Strong Racks PowerRax Double Bike Lift User manual

1

PowerRax Double Bike Lift

Model: Motorized and Manual

Table of Contents

2

Table of Contents

PAGES

Installation Support

3

Safety Information

4-5

Required Tools

6

Hardware Kit Contents

7

Part List

8

Steps

1 & 2 9

Step 3

10-12

Step

413

Step 5

14

Step 6

15

Step 7

16-17

Step

818

Step

919

Step 10

20

Step 11

21-24

Step

12 25-26

Appendix I

–Understanding Your Ceiling Support

System

27

Appendix

II –Storage Locator Worksheet 28

Appendix III

–Proper Mounting 29

Appendix

IV –Installation Help 30

3

Please Do Not Return This Product To The Store!

1-877-717-RACK (7225)

info@strongracks.com

If there are any missing or damaged parts, please contact us immediately for

replacement. In some cases, a new part can be shipped to you within 1-3 days.

Our quality control members hand check every box prior to shipment. We take this very

seriously and want you completely satisfied.

If you find that installation of our products might be a little more technical than you

anticipated, then we can simply guide you to a qualified installer and arrange for the

installation. Our vast installation support network allows us to offer you the extra

support you might need with busy schedules.

Please review our list of dealers at www.strongracks.com or contact us for help. Refer

to Appendix IV for additional installation help.

Installation

Support

4

STOP: Ensure that you understand your

ceiling support structure prior to

installing.

Ensure that you know your load prior to

loading items on your ceiling storage

system.

Our products are designed for installation into properly constructed

wood ceiling joists, TGI’s or floor joists. Do not install into metal

studs or ceiling concrete floors. We do not warranty or make any

claim to the construction of your home. If you have any questions

about your homes construction, check with your local builder. If

you are not comfortable with installing this product, call one of

our authorized dealers for support.

Do not use this unit for any other purpose than what was intended.

Proper operation and usage lies with the user.

Safety Information

5

Safety Information

You must read this entire manual before attempting to install this product. We also suggest you

visit www.strongracks.com to review our installation video. If you have any additional

questions or need to speak with an installation professional, do not hesitate to call us directly.

We will provide timely responses to your questions.

1-877-717-RACK (7225) Monday - Friday 9am-5pm Arizona Time

We have hundreds of qualified dealers throughout North America. Visit www.strongracks.com

to contact your local installer.

!!

Warning Warning

!!

Warning Warning

Electrical , Plumbing or Gas Lines

May Be In The Ceiling or Walls

Be Aware of Falling Items or

Personal Fall Hazard

Prior to drilling, you must identify where

your electrical, plumbing and gas lines

are inside your walls or ceilings. Failure

to do so may result in damage or serious

injury. Contact a professional to locate.

Be aware when climbing a ladder. Do

not have your hands full when climbing.

Do not lean out away from the ladder to

load or install the system. Do not

overreach or overextend from ladder.

Ceiling Joist, Truss and Wall Stud

Overloading Potential

This system can be installed into 2 or 4

Ceiling Joists. We recommend that you

install into 4. You can also install the

system into the wall studs. If you install

into 2 joists, do not install another unit

into the same joists.

System May Be A Personal

Injury Hazard

Failure to read and follow these

installation instructions, per the

manufacturer’s guidelines, may result in

serious injury or death. If you are

uncomfortable installing yourself, please

contact us or visit our website to

identify an installer of our products.

6

Required Tools

Electric Drill with 1/8” bit

Stud

Finder

We recommend that you use the Storage Locator Worksheet (Appendix II),

to note where you would like to install our products. You can also draw out

the position / direction of your ceiling trusses, as it relates to our systems.

Keeping good notes will ensure proper installation and support future

installations.

Tape

Measure

and Pencil

Standard

Socket

Set

Metal Hack Saw

Electric Hammer Drill

Optional Tools

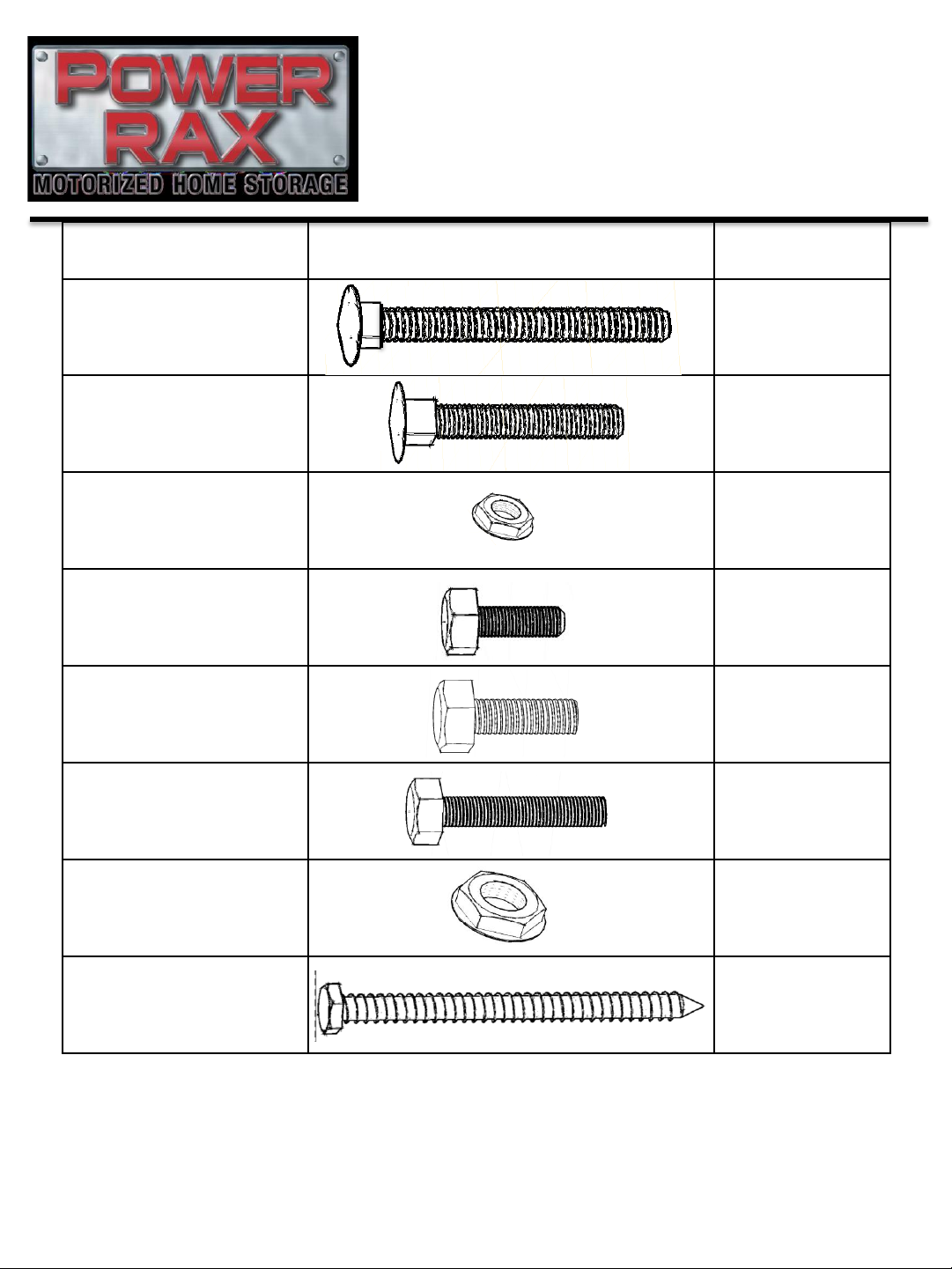

Hardware Kit Contents

7

Letter and Name

Picture Quantity

Large Carriage

Bolt [2 ½”] X8

Small Carriage

Bolt [1 ½”] X8

Small Nut x16

Small Bolt [¾”] x4

Medium Bolt

[1 ½”] x8

Large Bolt

[1 ¾”] x4

Large Nut x12

3” Lag Screw x8

Note: Extra hardware may be included in kit.

Part # and Name Picture

Quantity

Mounting Track x2

Down Tube x2

Inner Tube x2

Upper Swing-Arm

Tube x2

Swing-Arm

Connection Tube x2

Lower Swing-Arm

Tube x2

Support Tube x4

Bike Hook x4

Pick Point or x1

Mounting Tracks

w/additional holes

(motorized version only*)

x2

8

Part List

1

Determine your ceiling support system. To understand your truss direction, spacing or

placement, you may need to enter your attic. You may also need to consult your builder or a

licensed contractor. As an additional resource, refer to Appendix I. Tip: The direction of your

ceiling outlets will indicate the direction of your trusses, just as the location of your garage door

support will indicate the location and spacing of your trusses.

2

Determine what section of the garage will house your new Bike Lift. Make sure there are no

obstructions within the designated space (i.e., lights, attic door, sprinklers, etc.). If you have

cabinets in your garage, make sure there is adequate clearance for doors to open.

9

10

You may secure your

Mounting Track into a

single truss by

inserting the lag bolts

through the center

holes.

You may secure your

Mounting Track into two

separate trusses: from the

center of the mounting

track measure

approximately 1 ¼” in

each direction to pinpoint

the appropriate drilling

locations.

Four lag screws secure

each mounting track into

two trusses

Two lag screws

secure each

mounting track

onto a single

truss

OR

Follow

Instructions 3A 3B

There are two methods to install the mounting tracks.

Determine which is needed for your placement before

proceeding.

Follow

Instructions

3A

When installing down the center of the Mounting Track: find the center of the truss (for more in

depth information please see Appendix III), drill a pilot hole, secure the Mounting Track with one

Lag Screw firmly (Do not over tighten). Square the Mounting track by measuring from a fixed

point to your first Lag Screw, carry that measurement to your next Lag Screw evenly and securely

tighten both.

11

Hardware Required:

x4

Ensure the lag screw is in

the center of the truss.

Refer to Appendix III for

additional information

regarding proper

mounting.

No!

Yes!

If your truss spacing is 24”

center to center, you will

attach your Mounting Tracks

24” apart.

When installing down the center of a truss:

If your truss spacing is 16” center to

center, you will attach your Mounting

Tracks to two trusses measuring 32”

apart (skipping the center truss).

24”

32”

3B

When installing the Mounting Track into separate trusses: find the center of the truss (for more

in depth information please see Appendix III), drill a pilot hole, secure the Mounting Track with

one Lag Screw firmly (Do not over tighten). Square the Mounting track by measuring from a

fixed point to your first Lag Screw, carry that measurement to your next Lag Screw evenly and

securely tighten both. Four Lag screws per Mounting track should be used.

12

Hardware Required:

x8

Ensure the lag screw is in

the center of the truss.

Refer to Appendix III for

additional information

regarding proper

mounting.

No!

Yes!

24”

Mounting Tracks should be installed 24” Center to Center.

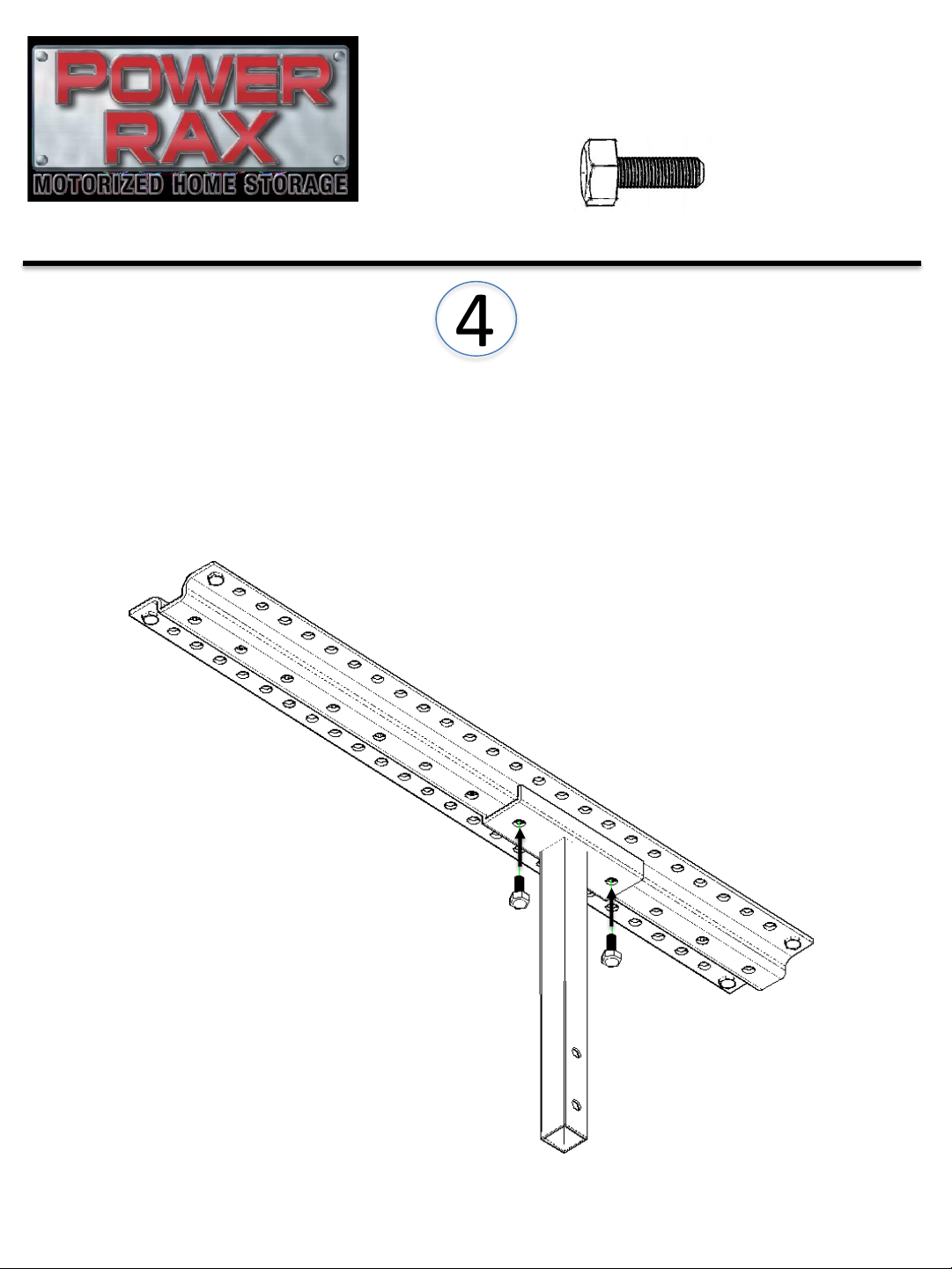

4

13

Hardware Required:

x4

Secure each of the Down Tubes to the Mounting track using two

Small Bolts per tube. Ensure the Down Tubes are in the same

position on the Mounting Track by counting the holes to keep

them in line with one another. You may choose any location on

the track that suits your needs.

Measure from the center of the hole

in the backstop to the floor. This

measurement will be used to

determine the overall length of the

swing-arm tubes. The full swing-arm

consists of the upper, connector, and

lower swing-arm tubes.

14

Floor

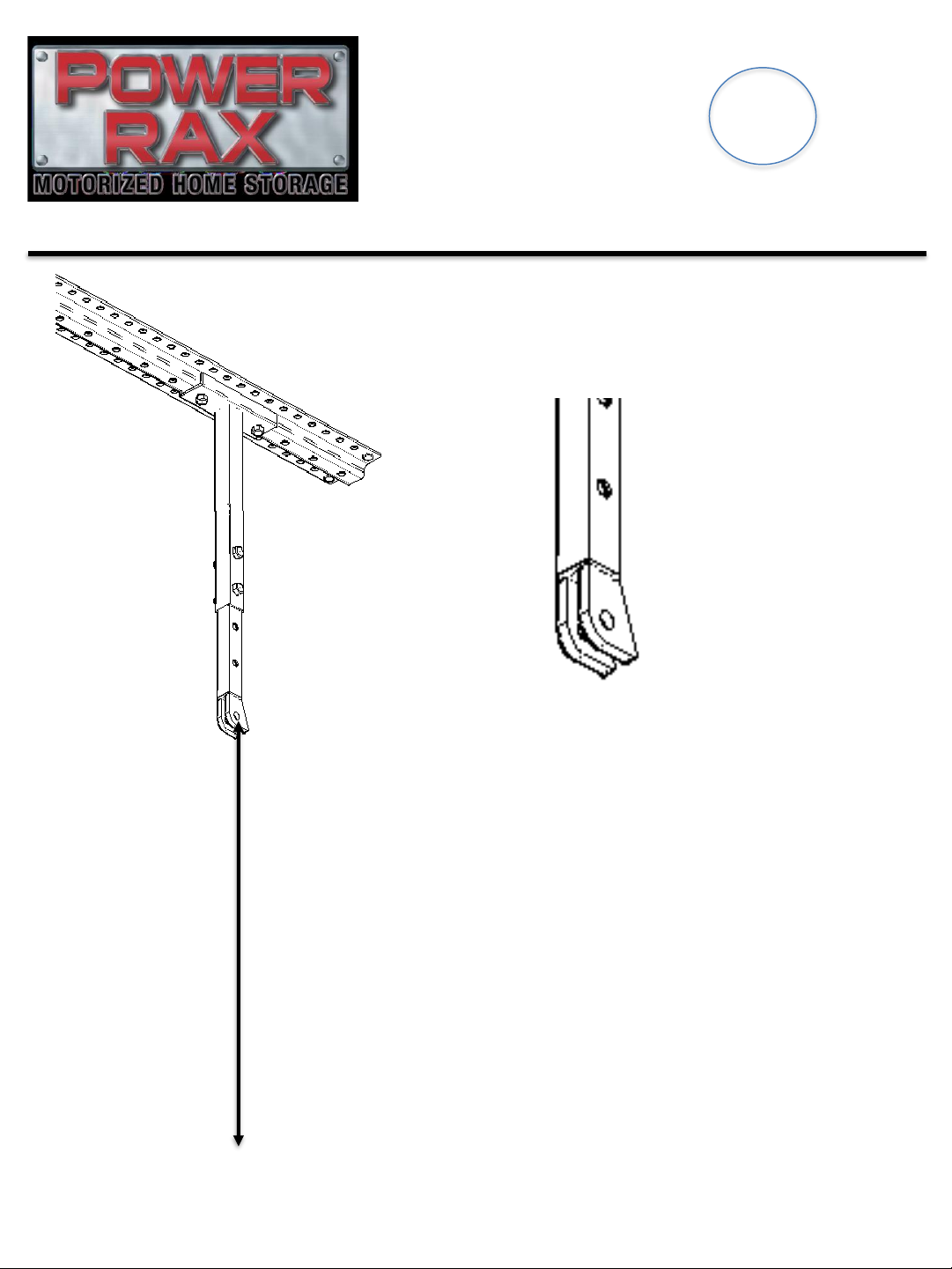

5

Swing

Arm

6

To assemble the Swing-Arm: slide the connector tube into the Upper Swing-arm tube and slide

the Lower Swing-arm tube onto the connector tube. Using your measurement from the

previous page: lay your tape measure from the hole on the Upper Swing-arm tube along the side

of the tubes and adjust until you are 1”to 3”less than your measurement (this will ensure when

the arm swings down it will have a gap from the floor).

15

For maximum extension, the connector tube should have 6 holes inside each of the upper and lower

swing-arm tubes –this should never be exceeded.

Before

After

1” to 3”

for gap

Upper/Lower Connector

1 2 3 4 5 6

7

Continued:

Once the length has been determined: Secure the Upper Swing-Arm

Tube with the Swing-Arm Connection Tube using 2 Small Carriage Bolts

and 2 Small Nuts, Secure the Lower Swing-Arm Tube with the Swing-Arm

Connection Tube using 2 Small Carriage Bolts and 2 Small Nuts.

Repeat for the other Swing-Arm, ensuring the same length and hole

usage.

16

Hardware Required:

x8

x8

Connector

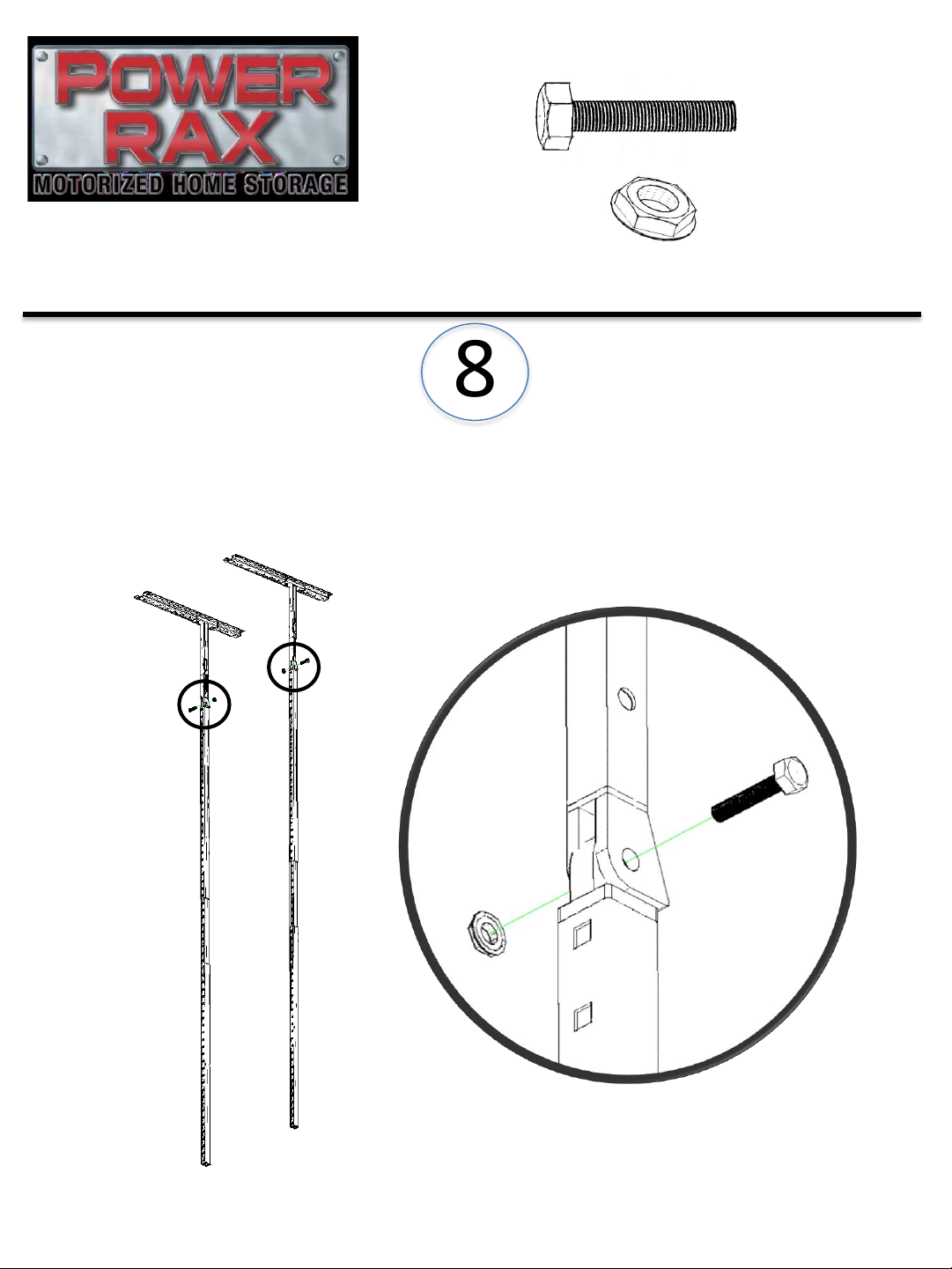

8

Attach both Swing-Arm assemblies to the Inner tubes

using 1 Large Bolt and 1 Large Nut per tube.

17

Hardware Required:

x2

x2

9

Attach one support tube using the bottom hole of each

Swing assembly. Secure using 2 Large Carriage Bolts and

2 Small Nuts.

18

Hardware Required:

x2

x2

10

Attach one support tube using the top hole of each Swing

assembly (just below the pivot point). Secure using 2

Large Carriage Bolts and 2 Small Nuts.

19

Hardware Required:

x2

x2

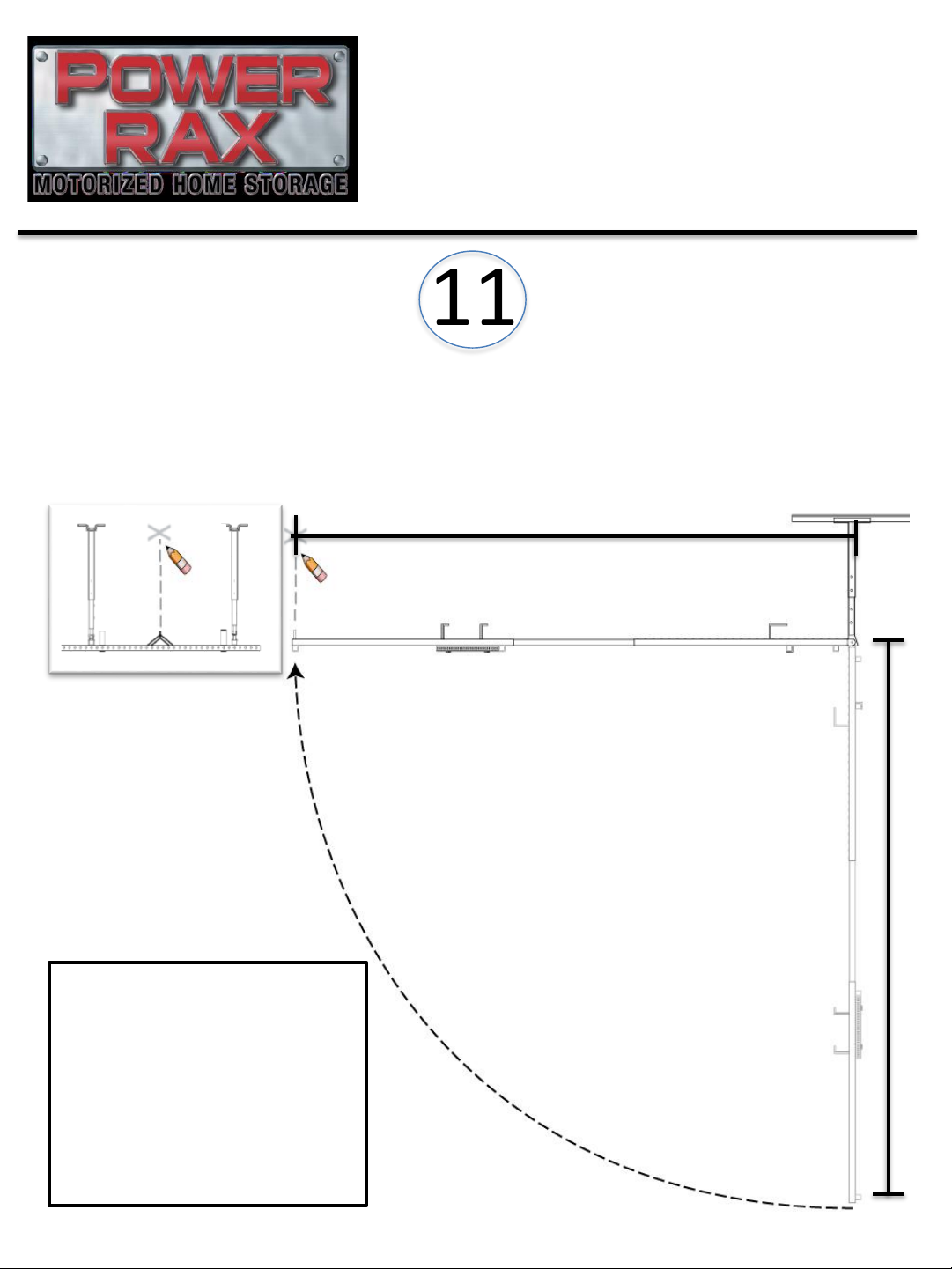

11

Option 1: Flex the system until it is level. Directly above

the pick point, in the center of the unit, place a pencil

mark on the ceiling. This mark is going to be

representative of your motor hook.

20

X

X

End View Side View

A

B

Option 2: Measure

the length point “A” to

point “B” and use that

measurement to

create your pencil

mark on the ceiling

Table of contents