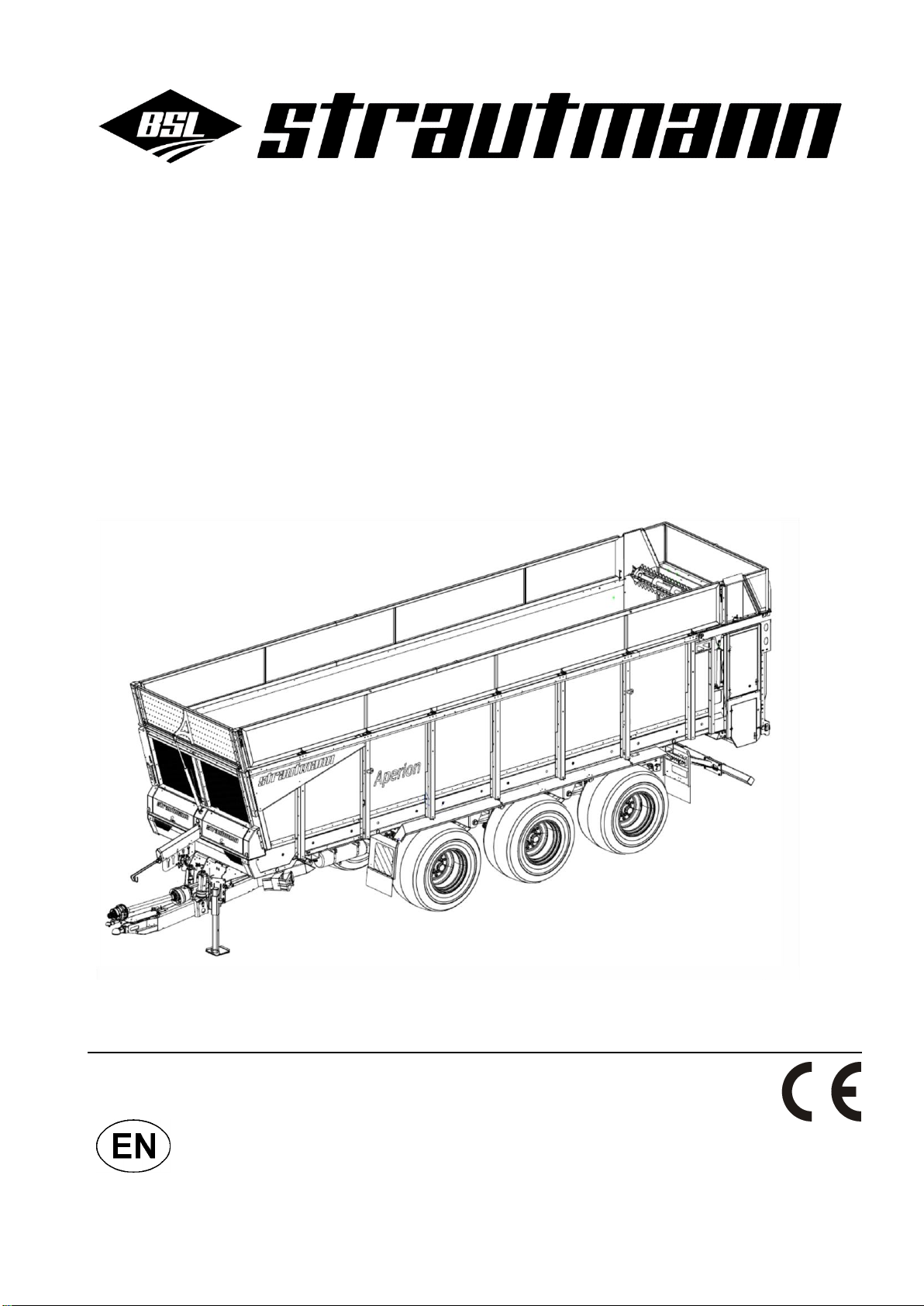

Aperion 2101, Aperion 2401, Aperion 3401 04.18

5.6.2 Lower hydraulic supporting leg to support position................................................................85

5.6.3 Lift mechanical supporting leg to transport position ..............................................................86

5.6.4 Lower mechanical supporting leg to support position............................................................86

5.6.5 Lift mechanical supporting leg in combination with hydro-pneumatic drawbar suspension to

transport position ...................................................................................................................87

5.6.6 Lower mechanical supporting leg in combination with hydro-pneumatic drawbar suspension

to support position..................................................................................................................87

5.7 Adjust length of propeller shaft to tractor...................................................................................88

5.8 Hitch machine ............................................................................................................................89

5.8.1 Connect hydraulic hose pipes................................................................................................90

5.8.1.1 Open hydraulic system ......................................................................................................90

5.8.1.2 Load-sensing mode ...........................................................................................................91

5.8.2 Couple drawgear....................................................................................................................91

5.8.2.1 Tow-hook (hitch hook) and drawbar lug (hitch ring) ..........................................................91

5.8.2.2 Draw pin (Piton-Fix) and drawbar lug (hitch ring)..............................................................92

5.8.2.3 Ball-type coupling and shell...............................................................................................92

5.8.3 Couple forced steering axle...................................................................................................93

5.8.4 Connect brake system...........................................................................................................96

5.8.4.1 Connect dual-line service brake system............................................................................96

5.8.4.2 Connect hydraulic brake system........................................................................................97

5.8.4.3 Connect emergency brake valve .......................................................................................97

5.8.5 Couple propeller shaft............................................................................................................98

5.9 Unhitch machine ........................................................................................................................99

5.9.1 Uncouple drawgear................................................................................................................99

5.9.1.1 Tow-hook (hitch hook) and drawbar lug (hitch ring) ..........................................................99

5.9.1.2 Draw pin (Piton-Fix) and drawbar lug (hitch ring)..............................................................99

5.9.1.3 Ball-type coupling and shell.............................................................................................100

5.9.2 Disconnect hydraulic hose pipes .........................................................................................100

5.9.3 Disconnect brake system.....................................................................................................100

5.9.3.1 Disconnect dual-line service brake system......................................................................101

5.9.3.2 Disconnect hydraulic brake system.................................................................................101

5.9.3.3 Disconnect hydraulic brake system with emergency brake valve ...................................101

5.9.4 Uncouple propeller shaft......................................................................................................102

5.10 Manoeuvre unhitched machine by means of a manoeuvring vehicle......................................103

5.11 Mount/Set extension sections on cargo space ........................................................................104

5.11.1 Mount extensions in rigid position........................................................................................104

5.11.2 Mount extensions in folding position....................................................................................105

5.11.3 Retract and extend telescoping extensions.........................................................................105

5.12 Set tailgate ...............................................................................................................................106

5.13 Beaters.....................................................................................................................................108

5.13.1 Mount beaters......................................................................................................................108

5.13.2 Remove beaters...................................................................................................................109

5.14 Switch potato gate over............................................................................................................110

5.15 Insert inspection glasses..........................................................................................................110

6Operation.........................................................................................................111

6.1 Operation with direct control and forced steering axle system ................................................111

6.2 Operation via E-control ............................................................................................................112

6.2.1 Operation via E-control........................................................................................................112

6.2.2 Functions and their symbols................................................................................................113

6.2.2.1 Switch control set on/off/Switch road travel mode on......................................................113

6.2.2.2 Switch work lights on / off ................................................................................................113

6.2.2.3 Lift/Lower telescopic extension........................................................................................114

6.2.2.4 Open/Close cargo space cover .......................................................................................114

6.2.2.5 Open/Close front panel....................................................................................................115

6.2.2.6 Close/Open tailgate .........................................................................................................115

6.2.2.7 Power/Reverse transport floor in discharging direction...................................................116

6.2.2.8 Adjust transport floor speed.............................................................................................116

6.2.2.9 External operation for transport floor feed .......................................................................117

6.2.2.10 Lock/Unlock steering axle................................................................................................117