9

LIMITED WARRANTY

WARRANTY

The manufacturer warranties trouble-free quality

an will cover the cost of replacing parts which are

foun to be faulty in material or workmanship within

the prescribe warranty perio after the ate of

purchase. Please note that specific warranty

con itions may vary from country to country. If in

oubt, ask your equipment ven or. He is responsible

for warranty matters. Solo Inc. provi es the initial

purchaser with a 2 year engine warranty.

We hope you will un erstan that we cannot be

liable for amage resulting from the following causes:

• Non-compliance with the operating instructions.

• Neglecting essential maintenance an repair work.

• Damage cause by incorrect carburetor a justment.

• Wear in normal use.

• Obvious overloa by continuously excee ing the

maximum performance limit of the pro uct.

• Using non-authorize tools.

• Use of force, incorrect treatment, misuse an

acci ents.

• Damage from excessive heat ue to irt buil up

aroun the cooling fan housing.

• Attempte a justments an repairs by unqualifie

persons.

• Use of unsuitable spare parts or thir party parts, if

these are the cause of the efect.

• Use of unsuitable or stale fuel.

• Damage cause by using the pro uct in the hire or

rental in ustry.

Normal cleaning, a justments or maintenance work

fall outsi e the warranty provisions.

A service center authorize by the manufacturer

must carry out all warranty work.

PARTS SUBJECT TO WEAR AND TEAR

Various parts are subject to application-specific or

normal wear an must be replace in goo time, when

require . The following parts are subject to normal wear

an are not covere by the manufacturer's warranty:

• Air filter

• Fuel filter

• All rubber parts which come into contact with fuel

• Clutch

• Spark plug

• Starter (Recoil)

• Bla es

CE DECLARATION OF CONFORMITY

In accor ance with EG Directives 98/37/EC,

2000/14/EC an 89/336/EEC (amen e by

92/31/EEC), SOLO Kleinmotoren GmbH,

Stuttgarter Strasse 41, D-71069 Sin elfingen,

being solely responsible, states that the pro uct

referre to in this eclaration complies with the

requirements of the Machinery Directive.

Description of pro uct: Ice Auger

(EN ISO 3744, EN ISO 22868)

Applie stan ar s: EN ISO 12100, EN 11806,

ISO 14865, EN ISO 14982

Conformity assessment proce ures

(98/37/EG) Appen ix V

(2000/14/EG) Appen ix V

Serial number, Buil year Type plate

This eclaration of conformity loses its vali ity, if

the equipment is converte or mo ifie without the

manufacturer's consent.

Sin elfingen, 1st January 2006

SOLO Kleinmotoren GmbH Wolfgang Emmerich

Executive Director

FOR USA ONLY

Emissions Control Warranty Statement

The Environmental Protection Agency an Solo are

please to explain the emission control system on your

small non-roa power equipment engine. In the US new

small non- roa engines must be esigne , built, an

equippe to meet the Environmental Protection

Agency's stan ar s. Solo must warrant the emission

control system on your small non- roa engine for the

perio of time liste below provi e there has been no

abuse, neglect, or improper maintenance of your small

non-roa engine.

Your emission control system inclu es parts such as the

carburetor, the ignition system, an the exhaust system.

Where a warrantable con ition exists, Solo will repair

your small non-roa power equipment engine at no cost

to you inclu ing iagnosis, parts, an labor.

Manufacturers Warranty Coverage

Solo's small non-roa power equipment engines are

warrante for a perio of two years. If any emission

control relate part on your engine is efective, the part

will be repaire or replace by Solo.

Contact Information for Authorize Service Center

Locations, Replacement Parts,

Warranty an Technical Information:

Warranty repairs must be complete by a SOLO

Authorize Service Center.

SOLO USA, Inc. 1-800-765-6462

5100 Chestnut Avenue

Newport News, VA 23605

www.solousa.com/support

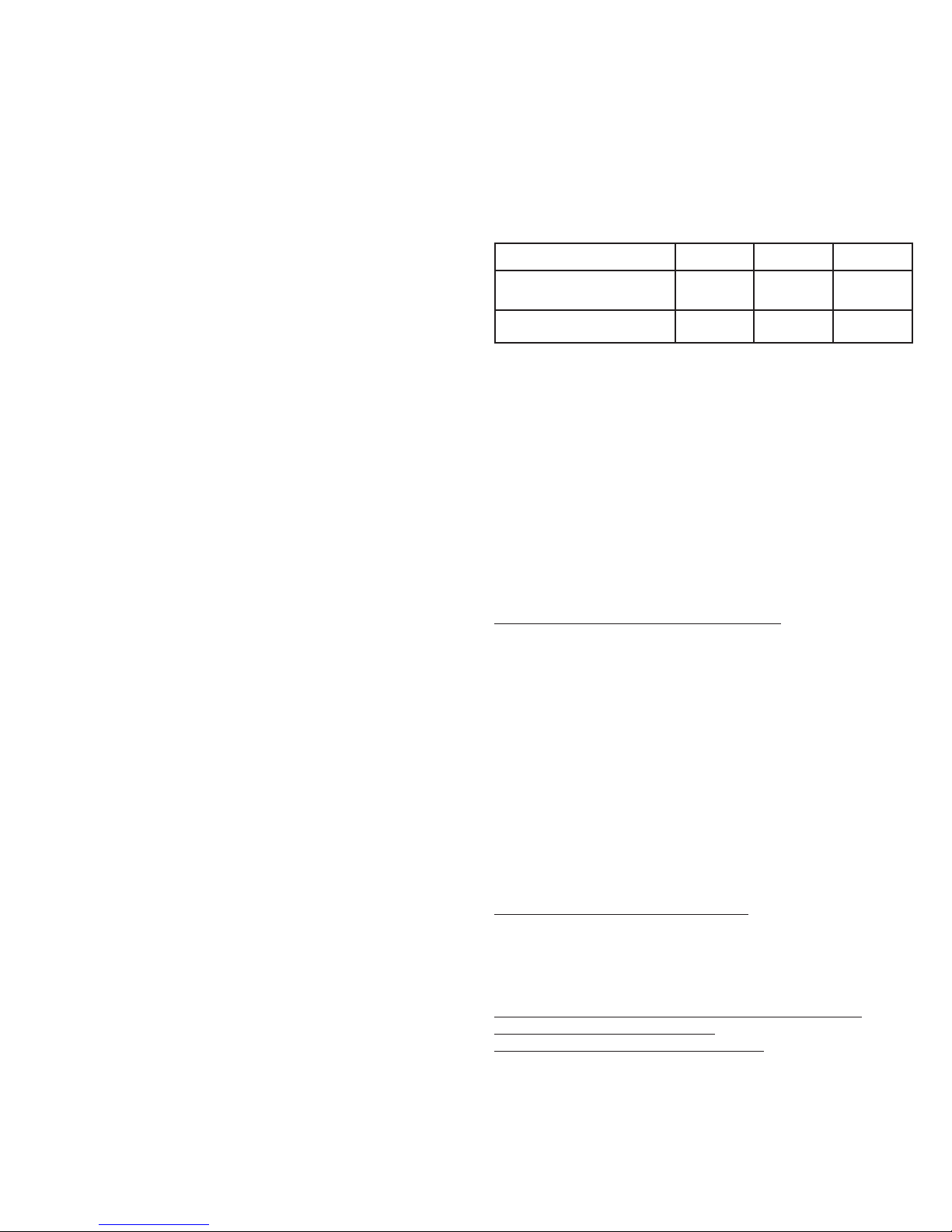

Model/Type description 137 142 154

Sound power level

Guaranteed sound 112 112 112 dB(A)

Actual sound 111 111 111 dB(A)

Solo® Germany The registered Solo® trademark is licensed for

use in the U.S. to the German company Solo leinmotoren Gmbh

by the U.S. affiliate, Solo incorporated.