Strong International XENON User manual

STRONG INTERNATIONAL

adivisionofBallantyneofOmaha,Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

www.strongint.com

XENON POWER SUPPLY

for 10 kW Britelight Lamphead

Rev. June 2004

CONTENTS

Page

PREFACE .............................................. 1

INSTALLATION ................................... 1

Tap Adjustment................................ 2

INSTALLATION DIAGRAM ............... 5

TROUBLESHOOTING ........................ 6

MAINTENANCE .................................. 9

WIRING DIAGRAM ............................ 10

PARTS ILLUSTRATIONS

Figure 1............................................ 11

Figure 2............................................ 13

Figure 3............................................ 14

PREFACE

THIS XENON POWER SUPPLY manufactured by Strong International is a dual-

chassis, high reactance 10,000 watt unit utilizing silicon diodes as the power conversion elements. All

models are designed for 50/60 Hertz operation, and are available in varyingAC input types, depend-

ing upon the configuration of the main power transformers. Check the Equipment Data Plate to

determine the exactAC requirement prior to installation.

COARSE AND FINE TAPS are easily set to regulate the DC current to the xenon

bulb. Some models of this power supplies have the capability of overdriving a xenon bulb; carefully

check the power requirements specified by the bulb manufacturer and do not exceed the maximum

current stated.

DC OUTPUT to the xenon bulb is filtered by means of filter capacitors. A relay-

operated resistor circuit reduces the inrush current upon ignition to prolong bulb life. Suppression

capacitors prevent RF interference.

OVERSIZE HEAT SINKS disperse the heat normally generated by the silicon diodes.

Eachpower supplychassisinclude aninternally wired blower for additionalheat dissipation. Thermal

switches on the rectifier heat sinks act as safety interlocks to shut down the power supply and protect

the rectifier diodes in case temperatures reach excessive levels.

INSTALLATION

CHECK THE EQUIPMENT DATA PLATE and make certain that the AC source

conforms to the power requirements of the main power transformers. See the Installation Diagram

on Page 5 for detailed AC hook-up, line protection, and lamp connections. The AC service wiring

shouldbe installed by a licensedelectrician inconformance tolocal codes. The unit must beconnected

to an adequate earth ground.

THE AC LINE to the xenon power supply must include a marked line safety switch

or other power disconnect device adjacent to the unit and accessible to the operator. For operator

safety, it is necessary to turn off all power to the unit when adjusting or servicing the xenon power

supply. This safety switch or power disconnect should be tagged “OFF - UNITUNDER REPAIR”

when the power supply is being serviced.

1

INSTALLATION (continued)

OBSERVING ALL SAFETY PROCEDURES, install a xenon bulb of the desired

wattage into the lamphouse. Check the bulb manufacturer’s documentation to confirm the recom-

mended current range of the 10 kW bulb (165-210 amperes DC). A new bulb is normally first oper-

ated at “nominal” current, which is around 85% of the maximum level (180 A.). DO NOT, at any

time, exceed the maximum current level specified by the bulb manufacturer.

IGNITE THE XENON BULB and check the current as indicated on the control

panel ammeter. Allow (30) seconds for the current to stabilize and provide an accurate reading. If

the current is not within the above-noted range, extinguish the bulb. It will be necessary to increase or

decrease the DC output.

OUTPUT CURRENT ADJUSTMENT

WARNING

Turn off ALL primary AC power before making any

adjustments or performing service procedures. Allow

several minutes for the capacitors to drain stored en-

ergy. The power supply normally operates warm to

hot; allow the unit to cool to safe temperature.

2

INSTALLATION (continued)

FINE ADJUSTMENT of the DC current is made to the NUMBERED taps found on the upper

three terminal blocks (TB4, TB5, TB6). Fine taps are numbered 1-2-3-4, with “1” providing the

lowest output, increasing to “4,” yielding the highest output. A “fine” tap adjustment raises or

lowers the current approximately four amperes. The three fine tap terminal blocks are interconnected

by means of a three-lead jumper wire assembly attached to like-numbered terminals.

•Toincrease the DC output, move the jumper wire assembly to tap the next (3) higher numbered

terminals, for example, move from terminals “2” to terminals “3.” ALLTAPS MUST BE ONTHE

SAME NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too low

when terminals “4” are interconnected, see the following instructions for adjusting “coarse” taps.

•Todecrease the DC output, move the jumper wire assembly to tap the next (3) lower numbered

terminals, for example, move from terminals “3” to terminals “2.” ALLTAPS MUSTBE ON THE

SAME NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too high

when terminals “1” are interconnected, see the following instructions for adjusting “coarse” taps.

COARSE ADJUSTMENT of the DC current is made to the LETTERED taps found on the lower

three terminal blocks (TB1, TB2, TB3). Coarse taps are lettered W-X-Y-Z, with “W” providing the

lowest output, increasing to “Z” at the highest output. The coarse tap terminals connect to contactor

terminals T1, T2, and T3. The (3) contactor leads must connect to the same lettered step (W-W-W,

etc.). A “coarse” tap adjustment raises or lowers the current approximately twelve amperes.

•Toincrease the coarse DC output, move each of the contactor leads to tap the next higher lettered

terminals, for example, move from terminals “W” to terminals “X.” ALL TAPS MUST BE ON

THE SAME LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap

jumper on 1-1-1. Ignite the lamp, check the output, and increase the fine tap setting as required.

•Todecrease the coarse DC output, move each of the contactor leads to tap the next lower lettered

terminals, for example, move from terminals “Y” to terminals “X.” ALL TAPS MUST BE ON

THE SAME LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap

jumper on 1-1-1. Ignite the lamp, check the output, and increase the fine tap setting as required.

NOTE: Balance power supply output; i.e. set power supplies at or near the same output settings:

Power Supply “A” X-X-X, 4-4-4 (or as required)

Power Supply “B” Y-Y-Y, 1-1-1 (or as required)

INSPECT TAP CONNECTIONS to verify that the terminal is clamping the copper

conductor, not the insulation. Make certain all terminal clamping screws are tight.

3

INSTALLATION (continued)

WHENEVER MAKING A COARSE ADJUSTMENT, again check the ammeter

reading and make certain the current is within the desired range. A re-adjustment of the fine taps is

frequently required after changing coarse taps.

OBSERVE CURRENT (AMPERAGE) READING ONLY when setting the output.

The “voltage” reading can vary between individual xenon bulbs, and while wattage can be determined

bymultiplying volts times amperes, itis possibleto overdrive and damage thebulb byoperating it over

210 amperes. The arc voltage reading serves as a troubleshoooting tool detailed later.

REMOTE IGNITION CONTROL is enabled by connecting a dry contact across

Terminals TB3-1 and TB3-2 and placing the REMOTE/LOCAL switch on the control panel to

REMOTE. The lamphead will then ignite only when SYSTEM ON/OFF switch is in the ON posi-

tion and the remote control contact is closed.

AFTERPROLONGED OPERATION,the lightoutput of the xenon bulbwill decrease.

This is a normal factor of bulb aging, and can be compensated by raising the DC output of the xenon

power supply. If the bulb was first operated at “nominal” current, the power supply output can

gradually be increased to, but not in excess of, he maximum current specified by the bulb manufac-

turer. Increase the current as instructed above. Decrease the power supply output to its former

“nominal” current level upon the installation of a new replacement bulb.

TIMER PC BOARD OPERATION

TIMER PRINTED CIRCUIT BOARD ASSEMBLY (Part No. 32-70137) provides

timing functions to lamphead ignition and shutdown. Upon closure of the POWER “ON” switch

(“Local” mode), and assuming all interlocks are closed, Relays K2 and K3 latch and energize the

igniter circuit. The lamphead igniter will discharge and provide a pulsed arc between the electrodes of

thexenon bulb. A functional bulb willnormally igniteafter one or two ofthese pulses. Ifthe bulbdoes

not ignite within a period of one (1) minute, the relays will drop out and de-energize the igniter circuit

to protect the bulb electrodes. In this event, it is necessary to replace the xenon bulb or troubleshoot

the lamphead and power supply system.

THE “STRIKE” SWITCH on the control panel bypasses the above timing function

and provides an immediate ignition pulse assuming the system is “ON” and all interlocks closed.

AFTER EXTINGUISHING THEARC (POWER “OFF” setting), Time-Delay Relay

K4 will actuate and allow the cooling blowers to continue operating for 20 minutes. This measure is

necessary to properly cool the xenon bulb and insure full bulb life. Most xenon bulb manufacturers

will not grant warranty credit on bulbs that are not forced-air cooled after operation.

4

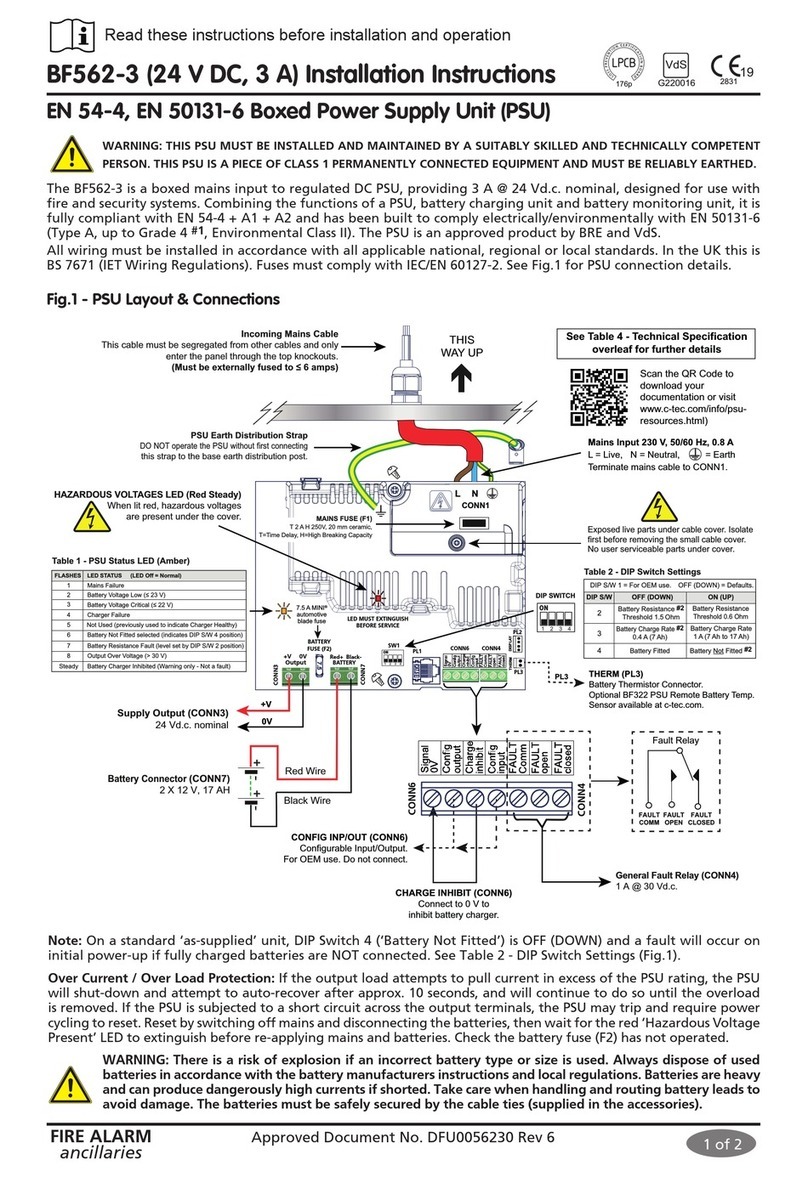

INSTALLATION WIRING DIAGRAM

5

PowerSource

Line

Safety

Switch

Fuse/Breaker

Panel

AC LINE PROTECTION

208/230 V. 380/440 V.

50 A. 25 A.

Lamphead Cable Assembly

P1

SYSTEM MUST BE GROUNDED

All wiring must conform to local

electrical code; shield lamphead

cable in conduit if required.

XENON

POWER

SUPPLY

OBSERVE CORRECT

POLARITY

BRITELIGHT LAMPHEAD

(Connections Prewired)

TB9 Connections:

1 Green

2 Orange

3 Blue

4 Red

5 Black

6 White

7 Brown

8 Yellow

AC Input

TROUBLESHOOTING

POWER LINE PROBLEMS

PRIMARYPOWER(AC source)problems aremost commonly(a) completeloss ofACpower,

or (b) phase loss, in which one phase loses power.

a) Check line safety switch (“ON”). Check fuses or breakers in supply line. Using anAC voltmeter,

measure input power at contactor terminals L1, L2, L3.

b) When power is lost on one phase, the current ripple will increase and trip the AC line circuit

breaker or blow an AC fuse. To detect a lost phase, measure the AC voltage phase-to-phase at

contactor input terminals L1, L2, and L3.

PROBLEMS of this nature, once detected, are generally corrected by the power supplier (i.e.

the local utility company).

BOOST CIRCUIT PROBLEMS

THE BOOST CIRCUIT generates the high open circuit (“no load”) DC voltage which, in

conjunction with the igniter pulse, will ignite the xenon bulb. The open circuit voltage should

measure at least 110 V.DC. It is displayed briefly on the lamphouse ammeter by pressing the “VOLT-

AGE” button at ignition, or the reading can be sustained by disabling lamphouse ignition by removing

one AC lead from the igniter feed.

A TERTIARY WINDING on the main transformer (T1) supplies the source for the Boost

Circuit. Three wires derive from the T1 transformer; two are single conductors, and the third is a

soldered pair. The Boost Circuit should be connected only to the (2) single conductors. Filter

capacitors store energy and also contribute to bulb ignition.

CONTROL CIRCUITRY

THE MAIN POWER TRANSFORMER is energized by contactor K1, which is pulled by (a)

aremote systemclosure or(b) manualactuation ofthe “ON”switch. All lamphouseinterlock switches

(“Door,” “Air,” etc.) must also be closed to complete the contactor circuit.

ANY INTERRUPTION of the control circuit will disable K1 and open the AC circuit to the

transformers. In addition to the above lamphouse interlock switches, thermal switches (S1), mounted

to the rectifier heat sinks, will open and disable K1 if the temperature at the heat sinks exceeds 190° F.

(88° C.). The S1 switches will automatically re-set when temperatures fall to safe levels.

WARNING: Exercise extreme caution when taking

voltage measurements in a power “ON” condition.

Allow the capacitors (2) minutes to discharge.

6

TROUBLESHOOTING (continued)

POWER CONVERSION PROBLEMS

RECTIFICATION (AC to DC) is performed by bridge diodes CR1 - CR6.

CR1, CR2, and CR3 are forward diodes, and CR4, CR5, and CR6 are reverse

diodes. The two types are not interchangeable.

AN OPEN DIODE will cause a pronounced flicker in the light output.

Two or more open diodes will disable bulb ignition. A shorted diode will trip the

circuit breaker (at the wall or in a power distribution panel) protecting the AC

input line. See the following DIODE TESTING & REPLACEMENT section.

THE BANKED CAN CAPACITORS C3 and C7 filter the rectified DC output. Filter capaci-

tors also store energy to contribute to the open circuit ignition discharge. Ashorted capacitor can trip

theAC circuit breaker.

RELAYK6, in the presence of high DC open circuit voltage, will pull and place the nichrome

resistor in series with the filter capacitors. This resistor limits the inrush surge and prolongs the

discharge of the filter capacitors to promote bulb ignition. If K6 relay fails, the nichrome resistor will

remain in circuit.

DIODE TESTING & REPLACEMENT

1. Disconnect the diode from its circuit. Inspect for discoloration, oxidation, or loose crimp at lead

junction.

2. A “shorted” diode will show low resistance in both directions. An “open” diode will have infinite

resistance in both directions. An ohmmeter test is required.

3. a)Analog VOM (Volt-Ohm Meter): Select R x 1 Ohm scale. With meter leads connected in one

direction, the reading should be zero (or nearly so); reversing the meter leads should show very

high resistance. If the diode does not exhibit these characteristics, replace it. NOTE DIODE

TYPE: forward or reverse.

b) Digital VOM: Select “Diode Test.” With meter leads connected in one direction, the reading

should be “OL” (overload); reversing the meter leads should display approximately .4 volt. If the

diode does not exhibit these characteristics, replace it. NOTE DIODE TYPE: forward or reverse.

4. Carefully clean the area of the heat sink in which the diode mounts. Apply heat sink compound

(Radio Shack #276-1373 or equivalent) using a wood or plastic spatula or stick. Athin layer is

adequate.

WARNING: HEATSINK COMPOUNDIS HIGHLYCAUSTIC. Do

not apply with fingers; keep away from eyes. Carefully follow

ALL the instructions printed on the package.

5. Install the new diode and tighten securely for maximum mechanical contact and electrical conduc-

tion. Clean and firmly secure the lead terminal to the buss.

7

TROUBLESHOOTING (continued)

Contactor does not energize (no audible “click”)

1. Line safety switch open. Turn “ON.”

2. AC line circuit breaker off. Turn “ON.”

3. Circuit breaker or fuse in AC line open. Check AC source.

4. REMOTE/LOCAL switch set incorrectly. Romote contact required when in REMOTE mode.

5. Lamphead interlock switch open. See lamphead manual.

6. Faulty K1 contactor coil or loose connection at coil terminals. Repair or replace.

7. Defective S1 thermal switch. Repair or replace.

8. Defective relay K1 or K6; Repair or replace.

Contactor pulls but lamphouse igniter does not fire

1. Faulty contactor contacts. With coil energized, check for continuity across the contacts from the

“L” side to the “T” side; repair or replace if defective.

2. Insufficient DC output. See INSTALLATION section; increase tap setting as required.

3. Faulty timer PC board assembly. If igniter fires when STRIKE switch is pressed, repair or replace

timer board.

4. Faulty igniter. See lamphead manual.

5. Low open circuit voltage (less than 110 V.DC).

a) Check ceramic resistors R1 & R2; should be in circuit and measure 100 Ohms.

b) Check boost diodes D2 and D3. See preceding DIODE TESTING section.

c) Check filter capacitors. Replace if defective.

Bulb requires multiple ignition pulses to light

1. Insufficient DC output. See INSTALLATION section; set tap setting as required.

2. Faulty or expired xenon bulb. Check for darkened envelope, worn electrodes; replace if required.

3. One or more faulty bridge diodes. See preceding DIODE TESTING section.

Bulb goes out during operation

1. Fuse F1 missing or open. Replace with same rated (3 ampere) fuse.

2. Excessive heat at rectifier heat sinks; thermal switch S1 opening. Check for free air flow, blower

operating at full speed. Check for loose connection.

3. Faulty lamphead interlock switch (“Door,” “Air,” etc.). See lamphead manual.

Excessive flicker in light output

1. Improper tap setting. All taps must be on same numbered or lettered step.

2. Faulty bridge diode. See preceding DIODE TESTING section.

3. Faulty xenon bulb. Check for cracked or sagging electrode(s).

4. Leaking xenon bulb. Check for white or bluish discolored envelope, high current and low voltage

(below 48 volts DC). Replace as required.

8

9

TROUBLESHOOTING (continued)

Bridge diodes (CR1-6) fail repeatedly

1. Insufficient air flow; defective blower. Clean, repair, or replace as required.

2. Incorrect replacement diode. Use only the specified rated diode(s).

Reduced light output

1. AC line voltage drop. Check AC line voltage; re-set DC output taps to compensate.

2. Bulb envelope discoloring with normal aging. Increase DC output setting; do not exceed 210

amperes.

3. Faulty xenon bulb. Check for cracked or sagging electrode(s). Replace as required.

4. Leaking xenon bulb. Check for white or bluish discolored envelope, high current and low voltage

(below 48 volts DC). Replace as required.

Elapsed Time Meter fails to record hours

1. Current sensor PC board not in contact with DC lead. PCB must be tie-wrapped to the insulation

of one of the heavy DC output leads from the xenon power supply.

2. Defective component on current sensor PCB. Repair or replace; secure replacement board to DC

lead as noted above.

3. Defective hour meter. Replace as required.

MAINTENANCE

VERY LITTLE MAINTENANCE is required to keep this power supply in good

operating condition. Like most lighting equipment, regularly scheduled cleaning is most important.

1. Remove all accumulated dust and dirt from the rectifier. Vacuum the heat sinks. Make certain all

air inlets and outlets are unobstructed.

2. Regularly check all electrical connections for tightness. Clean, retighten, or replace any discolored

connections or terminals.

3. The blower motors contains sealed bearings and requires no lubrication.

WARNING

TurnoffALLprimaryACpower beforemaking anyadjustments

or performing service procedures. Allow several minutes for

the capacitors to drain stored energy. Allow the power supply

to cool to ambient temperature.

10

WIRING DIAGRAM

Britelight 10 kW

Xenon Power Supply

11

FIGURE 1

12

3

4

6

7

8

9

10

11

12 3

13

14 15

5

12

Item Part No. Description

1 32-00215 Top Cover Panel

- 4100621 Mounting Screw, 10-32 x 5/8"

- 4107101 Flatwasher, #10

2 32-00412 Rear Panel

- 4100621 Mounting Screw, 10-32 x 5/8"

- 4107101 Flatwasher, #10

3 32-90014 Power Supply Chassis Assembly (see Figure 3)

- 4250752 Mounting Screw, 1/4-20 x 3/4"

- 4254001 Lockwasher, 1/4"

- 4257102 Flatwasher, 1/4"

4 32-70137 Timer Printed Circuit BoardAssembly

(includes Relays K2, K3, & K4)

5 32-00223 Control Panel Assembly (see Figure 2)

6 32-00414 End Panel, Control Side

- 4100621 Mounting Screw, 10-32 x 5/8"

- 4107101 Flatwasher, #10

7 32-00222 Bottom Panel

8 31-62011 Terminal Section (8 req’d.)

- 31-62012 Terminal Strip End

9 31-62025 Barrier Strip

10 32-00019 Capacitor Assembly (2 req’d.)

- 31-08133 Power Factor Capacitor, 60µf, 370 V.AC

- 32-40724 Bracket

11 31-62044 Barrier Strip (2 req’d.)

12 32-00410 Front Panel

- 4100621 Mounting Screw, 10-32 x 5/8"

- 4107101 Flatwasher, #10

13 32-00413 Blower Panel

- 4100621 Mounting Screw, 10-32 x 5/8"

- 4107101 Flatwasher, #10

14 71627000 Blower, 220 V.AC, 50/60 Hz. (2 req’d.)

15 32-00192 Frame,WeldedAssembly

PARTS LIST

Figure 1

13

FIGURE 2

1 2 3 4 5

15 14 13 12 11 10 9 8 7 6

Item Part No. Description

1 31-30005 Indicator Light, Red

2 31-30006 Indicator Light, Green

3 31-32004 Elapsed Time Meter

4 31-32007 Volt Meter

5 31-32006 Ammeter

6 32-00218 Panel (less Components)

7 4100621 Mounting Screw, 10-32 x 5/8"

8 31-98160 Test Point Socket, Black

9 31-98162 Test Point Socket, Red

10 31-61049 “Focus” Switch, Momentary

- 11-98150 Rubber Switch Boot

11 31-61030 “Strike” Switch, SPST Pushbutton

- 31-61065 Rubber Switch Boot

12 31-61048 “On-Off” Switch, DPDT

13 31-61048 “Remote/Local” Switch, DPDT

- 11-98150 Rubber Switch Boot

14 31-61015 Switching Circuit Breaker, 5A.

- 31-61126 Rubber Boot

15 31-30076 Indicator Light, Amber

MOLEX CONNECTORS

(not shown)

Part No. Description

31-13283 Two-Pin, Male

31-13288 Two-Pin, Female

31-13033 Six-Pin,Male

31-13288 Six-Pin,Female

31-13262 Twelve-PinMale

14

XENON POWER SUPPLYCHASSIS

FIGURE 3

1234

5

6

7 7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PARTS LIST

Figure 3

15

Item Part No. Description

1 82-40264 Capacitor Mounting Bracket

2 61-06001 Capacitor Clamp (2 req’d.)

3 61-08027 Filter Capacitor, 5400 µf, 200 V.DC (C3, C7)

4 82-40248 Shorting Bar

5 82-40047 Terminal Board Mounting Plate, Phenolic

6 91-64011 Power Transformer (T1), 208/230 V.AC, 50/60 Hz. Input

6 91-64007 Power Transformer (T1), 380/440 V.AC, 50/60 Hz. Input

Item 6 Transformer includes Item 5 Mounting Plate & (6) Item 24 Terminal Blocks.

7 82-40040 Support Bracket, Rectifier Heat Sinks

8 81-46026 Ceramic Resistor (R1, R2), 100 Ohm, 100 W.

9 82-40254 Heat Sink Mounting Plate, Phenolic

10 81-45016 Relay (K6)

11 21-62067 Terminal Block Segment (3 req’d.)

- 21-62066 Terminal Block End

12 31-21054 Fuse Block

13 31-21038 Fuse, 30 A. 250 V.

14 32-40624 Chassis Plate,WeldedAssembly

15 82-40255 Heat Sink Mounting Plate

16 82-20032 Heat Sink

17 81-47004 Forward Diode (CR1,2,3), 100 A. 300 V. (1N3290)

18* 61-71010 Positive Lead (Red)

19* 61-71009 Negative Lead (Black)

- 94129000 Ring Terminal (2 per lead req’d.)

- 32-70140 Current Sensor Printed Circuit Board Assembly

20 91-98031 Buss Bar (3 req’d.)

21 81-47001 Reverse Diode (CR4,5,6), 100 A. 300 V. (1N3290R)

22 81-33026 Squirrelcage Blower, 230 V.AC, 50/60 Hz.

23 81-14003 Contactor (K1)

24 81-62001 Tap Terminal Block (6 req’d.)

* Order by foot

Table of contents

Other Strong International Power Supply manuals