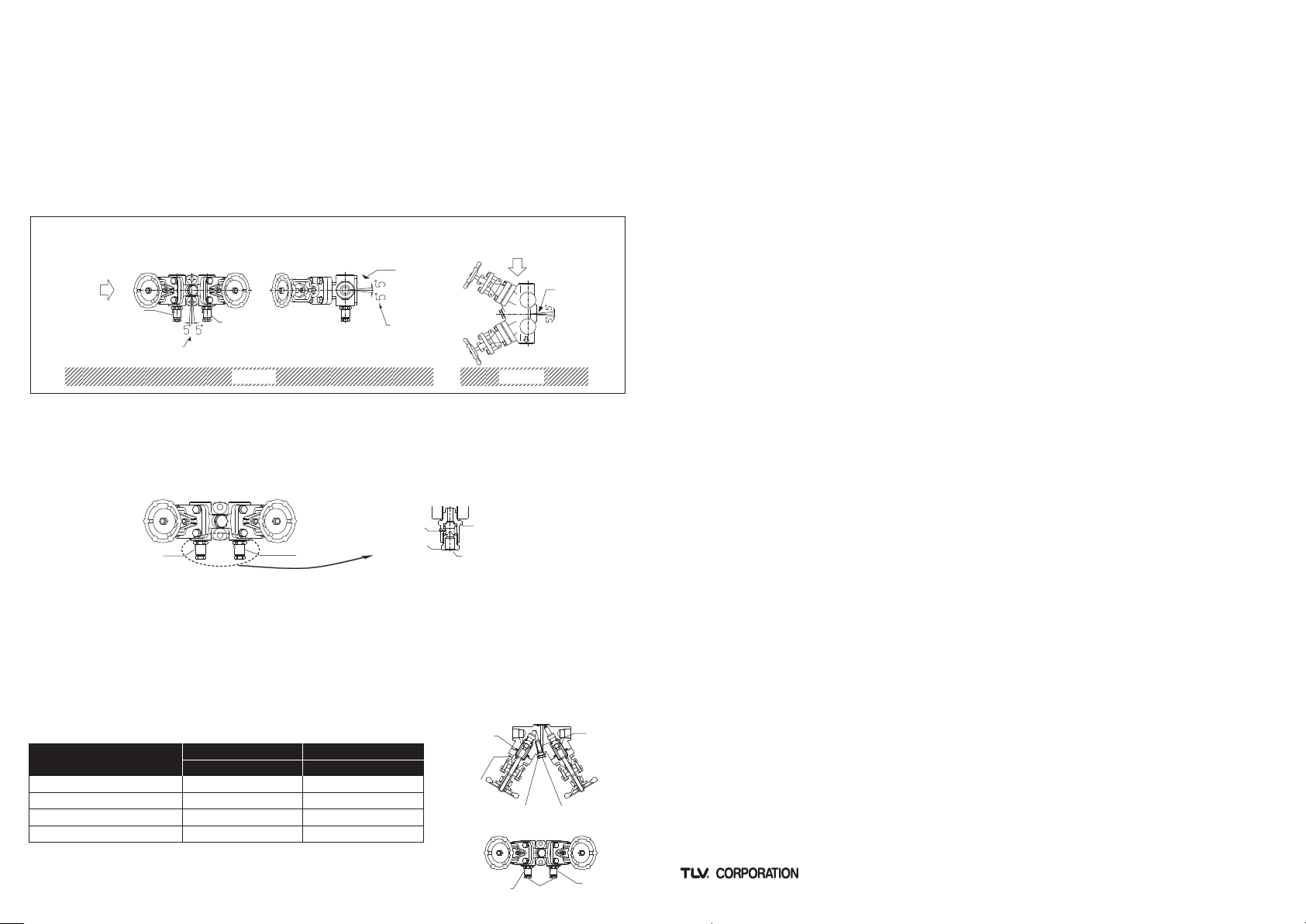

Model V1-RL / V1-RB / V1-LB V2-RL / V2-RB / V2-LB

Model V1-RL V1-RB V1-LB

Appearance

Flow Diagram

Flow Direction

Blowdown Valve

Test Valve

Right or Left

Right

●

●

Left

●

●

Model V2-RL V2-RB V2-LB

Max. Allowable Press. PMA*1/

Max. Allowable Temp. TMA*1

Max. Operating Press. PMO*2/

Max. Operating Temp. TMO*2

Connectable TLV products

(Trap Unit Models)

NOTE: Some models may not be

available in all regions.

Installation Availability of Spare Parts

Table of Tightening Torques

Blowdown Valve / Test Valve Operation

1. Before installation, be sure to remove all protective seals.

2. Before installing the product, blow out the piping to remove any piping scraps, dirt and oil.

3. Install the product so the arrow on the body is pointing in the direction of condensate flow.

4. The handwheels should be facing the operator. At this time, make sure that the installation surface for the trap unit is

vertical to the ground. If a blowdown valve or test valve is installed on the product, connect the piping by making sure the

discharge outlet is facing downwards (toward the ground).

5. If a blowdown valve or test valve is installed on the product, install the product horizontally on the piping. The allowable

inclination from horizontal, and for the installation surface for the trap unit, is within 5° as shown below.

6. If a blowdown valve or test valve is not installed on the product, the product may be installed in either vertical or

horizontal orientation. However, ensure the inlet is facing upwards for vertical piping. The allowable inclination for the

installation surface for the trap unit is within 5° as shown below.

7. Install the trap unit onto the trap station. For installation instructions see the instruction manual shipped with the trap unit.

8. Connect the outlet piping.

9. Open the inlet and outlet valves slowly and check to make sure that the product functions properly.

1. The BD2 valve is in the closed position when the Trap Station is shipped from the factory. Before attempting to operate

the blowdown valve and the test valve, reconfirm that the BD2 valve is still in the closed position. Locate the blow outlet

and, during operation, stand to the side and well clear of it, as the jet of condensate or steam could cause burns.

2. Remain in the area the entire time the BD2 valve is in the open position. Before opening the BD2 valve, grip the BD2 valve

seat with a wrench and hold firmly in place so that it will not rotate when the BD2 valve is loosened. Grip the BD2 valve

with another wrench and slowly loosen. Condensate and steam will discharge from the discharge hole in a jet stream. Be

careful not to loosen the BD2 valve so far that it becomes removed from the BD2 valve. (If the valve stopper pin becomes

damaged, large quantities of steam will be discharged in a jet stream.)

NOTE: Do not leave the vicinity while the BD2 valve is in the open position.

3.

Close the BD2 valve until the flow of fluid completely stops. If the flow of fluid does not stop, re-open the valve (as in step 2)

to blow out any scale or dirt that may be caught in the valve. Re-tighten the valve until the flow of fluid stops completely.

NOTE: Coat all threaded portions with anti-seize. If drawings or

other special documentation were supplied for the product, any torque

given there takes precedence over values shown here.

Avoid the use of excessive tightening torques, as threaded parts may

become damaged.

The blowdown valve uses internal pressure to blow out condensate or other fluids from inside the unit to the atmosphere in

order to remove scale and dirt. The test valve is installed at the outlet of the trap. By closing the outlet valve for the trap station

and opening the test valve it becomes possible to test the operation of the trap. The TLV blowdown valve BD2 is used for both

the blowdown valve and the test valve. For operation refer to the BD2 operation instructions below.

Aside from parts ①−⑤shown in the figures under “Table of Tightening Torques”, replacement parts are not normally

supplied. Consult TLV if other parts are needed.

Subject to the limitations set forth below, TLV Corporation, a North Carolina corporation (“TLV”) warrants that products which are

sold by it, TLV CO., LTD., a Japanese corporation (“TLVJ”) or TLV International, Inc., a Japanese corporation (“TII”), (hereinafter the

“Products”) are designed and manufactured by TLVJ, conform to the specifications published by TLV for the corresponding part

numbers (the “Specifications”) and are free from defective workmanship and materials. With regard to products or components

manufactured by unrelated third parties (the “Components”), TLV provides no warranty other than the warranty from the third party

manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by other than TLV or service representatives authorized by TLV; or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and maintenance by other than TLV or service representatives

authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water, nitrogen, carbon dioxide and inert gases (helium,

neon, argon, krypton, xenon and radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the Product.

Duration of Warranty

This warranty is effective for a period of the earlier of: (i) three (3) years after delivery of Products to the first end user in the case of

sealed SST-Series Products for use in steam pressure service up to 650 psig; (ii) two (2) years after delivery of Products to the first

end user in the case of PowerTrap® units; or (iii) one (1) year after delivery of Products to the first end user in the case of all other

Products. Notwithstanding the foregoing, asserting a claim under this warranty must be brought by the earlier of one of the foregoing

periods, as applicable, or within five (5) years after the date of delivery to the initial buyer if not sold initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY OPERATION OF LAW, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT

NEGATED HEREBY, ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN DURATION TO ONE (1) YEAR FROM THE

DATE OF SHIPMENT BY TLV.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS WARRANTY OR UNDER ANY IMPLIED

WARRANTIES NOT NEGATED HEREBY (INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE), IS

REPLACEMENT;

PROVIDED: (a) THE CLAIMED DEFECT IS REPORTED TO TLV IN WRITING WITHIN

THE APPLICABLE WARRANTY PERIOD, INCLUDING A DETAILED WRITTEN DESCRIPTION OF THE CLAIMED DEFECT AND HOW

AND WHEN THE CLAIMED DEFECTIVE PRODUCT WAS USED; AND (b) THE CLAIMED DEFECTIVE PRODUCT AND A COPY OF

THE PURCHASE INVOICE IS RETURNED TO TLV, FREIGHT AND TRANSPORTATION COSTS PREPAID, UNDER A RETURN

MATERIAL AUTHORIZATION AND TRACKING NUMBER ISSUED BY TLV. ALL LABOR COSTS, SHIPPING COSTS, AND

TRANSPORTATION COSTS ASSOCIATED WITH THE RETURN OR REPLACEMENT OF THE CLAIMED DEFECTIVE PRODUCT ARE

SOLELY THE RESPONSIBILITY OF BUYER OR THE FIRST END USER. TLV RESERVES THE RIGHT TO INSPECT ON THE FIRST

END USER’S SITE ANY PRODUCTS CLAIMED TO BE DEFECTIVE BEFORE ISSUING A RETURN MATERIAL AUTHORIZATION.

SHOULD SUCH INSPECTION REVEAL, IN TLV’S REASONABLE DISCRETION, THAT THE CLAIMED DEFECT IS NOT COVERED BY

THIS WARRANTY, THE PARTY ASSERTING THIS WARRANTY SHALL PAY TLV FOR THE TIME AND EXPENSES RELATED TO

SUCH ON-SITE INSPECTION.

Exclusion of Consequential and Incidental Damages

IT IS SPECIFICALLY ACKNOWLEDGED THAT THIS WARRANTY, ANY OTHER EXPRESS WARRANTY NOT NEGATED HEREBY,

AND ANY IMPLIED WARRANTY NOT NEGATED HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR TLVJ WILL IN ANY EVENT BE LIABLE

FOR, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO LOST PROFITS, THE COST OF

DISASSEMBLY AND SHIPMENT OF THE DEFECTIVE PRODUCT, INJURY TO OTHER PROPERTY, DAMAGE TO BUYER’S OR THE

FIRST END USER’S PRODUCT, DAMAGE TO BUYER’S OR THE FIRST END USER’S PROCESSES, LOSS OF USE, OR OTHER

COMMERCIAL LOSSES. WHERE, DUE TO OPERATION OF LAW, CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER THIS

WARRANTY, UNDER ANY OTHER EXPRESS WARRANTY NOT NEGATED HEREBY OR UNDER ANY IMPLIED WARRANTY NOT

NEGATED HEREBY (INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE) CANNOT BE EXCLUDED, SUCH DAMAGES ARE EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE PRICE OF

THE DEFECTIVE PRODUCT. THIS EXCLUSION OF CONSEQUENTIAL AND INCIDENTAL DAMAGES, AND THE PROVISION OF

THIS WARRANTY LIMITING REMEDIES HEREUNDER TO REPLACEMENT, ARE INDEPENDENT PROVISIONS, AND ANY

DETERMINATION THAT THE LIMITATION OF REMEDIES FAILS OF ITS ESSENTIAL PURPOSE OR ANY OTHER DETERMINATION

THAT EITHER OF THE ABOVE REMEDIES IS UNENFORCEABLE, SHALL NOT BE CONSTRUED TO MAKE THE OTHER

PROVISIONS UNENFORCEABLE.

Exclusion of Other Warranties

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND ALL OTHER WARRANTIES, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSLY DISCLAIMED.

Severability

Any provision of this warranty which is invalid, prohibited or unenforceable in any jurisdiction shall, as to such jurisdiction, be

ineffective to the extent of such invalidity, prohibition or unenforceability without invalidating the remaining provisions hereof, and

any such invalidity, prohibition or unenforceability in any such jurisdiction shall not invalidate or render unenforceable such provision

in any other jurisdiction.

13901 South Lakes Drive, Charlotte, NC 28273-6790, U.S.A.

Tel: [1]-704-597-9070 Fax: [1]-704-583-1610

Tolerance Angle for

Installation

Horizontal Installation

(all products installable)

Blowdown Valve

(BD2)

Vertical Installation

(only products without blowdown/test valve

can be installed)

Test Valve

(BD2)

Installation

surface for

trap unit

For products with

blowdown valve or test valve

For all

products

Installation

surface for

trap unit

Screen Holder Plug

Bonnet Bolt

Blowdown Valve/Test Valve

BD2 Valve

60

60

60

30

(44)

(44)

(44)

(22)

22

22

22

17

()

()

()

( )

N・m (lbf・ft) mm (in)

Part Name Torque Distance Across Flats

8

7

/

8

7

/

8

7

/

32

21

/

(1 N.m 10 kg.cm)

〜

〜

TLV EXPRESS LIMITED WARRANTY

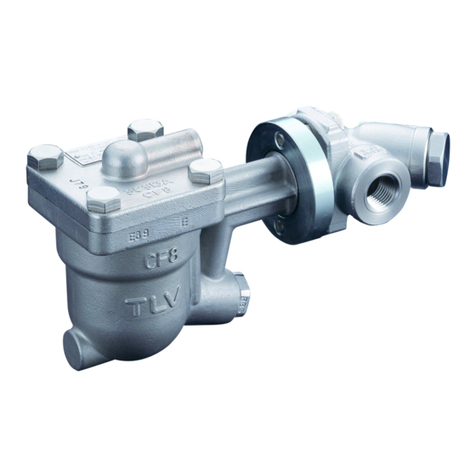

Discharge Hole

BD2 Valve

Valve Stopper Pin BD2 Valve Seat

Blowdown Valve

(BD2)

Test Valve

(BD2)

<Construction> BD2 (configuration)

Bonnet

Bolt

Screen

①

Screen Holder

Plug

BD2 Valve

Bellows

Gasket

(Lower) ⑤

Blowdown

Valve

Gasket ③

Test Valve

Gasket ④

Screen Holder

Gasket

②

GroundGround

PAC-65386-a Rev. 10/2021 (M)

Printed on recycled paper.

This manual suits for next models

7

Other TLV Industrial Equipment manuals

TLV

TLV PowerDyne P46S User manual

TLV

TLV PowerDyne QuickTrap P46UC-Y User manual

TLV

TLV SS1VG-M User manual

TLV

TLV SS3 Series User manual

TLV

TLV JH-P Series User manual

TLV

TLV SW1U-A User manual

TLV

TLV UFO Series User manual

TLV

TLV JH-X Series User manual

TLV

TLV JL14-X User manual

TLV

TLV QuickTrap FJ32-X User manual

TLV

TLV DC3-L User manual

TLV

TLV SR-B1.5 User manual

TLV

TLV QuickTrap FP32 User manual

TLV

TLV QuickTrap FL Series User manual

TLV

TLV BT3N User manual

TLV

TLV LV6-CE User manual

TLV

TLV QuickTrap FS Series User manual

TLV

TLV QS10 Series User manual

TLV

TLV PowerDyne HR-A Series User manual

TLV

TLV RT3A User manual