STRIDE SGW Series User manual

Manual Number: SGW-USER-M

Modbus Gateway

USER MANUAL

SGW Series

Page W–1Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

~WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs

or uses this equipment should read this publication (and any other relevant publications) before

installing or operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area

to area and usually change with time. It is your responsibility to determine which codes should be

followed, and to verify that the equipment, installation, and operation is in compliance with the latest

revision of these codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There may be

local regulatory or government offices that can also help determine which codes and standards are

necessary for safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation,

or operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale

as on-line control equipment in hazardous environments requiring fail-safe performance, such as in

the operation of nuclear facilities, aircraft navigation or communication systems, air traffic control,

direct life support machines, or weapons systems, in which the failure of the product could lead

directly to death, personal injury, or severe physical or environmental damage (“High Risk Activities”).

AutomationDirect specifically disclaims any expressed or implied warranty of fitness for High Risk

Activities.

For additional warranty and safety information, see the Terms and Conditions on our website. If

you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was published. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right

to make changes to the products and/or publications at any time without notice and without any

obligation. This publication may also discuss features that may not be available in certain revisions of

the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies.

The product and company names may be trademarked and are the sole property of their respective

owners. AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2018–2021 Automationdirect.com® Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior,

written consent of Automationdirect.com® Incorporated. AutomationDirect retains the exclusive

rights to all information included in this document.

Page W–2 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

~ADVERTENCIA ~

Gracias por comprar equipo de automatización de Automationdirect.com®. Deseamos que su nuevo

equipo de automatización opere de manera segura. Cualquier persona que instale o use este equipo debe

leer esta publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos

de seguridad locales o nacionales aplicables que regulan la instalación y operación de su equipo.

Estos códigos varian de área en área y usualmente cambian con el tiempo. Es su responsabilidad

determinar cuales códigos deben ser seguidos y verificar que el equipo, instalación y operación estén en

cumplimiento con la revisión mas reciente de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional

Eléctrico, y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber

oficinas de normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son

necesarios para una instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias

a personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su

aplicación en particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación

u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para

uso o reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin

fallas, tales como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación,

control de tráfico aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla

del producto puede resultar directamente en muerte, heridas personales, o daños físicos o ambientales

severos (“Actividades de Alto Riesgo”). Automationdirect.com específicamente rechaza cualquier garantía

ya sea expresada o implicada para actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos

y Condiciones. Si tiene alguna pregunta sobre instalación u operación de este equipo, o si necesita

información adicional, por favor llámenos al número 770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de la publicación. En

Automationdirect.com nos esforzamos constantemente para mejorar nuestros productos y servicios,

así que nos reservamos el derecho de hacer cambios al producto y/o a las publicaciones en cualquier

momento sin notificación y sin ninguna obligación. Esta publicación también puede discutir

características que no estén disponibles en ciertas revisiones del producto.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías.

Los nombres de las compañías y productos pueden tener marcas registradas y son propiedad única de

sus respectivos dueños. Automationdirect.com, renuncia cualquier interés propietario en las marcas y

nombres de otros.

Propiedad Literaria 2018–2021, Automationdirect.com® Incorporated

Todos los derechos reservados

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo

consentimiento por escrito de Automationdirect.com® Incorporated. Automationdirect.com retiene

los derechos exclusivos a toda la información incluida en este documento. Los usuarios de este equipo

pueden copiar este documento solamente para instalar, configurar y mantener el equipo correspondiente.

También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

Page W–3Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

~AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com®, en faisant

des affaires comme AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation

fonctionne en toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente

publication (et toutes les autres publications pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les

codes locaux et nationaux applicables régissant l’installation et le fonctionnement de votre équipement.

Ces codes diffèrent d’une région à l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de

déterminer les codes à respecter et de vous assurer que l’équipement, l’installation et le fonctionnement

sont conformes aux exigences de la version la plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention

des incendies, du Code national de l’électricité et des codes de la National Electrical Manufacturer’s

Association (NEMA). Des organismes de réglementation ou des services gouvernementaux locaux peuvent

également vous aider à déterminer les codes ainsi que les normes à respecter pour assurer une installation

et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages

à l’équipement ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits

décrits dans cette publication conviennent à votre application particulière et nous n’assumons aucune

responsabilité à l’égard de la conception, de l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou

la revente en tant qu’équipement de commande en ligne dans des environnements dangereux nécessitant

une sécurité absolue, par exemple, l’exploitation d’installations nucléaires, les systèmes de navigation

aérienne ou de communication, le contrôle de la circulation aérienne, les équipements de survie ou

les systèmes d’armes, pour lesquels la défaillance du produit peut provoquer la mort, des blessures

corporelles ou de graves dommages matériels ou environnementaux («activités à risque élevé»). La

société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en ce qui a trait aux

activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section

Modalités et conditions de notre documentation. Si vous avez des questions au sujet de l’installation

ou du fonctionnement de cet équipement, ou encore si vous avez besoin de renseignements

supplémentaires, n’hésitez pas à nous téléphoner au 770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de la publication. À la société

AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi

nous nous réservons le droit d’apporter des modifications aux produits ou aux publications en tout

temps, sans préavis ni quelque obligation que ce soit. La présente publication peut aussi porter sur des

caractéristiques susceptibles de ne pas être offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres

entreprises. Les désignations des produits et des entreprises peuvent être des marques de commerce et

appartiennent exclusivement à leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les

autres marques et désignations.

Copyright 2018–2021 Automationdirect.com® Incorporated

Tous droits réservés

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans

le consentement préalable écrit de la société Automationdirect.com® Incorporated. AutomationDirect

conserve les droits exclusifs à l’égard de tous les renseignements contenus dans le présent document.

Page W–4 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Warnings

WARNING:

SuItAble foR uSe IN ClASS I, DIvISIoN 2, GRoupS A, b, C AND D HAzARDouS loCAtIoNS, oR

NoNHAzARDouS loCAtIoNS oNly.

Cet AppAReIllAGe eSt utIlISAble DANS leS emplACemeNtS De ClASSe I, DIvISIoN 2, GRoupeS A, b, C

et D, ou DANS leS emplACemeNtS NoN DANGeReux SeulemeNt.

WARNING: exploSIoN HAzARD

• DoNot DISCoNNeCt equIpmeNt WHIle tHe CIRCuIt IS lIve oR uNleSS tHe AReA IS kNoWN

to be fRee of IGNItAble CoNCeNtRAtIoNS.

• SubStItutIoN of ANy CompoNeNt mAy ImpAIR SuItAbIlIty foR ClASS I, DIvISIoN 2.

AveRtISSemeNt: RISque D’exploSIoN

• AvANt De DeCoNNeCteR l’equIpemeNt, CoupeR le CouRANt ou S’ASSuReR que

l’emplACemeNt eSt DeSIGNe NoN DANGeReux.

• lASubStItutIoN De CompoSANtS peut ReNDRe Ce mAteRIel INACCeptAble pouR leS

emplACemeNtS De ClASSe I, DIvISIoN 2.

Page H–iStride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Stride® MB Gateway

User ManUal revision History

Please include this Manual Number and the Manual Issue, both shown below, when communicating with

AutomationDirect Technical Support regarding this publication.

Manual Number: SGW-USER-M

Manual Issue: 1st Edition, Revision F

Issue Date: April 1, 2021

Publication History

Issue Date Description of Changes

First Edition 03/28/2018 Initial Release

1st Edition, Revision A 06/29/2018 Clarified input voltage range, clarified supported web browsers.

1st Edition, Revision B 10/26/2018 Updated IP addresses in Application Examples.

1st Edition, Revision C 09/09/2019 Updated screenshots, minor clarifications.

1st Edition, Revision D 02/12/2020 Added Appendix D: Security Considerations for Control Systems Networks.

1st Edition, Revision E 08/17/2020 Clarified imported configuration filenames.

1st Edition, Revision F 04/01/2021 Corrected terminating resistor on RS-485 wiring diagrams.

Page H–ii Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

User Manual Revision History

BLANK

PAG E

TOC–1Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Stride® ModbuS Gateway

User ManUal Table of ConTenTs

ConTenTs

ConTenTs

ConTenTs

Chapter 1: GettinG StartinG . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

User Manual Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Product Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Hardware � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Hardware Reset Button � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

DIP Switches � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

LEDs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Installation, DIN Rail Mounting� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–6

Dimensional Drawings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–7

Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Power � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Ethernet Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–9

Serial Port Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–10

Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–11

Transparent Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–11

Agent Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–11

Chapter 2: Summary of modbuS modeS . . . . . . . . . . . . . . . . . . . . . 2–1

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–2

Mode 1: Transparent, RTU Master mode:

Modbus TCP Client/Master Device to Gateway to Modbus RTU Slave Devices � � � � � � 2–3

Mode 2: Agent, RTU Master mode:

Modbus TCP Client/Master Device to Gateway Memory� Gateway Talks Directly to Modbus

RTU Slave Devices � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–4

Mode 3: Transparent, RTU Slave mode:

Modbus RTU Master Device to Gateway to Modbus TCP Server/Slave Devices � � � � � � 2–6

Mode 4: Agent, RTU Slave mode:

Modbus RTU Master Device to Gateway Memory� Gateway Talks Directly to Modbus TCP

Server/Slave Devices � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–7

Chapter 3: Web ConSole ConfiGuration . . . . . . . . . . . . . . . . . . . . . 3-1

Initial Connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-2

Device Info Page� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-3

Network Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-4

Operating Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-5

For Modbus RTU/ASCII Master to Modbus TCP Servers (Slaves) � � � � � � � � � � � � � � � � 3-5

For Modbus TCP Master (Client) Device to Modbus RTU/ASCII Slave Devices � � � � � � � � � 3-6

Serial Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-7

TOC–2 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Table of Contents

Agent Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-8

Gateway Settings� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-8

Message List � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-9

Data in Gateway Memory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-11

Import/Export � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-12

Export � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-12

Import� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3-12

Upgrade Firmware� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-13

Change Password � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-14

Load Factory Default � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-15

Reboot � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3-16

appendix a: appliCation exampleS . . . . . . . . . . . . . . . . . . . . . . . . . a–1

Example 1:

Using Modbus Poll to STRIDE Modbus Gateway with BRX Slave � � � � � � � � � � � � � � A–2

Example 2:

Using Modbus Poll to STRIDE MB Gateway with CLICK Slave � � � � � � � � � � � � � � � � A–9

Example 3:

Using P3000 as Master (Client) to STRIDE Modbus Gateway with CLICK Slave� � � � � � �A–17

appendix b: Stride modbuS GateWay operatinG mode exampleS . . . . . . . . b–1

Example 1:

TRANSPARENT Mode, with Modbus TCP Master (Client) Devices to

Modbus RTU/ASCII Slave Devices� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � B–2

Example 2:

TRANSPARENT Mode, with Modbus RTU/ASCII Master Devices to

Modbus TCP Slave (Server) Devices� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � B–6

Example 3:

AGENT Mode, with Modbus TCP Master (Client) Devices to

Modbus RTU/ASCII Slave Devices� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � B–11

Example 4:

AGENT Mode, with Modbus RTU/ASCII Master Devices to

Modbus TCP Slave (Server) Devices� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � B–16

appendix C: modbuS error CodeS . . . . . . . . . . . . . . . . . . . . . . . . . C–1

Modbus Error Codes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � C–2

appendix d: SeCurity ConSiderationS for Control SyStemS netWorkS . . . . . d-1

Security Considerations for Control Systems Networks � � � � � � � � � � � � � � � � � � � � D-2

GettinG Started 1

1

1

Chapter

Chapter

Chapter

Page 1–1Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

inthiS Chapter...

User Manual Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–2

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Product Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Hardware � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Hardware Reset Button � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

DIP Switches � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

LEDs� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Installation, DIN Rail Mounting� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–6

Dimensional Drawings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–7

Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–8

Power � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Ethernet Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–9

Serial Port Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–10

Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–11

Transparent Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–11

Agent Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–11

Chapter 1: Getting Started

Page 1–2 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

User Manual Overview

The Purpose of this User’s Manual

Thank you for purchasing our STRIDE® Modbus Gateway. This User Manual describes the gateway

and its specifications, and guides you in the installation, configuration, and methods of operation

of the STRIDE®Modbus gateway.

Who Should Read This Manual

This manual contains important information for those who will install, maintain, and/or operate a

STRIDE® Modbus Gateway.

Technical Support

By Telephone: 770-844-4200

(Mon.–Fri., 9:00 a.m.–6:00 p.m. E.T.)

On the Web: www.automationdirect.com

Our technical support group is glad to work with you in answering your questions. If you cannot

find the solution to your particular application, or, if for any reason you need additional technical

assistance, please call technical support at 770-844-4200. We are available weekdays from 9:00

a.m. to 6:00 p.m. Eastern Time.

We also encourage you to visit our web site where you can find technical and non-technical

information about our products and our company. Visit us at www.automationdirect.com.

Special Symbols

NOTE: When you see the “notepad” icon in the left-hand margin, the paragraph to its immediate

right will be a special note.

SECURITY NOTE: When you see the “padlock” icon in the left-hand margin, the paragraph to its

immediate right will be a security-related suggestion or note.

WARNING: WheN you see the “exclAmAtIoN mARk” IcoN IN the left-hANd mARGIN, the pARAGRAph to

Its ImmedIAte RIGht WIll be AWARNING. thIs INfoRmAtIoN could pReveNt INjuRy, loss of pRopeRty, oR

eveN deAth (IN extReme cAses).

Chapter 1: Getting Started

Page 1–3Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Introduction

Modbus is one of the most popular communication protocols in the automation industry because

it supports both traditional RS-232/422/485 devices and industrial Ethernet devices. Many

industrial devices, such as PLCs, HMIs, instruments and meters use Modbus as their standard

communication protocol. However, the Modbus protocols running over serial and Ethernet are so

different that a communication gateway is needed as a bridge for integrating devices from these

two networks. The STRIDE® Modbus Gateway provides that bridge between Modbus RTU (Serial)

products and Modbus TCP (Ethernet) products.

The gateway converts bidirectionally between Modbus RTU or Modbus ASCII protocols and

Modbus TCP. In addition to its compact size, the gateway features up to two 10/100 Mbps Ethernet

ports and up to four RS232/422/485 serial ports.

SECURITY NOTE: When implementing any method of remote access to your equipment, you

need to consider the security exposure in order to minimize the risks to your processes and

your equipment. Security should always be carefully evaluated for each installation. Refer to

“Appendix D: Security Considerations for Control Systems Networks” for more information. .

Product Overview

Key features include:

9

Industrial 1, 2, or 4 serial port, and 1 or 2 Ethernet port Modbus Gateways

(Modbus RTU/ASCII <-> ModbusTCP)

9

Automatic read function “Agent Mode”

9

Ethernet ports each support up to 16 TCP devices, client or server

9

Serial ports each support up to 128 slave devices or 1 master device

9

DIP switch selectable termination resistor for RS-485 2-wire mode

9

High Serial Isolation Voltage (2kV)

9

UL61010 with Class 1 Division 2 hazardous location rating

9

Metal housing with wide temperature rating (−40 to +75°C)

Hardware

STRIDE Modbus Gateway Models

Part Number Ethernet Ports

RJ45, 10/100Mbps

Serial Ports

D-sub 9 pin

SGW-MB1511-T 1 1

SGW-MB1512-T 1 2

SGW-MB1524-T 2 4

Ethernet Interface

Port Shielded RJ45

Speed 10/100 Mbps

Protection Built-in 1�5 kV magnetic isolation

Protocol Supported Modbus TCP/IP client and server

Modbus TCP devices supported 16 simultaneous Modbus TCP connections per Ethernet port

Cable Type Autodetects Ethernet cable types (MDI/MDIX)

Default IP address 192�168�0�249

192�168�1�249 (Ethernet Port 2, SGW-MB1524-T)

Chapter 1: Getting Started

Page 1–4 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Serial Interface

Port D-sub 9-pin male port

Interface mode RS-232, RS-485 and RS-422, software selectable

Supported Baud Rates 300, 600, 1200, 4800, 9600, 14�4k, 19�2k,

38�4k, 57�6k, 115.2k, 230�4k, 460�8k

Parity Odd, Even or None

Data Bits 7 or 8bits

Stop Bits 1or 2

Flow control RTS/CTS, XON/XOFF or None

Termination DIP switch to enable/disable 120Ω matching resistor

for RS-485 2-wire

ESD Protection 15kV for all signals

Isolation Protection 2kV

Serial Devices Supported 128 slaves or 1 master per port

Protocols Supported Modbus RTU, Modbus ASCII

Note: Default values are shown in bold text.

Power Details

Power Consumption

SGW-MB1511-T 1�8 W

SGW-MB1512-T 1�8 W

SGW-MB1524-T 3�2 W

Power Input Redundant input terminals

Input Voltage 12 / 24 / 48 VDC

Max. Input Voltage Range 9�6 – 60 VDC

Appliance Class Class III, SELV power source

Reverse Power Protection Yes

Overload Protection Yes

Environmental

Operating Temperature Range -40 to +75 °C [-40 to +167 °F]

Storage Temperature Range -40 to +85 °C [-40 to +185 °F]

Humidity 5 to 95% RH (non-condensing)

Maximum Altitude 2000m

Environmental Air For use in Pollution Degree 2 Environment

Protection level Metal case, IP40

Agency Approvals

UL61010-1, UL61010-2-201, Class I Div 2 12�12�01-

2015; CSA C22�2 No� 213-16; CAN/CSA No� 61010-1-12;

CAN/CSAC22�2 No� 61010-2-201:14, CE, FCC

EMI EN 55032 Class A

FCC Part 15 Subpart B Class A

EMS

IEC 61000-4-2 (ESD): ±6kV (contact), ±8kV (air)

IEC 61000-4-3 (RS): 10V/m (80MHz–2GHz)

IEC 61000-4-4 (EFT): Power Port: ±2kV; Data Port: ±1kV

IEC 61000-4-5 (Surge): PowerPort: ±1kV/DM, ±2kV/CM;

Data Port: ±1kV

IEC 61000-4-6 (CS): 10V (150KHz–80MHz)

Mechanical Standards

IEC 60068-2-6 (Vibration)

IEC 60068-2-27 (Shock)

IEC 60068-2-32 (Free Fall)

Chapter 1: Getting Started

Page 1–5Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

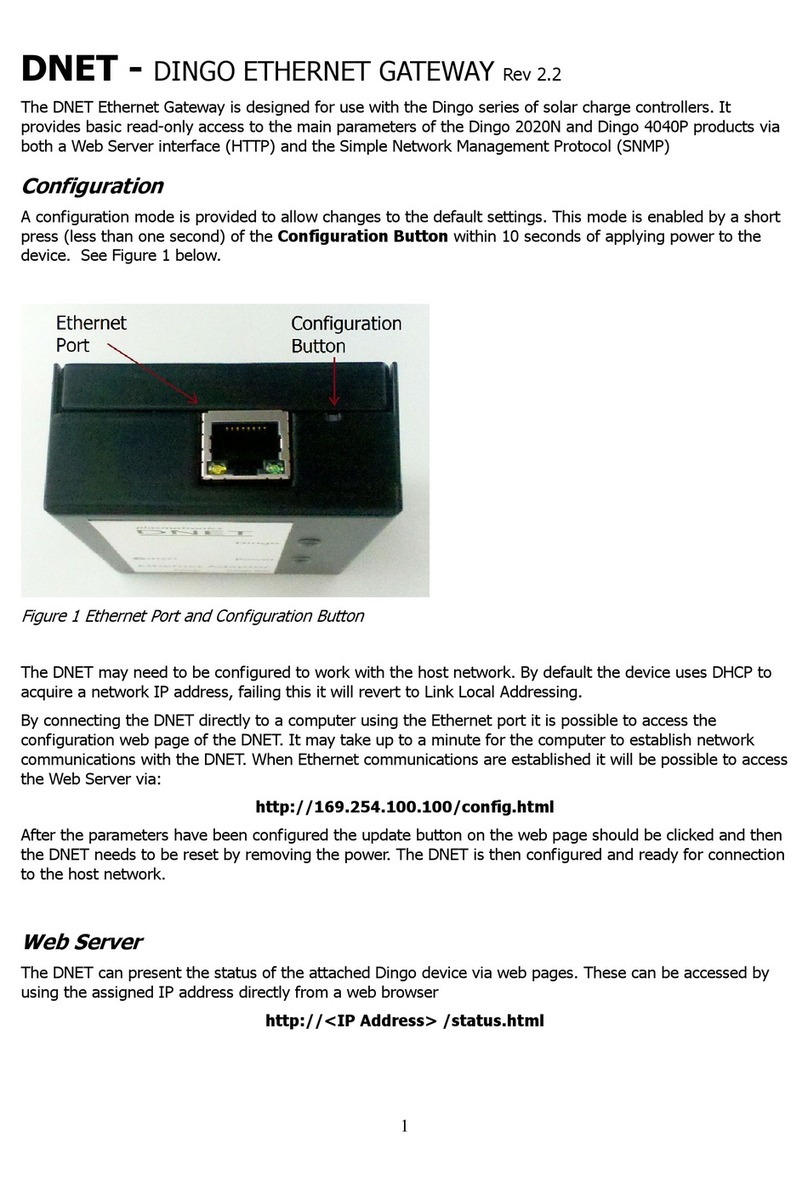

Hardware Reset Button

The Hardware Reset Button is a small

recessed button located on the top of the

device. Pressing the button will reset all

settings to their default values.

DIP Switches

A 120Ω termination resistor for each serial

port configured for RS485 2-wire is enabled

(ON) or disabled (OFF) by the corresponding

DIP switch.

LEDs

The front panel provides status via the

following LEDs:

PWR1 (Green)

LED ON indicates voltage is applied to

Power1terminals.

PWR2 (Green)

LED ON indicates voltage is applied to

Power2terminals.

RUN (Green)

Blinking Indicates the device is functioning

normally. Steady on indicates power is on

and device is booting up.

SPEED (RJ45 Yellow)

There is one yellow SPEED LED for each

Ethernet port. LED ON indicates Ethernet

speed is 100Mbps. LED OFF indicates

Ethernet speed is 10Mbps.

Link/Activity (RJ45 Green)

There is one green Link/Activity LED for each

Ethernet port. The Link/Activity LED is ON

when a valid link is established, and flashes to indicate that the gateway sees data traveling on

the Ethernet network. If any network device is sending or receiving data, the Link/Activity LED will

be flashing. During heavy communication loads, this indicator will be steady ON. If the LED is OFF,

then a problem with the Ethernet connection has been detected.

T (Serial port Transmit, Green)

The T or trAnsmit DAtA LED flashes to indicate that the gateway is sending data through the serial port.

R (Serial port Receive, Green)

The R or receive DAtA LED flashes to indicate that the gateway is receiving data through the serial port.

Chassis Ground

Power Connection

Dip Switches

Hardware Reset Button

Chapter 1: Getting Started

Page 1–6 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Installation, DIN Rail Mounting

NOTE: The gateway can also be panel mounted with purchase of accessory mounting bracket

(part #SE2-PM1 for SGW-MB1511-T and SGW-MB1512-T, part #SE2-PM3 for SGW-MB1524-T).

These devices are open-type and are meant to be installed in an enclosure which is only accessible

with the use of a tool and suitable for the environment when installed in Class 1, Division 2

Hazardous Locations. The gateway can be snapped onto a standard 35mm x 7.5 mm height DIN

rail (Standard: CENELEC EN50022) and can be mounted either vertically or horizontally. Allow

20mm [0.79”] of clearance between the gateway and other equipment on the DIN rail, side-to-side

and top-to-bottom.

DIN rail mounting steps:

1) Hook top back of unit over the DIN rail.

2) Push bottom back onto the DIN rail until it snaps into place.

DIN rail removal steps:

1) Push the unit down to free the bottom of the DIN rail.

2) Rotate the bottom of the unit away from the DIN rail.

3) Unhook top of unit from DIN rail.

Mounting

Removal

Chapter 1: Getting Started

Page 1–7Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Dimensional Drawings

NOTE: Allow 20mm [0.79”] clearance around each gateway for proper cooling.

Dimensions

Part No. Weight Width (A) Depth (B) Height (C)

mm [inches]

SGW-MB1511-T 0.17 kg [0.36 lb] 30.0 [1.18] 68.0 [2.68] 115.0 [4.53]

SGW-MB1512-T 0.17 kg [0.36 lb]

SGW-MB1524-T 0.32 kg [0.71 lb] 54.0 [2.13] 106 [4.17] 135.0 [5.32]

Chapter 1: Getting Started

Page 1–8 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Wiring

Power

The switch can be powered from the same DC source that is used to power your other devices. To

maintain the UL listing, this must be an SELV (Safety Extra Low Voltage) power supply. A DC voltage

in the range of 12 to 48VDC needs to be applied between the P1+ terminal and the P1- terminal

as shown below. The chassis screw terminal should be tied to panel or chassis ground. To reduce

down time resulting from power loss, the switch can be powered redundantly with a second

power supply as shown below. A recommended DC power supply is AutomationDirect.com part

number PSL-24-010.

Terminal block connector is Degson 2EDGK-5.08-04P-14-1000AH or equivalent.

Ferrule required for stranded wire.

Wire Size Range: 24 – 12 AWG

Wire Strip Length: 7mm

Maximum terminal screw torque is

4.43 lb-in (0.5 N·m).

Redundant DC Power

Chassis

GND

(panel)

Optional Dual DC Supplies

P1+P2-P1-P2+

–+–+

befoRe peRfoRmING ANy WIRING to these sWItches mAke suRe...

• the AReA Is cuRReNtly NoNhAzARdous (especIAlly WheN WoRkING IN clAss 1, dIv 2 oR zoNe 2

hAzARdous locAtIoNs).

• poWeR Is off to the sWItch

• the scReW teRmINAl block Is uNpluGGed. thIs Is especIAlly ImpoRtANt due to the AlumINum

housING. coNNectING oR dIscoNNectING WIRes to the scReW block WheN It’sIN plAce ANd poWeR

Is tuRNed oN cAN AlloW the scReWdRIveR to shoRt the poWeR to the cAse.

Chapter 1: Getting Started

Page 1–9Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Ethernet Wiring

Use data-quality (not voice-quality) twisted pair cable rated category 5e (or better) with standard

RJ45 connectors. Straight-through or crossover Ethernet cable can be used for all devices the

switch is connected to because all the ports are capable of auto-MDI/MDIX-crossover detection.

The RJ45 Ethernet port connector bodies on these products are metallic and connected to the

Chassis GND terminal. Therefore, shielded cables may be used to provide further protection. To

prevent ground loops, the cable shield should be tied to the metal connector body at one end of

the cable only. Electrical isolation is also provided on the Ethernet ports for increased reliability.

Ethernet Cable Wiring

Ethernet Port

Pin MDI-X Signal MDI Signal

1Receive Data + (RD+) Transmit Data + (TD+)

2Receive Data – (RD–) Transmit Data – (TD–)

3Transmit Data + (TD+) Receive Data + (RD+)

6Transmit Data – (TD–) Receive Data – (RD–)

4, 5, 7, 8 Unused Unused

Note: + and – indicate level polarities.

Straight-thru Cable Wiring

Pin 1 Pin 1

Pin 2 Pin 2

Pin 3 Pin 3

Pin 4 Pin 4

Pin 5 Pin 5

Pin 6 Pin 6

Pin 7 Pin 7

Pin 8 Pin 8

Cross-over Cable Wiring

Pin 1 Pin 3

Pin 2 Pin 6

Pin 3 Pin 1

Pin 4 Pin 4

Pin 5 Pin 5

Pin 6 Pin 2

Pin 7 Pin 7

Pin 8 Pin 8

Ethernet

Plug & Connector

Pin Positions

8

1

1

8

NOTE: For reference only. Either cable wiring will work.

Chapter 1: Getting Started

Page 1–10 Stride®MB Gateway User Manual – 1st Edition Rev. F – April 2021

Serial Port Wiring

Serial Port Pinout

1

2

3

4

5

Serial Port

Pin RS-232 RS-422/485

4-wire

RS-485

2-wire

1CTS RXD – –

2RXD RXD + –

3TXD TXD – Data –

4RTS TXD + Data +

5GND GND GND

6–––

7–––

8–––

9–––

RS232 Wiring

Shield

RS-232

Gateway Slave

Recommended Cable - AutomationDirect L-19772 shielded cable or equivalent

1

2

3

4

5

6-9

RXD

GND

TXD

GND

(NC)

RXD

TXD

RTS

GND

CTS

RS422/RS485 4-wire Wiring

TD-

TD+

RD-

RD+

GND

*

* User Supplied

120Ω Termination

Resistor

(NC)

RS-422/RS-485

Gateway Slave 1Slave 2 Last Slave

Recommended C

able - AutomationDirect L-19773 shielded cable or equivalen

t

1

2

3

4

5

6-9

RXD-

RXD+

TXD-

TXD+

GND

TD-

TD+

RD-

RD+

GND

TD-

TD+

RD-

RD+

GND

RS485 2-wire Wiring

D-

D+

GND

*

* User Supplied

120Ω Termination

Resistor

The Gateway contains a DIP switch selectable120Ω

Termination Resistor between TXD+ and TXD- for

each serial port on RS-485 2-wire, when the

Gateway is wired at one end of the serial network.

(NC)

RS-485

Gateway Slave 1Slave 2 Last Slave

Recommended C

able - AutomationDirect L-19954 shielded cable or equivalen

t

1

2

3

4

5

6-9

RXD-

RXD+

TXD-

TXD+

GND

D-

D+

GND

D-

D+

GND

This manual suits for next models

3

Table of contents

Other STRIDE Gateway manuals

Popular Gateway manuals by other brands

RTA

RTA 460MCBS-N2E Product user guide

Grace Digital

Grace Digital Xlink ITC-BT owner's manual

IOGear

IOGear GWA501 quick start guide

Planet Networking & Communication

Planet Networking & Communication LCG-300 Series user manual

Dinstar

Dinstar DAG1000-4O Quick installation guide

RTA

RTA 460ESUS-NNA4 Product user guide