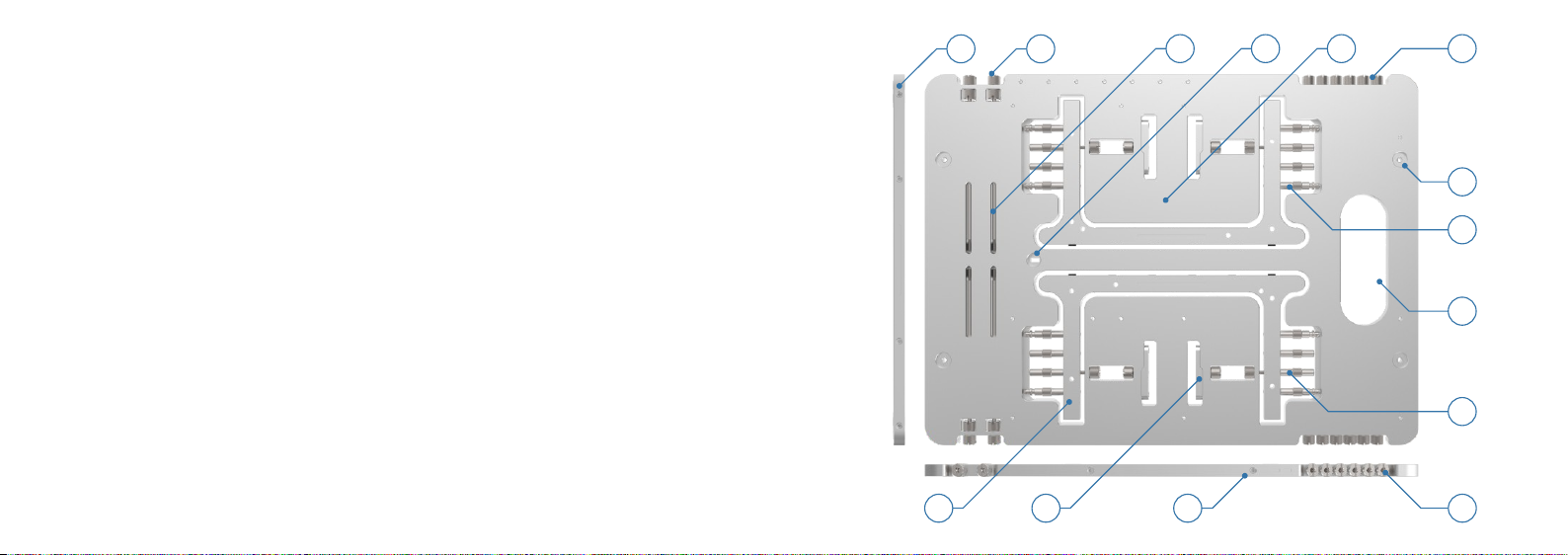

Streacom BC1 User manual

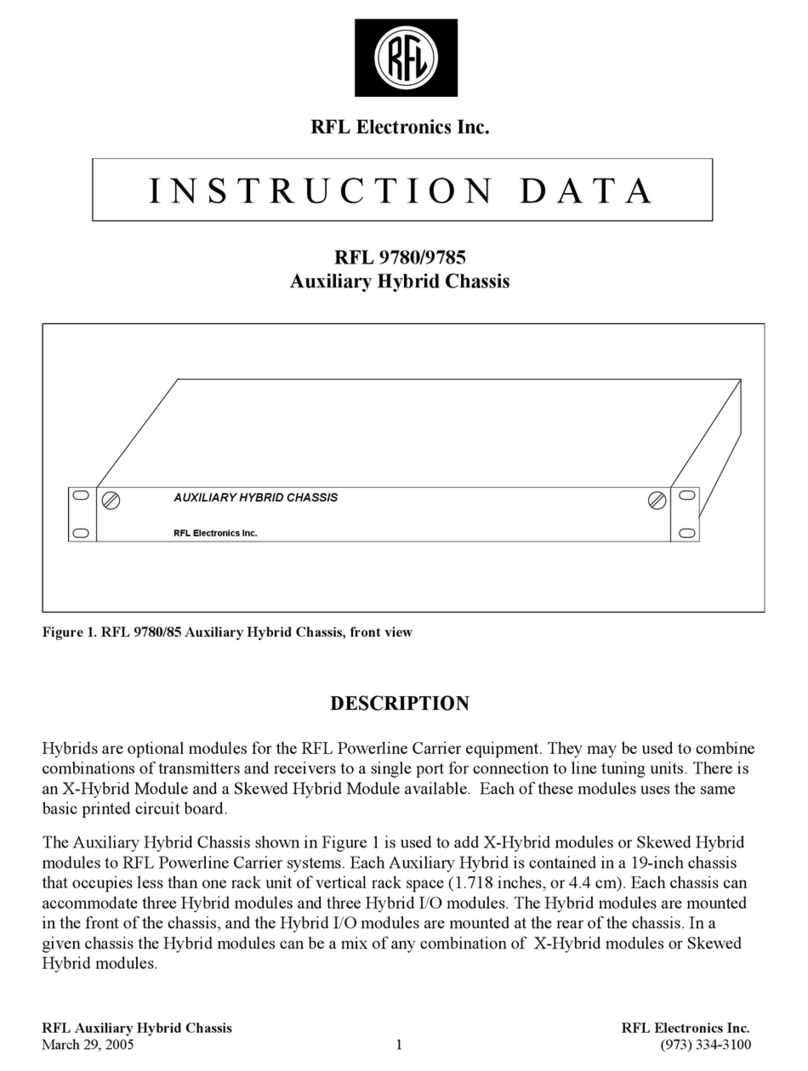

6 - 6#32 thumbscrews x 6

5 - Main body

8 - Pushpin standoff x 8

4 - Kensington lock

7 - Foot mounting hole x 4

13 - Bracket x 4

3 - Drive slots x 2

14 - Foot x 2

12 - Left/Right bracket mounting point x 4

9 - Integrated carry handle

11 - M3 thumbscrews x 6

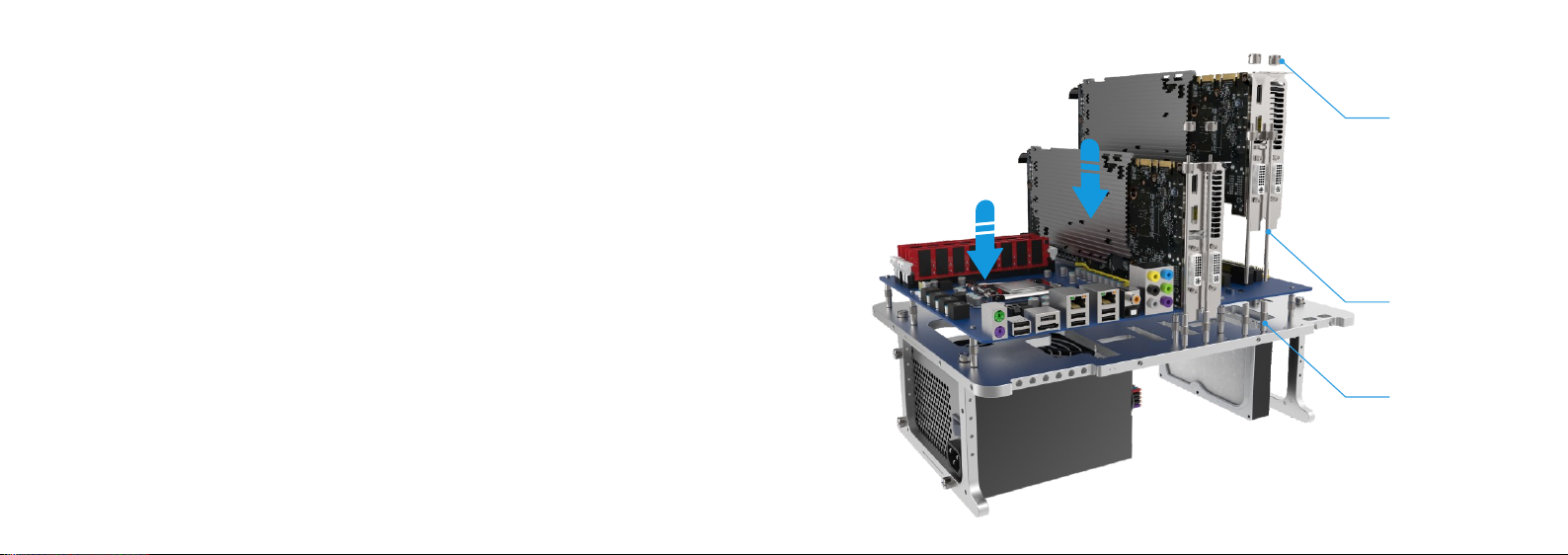

BC1 Overview

2 - PCI thumbscrew & nut x 4

1 - Top/Bottom bracket mounting point x 8

10 - Threaded standoff x 8

BC1 Specification

Width - 260mm

Assembled height - 115mm

Weight - 1.82Kg

Length - 370mm PSU support - ATX 12V / BTX, ATX large and ATX-EPS

Thickness - 8mm

Table material - AL5052

Screw material - SS304

Drive support - Up to 2 x 2.5" or 2 x 3.5"

Motherboard support - XL, E, Mini, & Micro- ATX, Mini ITX

Max total load capacity - 25Kg

Motherboard standoff height - 25mm

Bracket cooling support - 240, 140, 120, 92, 80 mm

PSU max weight - 10Kg

Max bracket weight - 5Kg 8

6

7

14

2

9

10

1113

1

12

5

34

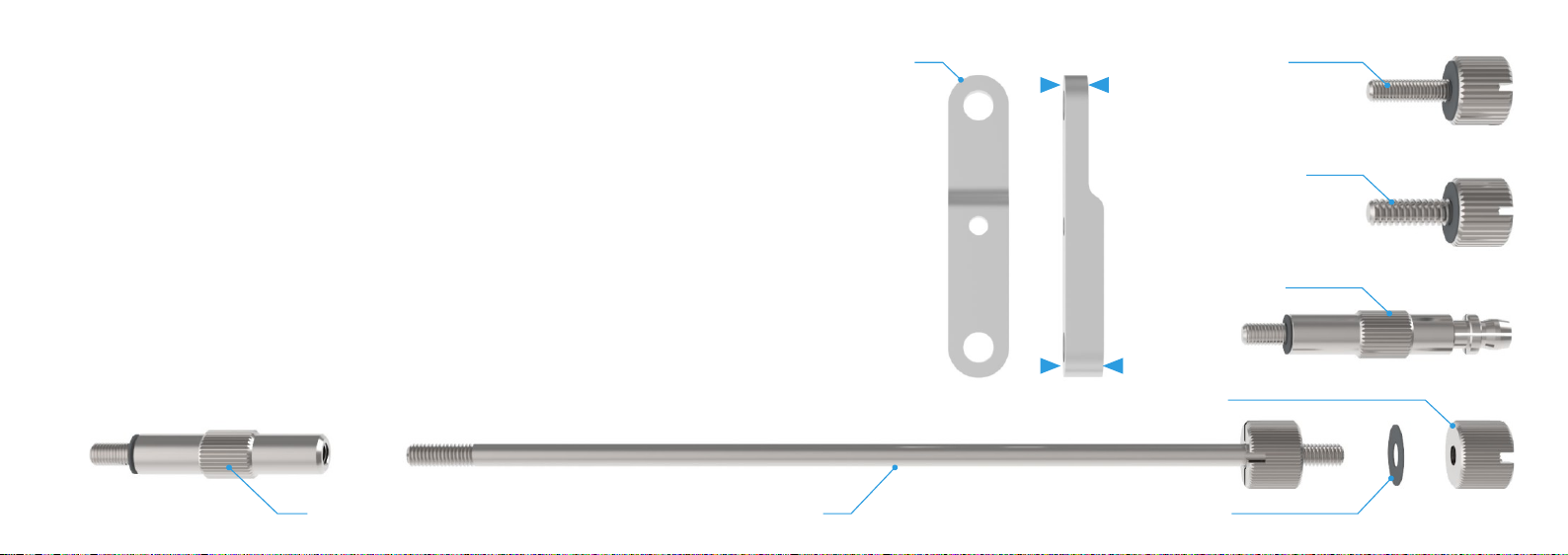

The difference between the M3 and 6#32 thumbscrew thread is subtle, so ensure the correct one is

used to avoid damage to your BC1. The M3 and 6#32 thumbscrews also feature an inner thread on the

head of the screw which allows M3 screws to be secured, giving additional stacked mounting options.

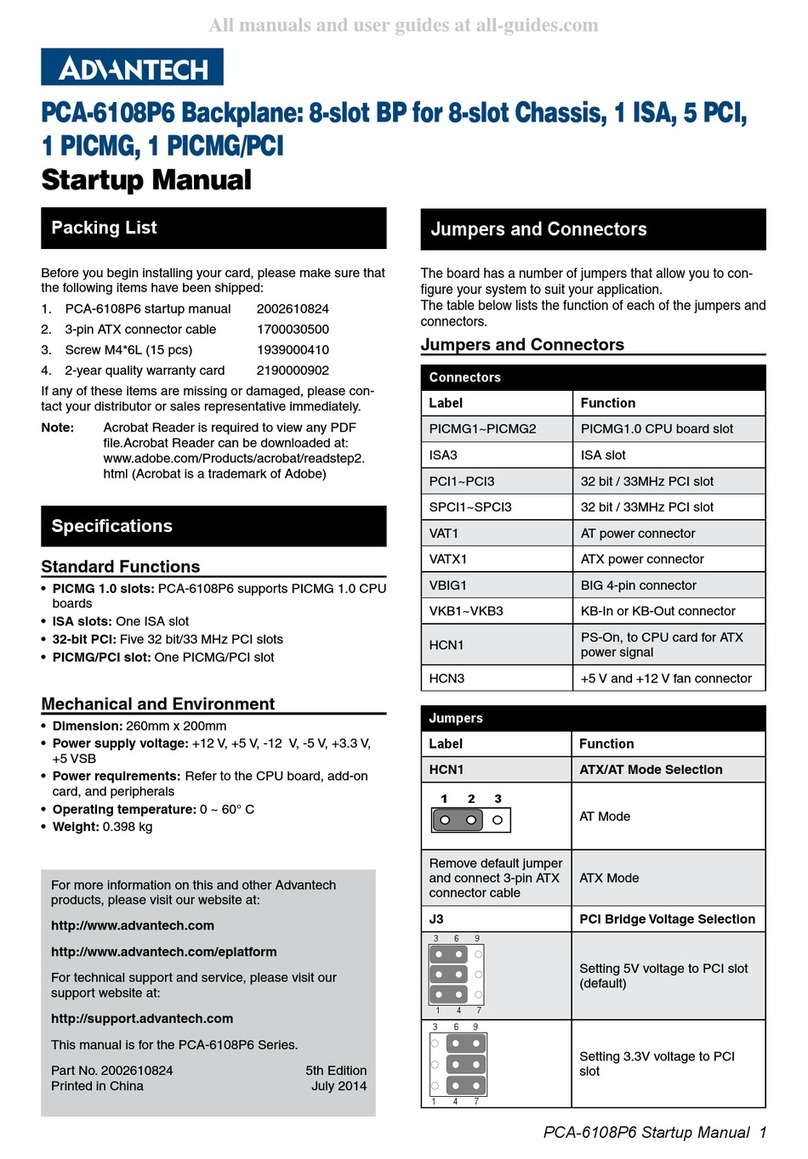

Introduction to the screws & brackets

The BC1 is supplied with 5 different types of screw which are used to mount all the various hardware to

the table. All screw threads are M3 except for the 6#32 thumbscrews which are used to attach 3.5" drives

and the PSU.

The BC1 brackets are used to fix additional components to the main body and feature a thick and thin side

which are interchangeable and designed to accommodate various screw lengths and thread depths,

depending on the hardware being fitted.

Note that all the screws feature a thin plastic washer at the base to ensure there is minimal damage to the

aluminium surface at the point of contact. The PCI thumbscrews are packed with extra washers which

should be used between the brackets and main body to minimise damage.

1M3 thumbscrew

Threaded standoff

6#32 thumbscrew

Pushpin standoff

Washer

PCI thumbscrew

Bracket

5mm

3mm

PCI nut

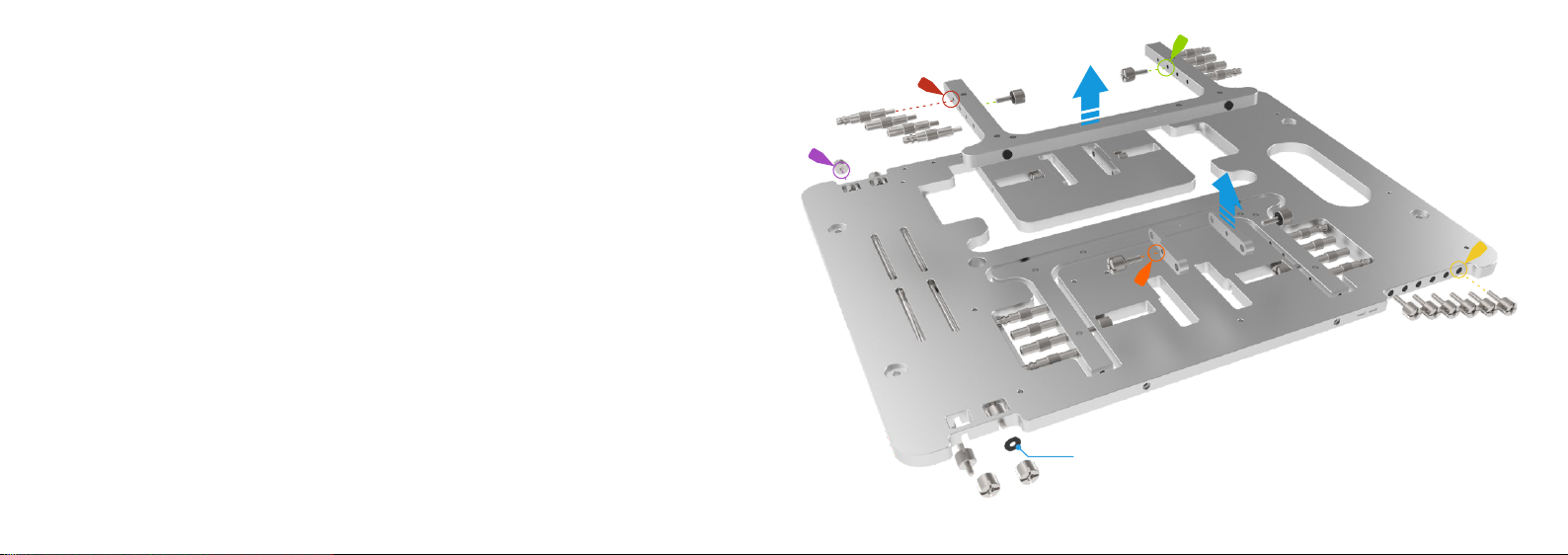

Removing feet, brackets and screws from the main body

The BC1 features a unique self contained design which means all the parts required for assembly

are stored and fitted directly to the main body. Before you can begin any assembly, the critical

parts (e.g. feet) and those that will be required by accessories (e.g. side brackets) should be

removed from the main body. This is done by simply removing the thumbscrews used to secure

each of the parts, or in the case of thumbscrews, simply unscrewing from the main body.

The feet are each held in place by 2 thumbscrews on either side. The same thumbscrews used

to secure the feet when stored will be used to attached the feet in the assembled position

although any of the M3 thumbscrews can be used as they are identical and interchangeable.

The pushpin and threaded standoffs are secured to the feet and can be removed at this point

depending on how many are required by the hardware being installed.

The PCI thumbscrews are removed by loosening or removing the nut at the top, then angling

the screw downwards and away from the table. It is recommend that you remove them in sets

of 2 on opposite sides, as the slots they occupy are used to mount drives.

2

Washer for use with brackets

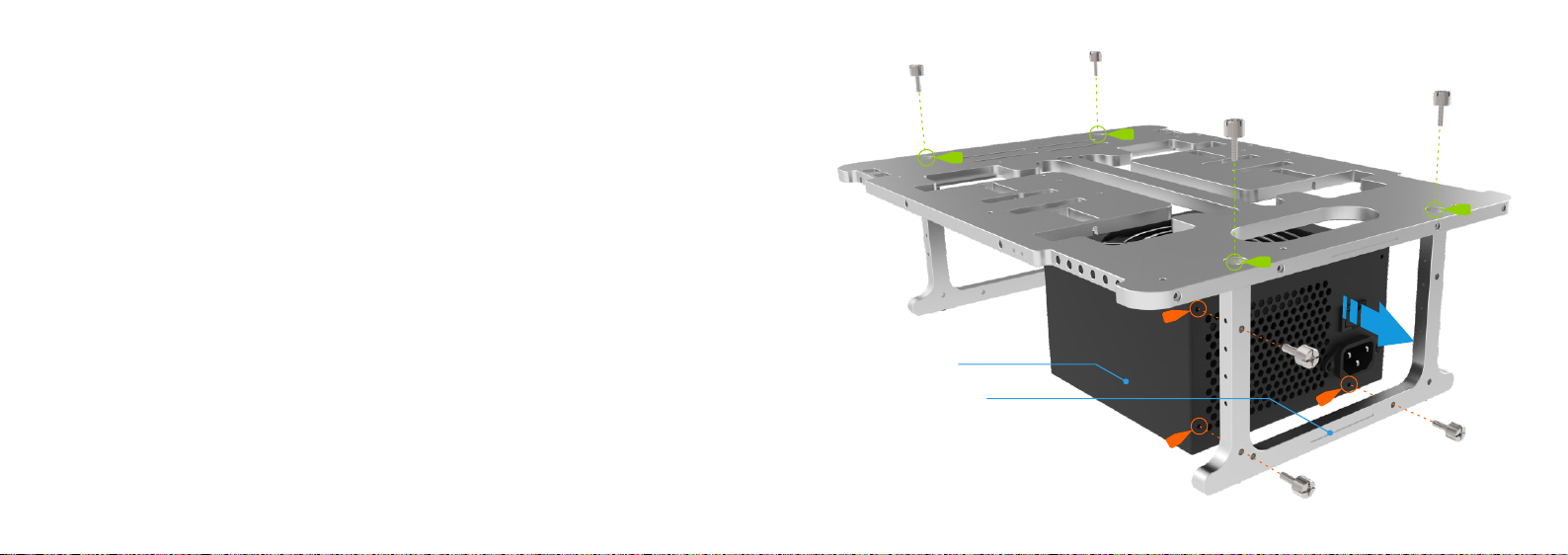

To install the feet, ensure the engraved line on the bottom of both feet is facing outwards, then

secure them to the main body using the M3 thumbscrews from the top and through the enlarged

circular holes.

Make sure the thumbscrews are properly tightened and if necessary use a screwdriver as this is

critical for a stable platform.

Fitting the feet and PSU

With the feet secured, it is now possible to fit the PSU which attaches directly to the right side foot

under the table. Only 3 thumbscrews are required, but it is important to check if your PSU

requires M3 or 6#32 threaded screws. The BC1 allows for both orientations of the PSU, so it

can be flipped if required, with the fan facing downward.

3

Engraved Line

ATX PSU

The BC1 supports 2 x 3.5" or 2 x 2.5" drives which mount

vertically to the underside of the main body using the 6#32 for

3.5" drives or M3 thumbscrews for 2.5" drives.

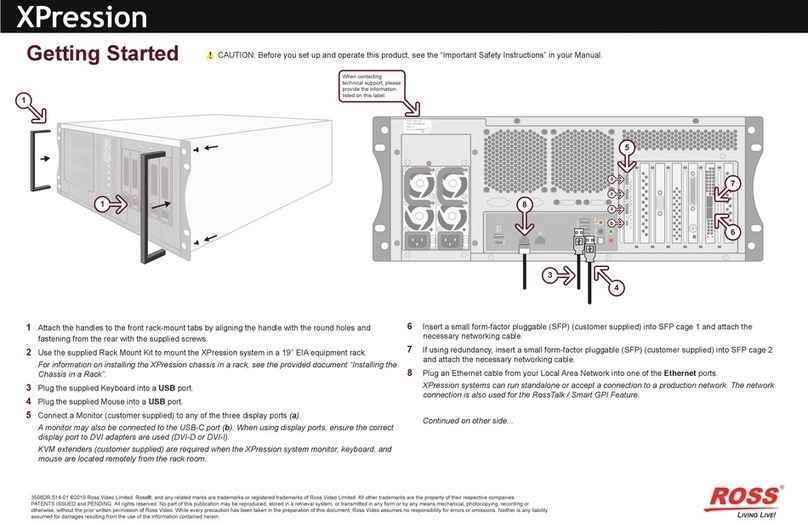

Fitting hard drives & standoffs to the main body

Note that threaded standoffs can also be used instead of

pushpin ones or in combination and require M3 screw in

order to lock the motherboard more securely for permanent

setups.

In preparation for fitting the motherboard and PCI cards,

standoffs must be fitted to the upper surface of the main body.

Depending on what size motherboard and how many cards

are being installed, use the correct number of standoffs in the

matching locations. The motherboard uses pushpin or

threaded standoffs whilst the PCI card supports require

threaded standoffs.

4

mITXmATXATX

PCI card

mounting holes

Motherboard

mounting holes

2.5" Drive

3.5" Drive

Pushpin or threaded standoff

Threaded standoff

With the standoffs fitted to the main body and after verifying the correct support locations have

been installed, carefully lower the motherboard onto the pushpin standoffs and with a slight

amount of pressure, force them through the motherboard holes. This will securely lock the

motherboard in place. Note that any CPU retention plates should be fitted prior to installing the

motherboard for ease of use. If using threaded standoffs to secure the motherboard, install the

M3 screws to lock the motherboard in place.

A total of 4 PCI support screw sets are supplied, and can be used individually or in pairs for dual

width cards as required.

PCI cards are secured to the BC1 using the PCI thumbscrews which should first be screwed into

the threaded standoffs fitted to the PCI support mounting holes. The PCI card can then be

installed into the motherboard slot ensuring the card mounting bracket hole aligns with the top

of the PCI thumbscrew. Finally screw the PCI nut to the top of the PCI screw to lock the card in

place.

Fitting the motherboard and PCI cards

5

Threaded standoff

PCI thumbscrew

PCI nut

1

2

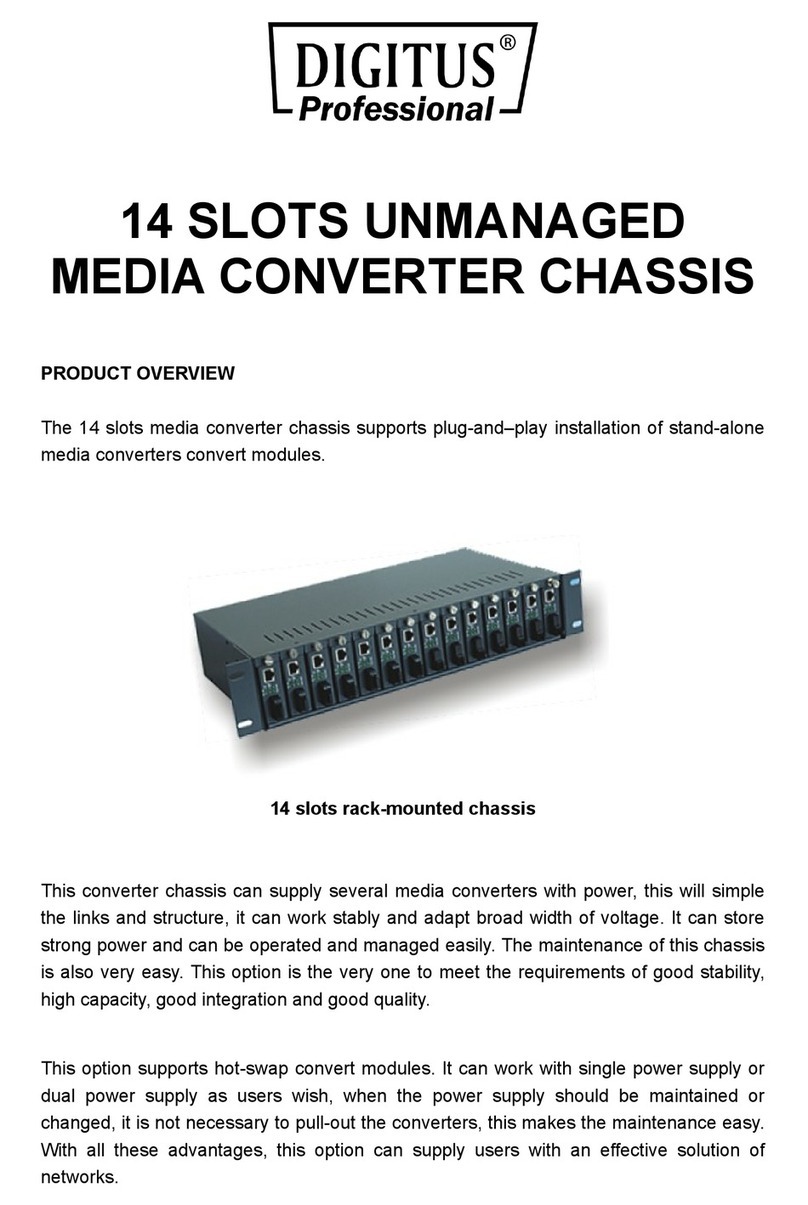

Using the side brackets

The washers supplied with the BC1 should be placed between the

bracket and table to avoid surface damage.

The hardware+bracket assembly can then be screwed to the side

of the table using the M3 thumbscrews. The mounting holes are

located along all 4 sides of the main body with brackets that are

designed to pivot in order to fit different hole spacings. These

include those used by 120mm, 140mm, and 240mm cooling fans.

The BC1 includes 4 side brackets which can be used for fixing

radiators, fans and virtually anything else that has a screw hole

mounting to the table. The brackets should first be fitted to the

hardware which you plan to mount using either screws that are

supplied with the hardware or the thumbscrews supplied with the

BC1. The bracket orientation is reversible, so choose between the

thick or thin side according to the length of the screw used to attach

the hardware.

6

240mm

Washer

140mm

Bracket

Cable routing is not shown, but this should be considered whilst planning the build and applied

accordingly.

To disassemble the BC1 simply reverse the procedure and when packing the screws and parts

ensure you replace them in the correct location, especially the M3 and 6#32 thumbscrews.

Most of these steps can be performed in any order and this guide is simply an overview of the

general procedure. It also demonstrates how parts can be used but as this is an open platform

designed for flexibility, there are multiple variations which are not shown.

When removing the motherboard make sure to pry it away carefully from the pushpin standoffs

to ensure no damage occurs.

Final notes

7

COPYRIGHT NOTICE

Copyright © 2018 All Rights Reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or in any means – by electronic, mechanical,

photocopying, recording or otherwise – without prior written permission. All trademarks and

registered trademarks in this publication are the property of their respective owners.

Table of contents

Other Streacom Chassis manuals

Popular Chassis manuals by other brands

National Instruments

National Instruments PXI Express Series user manual

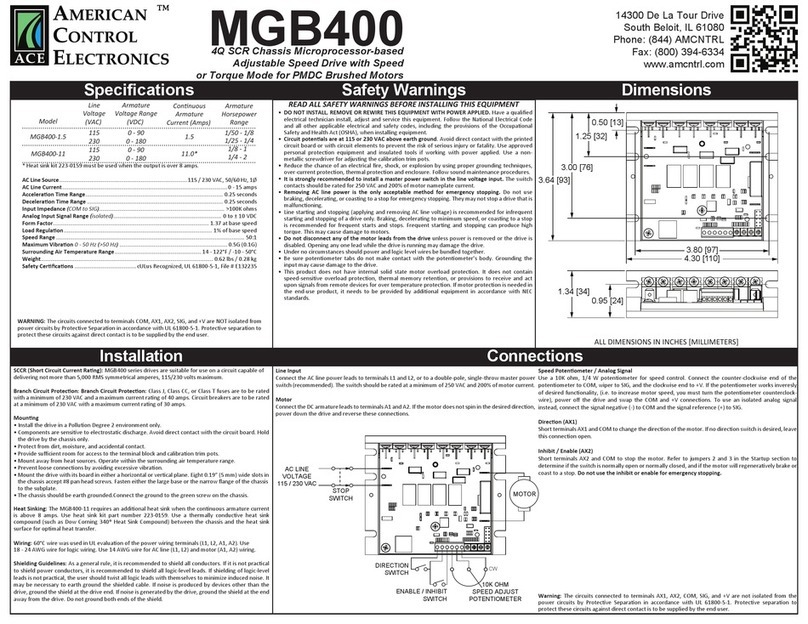

American Control Electronics

American Control Electronics MGB400 quick start guide

Cisco

Cisco CRS-1 - Carrier Routing System Router System description

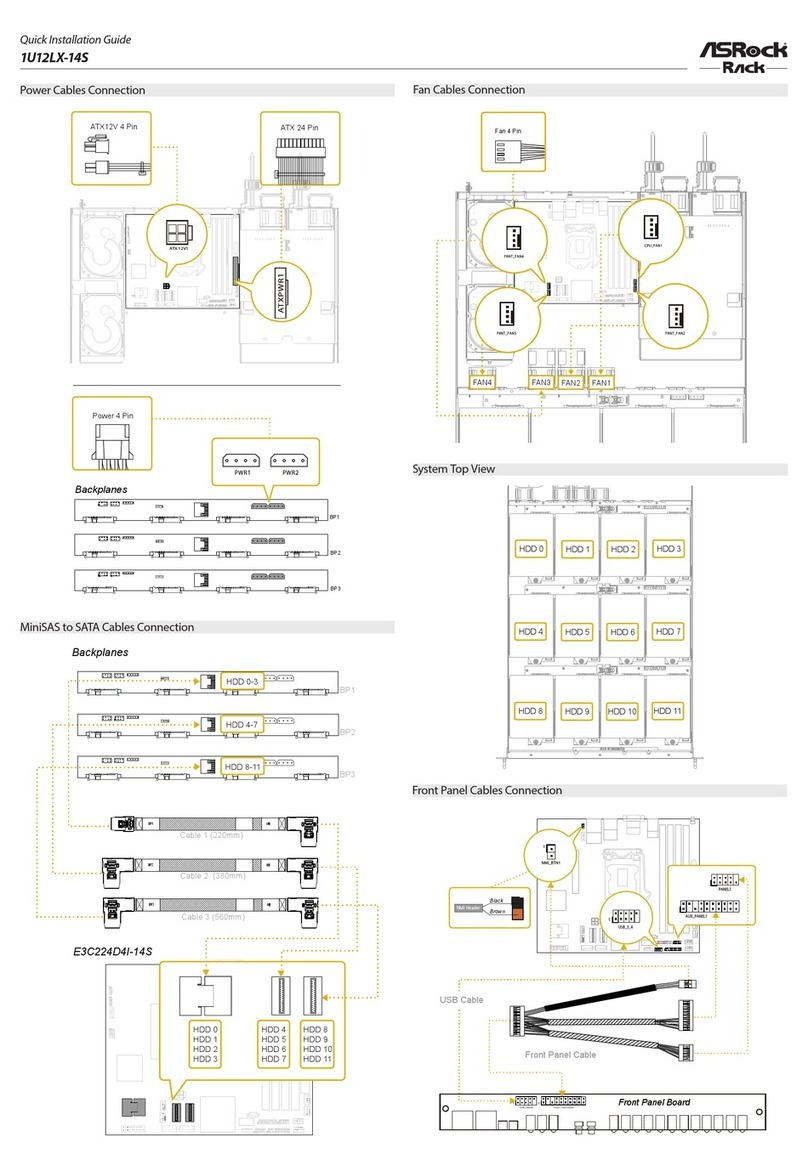

ASROCK

ASROCK 1U12LX-14S Quick installation guide

Keysight Technologies

Keysight Technologies M9502A AXIe Firmware Revision Guide

AJA

AJA OG-X-FR Installation and operation guide